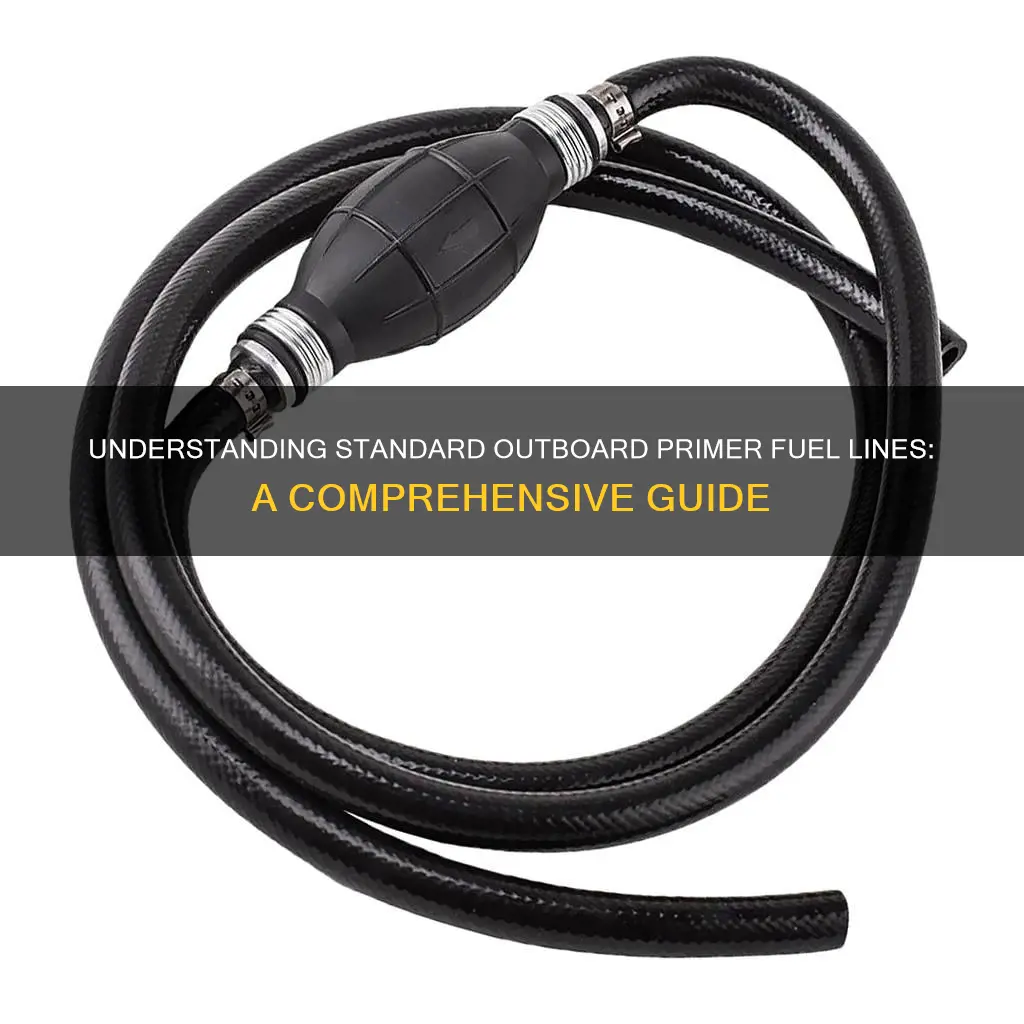

Outboard engines require a reliable fuel supply system to ensure optimal performance. One crucial component of this system is the standard outboard primer fuel line, which plays a vital role in delivering fuel to the engine's carburetor or fuel injection system. This paragraph will explore the essential functions and considerations of this standard component, highlighting its significance in maintaining the efficient operation of outboard engines.

| Characteristics | Values |

|---|---|

| Material | Typically made of rubber or vinyl |

| Diameter | Standard diameter is 3/8" (0.95 cm) |

| Length | Varies depending on the engine model, but commonly ranges from 12 to 24 inches (30.5 to 61 cm) |

| Compatibility | Specific to the outboard engine brand and model |

| Primer Location | Usually attached to the fuel tank or near the engine's fuel intake |

| Function | Facilitates the flow of fuel from the tank to the carburetor or fuel injection system |

| Ease of Replacement | Often designed for easy installation and removal |

| Durability | Built to withstand fuel exposure and engine vibrations |

| Color | May vary, but often includes a clear or translucent section to inspect fuel levels |

What You'll Learn

- Primer Type: Standard outboard engines use small-bore primer lines for quick-start fuel delivery

- Material: Fuel lines are typically made of rubber or plastic for flexibility and durability

- Length: Standard length varies by engine model, typically 1-2 feet

- Fitting: Inboard fittings ensure a secure connection to the fuel tank and carburetor

- Compatibility: Check engine manual for compatible fuel line sizes and types

Primer Type: Standard outboard engines use small-bore primer lines for quick-start fuel delivery

Standard outboard engines rely on a specific type of primer system to ensure a quick and efficient start-up process. This system is designed to deliver fuel to the engine's carburetor rapidly, allowing for a swift and smooth ignition. At the heart of this mechanism is the primer line, a crucial component that facilitates the transfer of fuel from the primer bulb to the carburetor.

