Many car owners often wonder about the inner workings of their vehicles, especially when it comes to the fuel system. Understanding whether your car has a carburetor or fuel injection can be crucial for maintenance and performance. Carburetors were once the standard, but fuel injection has become more prevalent in modern vehicles. This guide will help you determine which system your car uses, providing insights into the differences and benefits of each.

What You'll Learn

- Carburetor Basics: Understanding the function and components of a carburetor in a car's engine

- Fuel Injection Technology: How fuel injection systems deliver fuel to the engine for combustion

- Performance Differences: Comparing the performance and efficiency of carbureted vs. fuel-injected engines

- Maintenance and Care: Tips for maintaining and troubleshooting both carburetor and fuel injection systems

- Upgrades and Modifications: Exploring modifications to enhance the performance of carburetor or fuel injection systems

Carburetor Basics: Understanding the function and components of a carburetor in a car's engine

A carburetor is a crucial component in the internal combustion engine of a car, responsible for mixing and supplying the correct amount of air and fuel to the engine's cylinders. This process is essential for efficient combustion and optimal engine performance. The primary function of a carburetor is to ensure that the engine receives the right fuel-air mixture, which is critical for power, efficiency, and emissions control.

The basic structure of a carburetor includes several key components. Firstly, the float bowl, which is a reservoir that holds the fuel. It is equipped with a float that rises and falls with the fuel level, ensuring a constant supply. The carburetor also features a series of passages and orifices that direct the air and fuel mixture. The throttle plate, a critical part, controls the airflow into the engine by opening and closing, allowing for the regulation of the fuel-air mixture. The carburetor body houses these components and is where the mixing and distribution of air and fuel take place.

The process begins with the fuel being drawn from the float bowl and atomized into a fine spray. This spray is then mixed with air as it passes through the carburetor's passages. The throttle plate plays a vital role here, as it controls the amount of air entering the engine. By adjusting the throttle, the driver can regulate the fuel-air mixture, allowing for varying engine speeds and power outputs. This mechanism ensures that the engine receives the optimal mixture for efficient combustion.

One of the critical advantages of a carburetor is its simplicity and reliability. Unlike fuel injection systems, which are more complex and electronic, carburetors are mechanical and do not require electricity to function. This makes them less prone to electrical issues and more suitable for older vehicles or those with simpler engine management systems. However, it's important to note that carburetors may not provide the same level of precision in fuel delivery as fuel injection, which can lead to less efficient combustion and higher emissions.

In summary, understanding the carburetor's function and components is essential for car owners and mechanics alike. It is a fundamental part of the engine's fuel system, ensuring the engine receives the correct mixture of air and fuel for optimal performance. While modern vehicles often use fuel injection, knowing the basics of carburetors is valuable for maintaining and troubleshooting older or classic cars.

White Fuel: A Comprehensive Guide to Its Use in Cars

You may want to see also

Fuel Injection Technology: How fuel injection systems deliver fuel to the engine for combustion

Fuel injection technology has revolutionized the way engines operate, offering a more efficient and precise method of delivering fuel to the combustion chamber. This system has become a standard feature in modern vehicles, replacing the traditional carburetor setup. The primary advantage of fuel injection is its ability to optimize fuel-air mixture preparation, ensuring a more complete and efficient combustion process.

