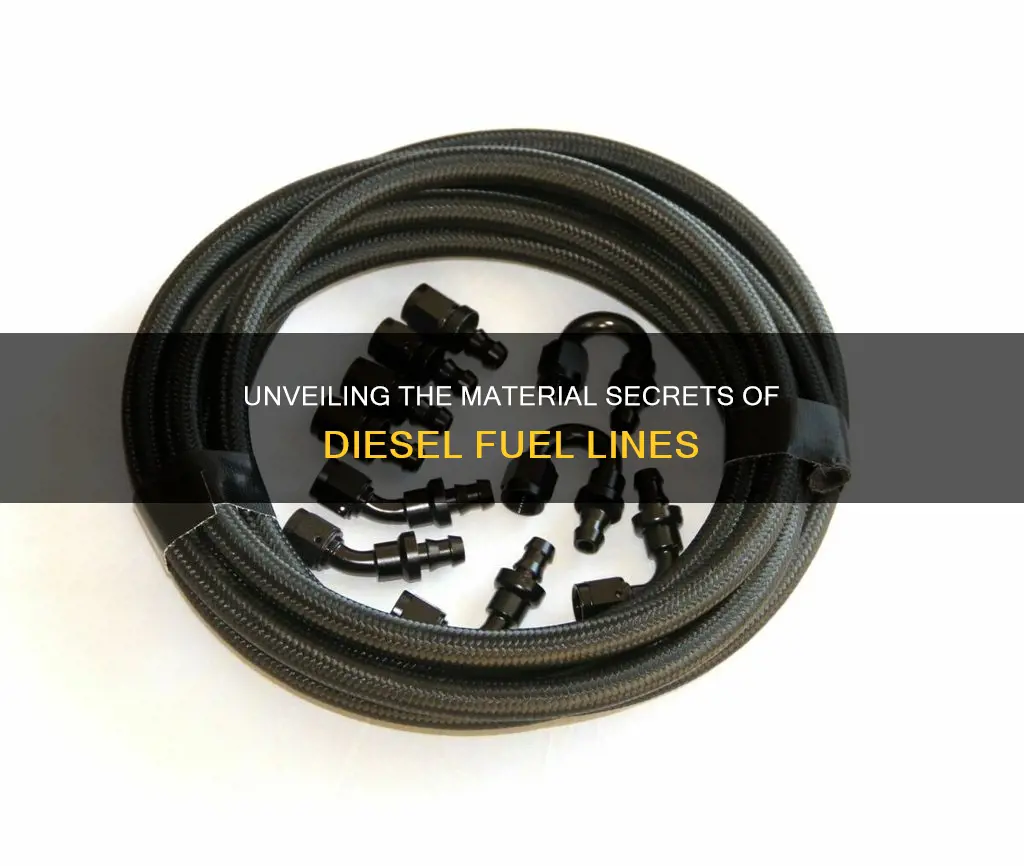

Diesel fuel lines are an essential component of any diesel engine, and their material composition is crucial for optimal performance and longevity. These lines are typically made from high-quality materials that can withstand the high pressure and temperature conditions within the engine. Common materials include steel, which is known for its strength and durability, and various types of rubber or synthetic compounds, which offer flexibility and resistance to fuel degradation. The choice of material depends on factors such as engine design, operating conditions, and regulatory requirements. Understanding the composition of diesel fuel lines is vital for maintenance and repair, ensuring that the engine operates efficiently and safely.

| Characteristics | Values |

|---|---|

| Material | Typically made of high-strength, flexible materials such as steel, aluminum, or a composite blend. |

| Construction | Often constructed with a braided or spiral design for added flexibility and durability. |

| Diameter | Varies depending on the engine and application, typically ranging from 3/8" to 1/2" in diameter. |

| Length | Customizable, can be cut to fit specific engine configurations. |

| Resistance | Designed to withstand high-pressure fuel, heat, and chemical corrosion. |

| Flexibility | Able to bend and move with the engine without kinking or breaking. |

| Compatibility | Compatible with diesel fuel and resistant to fuel-related degradation. |

| Temperature Range | Capable of operating in a wide temperature range, from sub-zero to high temperatures. |

| Color | Often black or dark grey, though other colors may be used for identification or aesthetic purposes. |

| Standards | Adhere to industry standards and regulations for fuel system components. |

