Rubber fuel lines are an essential component of any vehicle's fuel system, responsible for transporting fuel from the tank to the engine. While they are designed to be durable and long-lasting, rubber fuel lines can fail over time due to various factors such as age, exposure to heat and sunlight, and chemical degradation. Understanding the potential causes and signs of failure is crucial for vehicle owners to ensure optimal performance and prevent costly repairs. This introduction aims to explore the possibility of rubber fuel line failure and its implications.

| Characteristics | Values |

|---|---|

| Material | Rubber |

| Common Issues | Cracks, Leaks, Softening, Swelling, Discoloration |

| Causes | Age, Heat, Fuel Contamination, Chemical Exposure, Physical Damage |

| Symptoms | Fuel leaks, Engine misfires, Reduced performance, Strange odors |

| Lifespan | Typically 5-10 years, depends on conditions |

| Maintenance | Regular inspections, Replacing old lines, Using fuel stabilizers |

| Alternatives | Plastic fuel lines, Braided steel lines |

| Safety | Can lead to engine damage, Fire hazard if fuel leaks and ignites |

| Cost | Repair or replacement can range from $50 to $200 or more |

What You'll Learn

- Rubber Fuel Line Cracks: Age, heat, and UV exposure can cause cracks and brittleness

- Fuel Leakage: Rubber fuel lines can develop leaks due to wear and tear

- Fuel Contamination: Rubber lines may absorb fuel contaminants, leading to performance issues

- Flexibility Loss: Over time, rubber fuel lines can lose flexibility, making them more prone to breakage

- Corrosion: Exposure to fuel and moisture can cause corrosion, weakening the rubber material

Rubber Fuel Line Cracks: Age, heat, and UV exposure can cause cracks and brittleness

The integrity of a vehicle's fuel system is crucial for optimal performance and safety. One often overlooked component is the rubber fuel line, which can be susceptible to deterioration over time. Age, heat, and ultraviolet (UV) exposure are primary factors that contribute to the cracking and brittleness of these lines, potentially leading to fuel leaks and reduced engine efficiency.

As rubber fuel lines age, they undergo a natural degradation process. The continuous flexing and movement of the line during engine operation can cause micro-tears and cracks, especially at points of stress concentration. These cracks may initially be small and inconspicuous, but with time, they can grow and spread, leading to a complete failure of the fuel line. The aging process is accelerated by the presence of heat, as high temperatures can cause the rubber to become more pliable and prone to cracking.

Heat is a significant contributor to the deterioration of rubber fuel lines. When a vehicle is parked in direct sunlight or near heat sources, the fuel line can absorb and retain heat, leading to a rise in temperature. Over time, this can cause the rubber to become brittle and crack. The cracks may start as small, hairline fractures, but as the heat continues to affect the line, they can expand and become more pronounced, potentially leading to fuel leakage.

UV exposure is another critical factor, especially for vehicles parked outdoors. Ultraviolet rays from the sun can break down the molecular structure of the rubber, causing it to become brittle and crack. This is particularly problematic in regions with high UV intensity, where the fuel lines are constantly exposed to the sun's rays. The cracks can initiate at the surface and progress inward, potentially reaching the fuel-carrying capacity of the line.

To prevent these issues, regular inspections of the fuel lines are essential. Drivers should look for any signs of cracking, brittleness, or discoloration. If any issues are detected, it is recommended to replace the fuel line promptly to avoid potential fuel leaks and engine performance problems. Additionally, parking vehicles in shaded areas or using sunshades can help minimize UV exposure and slow down the aging process of the rubber fuel lines.

Unclog Fuel Lines: The Ultimate Gas Additive Guide

You may want to see also

Fuel Leakage: Rubber fuel lines can develop leaks due to wear and tear

Fuel leakage is a critical issue that can arise from the deterioration of rubber fuel lines, which are essential components in vehicle fuel systems. Over time, these lines can develop cracks, splits, or holes due to various factors, leading to potential safety hazards and performance problems. Rubber fuel lines are designed to withstand the pressure and temperature fluctuations associated with fuel transport, but they are not indestructible. The material's inherent flexibility and durability make it suitable for this application, but it is not immune to the effects of aging and environmental factors.

Wear and tear is a natural process that occurs as vehicles age, and rubber fuel lines are no exception. The constant expansion and contraction of the fuel lines due to temperature changes can cause the material to weaken and become more susceptible to damage. Additionally, the constant vibration and movement within the engine compartment can accelerate this wear, leading to cracks and eventual failure. As the rubber ages, it may become brittle, losing its ability to absorb shocks and vibrations effectively, which can result in microscopic tears and cracks that are not visible to the naked eye.

Environmental factors also play a significant role in the deterioration of rubber fuel lines. Exposure to sunlight, ozone, and other chemicals in the air can cause the rubber to degrade, becoming more prone to cracking and leaking. This is particularly true for fuel lines that are exposed to the elements, such as those on the outside of the vehicle. The intense heat from the sun and the corrosive effects of road salt and other contaminants can accelerate the aging process, making these fuel lines more susceptible to failure.

