Fuel injection systems in conventional gasoline vehicles have been refined over the years to optimize engine performance and fuel efficiency. However, with the rise of Compressed Natural Gas (CNG) as an alternative fuel source, the question arises: Can these systems be adapted for CNG cars? This paragraph will explore the feasibility and challenges of performing fuel injection services on CNG vehicles, considering the unique properties of natural gas and the specific requirements of these engines.

| Characteristics | Values |

|---|---|

| Fuel Injection in CNG Cars | CNG (Compressed Natural Gas) vehicles typically use a different fueling system compared to gasoline or diesel engines. They usually have a direct injection system where CNG is injected directly into the combustion chamber. |

| Service and Maintenance | Fuel injection services on CNG cars may involve: - Cleaning or replacing fuel injectors to ensure optimal performance and prevent clogging. - Calibrating the fuel injection system to match the specific CNG requirements. - Regular maintenance checks to identify and fix any issues related to fuel injection. |

| Compatibility | The fuel injection system in CNG cars is designed to work with the unique properties of CNG. It requires specialized equipment and knowledge to service effectively. |

| Advantages | - Improved performance and efficiency compared to older CNG systems. - Enhanced power output and reduced emissions. - Better control over fuel delivery, leading to smoother operation. |

| Considerations | - CNG vehicles may have different service requirements compared to conventional fuel-injected cars. - Specialized tools and expertise are often necessary for maintenance. - Regular servicing ensures longevity and optimal performance. |

What You'll Learn

- Fuel Injection Basics: Understanding the role of fuel injectors in CNG cars

- CNG Injection Systems: How CNG-specific fuel injection systems differ from gasoline

- Service Procedures: Step-by-step guide to performing fuel injection service on CNG vehicles

- Diagnosis Techniques: Methods for identifying fuel injection issues in CNG cars

- Maintenance Tips: Best practices to ensure optimal performance of CNG fuel injectors

Fuel Injection Basics: Understanding the role of fuel injectors in CNG cars

Fuel injectors play a crucial role in the operation of CNG (Compressed Natural Gas) vehicles, and understanding their function is essential for maintaining optimal performance. In these cars, fuel injectors are responsible for delivering the precise amount of fuel required for combustion, ensuring efficient and environmentally friendly operation. This is particularly important as CNG, being a cleaner-burning fuel, demands a more sophisticated fueling system compared to traditional gasoline or diesel engines.

The primary function of fuel injectors in CNG cars is to spray a fine mist of fuel into the engine's intake manifold or directly into the combustion chamber. This process is highly regulated and precise, as it directly impacts the engine's performance and emissions. Unlike older fuel injection systems, modern CNG injectors are designed to handle the unique properties of natural gas, which has a different energy density and combustion characteristics compared to gasoline.

In CNG vehicles, fuel injectors are often part of an electronic fuel injection system, which uses sensors and a central computer to control the fuel delivery. These sensors monitor various parameters such as engine speed, temperature, and load, allowing the system to adjust the fuel-air mixture accordingly. The electronic control unit (ECU) calculates the optimal fuel injection timing and amount, ensuring that the engine operates efficiently and produces minimal emissions.

When a driver starts the CNG vehicle, the fuel injectors activate to deliver the required fuel for the initial combustion process. As the engine operates, the injectors continue to spray fuel, adjusting the mixture based on real-time feedback from the sensors. This dynamic adjustment is crucial for maintaining stable engine performance, especially during rapid acceleration or changes in driving conditions.

Regular maintenance and service of fuel injectors are essential to ensure the longevity and efficiency of CNG vehicles. Over time, fuel injectors can become clogged or worn, leading to reduced performance and increased emissions. Cleaning or replacing the injectors as part of routine maintenance can help optimize fuel delivery, improve engine efficiency, and ensure that the vehicle meets environmental standards. Understanding the role of fuel injectors in CNG cars empowers vehicle owners to take proactive measures in maintaining their vehicles for optimal performance and environmental sustainability.

Understanding Fuel Injection: Can You DIY Your Car's Injection System?

You may want to see also

CNG Injection Systems: How CNG-specific fuel injection systems differ from gasoline

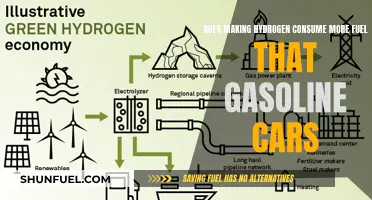

The use of compressed natural gas (CNG) as a vehicle fuel has gained popularity due to its environmental benefits and cost-effectiveness. CNG-powered vehicles require specialized fuel injection systems to optimize performance and efficiency. These CNG injection systems differ significantly from those used in gasoline vehicles, and understanding these differences is crucial for mechanics and car owners alike.

One of the primary distinctions is the fuel type itself. CNG is a gaseous fuel, whereas gasoline is a liquid. This fundamental difference necessitates unique injection methods. In CNG injection systems, the fuel is typically compressed and stored in a cylinder at high pressure. When the engine needs fuel, it is released in a controlled manner, often through a process called 'pressure regulation'. This regulated release ensures that the CNG is delivered to the engine at the precise pressure required for efficient combustion.

