If you suspect a fuel line leak, it's crucial to address the issue promptly to prevent potential hazards. Taping a leak might seem like a temporary fix, but it's important to understand the risks and explore safer alternatives. This paragraph will delve into the potential dangers of using tape as a repair method and discuss the importance of seeking professional assistance to ensure a safe and effective resolution to your fuel line leak.

What You'll Learn

- Fuel Line Inspection: Check for signs of damage, corrosion, or leaks using visual and tactile inspections

- Temporary Fix: Use a fuel line clamp or tape to temporarily seal small leaks, but seek professional repair

- Tape Selection: Choose a high-temperature, fuel-resistant tape like silicone or rubber for effective sealing

- Safety Precautions: Ensure proper ventilation and avoid sparks when working with fuel to prevent fire hazards

- Long-Term Solutions: Consider professional repairs or replacing the fuel line to ensure a safe and reliable system

Fuel Line Inspection: Check for signs of damage, corrosion, or leaks using visual and tactile inspections

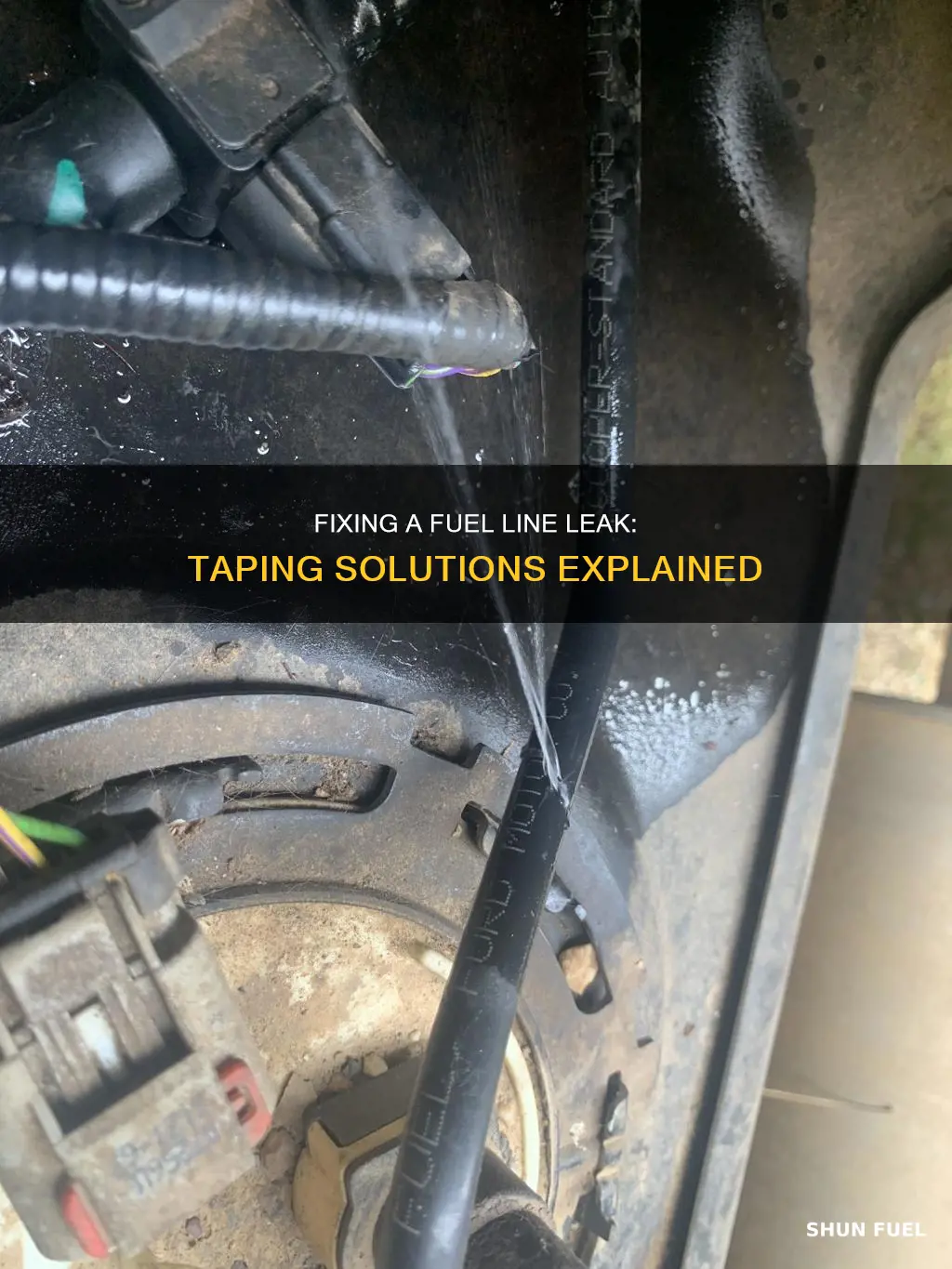

When it comes to inspecting your fuel lines for potential issues, a thorough visual and tactile examination is essential. Start by looking for any visible signs of damage, such as cuts, punctures, or tears in the fuel line itself. These can often be identified by discolouration, such as a dark or rusty appearance, which may indicate corrosion or internal damage. Inspect the fuel lines for any signs of wear and tear, especially in areas where the lines are more susceptible to damage, such as under the vehicle or near the fuel tank. Look for any signs of bending, kinking, or twisting, as these can lead to restricted flow or potential leaks.

A tactile inspection is equally important. Feel the fuel lines for any rough spots, hard lumps, or areas of reduced flexibility. These could indicate the presence of corrosion or internal debris. Pay close attention to the connections and fittings, as these are common areas for leaks. Ensure that all connections are tight and secure, and check for any signs of corrosion or degradation around the threads or seals. If you notice any areas that feel spongy or soft, it could be a sign of internal damage or the presence of air bubbles, which can lead to fuel line issues.

