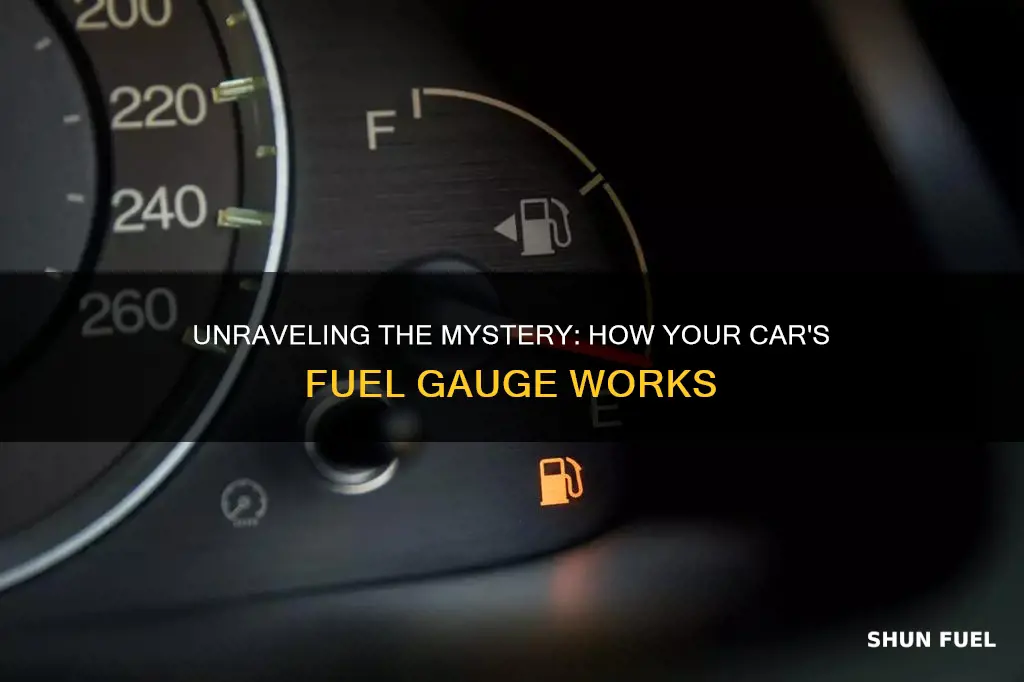

The car fuel meter is an essential component in modern vehicles, providing drivers with real-time information about their fuel levels. This device measures the amount of fuel in the tank and displays it on the dashboard, allowing drivers to monitor their fuel consumption and plan their journeys accordingly. Understanding how the fuel meter works can help drivers make informed decisions about fuel management, ensuring they have enough fuel for their trips and optimizing their vehicle's performance.

What You'll Learn

- Fuel Level Sensor: Measures the volume of fuel in the tank using a float or pressure sensor

- Send/Receive Signals: Transmits data to the dashboard, indicating fuel levels and usage

- Display Mechanism: Translates sensor data into a visual representation on the fuel gauge

- Calibration: Adjusts the meter's accuracy to ensure reliable fuel level readings

- Fuel Consumption Calculation: Calculates fuel usage based on engine data and driving patterns

Fuel Level Sensor: Measures the volume of fuel in the tank using a float or pressure sensor

The fuel level sensor is a crucial component in modern vehicles, providing accurate information about the amount of fuel remaining in the tank. This sensor plays a vital role in ensuring that drivers are aware of their fuel levels, enabling them to plan their journeys effectively and avoid running out of fuel. The primary function of this sensor is to measure the volume of fuel in the tank, which is typically achieved through the use of either a float or a pressure sensor.

In the case of a float-based sensor, it operates on a simple yet effective principle. A small float, often made of a lightweight material like plastic or aluminum, is attached to a thin wire or rod. This float is designed to rise and fall as the fuel level changes within the tank. When the fuel level is low, the float descends into the fuel, and when it's high, the float floats on the surface. The sensor then measures the position of this float using the wire or rod, which is connected to a small electrical circuit. This circuit sends a signal to the vehicle's engine control unit (ECU) indicating the fuel level. The ECU then uses this information to display the fuel level on the dashboard gauge or provide alerts when the fuel is low.

On the other hand, pressure sensors offer a more direct approach to measuring fuel volume. These sensors are typically located at the bottom of the fuel tank and are designed to measure the pressure of the fuel. As the fuel level decreases, the pressure in the tank also drops. The pressure sensor detects this change and sends a signal to the ECU, which then calculates the fuel level based on the pressure reading. This method is often preferred in modern vehicles due to its accuracy and reliability, especially in tanks with complex shapes or those that are difficult to access.

Both float and pressure sensors are designed to be durable and withstand the harsh conditions inside a fuel tank, including varying temperatures and fuel compositions. They are typically sealed to prevent any fuel from entering the sensor, ensuring accurate measurements. Additionally, these sensors are often calibrated to provide precise readings, compensating for factors like fuel density and temperature changes.

In summary, the fuel level sensor is a critical component that ensures drivers have accurate information about their vehicle's fuel status. Whether using a float or pressure sensor, the goal is to measure the fuel volume effectively, allowing for better fuel management and a more efficient driving experience.