Gasoline engines, on the other hand, use a different approach. The fuel is injected directly into the engine's intake manifold or directly into the combustion chamber. This process is more straightforward because gasoline is a liquid, allowing for easier handling and injection. However, CNG injection systems must account for the fuel's gaseous state, which requires more intricate pressure management.

The injection timing and control mechanisms also vary. CNG engines often employ a 'dual-fuel' injection strategy, where both gasoline and CNG are injected simultaneously. This approach ensures a balanced air-fuel mixture, optimizing combustion and power output. The timing of CNG injection is critical, as it must coincide with the engine's intake stroke to maximize efficiency. In contrast, gasoline engines typically use a single-fuel injection system, where the timing is more flexible and can be adjusted based on engine load and speed.

Additionally, the fuel injection system's design and components differ. CNG injectors are often smaller and more compact to fit within the limited space of a CNG vehicle's engine bay. These injectors must handle high-pressure gas and deliver it accurately. Gasoline injectors, while also high-pressure devices, are generally larger and designed to handle the different flow characteristics of liquid fuel. The overall system design in CNG vehicles is more complex, requiring precise control of multiple parameters to ensure optimal performance and safety.

In summary, CNG-specific fuel injection systems are tailored to the unique challenges of gaseous fuel. They require careful pressure management, dual-fuel injection strategies, and specialized components to deliver efficient and reliable performance. Understanding these differences is essential for mechanics when servicing CNG vehicles, ensuring that the fuel injection system operates optimally and safely.

Understanding Car Fuel Efficiency: The Average Fuel Economy Explained

You may want to see also

Service Procedures: Step-by-step guide to performing fuel injection service on CNG vehicles

Service Procedures: Step-by-Step Guide to Fuel Injection Service on CNG Vehicles

Performing a fuel injection service on a compressed natural gas (CNG) vehicle requires a systematic approach to ensure optimal performance and longevity of the engine. Here's a step-by-step guide to help you through the process:

- Preparation and Safety Checks: Begin by ensuring you have the necessary tools and equipment, including a fuel injection tester, pressure gauge, and CNG-specific diagnostic tools. Before starting, inspect the vehicle for any visible signs of damage or leaks. Confirm that the CNG system is depressurized and that all safety protocols are followed to prevent any hazards.

- Accessing the Fuel Injection System: Locate the fuel injection system, which is typically positioned near the engine. This system may include fuel injectors, a fuel rail, and associated wiring harnesses. Carefully inspect the system for any signs of contamination, blockages, or damage. It is crucial to identify the specific type of fuel injection system used in the CNG vehicle, as different designs may require unique procedures.

- Fuel Injection Tester Setup: Connect the fuel injection tester to the vehicle's diagnostic port or directly to the fuel injectors. Follow the manufacturer's instructions to calibrate the tester for CNG vehicles. This step ensures accurate readings and proper functioning of the testing equipment.

- Pressure and Flow Testing: Initiate the pressure test to verify the integrity of the CNG system. Check for any leaks or pressure drops that could affect performance. Simultaneously, conduct a flow test to measure the fuel delivery rate of each injector. Document any discrepancies or issues found during these tests.

- Injector Cleaning and Maintenance: If any contaminants or blockages are detected, proceed with cleaning the fuel injectors. This process may involve using specialized cleaning solutions and ultrasonic baths to remove deposits. Ensure that all injectors are properly lubricated and reassembled. Regular maintenance, including injector replacement if necessary, is vital to prevent performance degradation.

- System Calibration and Testing: After the cleaning process, recalibrate the fuel injection system to match the CNG vehicle's specifications. This step involves adjusting fuel pressure, spray patterns, and other parameters. Test the system's performance by running the engine and monitoring for any anomalies. Adjustments may be required to optimize power output and fuel efficiency.

- Final Inspection and Documentation: Once the service is complete, conduct a thorough inspection of the fuel injection system and the entire CNG vehicle. Verify that all components are functioning correctly and that there are no leaks or issues. Document the service procedures, including any repairs or replacements made, and provide a detailed report to the vehicle owner or maintenance records.

Remember, working on CNG vehicles requires specialized knowledge and equipment. Always refer to the vehicle's manual and consult with experienced professionals when performing fuel injection services to ensure the best results and maintain the vehicle's performance over time.

Fuel Filter Issues: Why Your Car Won't Start

You may want to see also

Diagnosis Techniques: Methods for identifying fuel injection issues in CNG cars

When dealing with fuel injection systems in CNG (Compressed Natural Gas) vehicles, diagnosing issues can be a complex task due to the unique characteristics of this alternative fuel. Here are some advanced techniques to identify and address fuel injection problems in CNG cars:

- Comprehensive Sensor Analysis: CNG vehicles rely on a network of sensors to monitor fuel quality, pressure, and injection timing. A thorough inspection of these sensors is crucial. Start by checking the CNG mass flow sensor, which measures the amount of fuel entering the engine. Malfunctioning or clogged sensors can lead to inaccurate fuel delivery. Inspect the pressure sensors as well, ensuring they provide precise data for the CNG system's operation. Advanced diagnostic tools can be used to read sensor data and identify any deviations from the expected values.

