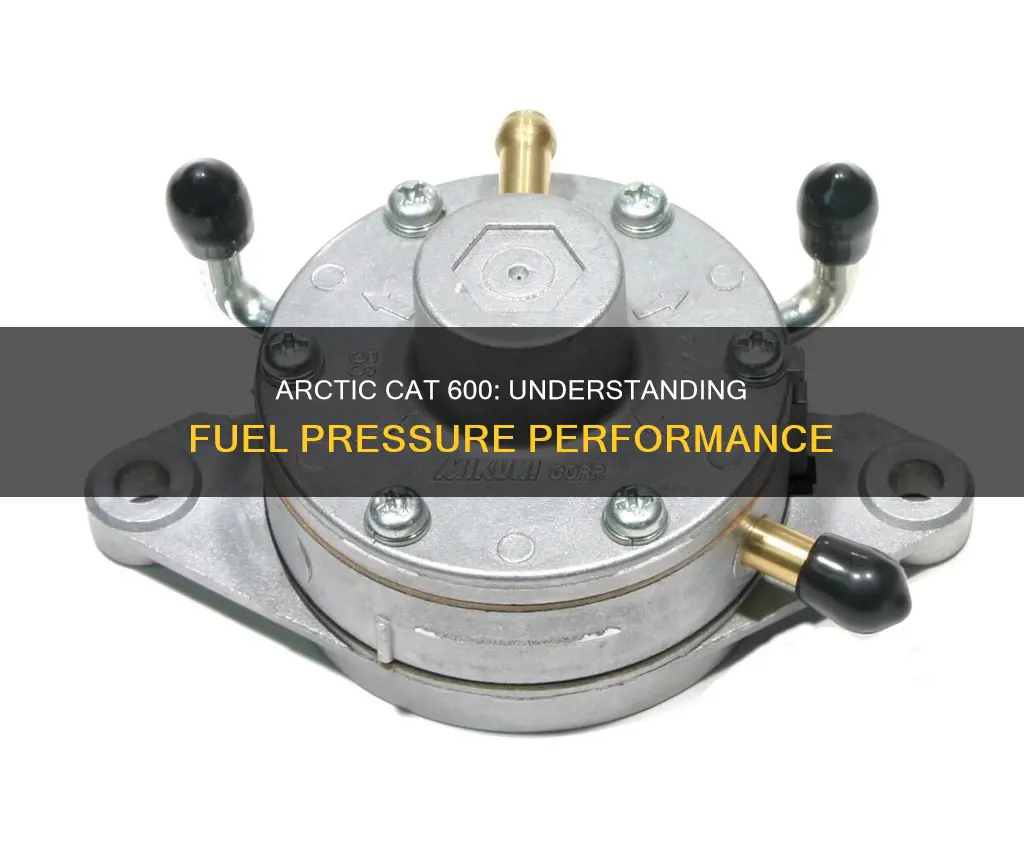

The fuel pressure for the Arctic Cat 600 varies depending on the model. For the 1998 ZR 600 EFI, the fuel pressure should be 36-38 PSI. For the ZL600 EFI, the fuel pressure should be 35-39 PSI at idle and 39 PSI at WOT. For the 2001 ZR 600 EFI, the fuel pressure should be about 38 PSI. It is important to note that the fuel pressure regulator should be set to the correct pressure to ensure optimal performance.

What You'll Learn

How to check fuel pressure

Checking the fuel pressure of your vehicle is a good first step when experiencing drivability issues. Here is a step-by-step guide on how to check the fuel pressure of your Arctic Cat 600:

Step 1: Identify the Pressure Line

Most vehicles have two fuel lines going to the engine: a pressure line and a return line. You will need to identify which line is the pressure line. Refer to your vehicle manufacturer's instructions or a mechanic to safely determine the correct line.

Step 2: Prepare for the Test

Before beginning, ensure you are working in a well-ventilated area as fuel vapors are highly flammable. Have a fire extinguisher nearby as a safety precaution.

Step 3: Bleed the Pressure

To do this, locate the power distribution box and remove the fuel pump relay. This will allow you to crank the vehicle and drain the pressure without engaging the fuel pump.

Step 4: Install the Pressure Gauge

Open up the system and install a pressure gauge. You may need to remove a safety clip and use a rag to catch any dripping fuel. Ensure that the gauge is securely installed and seated properly.