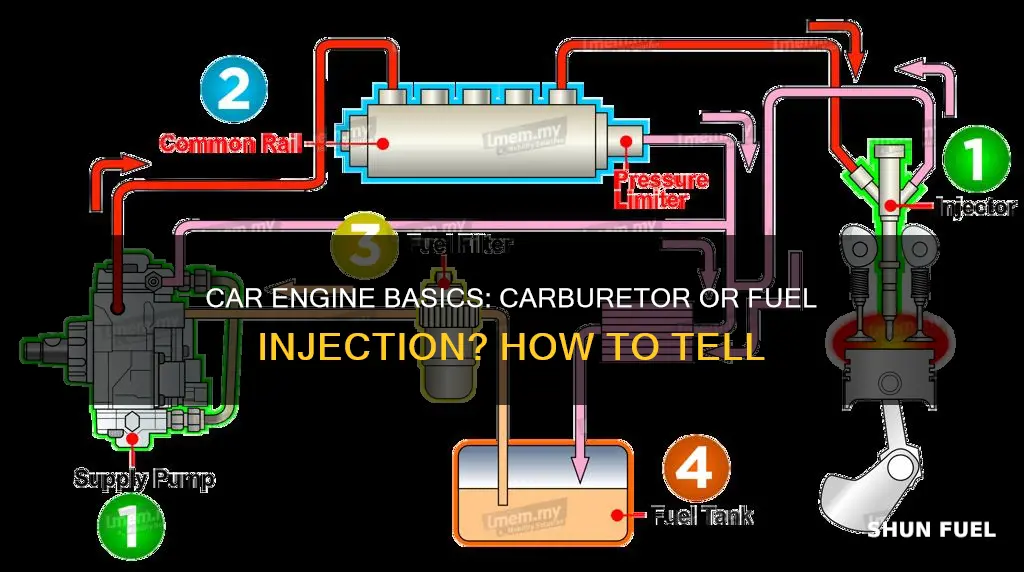

At its core, a fuel injection system is designed to inject fuel directly into the engine's cylinders or into a manifold, which then distributes the fuel to the cylinders. This direct approach ensures that the fuel is atomized and mixed with air in the correct proportions, creating an ideal environment for combustion. Unlike carburetors, which mix fuel and air in a separate chamber, fuel injection provides better control over the fuel-air ratio, resulting in improved performance and reduced emissions.

The process begins with the fuel pump, which draws fuel from the tank and pressurizes it. This pressurized fuel is then directed to the fuel injectors, which are strategically positioned to deliver the fuel into the engine's cylinders. Each cylinder has its own injector, ensuring precise control over the fuel delivery. The injectors use high pressure to spray the fuel as a fine mist, which mixes with air in the combustion chamber. This misty fuel-air mixture is then ignited by the spark plug, creating a controlled and efficient combustion process.

One of the key benefits of fuel injection is its ability to adapt to varying engine speeds and loads. The system can quickly adjust the fuel-air mixture, providing the engine with the exact amount of fuel required at any given moment. This adaptability results in improved throttle response, better fuel economy, and reduced emissions. For instance, when the engine is idling, the fuel injectors deliver a smaller amount of fuel, ensuring a stable running condition while minimizing fuel consumption. As the engine speed increases, more fuel is injected to meet the higher power demands.

Furthermore, fuel injection technology offers enhanced reliability and longevity. Since fuel is not passing through a carburetor, there is less wear and tear on moving parts, reducing the chances of mechanical failure. This system also provides better cold-start capabilities, ensuring the engine starts efficiently even in cold weather conditions. The precise control over fuel delivery contributes to improved engine performance and longevity, making fuel injection a preferred choice for automotive engineers.

Smaller Cars: Fuel Efficiency Benefits and Trade-offs

You may want to see also

Performance Differences: Comparing the performance and efficiency of carbureted vs. fuel-injected engines

The debate between carbureted and fuel-injected engines has been a long-standing discussion among automotive enthusiasts and engineers. Both systems have their unique advantages and play a crucial role in determining a vehicle's performance and efficiency. Understanding the performance differences between these two technologies is essential for car owners and enthusiasts alike.

Carbureted engines, often associated with older vehicles, rely on a carburetor to mix air and fuel. This mechanical process involves a series of steps where the carburetor atomizes the fuel and blends it with air, creating a combustible mixture. The performance of a carbureted engine is often characterized by its simplicity and reliability. These engines typically deliver a smooth power delivery, making them ideal for everyday driving and low-speed maneuvers. However, the performance is generally limited, and the engine may struggle to produce high power output, especially at higher RPMs. Carbureted engines are known for their ability to run on lower-octane fuels, which can be advantageous for cost-effective operation.

On the other hand, fuel-injected engines have revolutionized modern automotive performance. Fuel injection systems precisely control the fuel-air mixture by injecting fuel directly into the engine's cylinders. This process results in a more efficient combustion process, allowing for better performance and higher power output. Fuel-injected engines excel in delivering rapid acceleration and responsive handling, making them a favorite among performance enthusiasts. The direct injection of fuel ensures that the engine receives the optimal amount of fuel at any given RPM, leading to improved throttle response and overall power delivery. Additionally, fuel injection allows for more precise control over the air-fuel mixture, enabling the engine to run more efficiently and produce fewer emissions.