Ethanol Fuel: Can Your Car Run on It?

You may want to see also

Send/Receive Signals: Transmits data to the dashboard, indicating fuel levels and usage

The car fuel meter is an essential component of a vehicle's fuel management system, providing real-time data on the vehicle's fuel status. It operates by sending and receiving signals to and from the dashboard, ensuring that the driver is always aware of the fuel levels and usage. This process involves a series of intricate steps that work in harmony to deliver accurate and timely information.

When the vehicle is running, the fuel meter continuously monitors the fuel tank's content. It does this by measuring the pressure of the fuel in the tank and the volume of fuel consumed. This data is then converted into a readable format for the driver. The fuel meter uses sensors to detect changes in fuel levels, ensuring that it can provide up-to-date information. These sensors are typically located near the fuel tank and are designed to detect even the smallest variations in fuel volume.

The key to this system's functionality is the communication between the fuel meter and the dashboard. The fuel meter transmits data packets containing fuel level and usage information to the dashboard. These packets are sent via a dedicated data bus or a network of wires that connect various vehicle systems. The dashboard, equipped with a fuel gauge and other indicators, receives these signals and interprets them accordingly. It then displays the fuel level and usage data in a user-friendly manner, often with visual cues like a fuel gauge needle or a digital display.

The process of sending and receiving signals is a two-way communication system. The fuel meter not only transmits data but also receives instructions and feedback from the dashboard. For instance, when the driver fills the fuel tank, the dashboard sends a signal to the fuel meter, instructing it to update the fuel level reading. Similarly, when the fuel level is low, the fuel meter can send a warning signal to the dashboard, prompting the driver to refuel. This two-way communication ensures that the fuel meter provides accurate and relevant information at all times.

In summary, the car fuel meter's ability to send and receive signals is a critical aspect of its functionality. It enables the system to provide real-time fuel level and usage data to the driver, ensuring safe and efficient vehicle operation. This intricate process involves sensors, data transmission, and dashboard interpretation, all working together to keep the driver informed about the vehicle's fuel status. Understanding this mechanism can help drivers better manage their fuel consumption and maintain their vehicles effectively.

Are All-Wheel Drive Cars Less Fuel-Efficient? Unraveling the Truth

You may want to see also

Display Mechanism: Translates sensor data into a visual representation on the fuel gauge

The display mechanism of a car's fuel meter is a crucial component that brings the fuel level data to the driver's attention. It is responsible for translating the raw sensor information into a visual representation, typically a gauge or a digital display, allowing the driver to monitor the vehicle's fuel status. This process involves several key steps and components.

At the heart of this mechanism is the fuel sensor, which measures the volume or pressure of the fuel in the tank. This sensor provides critical data, such as the fuel level and sometimes even the fuel type (e.g., gasoline or diesel). The sensor's output is a raw measurement that needs to be interpreted and presented in a meaningful way.

The display unit, often a small instrument cluster or a dedicated fuel gauge, receives the sensor data. This unit is designed to process the information and convert it into a visual format. It typically consists of a gauge with a needle or a digital screen that moves or changes to indicate the fuel level. The display unit's primary function is to provide a clear and intuitive representation of the fuel status.

Inside the display unit, there is an electronic circuit that acts as the brain of the fuel gauge. This circuit takes the sensor data, which is often an analog signal, and converts it into a digital format that can be easily interpreted. It then processes this data to determine the fuel level and adjust the display accordingly. The circuit ensures that the fuel gauge's indication is accurate and reflects the actual fuel condition.

The visual representation on the fuel gauge is designed to be easily understandable. For example, a traditional fuel gauge uses a needle that moves from a full to an empty position, with various levels in between. Each position represents a specific fuel level, allowing the driver to quickly assess the remaining fuel. Modern digital displays may use bars, percentages, or other visual cues to convey the fuel status, often in conjunction with other vehicle information. This display mechanism is a vital safety feature, ensuring that drivers are aware of their fuel levels and can take appropriate actions to maintain safe operation.

Hydrogen vs. Electric: The Ultimate Car Comparison

You may want to see also

Calibration: Adjusts the meter's accuracy to ensure reliable fuel level readings

Calibration is a critical process in ensuring the accuracy and reliability of fuel level measurements in vehicles. It involves adjusting the fuel meter's settings to match the actual fuel volume in the tank, providing drivers with an accurate representation of their vehicle's fuel status. This process is essential as it compensates for any discrepancies that may arise due to variations in fuel density, temperature, or other environmental factors.

The fuel meter in a car is an electronic device that measures the amount of fuel in the tank and provides a visual indication of the fuel level to the driver. It operates based on the principle of measuring the pressure or volume of the fuel in the tank and converting it into a readable format. However, factors like temperature changes can affect the fuel's density, leading to inaccurate readings. Calibration addresses these issues by fine-tuning the meter's settings.