Step 5: Start the Vehicle

With the pressure gauge installed, start the vehicle and let it run for about 15 seconds. Then, release the valve and measure the fuel pressure.

Step 6: Check the Residual Pressure

Turn off the vehicle and observe the residual pressure. If the pressure drops quickly, it could indicate a hard start issue. Monitor the residual pressure for about 15 minutes. If the pressure remains stable, it means the check valve and pressure regulator are functioning correctly.

Step 7: Remove the Pressure Gauge

To remove the pressure gauge, use a removal tool and slowly slide it into the fuel line, being mindful of any residual pressure remaining in the system. Have a rag underneath the fuel line to catch any dripping fuel.

Understanding Fuel Pressure Readings:

The ideal fuel pressure for your Arctic Cat 600 will depend on the engine specifications. For a 2002 ZL600 EFI, the recommended fuel pressure is 35-36 psi at idle and 39 psi at wide-open throttle. If your reading is significantly lower, it could indicate an issue with the fuel pump or fuel pressure regulator.

If you are experiencing issues with your Arctic Cat 600, such as bogging or backfiring, it is important to check the fuel pressure and identify any potential problems with the fuel system.

Understanding Fuel Pressure: Delphi CFE Pump Performance

You may want to see also

Recommended fuel pressure

The recommended fuel pressure for the Arctic Cat 600 EFI is between 35-39 psi at idle and 39 psi at wide-open throttle (WOT). The fuel pressure regulator should be set to around 35-36 psi, as this seems to provide the best response and plug colour. However, it's important to note that the book specifies the fuel pressure should be 37.9 psi, plus or minus 2.2 psi.

To test the fuel pressure, you can put a "T" in the line going to the carbs and connect a fuel pressure gauge. Make sure the float bowls are full so that the engine can run long enough to give an accurate reading. The engine does not need to be running; simply apply 12 VDC to the fuel pump and read the gauge. If you're experiencing issues with low fuel pressure, it could be due to a faulty fuel pump, a clogged fuel filter, or a pinched fuel line.

It's important to maintain proper fuel pressure in your Arctic Cat 600 EFI to ensure optimal performance and prevent engine problems. If you suspect an issue with your fuel pressure, it's recommended to consult a professional or a mechanic familiar with these vehicles for further advice and guidance.

Understanding High-Pressure Electric Fuel Pumps: How Do They Work?

You may want to see also

Fuel pump replacement

Fuel pumps are small electric motors that transfer fuel from the fuel tank to the engine. They can be mechanical, although this is uncommon. If your fuel pump is not delivering enough fuel pressure, it may need to be replaced. Here is a step-by-step guide on how to do this safely and correctly:

Step 1: Park your vehicle and set the brake

It is important to ensure your vehicle is secure and will not move while you are working on it.

Step 2: Locate the fuel pump

On most vehicles, the fuel pump is located inside the fuel tank. To check if it is working, open the fuel cap and turn the key to the 'on' position. If the pump is working, you should hear a hum for two to three seconds.

Step 3: Check the fuel pump fuse and relay

If the pump is not working, check the fuse and relay. If the fuse is blown, replace it with one of the same amperage. If the fuse and relay are functional, check for power and ground at the fuel pump. If there is power and ground, the pump is faulty and needs to be replaced.

Step 4: Prepare the fuel system

Relieve the fuel system pressure by running the engine and pulling the fuel pump relay. Disconnect the negative battery cable. Siphon or drain as much fuel as possible from the tank.

Step 5: Remove the fuel tank

Disconnect the filler tube hose and electrical connection to the pump. Support the fuel tank with a jack and a block of wood, and remove any retaining straps or bolts holding the tank to the frame. Carefully lower the tank and disconnect the fuel lines.

Step 6: Remove and replace the fuel pump

Remove the old fuel pump from the tank and compare it to the new one to ensure you have the correct replacement. Install the new fuel pump, reconnecting the fuel lines and electrical connections.

Step 7: Reinstall the fuel tank

Lift the fuel tank back into place and secure it with the retaining strap. Reconnect the filler tube hose and the electrical connector, and reconnect the negative battery cable.

Step 8: Test the new fuel pump

Fill the tank with gas and conduct a road test to confirm that the new fuel pump is working correctly.

Additional Tips:

- Work in a well-ventilated area to minimise the risk of fire and inhaling harmful fumes.

