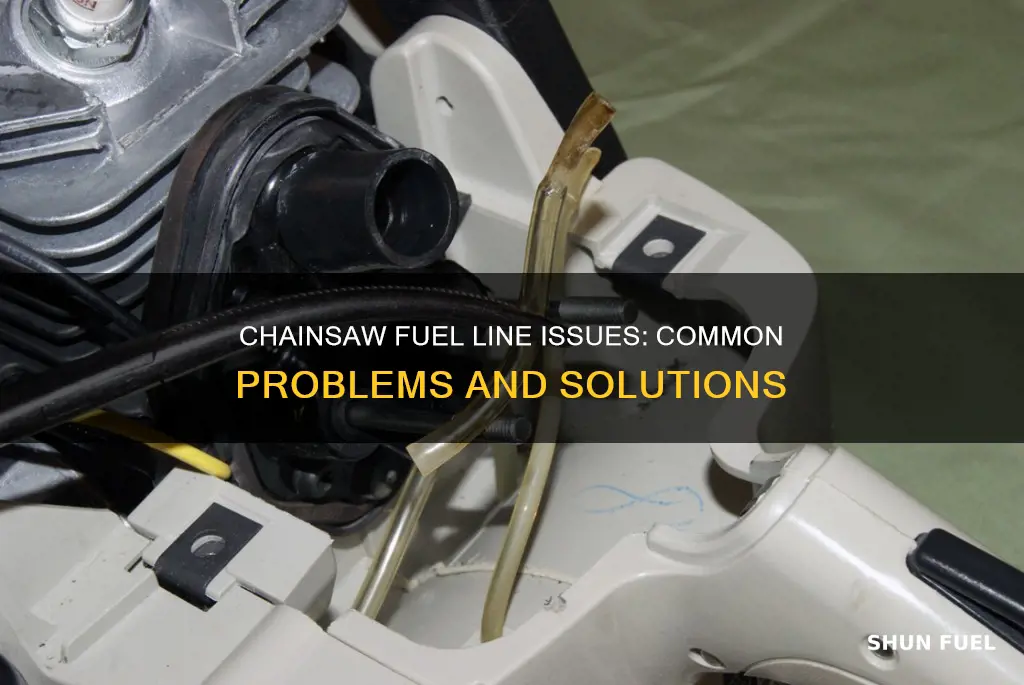

Chainsaws, essential tools for forestry and landscaping, often face a common issue: fuel line problems. These issues can range from fuel leaks to clogs, which can significantly impact the saw's performance and longevity. Understanding the reasons behind these problems is crucial for maintaining the chainsaw's efficiency and safety. This paragraph will explore the various factors contributing to the poor fuel lines in chainsaws, including the design, materials, and maintenance requirements of these critical components.

| Characteristics | Values |

|---|---|

| Fuel Line Material | Plastic or rubber |

| Fuel Line Design | Flexible and durable |

| Fuel Line Length | Varies depending on the model |

| Fuel Line Diameter | Typically 0.025 to 0.035 inches |

| Fuel Line Placement | Inside the saw's housing |

| Fuel Line Vulnerability | Prone to damage from impacts, vibrations, and sharp objects |

| Fuel Line Maintenance | Regular cleaning and inspection |

| Fuel Line Replacement | Required over time due to wear and tear |

| Fuel Line Issues | Clogging, cracking, and leaks |

| Fuel Line Solutions | Using high-quality fuel, proper storage, and regular maintenance |

What You'll Learn

- Design Flaws: Poor design choices lead to fuel line issues, causing frequent blockages and leaks

- Material Quality: Low-quality materials result in fuel lines that crack, degrade, and fail prematurely

- Installation Errors: Incorrect installation can cause fuel lines to kink, twist, or rupture, leading to performance issues

- Environmental Factors: Extreme temperatures and UV exposure accelerate fuel line degradation, reducing their lifespan

- Maintenance Neglect: Lack of regular maintenance, including cleaning and inspection, can lead to fuel line blockages and damage

Design Flaws: Poor design choices lead to fuel line issues, causing frequent blockages and leaks

The fuel lines on chainsaws are often plagued by issues due to design flaws that can lead to frequent blockages and leaks, causing significant problems for users. One common design issue is the use of narrow and rigid fuel lines, which are prone to becoming blocked by debris or clogs. These lines are typically made of a stiff material that doesn't allow for much flexibility, making it difficult to navigate around the various components of the chainsaw. As a result, the fuel lines can easily become restricted, leading to reduced fuel flow and potential performance issues.

In addition to blockages, poor design choices can also contribute to fuel leaks. Some chainsaws use fuel lines that are not properly sealed or connected, allowing fuel to escape and potentially causing environmental damage or safety hazards. The lines may have weak connections or seals that wear out over time, leading to constant leaks, especially when the chainsaw is in use or stored for extended periods. This not only results in wastage of fuel but also poses a risk of fire or explosion if the fuel comes into contact with ignition sources.