- Fuel Pressure Testing: Measuring fuel pressure is essential in CNG cars. Use a fuel pressure gauge to check the pressure at the fuel rail or injectors. Low pressure might indicate a faulty pump or clogged fuel lines. Compare the readings with the manufacturer's specifications to ensure the system operates within the required parameters. This test can help isolate issues related to fuel delivery and injection timing.

- Visual Inspection and Maintenance: Regular visual inspections can reveal potential problems. Look for any signs of fuel leaks, especially around the fuel injectors and lines. Even a small leak can lead to engine performance issues. Inspect the CNG storage tank for any corrosion or damage, as this can affect fuel quality. Additionally, maintaining the engine's cleanliness is vital; remove carbon deposits regularly to ensure optimal fuel atomization.

- Engine Performance Monitoring: Diagnosing fuel injection issues often requires monitoring the engine's performance. Use a scan tool to read error codes and engine parameters. Look for any warning signs such as misfires, rough idling, or reduced power output. These symptoms can indicate fuel injection problems, such as clogged injectors or faulty electronic control units (ECUs). By analyzing engine behavior, you can pinpoint specific components that require attention.

- Advanced Diagnostic Tools: Invest in specialized diagnostic equipment designed for CNG vehicles. These tools can provide detailed insights into the fuel injection system's performance. They can read live data, perform system diagnostics, and identify error codes specific to CNG engines. Advanced tools might also offer functions like fuel flow mapping, which helps visualize the fuel distribution within the engine.

Identifying fuel injection issues in CNG cars requires a systematic approach, combining sensor analysis, pressure testing, visual inspections, and performance monitoring. By utilizing these techniques, technicians can effectively diagnose and resolve problems, ensuring optimal performance and longevity of CNG vehicle fuel systems.

Understanding Fuel Transportation Rules: What You Need to Know

You may want to see also

Maintenance Tips: Best practices to ensure optimal performance of CNG fuel injectors

CNG (Compressed Natural Gas) fuel injectors require specific maintenance practices to ensure they function optimally and efficiently. Here are some essential tips to keep in mind for maintaining your CNG fuel injectors:

- Regular Cleaning and Inspection: CNG fuel injectors should be cleaned regularly to remove any deposits or contaminants that may accumulate over time. This can be done using specialized cleaning solutions or by professional service centers. During the cleaning process, inspect the injectors for any signs of damage, wear, or blockages. Look for cracks, leaks, or any debris that might affect performance. Regular inspections can help identify issues early on and prevent potential problems.

- Use of High-Quality CNG Fuel: The quality of fuel used is crucial for the longevity and performance of CNG injectors. Always use high-quality CNG fuel that meets the required specifications. Impure or contaminated fuel can lead to injector clogs and reduced performance. Ensure that the fuel is stored and transported in a clean environment to minimize the risk of contamination.

- Routine Maintenance and Servicing: Schedule regular maintenance checks for your CNG vehicle, including injector servicing. Professional mechanics can perform thorough inspections and cleanings, ensuring that the injectors are in optimal condition. They can also identify and address any potential issues before they become major problems. Regular maintenance helps to maintain the efficiency and reliability of your CNG system.

- Monitor Injector Performance: Keep an eye on the performance of your CNG fuel injectors. Listen for any unusual noises or changes in engine behavior. If you notice a decrease in power, fuel efficiency, or hear strange sounds during operation, it may indicate a problem with the injectors. Address these issues promptly to prevent further damage and ensure safe driving.

- Replace Worn Components: Over time, certain components of the CNG fuel injection system may wear out and require replacement. This includes injectors, valves, and related parts. Always use genuine or high-quality replacement parts to ensure compatibility and optimal performance. Regularly replacing worn-out parts will help maintain the overall efficiency of your CNG vehicle.

By following these maintenance tips, you can ensure that your CNG fuel injectors operate at their best, providing efficient and reliable performance. Remember, proper care and regular servicing are key to maximizing the lifespan of your CNG vehicle's fuel injection system.

Boost Your Car's Fuel Efficiency: Tips and Tricks

You may want to see also

Frequently asked questions

Absolutely! We specialize in CNG vehicle maintenance and can perform fuel injection services for your car. Our technicians are trained to handle the unique requirements of natural gas engines.

Our service process includes a thorough inspection of the fuel injection system, cleaning or replacing injectors, and ensuring proper calibration. We use specialized tools and equipment to optimize performance and maintain the longevity of your CNG engine.

It is recommended to have your CNG car's fuel injection system serviced every 10,000 to 15,000 miles or as per the manufacturer's guidelines. Regular maintenance helps prevent performance issues and ensures efficient fuel delivery.

CNG engines can experience unique challenges like fuel system deposits and potential issues with the electronic control unit (ECU). Our technicians are well-versed in identifying and resolving these problems to ensure optimal performance.

No, our professional fuel injection service will not void your vehicle's warranty. We use genuine parts and follow manufacturer-approved procedures, ensuring your car remains under warranty coverage.