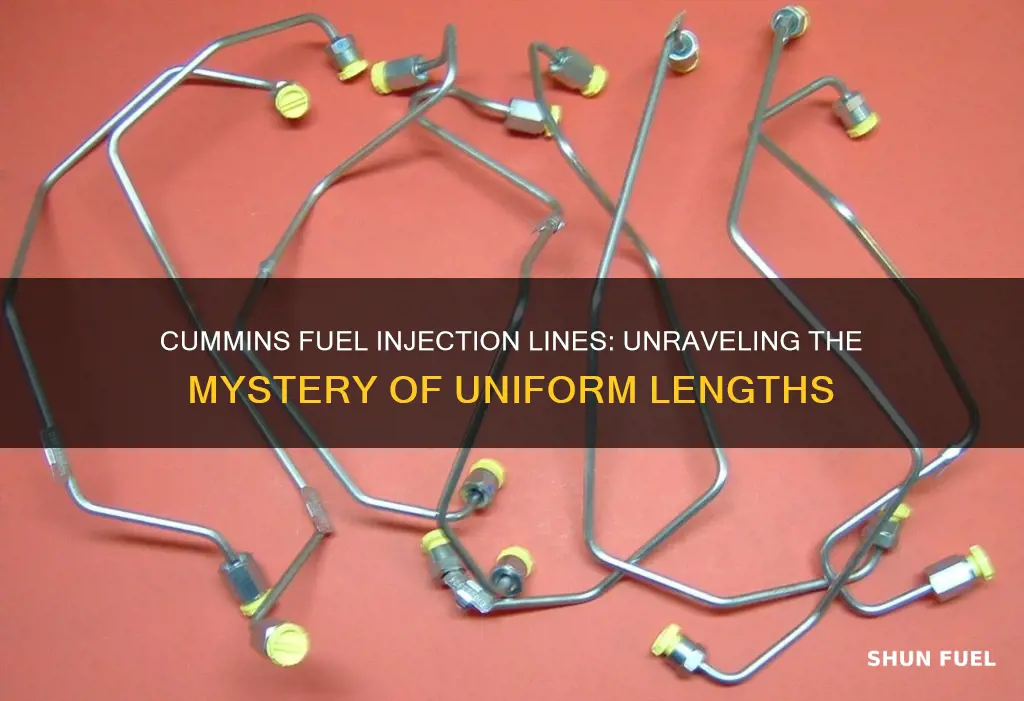

Cummins fuel injection lines are designed with a specific length for optimal performance and efficiency. Understanding why these lines are the same length is crucial for maintaining the engine's functionality. The uniform length ensures consistent fuel delivery, allowing for precise control over the combustion process. This design choice is a key factor in Cummins' reputation for reliable and powerful engines, where every component plays a vital role in achieving peak performance.

| Characteristics | Values |

|---|---|

| Fuel Efficiency | The consistent length of fuel injection lines in Cummins engines ensures optimal fuel delivery, promoting better fuel efficiency. |

| Performance | Equal-length lines provide a balanced fuel flow, resulting in improved engine performance and power output. |

| Reliability | This design feature enhances reliability by reducing the risk of fuel-related issues and ensuring consistent operation. |

| Engine Calibration | Cummins' fuel injection line length is carefully calibrated to match the engine's requirements, allowing for precise fuel management. |

| Emission Control | The uniform length contributes to better emission control by ensuring a consistent fuel-air mixture, leading to reduced pollutants. |

| Engine Life | By maintaining proper fuel injection, this design extends the engine's lifespan and reduces the need for frequent maintenance. |

| Cost-Effectiveness | Cummins' approach to fuel line length optimization can lead to cost savings in the long run due to improved engine efficiency and reduced fuel consumption. |

| Safety | Consistent fuel flow prevents fuel buildup or starvation, reducing the risk of engine damage and ensuring safe operation. |

What You'll Learn

- Engine Performance: Cummins fuel injection lines of equal length optimize fuel delivery for consistent power output

