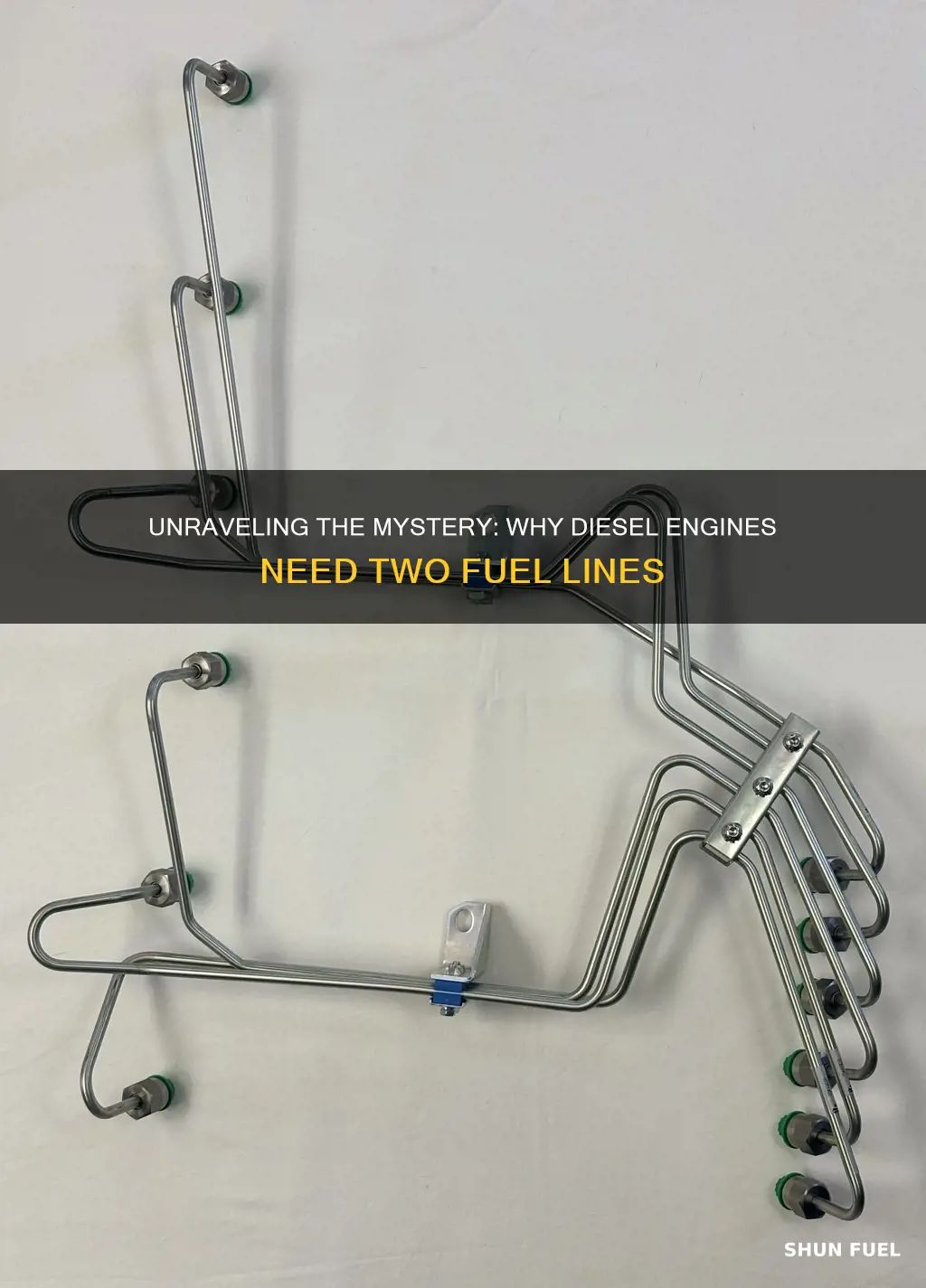

Diesel engines often feature two fuel lines for a specific purpose. The primary function of these lines is to ensure a consistent and reliable fuel supply to the engine, which is crucial for optimal performance and efficiency. The two fuel lines are designed to provide a steady flow of diesel fuel to the engine's injectors, allowing for precise control of the fuel-air mixture and efficient combustion. This setup helps maintain a consistent power output and reduces the risk of engine misfires or performance issues that can arise from a single fuel line. By having two fuel lines, diesel engines can achieve better fuel economy, lower emissions, and improved overall reliability.