During calibration, the process typically involves the following steps. First, the vehicle is parked on a level surface, ensuring that the fuel level is at a consistent height. Then, the driver is instructed to run the engine until it reaches a specific temperature, usually at idle. This step is crucial as it allows the fuel to reach a stable temperature, ensuring accurate measurements. Once the engine reaches the desired temperature, the driver is prompted to note the fuel level indicated on the meter and the actual fuel volume in the tank.

The next step is to compare the indicated fuel level with the actual reading. If there is a significant discrepancy, the fuel meter's calibration needs adjustment. Technicians use specialized tools to access the meter's settings and make the necessary adjustments. These settings may include fuel density compensation, temperature correction factors, and other parameters specific to the vehicle's fuel system. By fine-tuning these values, the calibration process ensures that the fuel meter provides accurate and reliable fuel level readings.

Regular calibration is essential, especially for vehicles with fuel-sensitive systems or those operating in varying environmental conditions. It ensures that the fuel meter remains accurate over time, providing drivers with confidence in their vehicle's fuel management. Additionally, proper calibration can prevent potential issues like running out of fuel unexpectedly or overfilling the tank, thus enhancing overall vehicle performance and safety.

Can Flex-Fuel Cars Run on Diesel? Exploring the Limits of Flexibility

You may want to see also

Fuel Consumption Calculation: Calculates fuel usage based on engine data and driving patterns

The fuel consumption calculation is a critical component of modern vehicle management systems, providing drivers with real-time insights into their fuel usage. This calculation is based on a combination of engine data and driving patterns, offering an accurate representation of fuel efficiency. Here's a detailed breakdown of how this process works:

Data Collection: The fuel consumption calculation begins with the collection of various engine and vehicle parameters. This includes measurements like engine speed, torque, and temperature, as well as vehicle speed, acceleration, and deceleration rates. Modern vehicles are equipped with sophisticated sensors that continuously monitor these data points. For instance, the engine control unit (ECU) records engine speed and load, which are essential for understanding the engine's performance and fuel consumption.

Engine Data Analysis: The collected engine data is then analyzed to determine the vehicle's power output and efficiency. This involves calculating the engine's fuel consumption rate, which is typically measured in liters per 100 kilometers (l/100 km) or miles per gallon (mpg). The ECU uses algorithms to interpret the engine's performance, considering factors like fuel injection timing, combustion efficiency, and engine load. By analyzing these data points, the system can identify patterns and trends in fuel usage.

Driving Pattern Recognition: In addition to engine data, the fuel consumption calculation takes into account the vehicle's driving patterns. This includes monitoring the frequency of acceleration and deceleration, as well as the duration of each event. For example, rapid acceleration and frequent stops contribute to higher fuel consumption. The system uses this information to calculate the vehicle's efficiency in different driving conditions. By recognizing patterns, it can provide accurate estimates of fuel usage for various driving scenarios.

Real-Time Fuel Consumption: The beauty of this calculation lies in its ability to provide real-time feedback. As the vehicle operates, the system continuously processes the collected data, allowing for instant fuel consumption calculations. This enables drivers to make informed decisions, such as adjusting their driving style or planning fuel stops. Modern infotainment systems often display this information, ensuring drivers have a clear understanding of their vehicle's fuel efficiency.

Accuracy and Calibration: To ensure accuracy, fuel consumption calculations are often calibrated against test cycle data or laboratory tests. This calibration process involves comparing the calculated fuel usage with known values under controlled conditions. Over time, the system learns and adapts, improving its accuracy. Regular software updates and sensor calibrations further enhance the system's performance, ensuring that fuel consumption calculations remain reliable and up-to-date.

Powering the Future: Unlocking Hydrogen Fuel Cell Car Secrets

You may want to see also

Frequently asked questions

A fuel meter, also known as a fuel gauge, is an essential component in a vehicle's dashboard. It measures and displays the amount of fuel left in the tank, providing real-time information to the driver. This gauge is crucial for safe driving, helping drivers know when to refuel and preventing unexpected fuel depletion during journeys.

Fuel meters utilize a float or a pressure sensor system. The float is attached to a thin metal rod, which rises and falls as the fuel level changes. This movement is then translated into a visual display on the dashboard. Alternatively, some modern cars use a pressure sensor that measures the fuel level by sensing the pressure of the fuel in the tank.

Fuel gauge accuracy can be affected by several factors. One common issue is a faulty sensor or wiring, which may provide incorrect fuel level data. Environmental conditions, such as temperature changes, can also impact the accuracy. Additionally, if the fuel tank has a complex shape, the fuel meter might not always provide a precise reading. Regular maintenance and calibration can help minimize these inaccuracies.

Yes, fuel meters can be calibrated to enhance their precision. This process involves adjusting the sensor or float mechanism to match the actual fuel level. Calibration is often performed during vehicle maintenance or when a fuel gauge shows significant discrepancies. It ensures that the fuel gauge provides reliable information to the driver.

If you notice any issues with your fuel gauge, such as erratic readings or a complete malfunction, it's advisable to consult a professional mechanic. They can diagnose the problem, which may include checking the sensor, wiring, or the gauge itself. In some cases, the fuel gauge might need to be replaced to ensure accurate fuel level monitoring.