One of the key performance differences lies in the throttle response. Fuel-injected engines offer a more immediate and linear power delivery, providing a quick response to throttle inputs. This characteristic is particularly beneficial during high-speed driving and racing situations, where rapid changes in power output are required. Carbureted engines, while capable of delivering smooth power, may lag in this aspect, resulting in a less responsive driving experience.

In terms of efficiency, fuel-injected engines have a clear advantage. The precise control over the fuel-air mixture allows for better combustion efficiency, resulting in improved fuel economy. Modern fuel injection systems can adapt to various driving conditions, optimizing the engine's performance and reducing fuel consumption. Carbureted engines, while efficient in their own right, may struggle to match the fuel efficiency of their fuel-injected counterparts, especially during high-speed cruising or continuous high-load operation.

In summary, the comparison between carbureted and fuel-injected engines highlights the advancements in automotive technology. Fuel injection systems offer superior performance, efficiency, and responsiveness, making them a preferred choice for modern vehicles. While carbureted engines have their merits in simplicity and reliability, fuel injection's ability to provide precise fuel control and improved combustion efficiency is a significant step forward in engine technology. Understanding these performance differences can guide car owners in making informed decisions regarding their vehicle's capabilities and maintenance.

Camshafts in Fuel-Injected Engines: Unlocking Power and Efficiency

You may want to see also

Maintenance and Care: Tips for maintaining and troubleshooting both carburetor and fuel injection systems

Understanding the basics of your car's fuel system is essential for proper maintenance and troubleshooting. Whether your vehicle utilizes a carburetor or fuel injection, regular care can ensure optimal performance and longevity. Here's a comprehensive guide to help you maintain and address issues with both systems.

Carburetor Maintenance:

- Cleaning: Over time, carburetor jets and passages can accumulate dirt, debris, and varnish. Use a carburetor cleaner and a small brush to gently clean these components. Ensure you follow the manufacturer's instructions to avoid damage.

- Inspection: Regularly inspect the carburetor for any signs of damage, cracks, or leaks. Pay attention to the float bowl and ensure it's free from excessive sediment. Replace any worn-out parts to prevent poor fuel mixture and performance issues.

- Adjustments: Carburetor adjustments, such as the idle screw and throttle plate, require careful attention. Fine-tune these settings to achieve the optimal air-fuel mixture. Adjustments might be necessary after cleaning or if you notice performance changes.

- Fuel Filter: Check and replace the fuel filter regularly to prevent contaminants from reaching the carburetor. Clogged filters can restrict fuel flow, leading to engine problems.

Troubleshooting Carburetor Issues:

- If your engine struggles to start or runs poorly, it could be due to a dirty or clogged carburetor. Cleaning and adjusting the carburetor might resolve these issues.

- Leaks in the carburetor can cause fuel wastage and performance problems. Inspect all connections and gaskets, and replace any damaged parts.

- Incorrect fuel mixture can lead to engine misfires. Adjust the carburetor settings to achieve the correct air-fuel ratio, ensuring your engine runs smoothly.

Fuel Injection System Care:

- Cleaning: Fuel injectors can become clogged with carbon deposits and contaminants over time. Use a fuel injection cleaner to flush the system and restore proper fuel atomization.

- Inspection: Regularly inspect the fuel injectors for any signs of damage or blockages. Clean or replace clogged injectors to ensure efficient fuel delivery.

- Pressure Testing: Check the fuel pressure using a gauge. Low pressure might indicate a faulty pump or clogged lines. Adjust or replace components to maintain optimal pressure.

- Engine Management: Modern fuel injection systems are computer-controlled. Ensure the engine management system is calibrated correctly. Regularly update software and monitor sensor readings for any anomalies.

Troubleshooting Fuel Injection Problems:

- Engine misfires or poor performance could be due to clogged or faulty fuel injectors. Cleaning or replacing these components is often the solution.