| Characteristics | Values |

|---|---|

| Fuel Injection System | Diesel engines use a two-line fuel system to supply fuel to the injectors. The primary line provides high-pressure fuel, while the secondary line is for low-pressure fuel return and filtering. |

| Fuel Pressure Regulation | Two fuel lines help regulate and maintain the required fuel pressure for efficient combustion. The high-pressure line delivers fuel to the injectors, while the low-pressure line ensures proper fuel flow and prevents pressure spikes. |

| Engine Performance | This setup allows for precise fuel delivery, optimizing engine performance, and reducing emissions. It ensures that the engine receives the correct amount of fuel at the right pressure for each cylinder. |

| Safety and Reliability | Having two fuel lines provides redundancy. If one line fails, the other can still supply fuel, ensuring the engine continues to run and preventing potential breakdowns. |

| Fuel Efficiency | The two-line system contributes to better fuel efficiency by minimizing fuel wastage and ensuring that only the required amount of fuel is injected into the engine. |

| Engine Design | Diesel engines are designed with specific fuel requirements, and the two-line system caters to these needs, providing a consistent and controlled fuel supply. |

| Maintenance and Diagnostics | The separate fuel lines make it easier to identify and troubleshoot issues related to fuel delivery, as problems can be isolated to either the high-pressure or low-pressure system. |

What You'll Learn

- Fuel Injection: One line delivers fuel to the injectors, while the other provides return fuel for pressure regulation

- Engine Performance: Two lines ensure precise fuel delivery, optimizing power and efficiency in diesel engines

- Safety: Redundant fuel lines prevent system failure, maintaining engine operation even if one line is compromised

- Fuel Pressure Regulation: Separate lines allow for independent control of fuel pressure, enhancing engine response and stability

- Emission Control: Dual fuel lines facilitate precise fuel-air mixture management, reducing emissions and improving engine performance

Fuel Injection: One line delivers fuel to the injectors, while the other provides return fuel for pressure regulation

The concept of dual fuel lines in diesel engines is an essential component of modern fuel injection systems, ensuring optimal performance and efficiency. One primary function of these two lines is to manage the fuel pressure within the engine. The primary fuel line, often referred to as the high-pressure line, is responsible for delivering fuel to the injectors with precision. This line is designed to withstand high pressures, typically ranging from 200 to 300 bar, ensuring that the fuel is atomized and injected into the combustion chamber at the correct timing and quantity. This high-pressure fuel is then directed to the injectors, which spray the fuel into the engine's cylinders, creating a controlled combustion process.

In contrast, the second fuel line, known as the return line, plays a crucial role in pressure regulation. This line is connected to the high-pressure fuel pump and is responsible for returning excess fuel from the injectors back to the fuel tank or reservoir. By doing so, it helps maintain a consistent and stable fuel pressure throughout the engine's operation. The return line ensures that the fuel system does not become overfilled, which could lead to fuel spillage and potential safety hazards. Moreover, it prevents the buildup of air bubbles in the fuel, which can negatively impact engine performance.

The dual-line system is a sophisticated design that allows for precise control of the fuel injection process. It ensures that the engine receives the correct amount of fuel at the right pressure, optimizing combustion efficiency. This is particularly important in diesel engines, where combustion must be carefully managed to meet emissions standards and maximize power output. The two fuel lines work in harmony, with the high-pressure line providing the necessary fuel for combustion and the return line regulating pressure to maintain a healthy engine operation.

In summary, the two fuel lines in a diesel engine's fuel injection system serve distinct purposes. The high-pressure line delivers fuel to the injectors, ensuring accurate and timely injections, while the return line regulates pressure by collecting excess fuel, preventing potential issues related to overfilling and air bubbles. This dual-line approach is a critical aspect of modern diesel engine technology, contributing to improved performance, efficiency, and reliability. Understanding these functions is essential for anyone seeking to optimize the performance of diesel engines.

E46 Fuel Line Location: A Comprehensive Guide

You may want to see also

Engine Performance: Two lines ensure precise fuel delivery, optimizing power and efficiency in diesel engines

The concept of dual fuel lines in diesel engines is an essential design feature that significantly enhances engine performance and efficiency. This design choice is primarily driven by the unique requirements of diesel fuel and the specific needs of these engines. Diesel engines operate under high-pressure conditions, and the fuel system must be designed to handle these pressures while ensuring precise fuel delivery to the engine's cylinders. This is where the two fuel lines come into play, providing a solution to the challenges posed by the fuel's properties and the engine's operational demands.

One of the critical functions of the two fuel lines is to facilitate the precise injection of diesel fuel into the engine's cylinders. Diesel engines rely on direct injection, where fuel is injected under high pressure directly into the combustion chamber. The first fuel line, often referred to as the high-pressure line, carries the fuel from the fuel pump to the injectors. This line is designed to withstand the high pressures required for efficient fuel injection, ensuring that the fuel is delivered with the necessary force and timing. The second line, typically a return line, recirculates the excess fuel back to the fuel tank or reservoir, maintaining a consistent fuel level and pressure.