What You'll Learn

- Materials: Common materials include steel, brass, and aluminum alloys

- Strength: Diesel fuel lines are often made of durable materials like stainless steel or high-strength plastics

- Flexibility: Some lines use flexible materials to withstand engine vibrations and temperature changes

- Corrosion Resistance: Materials like stainless steel offer protection against corrosion from fuel and engine components

- Temperature Tolerance: Lines may be made of materials that can handle extreme temperatures without degradation

Materials: Common materials include steel, brass, and aluminum alloys

The choice of material for diesel fuel lines is crucial, as it directly impacts the performance, durability, and reliability of the fuel delivery system. Common materials used for these lines include steel, brass, and aluminum alloys, each offering unique advantages and considerations.

Steel: This is a robust and durable material, often chosen for its strength and resistance to corrosion. It is an excellent option for diesel fuel lines due to its ability to withstand high pressure and temperature variations. Steel fuel lines are known for their longevity and are less susceptible to degradation from fuel contaminants. However, they can be heavier and more rigid compared to other materials, which might affect installation and flexibility.

Brass: Brass is a popular choice for fuel lines due to its excellent corrosion resistance and smooth interior surface. This material ensures minimal fuel contamination and provides a consistent flow of fuel. Brass lines are also known for their flexibility, making them easier to install and route through the engine compartment. Additionally, brass has good thermal conductivity, which can help regulate fuel temperature. Despite its advantages, brass is generally more expensive than steel and aluminum.

Aluminum Alloys: Aluminum alloys are lightweight and offer excellent corrosion resistance, making them a popular choice for diesel fuel lines in modern engines. These alloys provide a good balance of strength and flexibility, allowing for easy installation and routing. Aluminum's low weight reduces the overall system load, which can be beneficial in high-performance applications. Furthermore, aluminum's thermal properties can help dissipate heat, ensuring the fuel remains stable and efficient. However, aluminum may be more susceptible to oxidation over time, requiring careful maintenance.

When selecting the material for diesel fuel lines, it's essential to consider the specific requirements of the engine, including pressure, temperature, and environmental conditions. Each material has its strengths and weaknesses, and the choice should be based on the overall performance and longevity needed for the application.

GSXR 750 Fuel Line Leaks: Normal or Cause for Concern?

You may want to see also

Strength: Diesel fuel lines are often made of durable materials like stainless steel or high-strength plastics

Diesel fuel lines are an essential component of any diesel engine, and their construction is a critical aspect of the vehicle's performance and longevity. One of the key strengths of these fuel lines is the use of durable materials, which are specifically chosen to withstand the harsh conditions of diesel fuel and the engine's operation.

The primary materials used for diesel fuel lines are stainless steel and high-strength plastics, both of which offer exceptional durability and resistance to wear and tear. Stainless steel, for instance, is renowned for its strength and corrosion resistance, making it an ideal choice for fuel lines. It can withstand the high pressure and temperature variations that diesel fuel can exert on the system. This material is also known for its flexibility, allowing the fuel lines to move and bend without compromising their structural integrity.

High-strength plastics, on the other hand, provide a lightweight and cost-effective solution. These plastics are engineered to mimic the strength of metals while offering the added benefit of flexibility. They are often used in fuel lines due to their ability to resist fuel degradation and chemical attacks, ensuring the fuel remains stable and clean. The use of high-strength plastics also contributes to the overall weight reduction of the vehicle, which is a significant advantage in the automotive industry.

The combination of these materials ensures that diesel fuel lines can handle the demanding environment of a diesel engine. They are designed to resist kinking, cracking, and other forms of damage that could lead to fuel leaks or reduced engine performance. The durability of these fuel lines is crucial, as it directly impacts the reliability and efficiency of the vehicle.

