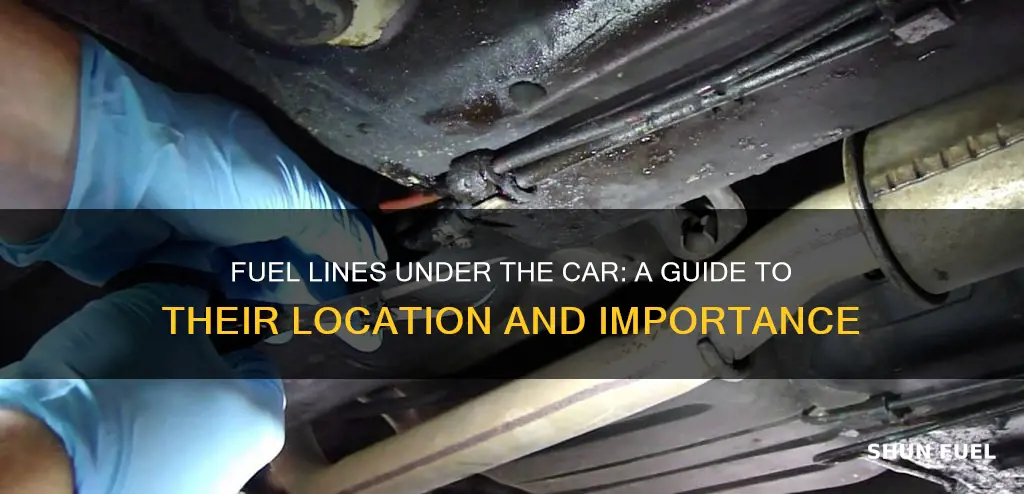

The fuel lines near the wheels under a car are a critical component of the vehicle's fuel system. These lines are responsible for transporting fuel from the fuel tank to the engine, where it is used to power the vehicle. Proper installation and maintenance of these fuel lines are essential to ensure the car's performance and safety.

What You'll Learn

- Fuel Line Placement: Positioning of fuel lines near wheels for easy access and efficient fuel supply

- Safety Considerations: Ensuring fuel lines are secure to prevent leaks and potential hazards

- Maintenance Access: Easy access for maintenance and inspections of fuel lines near wheels

- Fuel System Design: Efficient design of fuel lines to optimize fuel flow and reduce pressure

- Wheel Alignment: Proper alignment of wheels to prevent damage to fuel lines during driving

Fuel Line Placement: Positioning of fuel lines near wheels for easy access and efficient fuel supply

The positioning of fuel lines in a vehicle is a critical aspect of engine design, especially when considering accessibility and efficiency. One common practice is to place fuel lines near the wheels, which offers several advantages. This strategic placement ensures that the fuel lines are easily accessible for maintenance and repairs, reducing the time and effort required for any fuel-related tasks. By positioning the fuel lines close to the wheels, mechanics can quickly access the lines without extensive disassembly of the vehicle, making the process more efficient and cost-effective.

In the event of a fuel line issue, having them near the wheels allows for swift identification and resolution. This proximity enables technicians to inspect the lines for damage, leaks, or blockages without extensive crawling or lifting of the vehicle. Quick access to the fuel lines can significantly reduce downtime, ensuring that vehicles can be repaired promptly and minimizing the risk of further complications. Moreover, this placement facilitates the use of specialized tools and equipment, making the repair process more efficient and precise.

From an efficiency standpoint, fuel lines positioned near the wheels contribute to an optimized fuel supply system. The proximity to the wheels allows for shorter fuel lines, reducing the risk of fuel vaporization and ensuring a more consistent fuel supply to the engine. This is particularly important in high-performance vehicles where efficient fuel delivery is crucial for optimal engine operation. Additionally, the shorter lines minimize the chances of fuel contamination and reduce the potential for fuel-related engine issues.

When designing the fuel line layout, it is essential to consider the vehicle's overall structure and available space. The lines should be routed in a way that avoids sharp bends and excessive tension, as this can lead to wear and potential leaks over time. Proper insulation and protection should also be provided to safeguard the fuel lines from heat, vibration, and potential impact during vehicle operation.

In summary, placing fuel lines near the wheels under a car offers numerous benefits, including improved accessibility, efficient fuel supply, and reduced repair times. This strategic placement ensures that the fuel system is well-maintained and optimized for performance, contributing to the overall reliability and longevity of the vehicle. It is a practical and widely adopted approach in automotive engineering, reflecting the importance of fuel line positioning in vehicle design.