- Always wear safety glasses, gloves, and appropriate clothing to protect yourself from fuel spills.

- Drain the fuel tank to reduce the risk of spills and make it easier to handle.

- Clean around the fuel pump to prevent dirt and debris from falling into the fuel tank.

- Consider replacing related components, such as the fuel filter and fuel pump strainer.

It is important to note that fuel pump replacement can be a challenging task, and it is always recommended to consult a professional mechanic if you are unsure about any part of the process.

Understanding Fuel Line Pressure in 1988 D100 V6 Engines

You may want to see also

Fuel pressure regulators

The regulators are available in both return and non-return styles. Return-style regulators allow excess fuel to return to the tank, ensuring a steady fuel supply and pressure across different engine loads. This feature is crucial for maintaining performance and preventing fuel-related issues. On the other hand, non-return style regulators maintain consistent fuel pressure without returning excess fuel to the tank.

Adjustable fuel pressure regulators offer enhanced versatility, allowing drivers to fine-tune fuel delivery according to their vehicle's needs. Whether it's a high-performance race car or a daily driver, adjustable regulators ensure the engine receives the exact amount of fuel required for optimal performance.

Leading brands such as Holley, Aeromotive, MagnaFuel, Quick Fuel, and AEM offer a wide range of fuel pressure regulators for carbureted and fuel-injected applications. These regulators cater to a diverse range of engines, from stock pump gas engines to high-horsepower race engines, as well as diesel and E85 engines.

Additionally, fuel pressure regulators with return lines provide improved stability by effectively managing excess fuel, ensuring a consistent pressure level. This feature is vital for maintaining engine performance and preventing fuel-related issues.

Fuel Filter Element: High-Pressure Performance and Maintenance

You may want to see also

Fuel gauge placement

Understanding Fuel Gauges

Fuel gauges are standard instruments in vehicles, including snowmobiles like the Arctic Cat 600. They provide critical information about the amount of fuel in the tank, helping operators make informed decisions about refuelling and range. The gauge consists of two main components: the sending unit and the indicator. The sending unit is located inside the fuel tank and typically uses a float connected to a potentiometer or a modern printed ink design. As the fuel level changes, the float adjusts, altering the resistance measured by the potentiometer. This resistance change is then translated into an indication of fuel level on the dashboard indicator.

Placement Considerations

When it comes to fuel gauge placement in the Arctic Cat 600, there are several factors to consider. Firstly, the sending unit must be accurately positioned within the fuel tank to ensure precise fuel level readings. This involves calibrating the float mechanism to correspond to the actual fuel levels. Additionally, the indicator unit on the dashboard should be placed within the operator's line of sight for easy monitoring. This ensures that the operator can readily check the fuel level without distraction.

Mounting and Orientation

The fuel gauge in the Arctic Cat 600 is typically mounted on the dashboard, often near the speedometer and other vital instrumentation. This central location allows for quick visual checks while operating the snowmobile. In terms of orientation, the gauge should be positioned so that the needle's movement is easily discernible. Some gauges may have specific orientation requirements, especially if they are fluid-filled or use a pin-style valve. These gauges must be mounted according to the manufacturer's instructions to ensure accurate readings.

Safety and Reliability

Testing and Maintenance

To ensure accurate fuel gauge readings in the Arctic Cat 600, regular testing and maintenance are necessary. This involves checking the fuel pump pressure and the integrity of the fuel lines. Testing procedures may vary depending on the specific model of the Arctic Cat 600, so referring to the manufacturer's guidelines or seeking advice from experienced operators is recommended. Proper maintenance of the fuel system, including the fuel gauge, is essential for the safe and reliable operation of this high-performance snowmobile.

Understanding Fuel Rail Pressure Sensor: Circuit High Input Meaning

You may want to see also

Frequently asked questions

You can check the fuel pressure by putting a "T" in the line going to the carbs. Make sure the float bowls are full so the engine runs long enough to give an accurate reading.

The fuel pressure on an Arctic Cat 600 should be between 35-39 psi at idle and 39 psi when revved.

Trouble code "1" indicates a TPS issue. Check and change the TPS if necessary.

Low fuel pressure can be caused by a faulty fuel pump, regulator, or smart valves. Test each of these components to identify the issue.

If your fuel pressure drops when you rev the engine, it is likely that your fuel pump is faulty and needs to be replaced.