In addition to the visual and tactile checks, it's crucial to inspect the fuel lines for any signs of corrosion. Look for discolouration or a powdery substance on the fuel lines, especially in areas where moisture or road salt may be present. Corrosion can weaken the fuel lines over time, leading to potential leaks or reduced fuel efficiency. If you suspect corrosion, consider using a fuel line cleaner or a mild acid solution to remove it, ensuring you follow the manufacturer's instructions.

During your inspection, also check for any signs of fuel contamination. This can occur if the fuel lines are not properly sealed or if there is a breach in the system. Contaminated fuel can lead to engine performance issues and potential damage. Look for any unusual smells or colours in the fuel, as these could indicate the presence of water or other contaminants.

Remember, regular fuel line inspections are crucial for maintaining your vehicle's performance and safety. While you can perform a basic visual and tactile inspection, more complex issues may require professional attention. If you notice any significant damage or persistent leaks, it is best to consult a qualified mechanic who can provide expert advice and ensure your fuel system is in optimal condition.

Fuel Lines Under the Car: A Guide to Their Location and Importance

You may want to see also

Temporary Fix: Use a fuel line clamp or tape to temporarily seal small leaks, but seek professional repair

If you find a small leak in your fuel line, it's important to act quickly to prevent further damage and potential safety hazards. While it's not recommended to use tape as a long-term solution, it can be a temporary fix to get you to a mechanic or repair shop. Here's a step-by-step guide on how to use a fuel line clamp or tape to seal the leak:

Step 1: Assess the Situation

Before attempting any repairs, ensure the engine is off and the vehicle is in a safe, level position. Inspect the fuel line to determine the size and location of the leak. Small, pinpoint leaks are best addressed with tape, while larger leaks may require a clamp or professional intervention.

Step 2: Gather Materials

You'll need a fuel line clamp or a roll of high-temperature, automotive-grade tape. Clamps are available in various sizes, so choose one that fits the diameter of the fuel line. Automotive tape should be specifically designed for fuel lines and can be found at auto parts stores.