- Fuel Efficiency: Uniform line lengths enhance fuel economy by reducing pressure drops

- Engine Reliability: Consistent line lengths minimize stress points, improving long-term engine reliability

- Maintenance: Equal-length lines simplify maintenance, making it easier to access and replace fuel injectors

- Design Standardization: Cummins' consistent line lengths ensure uniform design across models for standardized performance

Engine Performance: Cummins fuel injection lines of equal length optimize fuel delivery for consistent power output

The design of Cummins fuel injection lines, where the lines are of equal length, is a crucial aspect of engine performance optimization. This design choice is not arbitrary but a strategic implementation to ensure consistent and efficient fuel delivery to the engine's cylinders. By maintaining equal line lengths, Cummins engineers have addressed a critical factor in engine operation, which is the timing and precision of fuel injection.

In an internal combustion engine, the timing of fuel injection is vital for optimal power output and efficient combustion. When fuel injection lines are of the same length, it ensures that the fuel pressure and flow rate are consistent across all cylinders. This consistency is key to achieving a balanced and synchronized power delivery, where each cylinder receives the precise amount of fuel required at the exact moment it needs it. As a result, the engine operates with improved throttle response, smoother power delivery, and reduced chances of engine knock or misfire.

The equal-length design also contributes to the overall reliability and longevity of the engine. With consistent fuel delivery, the engine's combustion process becomes more stable, reducing the stress on various components. This can lead to longer engine life and decreased maintenance requirements, as the engine is less prone to issues related to fuel system malfunctions. Additionally, the consistent fuel flow can enhance the engine's ability to maintain optimal operating temperatures, further contributing to its overall health and performance.

This design feature is particularly advantageous in heavy-duty applications, where engines are subjected to high loads and continuous operation. By ensuring uniform fuel distribution, Cummins engines can deliver sustained power output, even under demanding conditions. This is crucial for industries such as trucking, construction, and agriculture, where reliable and consistent engine performance is essential for operational efficiency and safety.

In summary, the equal-length design of Cummins fuel injection lines is a strategic engineering approach to optimize engine performance. It ensures precise fuel delivery, enhances throttle response, and contributes to the overall reliability and longevity of the engine. This design choice is a testament to Cummins' commitment to delivering powerful, efficient, and dependable engines for a wide range of applications.

Aluminum or Steel: Choosing the Right Fuel Line Material

You may want to see also

Fuel Efficiency: Uniform line lengths enhance fuel economy by reducing pressure drops

The concept of maintaining uniform line lengths in Cummins fuel injection systems is a critical design principle that significantly impacts fuel efficiency. This practice ensures that the fuel flow remains consistent and stable throughout the entire system, which is essential for optimizing engine performance and fuel economy. When fuel injection lines are of equal length, it minimizes the potential for pressure variations that can occur in systems with varying line lengths. Pressure drops along the fuel lines can lead to inefficient fuel delivery, causing the engine to consume more fuel than necessary. By keeping the lines uniform, Cummins engineers aim to create a balanced and efficient fuel distribution network.

In the context of fuel efficiency, the reduction of pressure drops is a key benefit. Pressure drops occur when fuel encounters resistance as it travels through the lines, which can be influenced by the length and diameter of the lines. Longer lines with varying diameters can create uneven pressure, forcing the engine to work harder to maintain optimal fuel-air mixture. This inefficiency results in increased fuel consumption and reduced mileage. Cummins' approach to uniform line lengths helps to maintain a consistent pressure profile, ensuring that the engine receives the precise amount of fuel required at any given moment.

The design philosophy behind this practice is rooted in the understanding that fuel injection systems operate under strict performance parameters. Cummins engineers aim to create a harmonious interplay between the fuel pump, lines, and injectors. When line lengths are equal, it simplifies the system's dynamics, allowing for better control over fuel delivery. This control is vital for achieving the desired power output while minimizing fuel wastage. As a result, the engine operates more efficiently, providing better fuel economy and reduced emissions.

