The 1964 Grand Prix was a pivotal moment in racing history, and one of the key questions surrounding this event is whether the cars featured a return fuel line. This technical detail is crucial to understanding the performance and efficiency of the vehicles, as it directly impacted their fuel management and overall race strategy. The presence or absence of a return fuel line could have influenced the outcome of the race, making it an essential aspect to explore when analyzing the 1964 Grand Prix.

What You'll Learn

- Fuel System Design: The 1964 Grand Prix's fuel system included a return line for efficient fuel flow

- Performance Enhancement: A return line improved engine performance by ensuring optimal fuel delivery

- Safety Measures: The return line was a safety feature to prevent fuel leaks and fires

- Maintenance Considerations: Regular maintenance of the return line is crucial for long-term reliability

- Historical Context: The 1964 Grand Prix's return line was a standard feature in racing cars of that era

Fuel System Design: The 1964 Grand Prix's fuel system included a return line for efficient fuel flow

The 1964 Grand Prix cars utilized an innovative fuel system design that incorporated a return line, a feature that significantly enhanced fuel flow efficiency. This design choice was a departure from the conventional approach of the time, where fuel was typically supplied directly to the engine without a return mechanism. The return line played a crucial role in optimizing the fuel delivery process, ensuring a consistent and efficient supply of fuel to the engine.

In the context of racing, where performance and reliability are paramount, the fuel system's design was a critical aspect. The return line addressed the challenge of maintaining a steady fuel pressure and flow rate, especially during high-speed maneuvers and rapid acceleration. By allowing fuel to be recycled and re-pressurized, the system ensured that the engine received the required amount of fuel at the right pressure, resulting in improved power output and overall engine performance.

This design feature was particularly advantageous in the high-performance environment of the Grand Prix circuit. The return line helped mitigate the issues associated with fuel vaporization and atomization, ensuring that the fuel-air mixture was optimally balanced for efficient combustion. As a result, the engine could operate at its peak, delivering the power required to compete at the highest level.

Furthermore, the inclusion of a return line contributed to the overall reliability of the fuel system. By preventing fuel from pooling at the bottom of the tank, it reduced the risk of fuel starvation during extended periods of high-speed driving. This was especially crucial in the fast-paced and demanding nature of Grand Prix racing, where mechanical failures could be costly.

In summary, the 1964 Grand Prix's fuel system design, with its return line, represented a significant advancement in automotive engineering. It showcased a thoughtful approach to fuel management, optimizing performance and reliability in a high-performance racing environment. This design choice continues to inspire and influence modern fuel system architectures, highlighting the importance of efficient fuel flow in automotive applications.

Replacing Fuel Line in Poulan Chainsaw: A Step-by-Step Guide

You may want to see also

Performance Enhancement: A return line improved engine performance by ensuring optimal fuel delivery

The concept of a return fuel line is an essential component in engine design, especially for high-performance applications like the 1964 Grand Prix. This system, often overlooked, plays a crucial role in enhancing engine performance and efficiency. By implementing a return line, the fuel delivery process becomes more controlled and precise, leading to improved power output and overall engine health.

In the context of the 1964 Grand Prix, the engine's performance could be significantly enhanced by incorporating a return fuel line. This system works by recirculating the excess fuel from the injectors back to the fuel tank or a reservoir, ensuring that the engine always receives the optimal fuel-air mixture. The process begins with the fuel pump, which delivers fuel to the injectors under pressure. Instead of allowing the excess fuel to escape, the return line redirects it, preventing wastage and ensuring that the engine receives a consistent and precise amount of fuel.

The benefits of this design are twofold. Firstly, it improves fuel efficiency by reducing the amount of fuel that is lost during the injection process. This is particularly important in high-performance engines where fuel consumption can be a limiting factor. Secondly, it enhances engine performance by ensuring that the correct fuel-air ratio is maintained at all times. A well-balanced fuel mixture results in more efficient combustion, producing more power and reducing the risk of engine knock or misfires.