- Fuel pump issues can cause low fuel pressure. Inspect the pump for leaks or damage and ensure it operates correctly.

- Sensor malfunctions can lead to incorrect fuel mixture calculations. Check temperature, pressure, and oxygen sensors for accuracy.

Remember, proper maintenance and timely troubleshooting can save you from costly repairs. Always refer to your vehicle's manual for specific instructions and recommendations tailored to your car's make and model.

Fuel Injector Cleaner: Safe for Modern Engines?

You may want to see also

Upgrades and Modifications: Exploring modifications to enhance the performance of carburetor or fuel injection systems

When it comes to optimizing the performance of your vehicle's fuel delivery system, whether it's a carburetor or fuel injection, there are several modifications and upgrades you can consider. These enhancements can lead to improved power, fuel efficiency, and overall driving experience. Here's an exploration of some key modifications:

Carburetor Upgrades: For vehicles equipped with a carburetor, there are various ways to enhance its performance. One popular modification is the installation of a high-performance carburetor. These upgraded carburetors often feature improved jetting and venturi designs, allowing for more precise fuel-air mixture control. This can result in increased horsepower and torque, especially at higher RPMs. Additionally, some enthusiasts opt for electronic fuel injection conversion kits, which can be retrofitted onto carburetor-equipped cars. This conversion provides the benefits of both worlds, combining the simplicity of a carburetor with the precision of fuel injection.

Fuel Injection Tuning: Fuel injection systems, commonly found in modern vehicles, offer excellent performance potential. One of the most effective modifications is tuning the fuel injection system. This involves adjusting the fuel pressure, spray patterns, and timing to optimize the air-fuel mixture. Custom tuning can be done through specialized software, allowing enthusiasts to fine-tune the engine's performance. Another upgrade is the use of high-flow fuel injectors, which provide a larger fuel volume, resulting in improved power and responsiveness. These injectors are particularly beneficial for high-performance modifications or when running higher octane fuels.

Intake System Modifications: The intake system plays a crucial role in the performance of both carburetor and fuel injection setups. Upgrading to a high-flow intake manifold or a cold air intake can significantly improve power. These modifications allow for more efficient air flow, reducing restriction and increasing the volume of air entering the engine. Additionally, intake systems with larger throttle bodies or electronic throttle body (ETB) conversions can further enhance performance by improving throttle response and power delivery.

Exhaust System Upgrades: While not directly related to the fuel delivery system, exhaust system modifications can indirectly impact performance. High-flow catalytic converters, performance exhaust manifolds, and headers can reduce backpressure, allowing the engine to breathe better. This results in increased power and improved throttle response. When combined with fuel system upgrades, these exhaust modifications can create a well-rounded performance enhancement.

In summary, modifying your vehicle's carburetor or fuel injection system offers numerous opportunities to enhance performance. From carburetor upgrades to fuel injection tuning and intake system modifications, each component plays a vital role in optimizing power output. It's important to research and understand your specific vehicle's setup before making any modifications to ensure compatibility and achieve the desired performance gains.

Tuning Your Car: Exploring Stock Fuel System Potential

You may want to see also

Frequently asked questions

The most straightforward way to identify the fuel system in your car is to check the engine bay. Carburetors are typically larger and more visible, with a series of tubes and a float bowl attached to the engine block. Fuel injection systems, on the other hand, often have smaller, more compact components, including an injectors, a fuel pump, and a fuel rail. If you notice a large, open-air float bowl, it's likely a carburetor.

Yes, there are a few other indicators. Carburetors usually require more maintenance, such as regular carburetor adjustments and cleaning. If you've noticed a decrease in engine performance or fuel efficiency, it might be a sign of a failing carburetor. Fuel injection systems, however, often provide better performance and fuel economy. You can also check your car's manual or look up the specific model online to find detailed information about the fuel system.

Converting an engine from a carburetor to fuel injection is possible but can be complex and costly. It requires significant modifications to the engine's wiring, fuel system, and computer controls. Many car enthusiasts opt for this conversion to improve performance and fuel efficiency. However, it's essential to consult with a professional mechanic or engineer to ensure the conversion is done correctly and safely.