The dual-line system also contributes to improved engine performance by allowing for better control over the fuel-air mixture. In diesel engines, the fuel is injected at a specific timing and pressure to ensure optimal combustion. With two fuel lines, the engine can maintain a precise and consistent fuel supply, even under varying load conditions. This precision in fuel delivery results in more efficient combustion, producing higher power output and better fuel economy. The dual-line system also helps in reducing emissions by ensuring that the fuel is injected in the correct ratio, minimizing the formation of harmful pollutants.

Furthermore, the two fuel lines enable the engine to operate efficiently across a wide range of speeds and loads. When the engine is under light load, the second fuel line can adjust the fuel flow to maintain the desired air-fuel mixture, ensuring efficient combustion. During high-load conditions, the high-pressure line delivers the required fuel volume to meet the increased power demands. This flexibility in fuel delivery is crucial for diesel engines, as they are commonly used in heavy-duty applications where performance and efficiency are critical.

In summary, the use of two fuel lines in diesel engines is a strategic design choice that optimizes engine performance and efficiency. By ensuring precise fuel delivery, this system enables diesel engines to operate with improved power output, better fuel economy, and reduced emissions. The dual-line configuration allows for better control over the fuel-air mixture, making it an essential component in the overall performance and reliability of diesel engines, especially in demanding applications. Understanding this design feature provides valuable insights into the intricate workings of diesel engines and their ability to deliver exceptional performance.

Choosing the Right Fuel Line for Your Outboard Motor: A Guide

You may want to see also

Safety: Redundant fuel lines prevent system failure, maintaining engine operation even if one line is compromised

The concept of having two fuel lines in a diesel engine is primarily driven by safety considerations and the need for redundancy in the fuel system. This design feature ensures that the engine can continue to operate even if one of the fuel lines becomes compromised or fails. Here's a detailed explanation of how this system enhances safety:

In diesel engines, fuel delivery is a critical process that requires precision and reliability. The two fuel lines are an essential part of this system, each serving a specific purpose. The primary fuel line is responsible for delivering the main supply of fuel from the tank to the engine. It is designed to handle the high pressure required to atomize the fuel for efficient combustion. However, relying solely on this single line could lead to catastrophic consequences if it were to rupture or become blocked. This is where the redundant fuel line comes into play.

The secondary or backup fuel line is a safety mechanism that ensures the engine can still receive fuel even if the primary line fails. This line is typically smaller in diameter and is used to provide a secondary path for fuel delivery. It is often connected to the primary line at various points along its length, allowing it to bypass potential issues in the main line. By having this redundant line, the engine's fuel supply is secured, and the risk of sudden power loss due to fuel starvation is significantly reduced.

The design of these two fuel lines is a testament to the engineering principles of fail-safe systems. When one line is compromised, the engine can automatically switch to the redundant line, ensuring that the fuel continues to flow. This automatic switching mechanism is often controlled by a sophisticated fuel management system that monitors pressure, flow rates, and engine performance. In the event of a primary line failure, the engine control unit (ECU) can activate the backup line, maintaining operation and preventing a dangerous situation.

Furthermore, the use of two fuel lines also allows for better control over the fuel injection process. Each line can be regulated independently, ensuring that the engine receives the precise amount of fuel required at any given moment. This level of control contributes to improved engine performance, better fuel efficiency, and reduced emissions. The redundant fuel lines, therefore, not only enhance safety but also optimize the overall functionality of the diesel engine.

In summary, the presence of two fuel lines in diesel engines is a safety-critical design feature. It ensures that the engine can maintain operation even if one line is damaged or fails, providing a robust and reliable fuel supply system. This redundancy is a key factor in the overall reliability and longevity of diesel engines, making them a preferred choice for heavy-duty applications where safety and performance are paramount.

Unveiling the Material Secrets of Diesel Fuel Lines

You may want to see also

Fuel Pressure Regulation: Separate lines allow for independent control of fuel pressure, enhancing engine response and stability

The concept of having two fuel lines in a diesel engine is primarily centered around fuel pressure regulation, which is a critical aspect of engine performance and stability. This design feature is a result of the unique requirements of diesel engines, which demand precise and independent control of fuel pressure to optimize combustion and overall engine operation.

In a diesel engine, fuel pressure must be carefully managed to ensure efficient and controlled fuel injection. The two fuel lines serve a specific purpose: one line is dedicated to supplying fuel to the engine, while the other is used for pressure regulation. This separation allows for a more precise and responsive fuel delivery system. By having a separate line for pressure control, the engine can maintain a consistent and optimal fuel pressure, even under varying load conditions. This is crucial because diesel engines operate at higher compression ratios compared to gasoline engines, and thus require a more robust fuel injection system to ensure complete combustion.