Another design flaw is the lack of proper ventilation in the fuel system. Chainsaws require a steady supply of fresh air to mix with the fuel, ensuring efficient combustion. However, some models have inadequate ventilation, causing a buildup of fuel vapor and potential fuel line corrosion. This can lead to frequent blockages and may even result in the fuel lines becoming brittle and prone to cracking, further exacerbating the issue of fuel delivery.

Furthermore, the placement of the fuel lines can also be a design flaw. If the lines are positioned in a way that makes them susceptible to damage, it can lead to frequent blockages and leaks. For example, fuel lines that run along the ground or are exposed to debris and dirt may become clogged or damaged easily. Proper design should consider the placement of these lines to protect them from potential hazards and ensure optimal performance.

To address these design flaws, manufacturers should focus on improving the flexibility and durability of fuel lines, ensuring proper sealing and connections, and implementing effective ventilation systems. By making these design choices, chainsaws can be made more reliable and user-friendly, reducing the frequency of fuel line issues and providing a better overall experience for operators.

2007 Honda Accent Fuel Line Location: Under the Hood

You may want to see also

Material Quality: Low-quality materials result in fuel lines that crack, degrade, and fail prematurely

The quality of materials used in the construction of fuel lines is a critical factor in determining their longevity and performance. When chainsaws are subjected to the rigors of outdoor work, the fuel lines play a vital role in delivering gasoline to the engine while withstanding the constant movement and vibrations. However, if the material quality is compromised, these fuel lines can become susceptible to various issues.

Low-quality materials often lack the necessary durability and flexibility required for fuel lines. These lines are typically made from rubber or synthetic compounds, and the choice of material significantly impacts their resistance to wear and tear. Inadequate materials may not possess the required elasticity, making them prone to cracking and brittleness over time. As a result, the fuel lines can become damaged, leading to fuel leaks, reduced engine performance, and even complete failure during operation.

Furthermore, the degradation of fuel lines due to poor material quality can accelerate under harsh environmental conditions. Exposure to sunlight, extreme temperatures, and moisture can cause the material to break down more rapidly. This degradation process can lead to a loss of structural integrity, causing the fuel lines to become soft, pliable, and more susceptible to damage from sharp edges or debris.

In some cases, the use of substandard materials may also result in fuel lines that are more prone to developing internal voids or bubbles. These voids can compromise the fuel flow, leading to inconsistent engine operation and potential starting issues. Additionally, the presence of voids can make the fuel lines more susceptible to corrosion, further reducing their lifespan.

To ensure optimal performance and longevity of chainsaws, it is essential to use high-quality materials for fuel lines. Manufacturers should invest in research and development to identify and utilize materials that offer superior durability, flexibility, and resistance to environmental factors. By doing so, they can provide users with reliable fuel lines that minimize the risk of premature failure and ensure consistent engine performance in demanding outdoor applications.

Fuel Line Dimensions for 2004 VW Beetle

You may want to see also

Installation Errors: Incorrect installation can cause fuel lines to kink, twist, or rupture, leading to performance issues

Incorrect installation of a chainsaw's fuel system can lead to a myriad of problems, with fuel lines being particularly susceptible to damage. The fuel lines are responsible for transporting gasoline from the tank to the carburetor, and any misalignment or improper attachment can result in kinking, twisting, or even rupturing. These issues can have a significant impact on the chainsaw's performance and overall functionality.

One common mistake is the failure to secure the fuel lines properly. When the lines are not tightly fastened, they can easily become dislodged during operation, causing them to rub against other components or hang loosely, which can lead to kinking. Kinking occurs when the line is bent or twisted, creating a restriction in the fuel flow, and can result in reduced power, stalling, or even complete engine failure. Additionally, kinked fuel lines may cause fuel to spill or leak, posing a safety hazard and potentially damaging the surrounding areas.

Another installation error is the incorrect routing of the fuel lines. The lines should be routed in a way that avoids sharp bends and tight spaces, as this can lead to twisting and potential damage. If the fuel lines are twisted, it can create a constriction in the fuel flow, causing the engine to run inefficiently or even stall. In some cases, twisted fuel lines may also cause fuel to spill, especially if the chainsaw is tilted or moved abruptly.

Furthermore, improper attachment of the fuel lines to the carburetor can lead to performance issues. If the lines are not securely connected, they may come loose during operation, causing fuel to spray out of the lines or even causing the carburetor to flood. This can result in poor engine performance, misfires, and reduced power output. In extreme cases, the fuel lines may even rupture, leading to a complete loss of engine functionality and potential damage to other components.

To avoid these installation errors, it is crucial to follow the manufacturer's instructions carefully. Properly secure the fuel lines, ensuring they are tightly fastened and free from any sharp bends or twists. Route the lines in a way that minimizes the risk of damage, and always double-check the connections to ensure a secure and reliable fuel supply to the engine. Regular maintenance and inspection of the fuel system can also help identify and rectify any installation errors before they cause significant performance issues.