In summary, the strength of diesel fuel lines lies in their construction from robust materials. Stainless steel and high-strength plastics are carefully selected to provide the necessary durability, ensuring that the fuel lines can withstand the challenges posed by diesel fuel and engine operation. This attention to material choice is a testament to the engineering prowess required to create reliable and efficient diesel vehicles.

Fuel Injector Linearity: A Matter of Efficiency and Precision

You may want to see also

Flexibility: Some lines use flexible materials to withstand engine vibrations and temperature changes

The design of diesel fuel lines is crucial for ensuring efficient and reliable fuel delivery to the engine. One key aspect of their construction is the use of flexible materials, which play a vital role in withstanding the demanding conditions within an engine bay. This flexibility is essential to accommodate the various stresses and strains that fuel lines endure during operation.

Engine vibrations are a significant factor in the life and performance of fuel lines. As the engine operates, it generates vibrations that can cause the fuel lines to flex and move. To combat this, manufacturers often utilize materials with inherent flexibility, such as rubber or certain types of plastic. These materials allow the fuel lines to bend and stretch, absorbing the energy from the vibrations and reducing the risk of damage or breakage. This flexibility is particularly important in high-performance engines or those with aggressive driving conditions, where the engine experiences more intense vibrations.

Temperature changes are another critical consideration for diesel fuel lines. Engines operate in a wide range of temperatures, from cold starts in winter to high-temperature operation during extended use. Flexible materials help fuel lines adapt to these temperature fluctuations. For instance, rubber fuel lines can expand and contract with temperature changes, ensuring a consistent fit and preventing leaks. This is especially important in engines where temperature variations are extreme, as it helps maintain the integrity of the fuel system.

The flexibility of diesel fuel lines is not just about withstanding vibrations and temperature changes but also about longevity and durability. Flexible materials can better resist wear and tear, reducing the chances of cracks or punctures over time. This is particularly beneficial in areas where fuel lines are more susceptible to damage, such as near the engine block or under the vehicle's underbody. By using flexible materials, manufacturers can ensure that fuel lines remain intact and functional even after years of use.

In summary, the flexibility of diesel fuel lines is a critical design feature that enables them to endure the harsh conditions of an engine environment. Through the use of flexible materials, these lines can absorb vibrations, adapt to temperature changes, and maintain their structural integrity over time. This attention to detail in fuel line construction is essential for the overall performance and longevity of diesel engines.

Pipe Thread Sealant: Essential for Fuel Line Maintenance?

You may want to see also

Corrosion Resistance: Materials like stainless steel offer protection against corrosion from fuel and engine components

When it comes to diesel fuel lines, corrosion resistance is a critical factor to ensure the longevity and reliability of the fuel system. Over time, diesel fuel can contain various contaminants and additives, which, when exposed to certain materials, can lead to corrosion and degradation of the fuel lines. This is especially important in the context of diesel engines, which are known for their robust performance and durability.

One of the primary materials used to combat corrosion in diesel fuel lines is stainless steel. This material is renowned for its exceptional corrosion resistance properties, making it an ideal choice for fuel system components. Stainless steel is an alloy composed primarily of iron, chromium, and nickel, with additional elements like molybdenum and nitrogen. The presence of chromium creates a protective oxide layer on the surface, which prevents further corrosion and ensures the material's durability.

The use of stainless steel in fuel lines offers several advantages. Firstly, it provides excellent protection against corrosion from the fuel itself. Diesel fuel can contain water, acids, and other contaminants that can lead to rusting and deterioration of the fuel lines. Stainless steel's inherent corrosion resistance ensures that the fuel lines remain intact and functional, even in the presence of these corrosive elements. Additionally, stainless steel is highly resistant to the corrosive effects of engine components, such as exhaust gases and lubricating oils, which can also contribute to the degradation of other materials.