The return line also contributes to the overall longevity of the engine. By preventing excessive fuel buildup, it reduces the chances of fuel-related issues such as carbon buildup and corrosion. This is especially critical in high-performance vehicles where the engine operates under extreme conditions. Proper fuel management through a return line helps maintain the engine's health and ensures it can withstand the demands of racing or high-performance driving.

In summary, the implementation of a return fuel line in the 1964 Grand Prix engine would have been a significant performance enhancement. It ensures optimal fuel delivery, improves efficiency, and contributes to the engine's long-term reliability. This simple yet effective system is a testament to the ingenuity of automotive engineering, showcasing how minor adjustments can lead to substantial gains in power and overall engine performance.

Kreem Fuel Tank Liner: A Comprehensive Guide to Installation and Benefits

You may want to see also

Safety Measures: The return line was a safety feature to prevent fuel leaks and fires

The 1964 Grand Prix cars utilized a return fuel line as a critical safety measure, a design feature that has since become a standard in racing and automotive engineering. This system was a direct response to the growing concerns about fuel-related accidents and the potential for catastrophic failures. The primary purpose of the return fuel line was to prevent fuel leaks and mitigate the risk of fires, which were significant threats in the high-performance environment of Grand Prix racing.

In the context of the 1964 season, fuel systems were more complex and often less reliable than modern designs. The return line was an innovative solution to an age-old problem. It worked by routing the fuel back to the fuel tank after it had passed through the engine, ensuring that any excess fuel was contained and not left to accumulate in the engine bay. This design feature was particularly important as it helped to reduce the risk of fuel spills and potential ignition sources, especially in the event of a crash or mechanical failure.

The return fuel line system was designed with multiple layers of protection. It was typically made of high-quality materials that could withstand high pressures and temperatures, ensuring the fuel's integrity. Additionally, the line was often insulated to prevent heat transfer from the engine to the fuel, further reducing the risk of vaporization and potential fire hazards. This insulation was crucial in maintaining the stability of the fuel system, especially during high-speed racing conditions.

Furthermore, the implementation of the return fuel line was a testament to the evolving safety standards in motorsports. As the sport gained popularity, the need for enhanced safety measures became increasingly apparent. The return line was one of several innovations that contributed to a more secure racing environment, including improved chassis designs, fire-resistant materials, and advanced engine management systems. These collective efforts aimed to minimize the risks associated with high-performance racing, ensuring the safety of both drivers and spectators.

In summary, the return fuel line in 1964 Grand Prix cars was a vital safety feature, addressing the critical issue of fuel management and fire prevention. Its implementation demonstrated a proactive approach to automotive safety, setting a precedent for future racing and automotive engineering. Understanding and appreciating these historical safety measures can provide valuable insights into the continuous development of safer vehicles and racing environments.

Stihl Trimmer Fuel Line Sizes: A Comprehensive Guide

You may want to see also

Maintenance Considerations: Regular maintenance of the return line is crucial for long-term reliability

The return fuel line is a critical component in any vehicle's fuel system, and its maintenance is often overlooked until it fails. For the 1964 Grand Prix, ensuring the proper functioning of this line is essential for optimal performance and longevity. Regular maintenance can prevent potential issues and costly repairs down the line.

One key aspect of maintenance is inspecting the return line for any signs of damage or wear. Over time, the line can develop cracks, leaks, or blockages due to factors like fuel contamination, age, or mechanical stress. Visual inspections should be conducted periodically to identify any visible issues. Look for signs of corrosion, especially if the line is made of metal, as this can lead to reduced flexibility and potential leaks. Additionally, check for any signs of fuel contamination, such as discoloration or sediment buildup, which may indicate a compromised fuel filter or pump.