Choosing the Right Pipe Sealant for Fuel Lines: A Guide

You may want to see also

Environmental Factors: Extreme temperatures and UV exposure accelerate fuel line degradation, reducing their lifespan

Extreme temperatures and UV exposure are significant environmental factors that contribute to the rapid degradation of fuel lines in chainsaws. These harsh conditions can cause the fuel lines to become brittle, crack, and eventually fail, leading to performance issues and potential safety hazards.

In regions with extreme weather variations, the fuel lines are subjected to constant temperature fluctuations. During hot summer days, the fuel lines can expand and become more susceptible to damage, while in colder climates, they may contract and become rigid, making them prone to cracking. This constant expansion and contraction can lead to micro-tears and structural weaknesses in the fuel line material, especially if the lines are made of lower-quality materials.

Ultraviolet (UV) radiation from the sun is another critical factor. UV rays can penetrate the fuel line material, causing it to degrade and become brittle over time. This degradation process is accelerated in areas with high UV exposure, as the sun's rays can break down the protective coatings and polymers used in the construction of fuel lines. As a result, the fuel lines may become less flexible, more prone to leaks, and ultimately fail, requiring replacement.

To mitigate these issues, it is essential to choose high-quality fuel lines designed to withstand the specific environmental conditions of your region. Some manufacturers offer fuel lines with UV-resistant materials and reinforced construction to enhance durability. Additionally, regular maintenance, such as inspecting and replacing fuel lines at recommended intervals, can help prevent unexpected failures and ensure optimal performance.

By understanding the impact of extreme temperatures and UV exposure, chainsaw users can take proactive measures to protect their equipment and ensure reliable operation, even in challenging environmental conditions. Proper maintenance and the use of suitable fuel lines can significantly extend the lifespan of chainsaw components and contribute to a safer and more efficient working experience.

Understanding Fuel Lines: A1 vs. B1 Differences Explained

You may want to see also

Maintenance Neglect: Lack of regular maintenance, including cleaning and inspection, can lead to fuel line blockages and damage

Neglecting regular maintenance is a common issue that can significantly impact the performance and longevity of your chainsaw. One of the critical components that often suffer due to this neglect is the fuel system, particularly the fuel lines. These lines are responsible for transporting gasoline from the tank to the engine, and over time, they can become a source of problems if not properly cared for.

The primary reason for fuel line issues is the accumulation of debris, varnish, and contaminants. When gasoline is stored for extended periods, it can degrade and form varnish, which clings to the walls of the fuel lines. This varnish buildup can restrict the flow of fuel, leading to blockages and reduced engine performance. Additionally, fuel lines can become damaged due to age, wear, or physical stress, especially if they are made of lower-quality materials.

In many cases, the consequences of maintenance neglect are evident in the form of hard starts, stalling, or a complete failure to start the chainsaw. These symptoms often indicate that the fuel lines are clogged or partially blocked, preventing the engine from receiving the necessary amount of gasoline. Over time, this can lead to more severe issues, such as engine damage, if the problem is not addressed promptly.

To prevent these issues, it is essential to establish a regular maintenance routine. This should include cleaning the fuel system, particularly the fuel lines, to remove any varnish or contaminants. A simple yet effective method is to run the chainsaw with a fuel stabilizer added to the gasoline, which helps prevent varnish formation. Additionally, inspecting the fuel lines for any signs of damage or wear is crucial. Cracks, leaks, or kinks in the lines should be addressed immediately to avoid further complications.

By implementing these maintenance practices, you can ensure that your chainsaw's fuel system remains in optimal condition, reducing the likelihood of fuel line blockages and damage. Regular care will not only improve the performance of your equipment but also extend its lifespan, saving you from potential costly repairs or replacements.

Honda Civic 1998 Fuel Line Sizes: A Comprehensive Guide

You may want to see also

Frequently asked questions

Fuel lines in chainsaws are prone to issues due to their design and the harsh operating conditions. These lines are typically made of flexible materials to accommodate the engine's movement, but this flexibility can lead to kinking, cracking, or splitting over time. The fuel lines are also exposed to high temperatures, vibrations, and fuel contaminants, which can cause degradation and failure.

The design of fuel lines in chainsaws often includes a curved or coiled path to allow for engine movement. While this design is necessary, it can also lead to fuel restriction or blockage. Curved lines may trap air bubbles, causing poor fuel flow and engine performance issues. Additionally, the coiled design can make the lines more susceptible to damage from sharp objects or rough terrain.

Yes, several factors can contribute to fuel line failure in chainsaws. These include age and wear, as older fuel lines may become brittle and more susceptible to damage. Clogging due to contaminated fuel or debris can also occur, especially if the fuel filter is not regularly maintained. External damage, such as being run over by the saw or impacted by debris, can also lead to fuel line leaks or ruptures.

Regular maintenance is key to preventing fuel line problems. Ensure you use fresh, clean fuel and replace the fuel filter at recommended intervals. Keep the fuel lines protected by avoiding contact with sharp objects and rough terrain. Regularly inspect the lines for any signs of damage, cracks, or kinks, and replace them if necessary. Properly securing the fuel lines during transportation and storage can also help prevent issues.