2003 Trailblazer Fuel Line Location: A Comprehensive Guide

You may want to see also

Safety Considerations: Ensuring fuel lines are secure to prevent leaks and potential hazards

The placement of fuel lines near wheels under a car is a common design choice, but it also presents unique safety challenges. These lines are crucial for delivering fuel to the engine, and their integrity is essential to prevent leaks and potential hazards. Here's an in-depth look at the safety considerations surrounding this critical component:

Understanding the Risks:

Fuel lines are designed to withstand pressure and temperature fluctuations, but they are also susceptible to damage. The proximity to the wheels introduces several potential risks. Firstly, during a collision or sudden impact, the fuel lines could be subjected to significant stress, leading to potential punctures or cracks. This could result in fuel leaks, which are highly dangerous due to the flammable nature of gasoline. Secondly, the weight of the vehicle and the movement of the wheels can cause the lines to rub against other components, leading to wear and tear over time. This wear can compromise the lines' integrity, making them more prone to leaks.

Securing the Fuel Lines:

Ensuring the security of fuel lines is paramount to maintaining vehicle safety. Here are some key practices:

- Routing and Placement: Engineers should carefully plan the route of fuel lines to avoid areas of high stress and potential damage. This might involve routing them away from the wheels or using protective sleeves to minimize friction.

- Clamping and Bracing: Securely clamping the fuel lines to the vehicle's frame or body can provide additional support. This prevents excessive movement and reduces the risk of damage during normal driving conditions.

- Regular Inspections: Routine vehicle inspections should include a thorough examination of the fuel lines. Look for any signs of wear, cracks, or damage, especially in areas near the wheels. Early detection can prevent potential leaks and ensure timely repairs.

- High-Quality Materials: Utilizing high-quality, durable materials for fuel lines can significantly enhance their resistance to wear and tear. This includes using materials that are less susceptible to corrosion and degradation over time.

Preventative Measures:

Implementing preventative measures can further mitigate the risks associated with fuel lines:

- Underbody Protection: Adding protective shields or guards under the vehicle can safeguard the fuel lines from potential impacts or damage during off-road driving or low-speed collisions.

- Regular Fuel System Maintenance: Regular maintenance, including fuel filter changes and system checks, can help identify and address potential issues before they become major problems.

- Driver Awareness: Educating drivers about the importance of regular inspections and reporting any unusual noises or leaks can contribute to swift issue resolution.

By adhering to these safety considerations, vehicle manufacturers and owners can significantly reduce the likelihood of fuel line-related incidents, ensuring a safer driving experience.

Fuel Line Removal: A Step-by-Step Guide for Your F-350

You may want to see also

Maintenance Access: Easy access for maintenance and inspections of fuel lines near wheels

When it comes to maintaining your vehicle's fuel system, easy access to the fuel lines near the wheels is crucial. These lines are often located in close proximity to the wheels, making them susceptible to damage from road debris, impacts, or even accidental contact during routine maintenance. Ensuring that you can inspect and maintain these fuel lines regularly is essential for the overall safety and performance of your vehicle.

The process of accessing the fuel lines near the wheels typically involves lifting the vehicle to gain a clear view and reachability. One common method is using a jack and jack stands to lift the car, providing a stable and secure platform for work. It is important to follow manufacturer guidelines and use the appropriate jack points to ensure the vehicle is safely supported. Once lifted, you can inspect the fuel lines for any signs of damage, wear, or potential leaks. Look for cracks, corrosion, or any signs of contamination that may indicate a compromised fuel system.

Regular maintenance and inspections can help identify issues early on, preventing potential fuel-related problems. For instance, if you notice any fuel line damage, it is crucial to replace it promptly to avoid fuel leaks, which can be hazardous and cause environmental damage. Additionally, keeping the fuel lines clean and free from debris can improve fuel efficiency and overall engine performance.

In some cases, you might need to remove the wheels to gain full access to the fuel lines. This step should be approached with caution and only performed if necessary. When removing wheels, ensure you have the right tools and follow a systematic approach to avoid any damage to the vehicle's components. After accessing the fuel lines, thoroughly inspect and clean them, and then reattach or replace any damaged parts.

Remember, proper maintenance and access to fuel lines can significantly contribute to the longevity of your vehicle and ensure a safe driving experience. Always prioritize safety and consult professional mechanics if you are unsure about any maintenance tasks.

Locating the Fuel Line: A 2005 Mazda 6 Guide

You may want to see also

Fuel System Design: Efficient design of fuel lines to optimize fuel flow and reduce pressure

The placement of fuel lines near the wheels of a vehicle is a strategic design choice that significantly impacts the overall performance and efficiency of the fuel system. When designing fuel lines, engineers aim to optimize fuel flow while minimizing pressure drops, ensuring a reliable and efficient supply of fuel to the engine. This is particularly crucial in high-performance vehicles where every second counts and fuel efficiency is paramount.