The independent control of fuel pressure is achieved through various mechanisms. One common method is the use of a pressure regulator, which is often located on the second fuel line. This regulator monitors and adjusts the fuel pressure to maintain a set value, ensuring that the engine receives the correct amount of fuel at the right pressure. This is especially important during acceleration or when the engine is under load, as it allows for a quick and efficient response to changing demands. For instance, when the driver demands more power, the engine can rapidly increase the fuel pressure to meet the higher fuel requirements, resulting in a more responsive and powerful performance.

Additionally, the separate fuel lines enable the engine to maintain stability under various operating conditions. By having independent control over fuel pressure, the engine can quickly adapt to changes in speed, load, and temperature. This adaptability is essential for diesel engines, as they are commonly used in heavy-duty applications where performance and reliability are critical. The ability to regulate fuel pressure independently ensures that the engine can consistently deliver the required power output, even in demanding environments.

In summary, the two fuel lines in a diesel engine are a crucial design feature that enables precise fuel pressure regulation. This setup allows for independent control, enhancing engine response and stability. By separating the fuel supply and pressure regulation functions, diesel engines can maintain optimal performance, ensuring efficient combustion and a responsive driving experience, even in the most challenging operating conditions. This design consideration highlights the complexity and sophistication of modern diesel engine technology.

F150 Fuel Line: Understanding Proper Ratings and Safety

You may want to see also

Emission Control: Dual fuel lines facilitate precise fuel-air mixture management, reducing emissions and improving engine performance

The concept of dual fuel lines in diesel engines is an essential aspect of modern emission control and performance enhancement. This design feature is a strategic implementation that allows for precise control over the fuel-air mixture, which is crucial for reducing harmful emissions and optimizing engine efficiency. By utilizing two separate fuel lines, one for low-pressure and one for high-pressure fuel injection, diesel engines can achieve a more controlled and efficient combustion process.

The primary purpose of these dual fuel lines is to ensure accurate fuel delivery and atomization. The low-pressure line is responsible for supplying fuel to the engine's injectors, creating a fine mist of fuel droplets. This process is vital as it enables the fuel to mix thoroughly with the incoming air, promoting complete combustion. The high-pressure line, on the other hand, provides additional fuel pressure, ensuring that the fuel is injected with sufficient force to create a strong, controlled spray. This dual-line system allows for a more precise and consistent fuel-air mixture, which is a key factor in reducing emissions.

In the context of emission control, the dual fuel lines play a critical role in minimizing the release of pollutants. By carefully managing the fuel-air ratio, diesel engines can achieve a leaner burn, which results in lower emissions of nitrogen oxides (NOx) and particulate matter. The precise control offered by dual fuel lines enables the engine to operate at optimal conditions, ensuring that the combustion process is efficient and clean. This level of control is essential for meeting stringent environmental regulations and reducing the environmental impact of diesel vehicles.

Furthermore, the dual fuel line system contributes to improved engine performance. The accurate fuel-air mixture management allows for better power output and torque delivery. With precise fuel injection, the engine can deliver the required power while maintaining optimal efficiency. This results in a more responsive and powerful engine, capable of delivering excellent performance without compromising on emissions. The dual fuel lines essentially act as a fine-tuning mechanism, allowing engineers to optimize the engine's capabilities.

In summary, the dual fuel lines in diesel engines are a sophisticated design feature that directly contributes to emission control and engine performance. By facilitating precise fuel-air mixture management, these lines ensure a more efficient and environmentally friendly combustion process. The ability to control fuel delivery and atomization is a significant advantage, leading to reduced emissions and improved overall engine efficiency. This technology is a testament to the ongoing advancements in diesel engine design, aiming to provide powerful and environmentally conscious solutions.

Choosing the Right Diameter Fuel Line for Your Yamaha Outboard

You may want to see also

Frequently asked questions

Diesel engines use two fuel lines to ensure efficient and precise fuel delivery. The primary line, often referred to as the high-pressure line, carries the fuel from the fuel tank to the common rail or injection pump. This high-pressure system is crucial for atomizing the fuel into a fine mist, allowing for better combustion. The secondary line, typically a return line, recirculates the excess fuel back to the tank, ensuring that the engine receives the exact amount of fuel required for optimal performance.

The dual fuel line system enhances engine performance by providing a consistent and controlled fuel supply. The high-pressure line delivers fuel at a precise rate, ensuring that each cylinder receives the correct amount of fuel for efficient combustion. This results in improved power output, better fuel efficiency, and reduced emissions. Additionally, the return line helps maintain a stable fuel pressure, allowing for quick responses to changes in engine load.

Yes, proper maintenance is essential to keep the dual fuel line system functioning optimally. Regular inspections should be conducted to check for any signs of damage, leaks, or contamination. Diesel fuel lines are typically made of durable materials, but they can be susceptible to wear and tear over time. It is recommended to use the correct type of fuel filter and to regularly replace it to prevent contamination. Keeping the fuel tank and lines clean is vital to avoid performance issues and potential engine damage.