Step 3: Prepare the Tape or Clamp

If using tape, ensure it is the correct type for fuel lines and has a strong adhesive. Cut a piece of tape slightly longer than the length of the leak. If using a clamp, ensure it is the right size and securely fits the fuel line.

Step 4: Apply the Temporary Fix

For tape: Clean the fuel line at the leak area to ensure a good bond. Wrap the tape around the leak, overlapping the edges slightly. Secure it firmly, but be careful not to overtighten, as this can restrict fuel flow. For a clamp: Slide the clamp over the fuel line, positioning it at the leak. Tighten the clamp securely, ensuring it is snug but not overly tight.

Important Note: This temporary fix should only be used as a short-term solution. It is crucial to have the fuel line repaired by a professional mechanic as soon as possible. Driving with a leaking fuel line can lead to engine damage, fuel leaks, and potential fire hazards. Always prioritize safety and seek professional help for a proper repair.

Shreveport's Best Fuel Line Sources: Your Ultimate Guide

You may want to see also

Tape Selection: Choose a high-temperature, fuel-resistant tape like silicone or rubber for effective sealing

When dealing with a fuel line leak, it's crucial to select the right tape to ensure a secure and long-lasting repair. The primary consideration here is the tape's ability to withstand high temperatures and resist fuel chemicals, as fuel lines are exposed to these conditions. Silicone and rubber tapes are excellent choices for this purpose.

Silicone tape is a popular and effective option for sealing fuel line leaks. It is known for its superior heat resistance, which is essential in the engine compartment where temperatures can soar. This type of tape can handle the extreme heat generated by the engine without losing its adhesive properties or integrity. Additionally, silicone is highly resistant to the chemicals present in fuel, ensuring that the repair remains effective over time.

Rubber tape is another reliable solution for sealing fuel line leaks. It offers excellent flexibility, which is crucial for accommodating the slight movements that can occur in fuel lines due to engine operation or temperature changes. This flexibility, combined with its inherent resistance to fuel chemicals, makes rubber tape a durable and practical choice. Rubber tapes are often used in high-temperature environments and can provide a strong, long-lasting bond.

Both silicone and rubber tapes are available in various thicknesses and adhesive strengths, allowing you to choose the best option based on the specific leak and your skill level. For a temporary fix, a thinner tape might suffice, but for a more permanent solution, consider a thicker tape with a stronger adhesive. It's important to ensure that the tape you choose is compatible with the fuel line material to avoid any potential damage.

In summary, when repairing a fuel line leak, opt for high-temperature, fuel-resistant tapes like silicone or rubber. These materials provide the necessary durability and resistance to ensure a successful and long-lasting repair, keeping your vehicle running safely and efficiently. Always remember to follow the manufacturer's guidelines for the best results.

Engine Trouble: What Happens When Your Fuel Line Seals Fail

You may want to see also

Safety Precautions: Ensure proper ventilation and avoid sparks when working with fuel to prevent fire hazards

When dealing with fuel leaks, it's crucial to prioritize safety to prevent any potential hazards. One of the primary concerns is the risk of fire, which can be mitigated by ensuring proper ventilation and avoiding sparks. Here's a detailed guide on the necessary safety precautions:

Ventilation: Working with fuel requires a well-ventilated space to disperse any volatile gases that might accumulate. Ensure you are in a well-ventilated area, preferably outdoors, to allow fresh air to circulate. If working in a confined space, use fans or open windows to create a constant airflow. Proper ventilation is essential to reduce the concentration of flammable gases and minimize the risk of ignition.

No Sparks: Fuel is highly flammable, and any source of ignition, including sparks, should be avoided. When repairing a fuel line leak, refrain from using any tools or equipment that could generate sparks, such as grinders, soldering irons, or even static electricity from rubbing. Instead, opt for non-sparking tools made of materials like bronze or aluminum. It's also advisable to wear protective gear, including heat-resistant gloves and safety goggles, to shield yourself from potential hazards.

Additionally, ensure that any nearby power sources, such as electrical outlets or switches, are turned off or unplugged to eliminate the risk of electrical sparks. If you must use power tools, consider using battery-operated models to further reduce the chances of ignition.