Furthermore, the uniform line length design also contributes to the overall reliability of the fuel injection system. Consistent line lengths reduce the risk of fuel-related issues, such as uneven atomization and improper fuel distribution. These problems can lead to poor engine performance and potential damage over time. By maintaining uniform lengths, Cummins ensures that the fuel is delivered in the correct ratio and at the right pressure, promoting a healthy combustion process.

In summary, the practice of using equal-length fuel injection lines in Cummins systems is a strategic approach to enhance fuel efficiency. It addresses the critical issue of pressure drops, ensuring a consistent and efficient fuel supply. This design consideration showcases Cummins' commitment to optimizing engine performance while delivering reliable and cost-effective solutions for various applications. Understanding and implementing this principle can lead to significant improvements in fuel economy and overall engine efficiency.

Engine Lines: Fuel Smell Causes and Solutions

You may want to see also

Engine Reliability: Consistent line lengths minimize stress points, improving long-term engine reliability

The concept of maintaining equal lengths for Cummins fuel injection lines is a critical design consideration that significantly impacts engine reliability. This practice ensures that the fuel pressure is distributed uniformly across the engine, which is essential for optimal performance and longevity. When fuel injection lines are of the same length, it eliminates potential stress points and pressure variations that could lead to premature wear and tear. These stress points often occur when lines of different lengths are used, causing uneven pressure distribution and potential damage over time.

Engineers and designers aim to create a balanced system by ensuring that the fuel lines are consistent in length. This approach minimizes the risk of fuel pressure fluctuations, which can lead to engine misfires, reduced power, and even potential engine damage. Consistent line lengths contribute to a more stable and reliable fuel delivery system, ensuring that the engine operates efficiently and consistently over its lifespan.

The benefits of this design choice extend beyond the immediate performance gains. By reducing stress points, the engine's overall reliability is enhanced. This means fewer breakdowns, lower maintenance costs, and increased operational uptime. Over time, this can lead to significant cost savings for both the manufacturer and the end-user, as engines with consistent line lengths are less likely to require frequent repairs or replacements.

Furthermore, this design principle aligns with Cummins' commitment to innovation and quality. By adhering to this practice, Cummins ensures that their engines meet and exceed industry standards for durability and performance. This attention to detail in fuel injection line design is a testament to Cummins' dedication to providing reliable and efficient power solutions.

In summary, maintaining equal lengths for Cummins fuel injection lines is a strategic design choice that directly contributes to engine reliability. It minimizes stress points, ensures uniform fuel pressure distribution, and ultimately leads to improved performance and longevity. This practice is a cornerstone of Cummins' engineering philosophy, ensuring that their engines remain a trusted and reliable power source for various applications.

Perfect Fuel Line Size for Your 1992 Dodge D150 Pickup

You may want to see also

Maintenance: Equal-length lines simplify maintenance, making it easier to access and replace fuel injectors

The design of Cummins fuel injection lines with equal lengths is a strategic choice that significantly impacts the vehicle's maintenance and repair process. This design feature simplifies the maintenance routine, making it more accessible and efficient for technicians to work on the fuel injection system. By ensuring that all fuel lines have the same length, Cummins has eliminated the complexity often associated with varying line lengths, which can make accessing and replacing fuel injectors a challenging task.

In the context of maintenance, equal-length lines provide a uniform approach to troubleshooting and repair. When a fuel injector needs to be replaced or serviced, technicians can quickly identify the correct lines and their connections without the need for extensive measurements or complex diagrams. This streamlined process reduces the time required for maintenance, allowing for faster turnaround times and minimizing vehicle downtime.

The simplicity of equal-length lines is particularly beneficial when dealing with multiple fuel injectors in a system. With traditional systems that use varying line lengths, identifying the correct lines for each injector can be a complex task, often requiring specialized knowledge or tools. However, Cummins' design approach simplifies this process, making it easier for mechanics to locate and work on specific fuel injectors without the risk of damaging other components.