Furthermore, the durability of stainless steel is well-suited for the demanding environment of a diesel engine. It can withstand high temperatures, pressure fluctuations, and mechanical stress without compromising its structural integrity. This makes it an ideal material for fuel lines, as it can handle the rigorous conditions experienced during engine operation. The corrosion-resistant nature of stainless steel also ensures that the fuel lines maintain their flexibility and tensile strength over time, preventing cracks or leaks that could lead to fuel leaks or engine performance issues.

In summary, the use of materials like stainless steel in diesel fuel lines is essential for ensuring corrosion resistance and maintaining the overall health of the fuel system. Its ability to protect against corrosion from both fuel and engine components makes it a reliable choice for diesel applications, where durability and longevity are paramount. By utilizing such advanced materials, engineers can design fuel systems that meet the rigorous demands of diesel engines while providing long-lasting performance.

Outboard Fuel Confusion: Diesel or Gasoline? Unraveling the Mystery

You may want to see also

Temperature Tolerance: Lines may be made of materials that can handle extreme temperatures without degradation

When it comes to diesel fuel lines, temperature tolerance is a critical aspect of their design and material selection. These lines are exposed to a wide range of temperatures, from the cold start-up conditions in winter to the high-temperature operation during extended use. Therefore, the materials used in their construction must be able to withstand these extreme conditions without any degradation that could compromise performance or safety.

One of the primary materials used for diesel fuel lines is rubber, specifically a type of synthetic rubber known as neoprene or nitrile rubber. These rubbers are chosen for their excellent temperature resistance, which allows them to maintain their flexibility and integrity even in the harshest environments. Neoprene, for instance, can withstand temperatures ranging from -40°F to 250°F (-40°C to 121°C), making it suitable for a wide variety of diesel engine applications. This temperature range ensures that the fuel lines can handle the cold starts in winter and the high temperatures generated during prolonged operation without any loss of performance.

In addition to rubber, some fuel lines may also incorporate materials like stainless steel braids or coverings. These materials are added to provide additional protection against temperature extremes and to reinforce the fuel lines, especially in high-pressure applications. The stainless steel braids, for example, can withstand temperatures up to 500°F (260°C), making them ideal for use in high-temperature environments. This combination of rubber and stainless steel ensures that the fuel lines can handle both the cold and hot extremes without any degradation.

Furthermore, the design of the fuel lines also plays a crucial role in their temperature tolerance. Engineers often design these lines with a slight curvature or flexibility to accommodate temperature-induced expansion and contraction. This design feature helps to prevent the lines from becoming brittle or cracking due to temperature changes, ensuring their longevity and reliability.

In summary, diesel fuel lines are engineered to withstand extreme temperatures, and their materials and design are carefully selected to ensure optimal performance. The use of temperature-resistant rubbers and additional protective materials, such as stainless steel braids, ensures that these lines can handle the cold and hot extremes without degradation. This temperature tolerance is essential for the safe and efficient operation of diesel engines, where fuel lines play a critical role in delivering fuel to the engine under various environmental conditions.

Fuel Line for Your 96 Civic: A Guide to Finding the Right Fit

You may want to see also

Frequently asked questions

Diesel fuel lines are typically made from materials like steel, brass, or aluminum alloys. These materials are chosen for their durability and ability to withstand the high pressure and temperature variations in diesel engines.

Steel fuel lines are often preferred for heavy-duty applications due to their strength and resistance to corrosion. They can handle higher pressure and are less susceptible to damage from fuel contaminants, making them ideal for commercial vehicles and off-road machinery.

Brass fuel lines offer excellent corrosion resistance and a smooth interior surface, which helps reduce fuel flow restrictions. This material is commonly used in marine applications where exposure to saltwater is a concern.

Aluminum alloy fuel lines are lightweight and have good heat dissipation properties, making them suitable for high-temperature environments. They are often used in racing applications or where weight reduction is crucial without compromising on durability.

Yes, the choice of material can impact engine performance. For instance, steel lines might offer better pressure containment, while aluminum alloys can contribute to improved engine response due to their lower weight. The material selection depends on the specific requirements of the vehicle or equipment.