Fire Safety: Keep a fire extinguisher nearby, specifically rated for fuel or hydrocarbon fires. In the event of a fire, act quickly and calmly. Use the extinguisher to suppress the flames, ensuring you follow the manufacturer's instructions. Have a plan in place for emergency response, and consider notifying emergency services if the situation becomes critical.

Training and Expertise: Working with fuel lines requires a certain level of expertise and training. If you're not confident in your abilities, it's best to seek professional assistance. Trained technicians have the knowledge to handle fuel safely and can ensure the job is done correctly, minimizing the risk of further complications.

Remember, safety should always be the top priority when dealing with fuel. By following these precautions, you can effectively manage fuel leaks while significantly reducing the chances of fire-related incidents.

Understanding the Choke Fuel Line: A Car's Essential Component

You may want to see also

Long-Term Solutions: Consider professional repairs or replacing the fuel line to ensure a safe and reliable system

While it might be tempting to temporarily fix a fuel line leak with tape, this is not a long-term solution and could lead to more serious issues. Fuel lines are crucial for delivering fuel from the tank to the engine, and any disruption can result in engine misfires, reduced performance, and even potential fire hazards. Here's why you should consider professional repairs or replacing the fuel line for a safe and reliable system:

Safety Concerns: Fuel is highly flammable, and a leak can create a dangerous situation. Tape, especially if it's not specifically designed for fuel containment, may not provide an adequate seal. Over time, the tape could degrade, come loose, or fail to prevent fuel from seeping through, leading to potential fires or explosions. Professional technicians have the expertise and tools to identify the root cause of the leak and ensure a safe repair.

Proper Repair Techniques: Repairing a fuel line requires specialized knowledge and skills. Technicians understand the importance of using compatible materials that can withstand fuel pressure and temperature changes. They also know how to properly secure the repair to ensure it doesn't come loose during operation. Attempting a DIY repair without the right expertise could lead to an incomplete fix, leaving the system vulnerable to further leaks and potential damage.

Long-Term Reliability: A professional repair or replacement ensures the fuel system's longevity. New fuel lines are designed to withstand the rigors of the automotive environment and provide a secure path for fuel delivery. This reduces the risk of future leaks and ensures your engine receives the necessary fuel for optimal performance. DIY tape jobs may provide a temporary fix, but they don't address underlying issues and could lead to recurring problems.

Code Compliance and Insurance: In some cases, fuel line repairs may be subject to specific automotive codes and regulations. Professional technicians are familiar with these standards and can ensure your vehicle meets the necessary requirements. Additionally, insurance companies may require professional repairs to validate coverage in the event of future issues.

When dealing with fuel lines, it's best to consult a qualified mechanic. They can provide a thorough inspection, diagnose the cause of the leak, and offer appropriate solutions. Whether it's a simple repair or a complete replacement, professional intervention ensures your vehicle's fuel system is safe, reliable, and compliant with automotive standards.

2003 Trailblazer Fuel Line Location: A Comprehensive Guide

You may want to see also

Frequently asked questions

No, it is not safe to tape a fuel line leak. Taping over a fuel leak can create a hazardous situation as it may not effectively seal the leak, leading to potential fire or explosion risks. It is crucial to address the issue immediately by contacting a professional mechanic or a qualified technician to repair or replace the damaged fuel line.

Ignoring a fuel line leak can have serious consequences. Fuel leaks can lead to engine misfires, reduced performance, and even complete engine failure. Over time, the fuel can corrode the internal components of the engine, causing extensive damage. Additionally, a fuel leak near a heat source or an ignition source can result in a fire hazard, posing a significant risk to the vehicle and its occupants.

While it is not recommended for a long-term solution, you can use a temporary fix to contain the leak and prevent further fuel loss. You can use a fuel line clamp or a temporary patch kit specifically designed for fuel lines. These kits typically include a clamp or a patch that can be applied over the leak to create a temporary seal. However, it is essential to have the fuel line repaired or replaced as soon as possible to ensure the safety and proper functioning of your vehicle.