Another important maintenance task is to ensure the line's proper connection and secure attachment. The return fuel line should be firmly attached to the fuel tank and engine, with no loose fittings or connections. Regularly check the line's attachments and tighten any loose components to prevent potential fuel leaks. It is also beneficial to inspect the fuel tank for any signs of damage or corrosion, as this can affect the line's integrity.

Furthermore, maintaining a clean fuel system is vital. Regularly replacing the fuel filter and performing fuel system flushes can help prevent the buildup of contaminants and ensure the return line's optimal performance. This simple maintenance routine can extend the life of the fuel system and reduce the risk of fuel-related issues.

In summary, regular maintenance of the return fuel line is essential for the 1964 Grand Prix's long-term reliability. By inspecting for damage, ensuring proper connections, and maintaining a clean fuel system, owners can avoid potential problems and ensure their vehicle's performance and efficiency. It is a cost-effective practice that can save time and money in the long run.

Dirt Bike Fuel Line: Location and Installation Guide

You may want to see also

Historical Context: The 1964 Grand Prix's return line was a standard feature in racing cars of that era

The 1964 Grand Prix era was a pivotal period in the history of motor racing, characterized by technological advancements and a focus on performance. One of the key innovations of this time was the introduction and widespread use of a return fuel line in racing cars. This feature, often overlooked by modern enthusiasts, played a crucial role in the development of fuel systems in automotive racing.

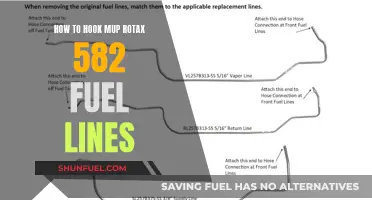

In the context of the 1960s, return fuel lines were a standard and essential component of racing car design. The primary purpose of this system was to ensure efficient fuel distribution and management, which was critical for maintaining optimal engine performance during high-speed races. The return line allowed fuel to be recirculated, ensuring a constant and precise fuel-air mixture in the engine, thereby improving power output and overall engine efficiency. This was particularly important in the era's Grand Prix races, where cars were pushing the boundaries of speed and power.

Historically, the use of return fuel lines can be traced back to the early days of racing, but it was in the 1960s that their implementation became more widespread and refined. The technology of the time demanded reliable and efficient fuel systems to meet the increasing demands of high-performance engines. The return line system provided a solution by allowing for better fuel management, especially during aggressive cornering and high-speed sections of the race track. This innovation was a significant step forward in the evolution of racing car technology.

The 1964 Grand Prix cars, with their return fuel lines, represented the pinnacle of automotive engineering at the time. These vehicles were designed to be fast, reliable, and capable of enduring the physical demands of racing. The return line system contributed to the overall performance and safety of these cars, ensuring that fuel was delivered efficiently to the engine, even under extreme conditions. This historical context highlights the importance of such technical details in shaping the sport and the automotive industry as a whole.

In summary, the presence of return fuel lines in 1964 Grand Prix cars was a standard and critical feature, reflecting the era's focus on technological innovation and performance. This historical perspective provides insight into the evolution of racing car design and the importance of fuel system advancements in the early days of motor racing.

Outboard Fuel Line Clogs: Causes and Solutions

You may want to see also

Frequently asked questions

Yes, the 1964 Grand Prix model, specifically the Ferrari 250 GTO, featured a return fuel line as part of its fuel system design. This line was used to ensure efficient fuel flow and pressure regulation, contributing to the car's performance and reliability.

The return fuel line was an essential component for maintaining optimal fuel levels and pressure in the engine. It allowed excess fuel to be recycled back to the fuel tank, preventing fuel accumulation in the lines and ensuring a steady supply of fresh fuel to the engine during operation.

By implementing the return fuel line, the 1964 Grand Prix benefited from improved fuel management, resulting in enhanced engine performance and efficiency. This design feature allowed for better fuel economy and reduced the chances of fuel-related issues, such as engine misfires or poor acceleration.