Regular maintenance and inspections are crucial in preventing fuel leakage. Vehicle owners should pay attention to any signs of damage, such as cracks, bulges, or leaks, and address them promptly. Visual inspections can help identify issues, but it is also essential to use specialized tools and techniques, such as pressure testing, to detect hidden leaks and ensure the integrity of the fuel system. By staying proactive, drivers can avoid the potential hazards and costly repairs associated with fuel line failures.

In the event of a fuel line leak, immediate action is necessary to prevent further damage and ensure safety. Drivers should pull over to a safe location and shut off the engine to avoid any potential hazards. It is recommended to have the vehicle towed to a qualified mechanic for a thorough inspection and repair. Ignoring a fuel line leak can lead to engine misfires, reduced performance, and even fire hazards, making prompt action essential to maintain a reliable and safe vehicle.

Understanding B1 Fuel Line: A Comprehensive Guide

You may want to see also

Fuel Contamination: Rubber lines may absorb fuel contaminants, leading to performance issues

Fuel contamination is a critical issue that can significantly impact the performance and longevity of a vehicle's fuel system. Rubber fuel lines, while durable, are not immune to the absorption of contaminants, which can lead to a range of problems. These lines, often made from synthetic rubber compounds, are designed to withstand the corrosive nature of fuel, but over time, they can become susceptible to degradation.

The primary concern with rubber fuel lines is their ability to absorb and retain contaminants. Fuel, especially when it contains impurities or has been exposed to environmental factors, can carry various substances that are detrimental to the engine's performance. These contaminants may include water, dirt, rust, and volatile organic compounds (VOCs). When rubber fuel lines come into contact with such contaminated fuel, they can absorb these harmful substances, leading to several performance issues.

One of the most common consequences of fuel contamination in rubber lines is the development of engine misfires. As the rubber absorbs water and other contaminants, it can become permeable, allowing moisture and impurities to enter the fuel system. This moisture can cause the fuel to become unstable, leading to erratic combustion in the engine. Engine misfires result in reduced power, poor acceleration, and a noticeable loss of performance. Over time, this can cause significant damage to the engine, including the potential for expensive repairs.

Additionally, rubber fuel lines may also contribute to fuel pump issues. Contaminants absorbed by the rubber can restrict the flow of fuel, causing the pump to work harder to deliver the required amount. This increased strain can lead to premature wear and failure of the fuel pump, resulting in expensive repairs or the need for a replacement. The contamination can also cause the pump to become noisy, indicating potential failure.

To prevent these issues, regular maintenance and fuel system inspections are essential. It is recommended to use fuel stabilizers and fuel system cleaners to minimize the risk of contamination. Keeping the fuel tank as full as possible can also help, as this leaves less room for contaminants to accumulate. Regularly checking for any signs of moisture or contamination in the fuel lines and replacing them if necessary is crucial to maintaining a healthy fuel system.

Mastering the Art of Painting Rubber Fuel Line Hose

You may want to see also

Flexibility Loss: Over time, rubber fuel lines can lose flexibility, making them more prone to breakage

The durability of rubber fuel lines is a critical aspect of vehicle maintenance that often goes unnoticed until it's too late. One of the primary reasons for their failure is the gradual loss of flexibility. Over time, the rubber material can become stiff and brittle, making it more susceptible to damage. This issue is particularly prevalent in older vehicles or those that have been exposed to extreme temperatures, as the rubber can degrade more rapidly under such conditions.

Flexibility in fuel lines is essential for several reasons. Firstly, it allows for slight movement and expansion as the engine operates, preventing excessive strain on the lines. This is crucial because rigid fuel lines can experience increased pressure and stress, leading to potential cracks or even complete rupture. When this happens, fuel can leak, causing reduced engine performance or, in severe cases, engine failure.

The loss of flexibility often occurs due to the aging process of the rubber material. As rubber ages, it undergoes a process known as 'aging degradation,' where the molecular structure of the rubber changes, making it more susceptible to damage. This is further exacerbated by environmental factors such as sunlight, heat, and cold, which can accelerate the aging process. For instance, prolonged exposure to the sun's UV rays can cause the rubber to harden and crack, while extreme cold can make it brittle and prone to splitting.

Regular inspections are vital to identifying this issue early on. Vehicle owners should look for any visible signs of damage, such as cracks, brittleness, or discolouration along the fuel lines. Additionally, checking for any fuel leaks, especially around the engine bay, can indicate potential problems with the fuel lines. If any issues are detected, it is recommended to replace the fuel lines promptly to prevent further damage and ensure optimal engine performance.

In summary, the flexibility of rubber fuel lines is a critical factor in their longevity and performance. Over time, the material can lose its flexibility, leading to increased breakage and potential engine failure. Understanding the causes and signs of flexibility loss can help vehicle owners take proactive measures to maintain their vehicles and avoid costly repairs. Regular maintenance and inspections are key to ensuring the reliability and safety of any vehicle's fuel system.