Moreover, the equal-length design enhances the overall durability and longevity of the fuel injection system. By ensuring consistent line lengths, Cummins has reduced the likelihood of stress concentrations or uneven wear, which can occur in systems with varying line lengths over time. This consistent design also contributes to better fuel delivery and performance, as the equal lengths help maintain a uniform pressure throughout the system.

In summary, the equal-length design of Cummins fuel injection lines is a thoughtful engineering solution that simplifies maintenance and repair procedures. It empowers technicians with a straightforward approach to accessing and replacing fuel injectors, ultimately reducing maintenance costs and improving the overall reliability of the vehicle's fuel injection system. This design choice is a testament to Cummins' commitment to providing efficient and user-friendly solutions for their customers.

Understanding 3/8 Fuel Line Dimensions: Inside Diameter Explained

You may want to see also

Design Standardization: Cummins' consistent line lengths ensure uniform design across models for standardized performance

Cummins, a renowned manufacturer of diesel engines, has implemented a unique and innovative approach to fuel injection line design, ensuring that all lines maintain the same length across various engine models. This standardization is a strategic decision that brings numerous benefits to the overall performance and reliability of their engines. By adhering to consistent line lengths, Cummins has achieved a level of uniformity that is crucial for standardized performance.

The primary advantage of this design approach is the simplification of the manufacturing process. When all fuel injection lines are of the same length, it becomes a straightforward task to assemble and integrate these lines into different engine models. This standardization reduces the complexity of the production line, allowing for efficient and cost-effective manufacturing. With a uniform design, Cummins can streamline its production processes, ensuring that each engine model receives the necessary fuel injection lines without the need for extensive customization.

Furthermore, this consistent line length design contributes to the overall performance and efficiency of the engines. Fuel injection lines play a critical role in delivering fuel to the engine's combustion chamber, and their length directly impacts the timing and precision of this process. By maintaining the same length across models, Cummins ensures that the fuel injection timing remains consistent, optimizing the engine's performance and power output. This level of standardization allows for fine-tuning and calibration of the fuel injection system, resulting in improved engine efficiency and reduced emissions.

In addition, the standardized design approach enhances the reliability and longevity of Cummins engines. Consistent line lengths minimize the chances of fuel leakage or blockages, as the uniform structure reduces potential weak points or areas of failure. This reliability is particularly important in heavy-duty applications where engines operate under demanding conditions. By ensuring that all fuel injection lines are of the same length and quality, Cummins can provide its customers with engines that are not only powerful but also dependable over extended periods.

In summary, Cummins' consistent line lengths in fuel injection systems are a testament to their commitment to design standardization. This approach simplifies manufacturing, optimizes engine performance, and enhances reliability. By maintaining uniformity across models, Cummins ensures that their engines deliver standardized performance, meeting the expectations of their customers in various industries. This strategic design choice highlights Cummins' dedication to innovation and excellence in the field of diesel engine technology.

Echo PB 200 Fuel Line Size: A Comprehensive Guide

You may want to see also

Frequently asked questions

Cummins fuel injection lines are designed to be of equal length to ensure optimal fuel delivery and performance. This design choice helps maintain a consistent fuel pressure throughout the system, allowing for precise control of the fuel-air mixture and efficient combustion in the engine.

The equal length of these lines is crucial for achieving a balanced fuel distribution, which directly affects the engine's power output and overall efficiency. It ensures that the fuel is delivered uniformly to all cylinders, promoting even combustion and reducing the chances of engine misfires or performance issues.

Yes, this design has several benefits. Firstly, it simplifies the manufacturing process, making it more cost-effective. Secondly, it reduces the risk of fuel pressure variations, which could lead to uneven power delivery and potential engine damage. The equal length also contributes to a quieter and smoother running engine.

While Cummins typically uses the same length for these lines, there might be cases where customization is necessary. Customization can be required due to engine modifications, space constraints, or specific performance goals. However, altering the line lengths without careful consideration can lead to fuel delivery issues and may require expert consultation to ensure optimal engine performance and longevity.