One key aspect of efficient fuel line design is the use of flexible, yet robust, materials. Fuel lines need to be flexible to accommodate the vehicle's movement during operation, especially around the wheels, which experience significant vibration and movement. However, they must also be durable to withstand the high-pressure environment and potential impact from road debris. Materials like high-pressure rubber hoses or braided steel hoses are commonly used, ensuring flexibility and strength. The choice of material also depends on the fuel type, with different materials suited for gasoline, diesel, or alternative fuels.

The route of the fuel lines is another critical design consideration. Fuel lines should be routed in a way that minimizes the length of the path, as longer lines can lead to increased pressure drops and fuel flow restrictions. This is especially important in high-performance engines where every millisecond of fuel delivery is vital. Designers often aim to keep the fuel lines as short as possible, running them directly from the fuel tank to the engine, with minimal bends and twists. This approach reduces the risk of fuel vaporization and ensures a consistent fuel supply.

Additionally, the use of fuel line filters and vents is essential for maintaining optimal fuel flow. Filters prevent contaminants from entering the system, ensuring clean fuel delivery to the engine. Vents, on the other hand, allow air to enter the fuel lines, which is crucial for fuel atomization and combustion efficiency. Proper ventilation also helps to reduce the risk of fuel line collapse due to vacuum effects, especially when the engine is idling or during rapid acceleration.

In summary, the design of fuel lines near the wheels of a car is a critical aspect of fuel system engineering. By utilizing flexible materials, optimizing line routing, and incorporating filters and vents, designers can achieve efficient fuel flow, minimize pressure drops, and ensure a reliable fuel supply to the engine. This attention to detail contributes to improved vehicle performance, fuel efficiency, and overall driving experience.

2001 Plymouth Neon Fuel Line Hose: Size Guide

You may want to see also

Wheel Alignment: Proper alignment of wheels to prevent damage to fuel lines during driving

The alignment of a vehicle's wheels is a critical aspect of maintenance that often goes overlooked, but it plays a significant role in ensuring the longevity and safety of various components, including the fuel lines. Fuel lines are positioned close to the wheels, especially in the undercarriage of a car, and proper alignment is essential to prevent potential damage during driving. Misaligned wheels can lead to a range of issues, with fuel lines being particularly vulnerable.

When wheels are not properly aligned, the tires wear unevenly, causing excessive stress on the suspension and steering systems. This misalignment can result in the fuel lines being subjected to excessive movement and vibration, especially during turns and speed changes. Over time, this can lead to the deterioration of the fuel lines, causing cracks, leaks, or even complete rupture. Such damage can result in fuel leaks, which pose a serious safety hazard and can also lead to engine performance issues.

To prevent these problems, regular wheel alignment checks are recommended. Wheel alignment involves adjusting the angles of the wheels to ensure they are parallel to each other and perpendicular to the ground. This process ensures that the tires wear evenly, reducing the stress on the fuel lines and other components. Technicians use specialized equipment to measure the wheel angles and make precise adjustments to the suspension and steering components.

During a wheel alignment service, mechanics will also inspect the fuel lines for any signs of damage or wear. They may use high-pressure air to test the lines for leaks and ensure they are securely attached to the fuel tank and engine. Proper alignment not only protects the fuel lines but also improves overall vehicle handling, tire life, and fuel efficiency.

In summary, maintaining proper wheel alignment is crucial for the health and safety of a vehicle's fuel system. By ensuring that the wheels are aligned correctly, drivers can prevent unnecessary wear and potential damage to fuel lines, ultimately saving money on repairs and ensuring a smoother, safer driving experience. Regular maintenance and attention to wheel alignment are key to avoiding costly and potentially dangerous issues down the road.

Mastering the Art of Removing Fuel Lines: A Comprehensive Guide

You may want to see also

Frequently asked questions

The fuel lines are typically located beneath the car, running along the frame rails towards the rear of the vehicle. They are often positioned close to the wheels to ensure a stable and secure path for the fuel to reach the engine.

Yes, fuel lines are strategically placed under the car near the wheels to minimize the risk of damage during a collision. This positioning helps protect the fuel lines from potential impacts and reduces the chances of fuel leaks in accident scenarios.

You can inspect your vehicle's underbody to locate the fuel lines. They are usually visible as thin, flexible tubes running along the frame rails. If you notice any damage or wear near the wheels, it's essential to have the fuel lines inspected by a professional mechanic.

Regularly inspecting the fuel lines for any signs of corrosion, cracks, or damage is crucial. Keep an eye out for any leaks or unusual noises coming from the fuel system. It's recommended to have the fuel lines flushed and inspected during routine maintenance to ensure optimal performance and prevent potential issues.