Fuel Line Blow-Off Filter: Causes, Fixes, and Prevention Tips

You may want to see also

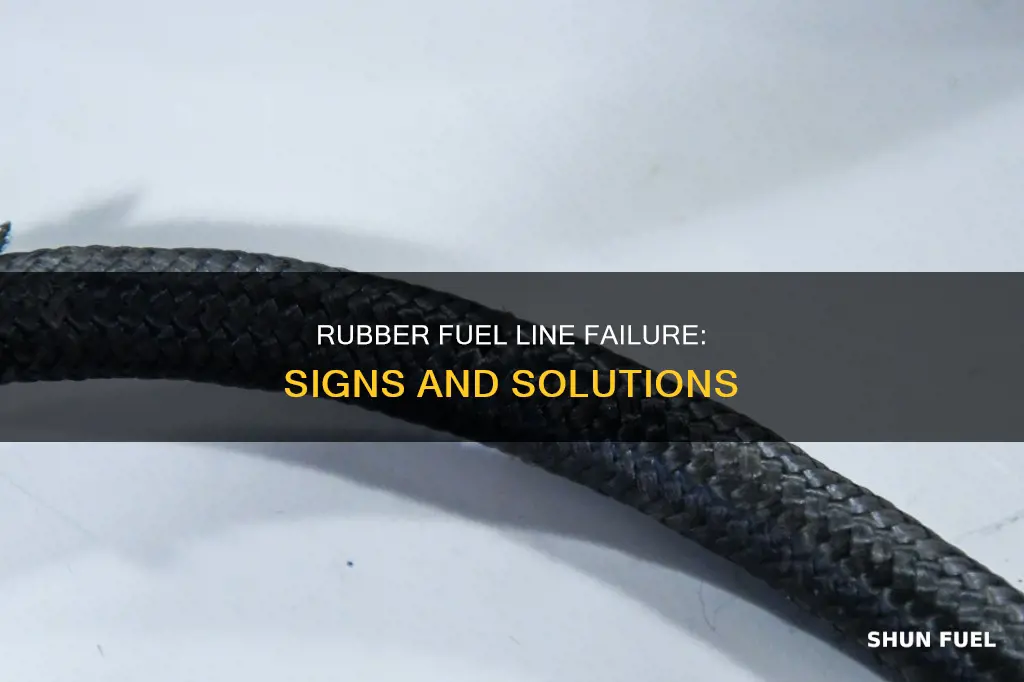

Corrosion: Exposure to fuel and moisture can cause corrosion, weakening the rubber material

Corrosion is a significant concern for rubber fuel lines, especially in the automotive industry. Rubber, while a durable material, is not immune to the effects of its environment, particularly when it comes to fuel and moisture. These two elements can lead to a process that weakens the rubber over time, ultimately causing the fuel line to fail.

When a rubber fuel line is exposed to fuel, the hydrocarbons in the fuel can begin to break down the molecular structure of the rubber. This process, known as hydrolysis, is accelerated by the presence of moisture. Moisture acts as a catalyst, facilitating the reaction between the fuel and the rubber, leading to the degradation of the material. As a result, the fuel line may become brittle, crack, or even rupture, causing potential fuel leaks and compromising the vehicle's performance.

The impact of corrosion on rubber fuel lines is often insidious and may not be immediately noticeable. Over time, the rubber can become discolored, soft, or even develop visible cracks. These changes in the material's properties indicate that the corrosion process has already begun and may have progressed to a critical stage. Ignoring these signs can lead to sudden and unexpected failures, potentially causing dangerous situations on the road.

To prevent such issues, regular maintenance and inspections are crucial. Vehicle owners should pay attention to any unusual noises, leaks, or changes in engine performance, as these could be early indicators of a failing fuel line. Additionally, keeping the vehicle's fuel system clean and dry can help mitigate the risk of corrosion. Using fuel stabilizers and ensuring proper ventilation in the fuel tank can also contribute to the longevity of the rubber fuel lines.

In summary, the combination of fuel and moisture is a corrosive agent that can significantly impact the integrity of rubber fuel lines. Understanding this relationship is essential for maintaining vehicle reliability and safety. By recognizing the signs of corrosion and implementing preventive measures, drivers can ensure that their fuel lines remain in optimal condition, reducing the likelihood of unexpected failures.

Fuel Line Clogs: The Angel's Parking Dilemma

You may want to see also

Frequently asked questions

Rubber fuel lines can degrade over time due to various factors. Exposure to fuel chemicals, UV radiation, temperature fluctuations, and mechanical stress are common culprits. The fuel's composition, especially if it contains ethanol, can accelerate degradation. Additionally, physical damage from sharp edges, vibrations, or improper installation can compromise the line's integrity.

Signs of a failing rubber fuel line include fuel leaks, engine misfires, reduced performance, and changes in fuel odor. You might notice a sweet or gasoline-like smell inside the car or see stains on the garage floor. Regular inspections and fuel line condition checks during maintenance can help identify issues early.

Yes, several preventive measures can extend the life of your rubber fuel lines. Using high-quality, ethanol-free fuel is essential. Regularly inspecting the lines for cracks, brittleness, or signs of damage is crucial. Ensuring proper installation and avoiding tight bends or kinks can also prevent premature failure. Additionally, using fuel line protectants and maintaining a clean fuel system can contribute to longevity.