The primer line is characterized by its small-bore design, which is a key feature that sets it apart from other fuel lines. This small bore is essential for the quick-start functionality, as it enables rapid fuel flow, ensuring the engine receives the necessary fuel volume in a short time. The small-bore primer line is typically made of flexible materials like rubber or plastic, allowing it to conform to the engine's contours and maintain a secure connection.

In the context of outboard engines, the primer line is often connected to a primer bulb, which is manually squeezed to initiate the priming process. When the bulb is pressed, it creates a vacuum that draws fuel from the primer line into the bulb. This fuel-filled bulb then acts as a temporary fuel reservoir, providing the initial burst of fuel required for engine start-up.

The design of the small-bore primer line is critical to the engine's performance. Its bore size is carefully chosen to balance the need for rapid fuel delivery with the requirement to maintain a steady flow. A bore that is too small may restrict fuel flow, while one that is too large might lead to excessive fuel consumption during start-up. Therefore, manufacturers carefully select the bore size to optimize the engine's performance and fuel efficiency.

Understanding the role and design of the standard outboard primer fuel line is essential for engine maintenance and troubleshooting. By recognizing the importance of this small-bore line, engine owners can ensure their outboard engines start reliably, even in challenging conditions. Regular inspection and maintenance of the primer line can help prevent starting issues and ensure the engine's overall reliability.

Understanding Fuel Line Hose Clamp Sizes: A Comprehensive Guide

You may want to see also

Material: Fuel lines are typically made of rubber or plastic for flexibility and durability

Fuel lines play a crucial role in the operation of outboard engines, and their material composition is an essential aspect to consider. Typically, these fuel lines are crafted from either rubber or plastic, both of which offer distinct advantages in terms of flexibility and durability.

Rubber, a natural or synthetic material, is renowned for its inherent flexibility. This property is vital for fuel lines as it allows them to withstand the various movements and vibrations experienced during the operation of an outboard engine. Rubber fuel lines can easily bend and adjust to the engine's movement, ensuring a consistent and secure connection between the fuel tank and the engine. This flexibility is particularly important in preventing fuel line damage and maintaining a reliable fuel supply.

Plastic, on the other hand, offers its own set of benefits. It is often preferred for its lightweight nature, which can reduce the overall weight of the fuel system, contributing to better handling and performance. Additionally, plastic fuel lines are known for their resistance to corrosion and chemical degradation, making them highly durable. This durability is especially advantageous in marine environments, where exposure to fuel, moisture, and UV radiation can be prevalent.

The choice between rubber and plastic often depends on the specific application and the engine's requirements. Rubber fuel lines are commonly used in older engines or those that operate in harsher conditions, where flexibility is a critical factor. Plastic fuel lines, with their lightweight and corrosion-resistant properties, are often favored in modern outboard engines, especially those designed for recreational boating.

In summary, the material of fuel lines is a critical consideration for outboard engine performance and longevity. Rubber and plastic, each with their unique properties, offer reliable solutions for fuel line flexibility and durability, ensuring a consistent and secure fuel supply to the engine. Understanding these materials' characteristics can guide the selection process, ensuring optimal engine performance and a longer lifespan.

Polaris Ranger 570 Fuel Line Fittings: A Comprehensive Guide

You may want to see also

Length: Standard length varies by engine model, typically 1-2 feet

The length of a standard outboard primer fuel line is a crucial aspect of engine performance and maintenance. This component is designed to ensure a consistent and efficient fuel supply to the engine, especially in outboard motor applications. The standard length of this fuel line can vary depending on the specific engine model and manufacturer. Typically, you can expect the length to range from 1 to 2 feet. This length is carefully chosen to optimize the fuel delivery process while maintaining a balance between convenience and functionality.

Engine manufacturers often provide detailed specifications for their outboard motors, including the recommended length of the primer fuel line. This ensures that the fuel line is long enough to reach the engine's fuel intake but not so long that it becomes cumbersome or prone to tangling. The ideal length allows for easy installation and access during routine maintenance or repairs.

For instance, a 1-foot length might be suitable for smaller outboard engines, providing a direct and efficient connection from the fuel tank to the engine's primer system. On the other hand, larger or more powerful engines may require a slightly longer fuel line, typically up to 2 feet, to accommodate the increased fuel flow and ensure a steady supply.

It's important to note that while the standard length is a good starting point, customization might be necessary in certain scenarios. Factors such as engine placement, fuel tank location, and personal preferences can influence the final choice of fuel line length. In some cases, extending or shortening the fuel line may be required to achieve the optimal setup for a specific boat or engine configuration.

Understanding the standard length of the outboard primer fuel line is essential for any boat owner or mechanic. It ensures that the fuel system is properly configured, promoting efficient engine operation and reducing the risk of fuel-related issues. Always refer to the manufacturer's guidelines for the most accurate and up-to-date information regarding fuel line specifications for your particular engine model.

Understanding SAE 307R7 Fuel Line: A Comprehensive Guide

You may want to see also

Fitting: Inboard fittings ensure a secure connection to the fuel tank and carburetor

When it comes to fuel systems in engines, the term "inboard fittings" refers to a specific type of connection used to secure and route fuel lines. These fittings are crucial for ensuring a reliable and efficient fuel supply to the engine, particularly in applications where the fuel tank and carburetor are located inboard, closer to the engine block.

Inboard fittings are designed to provide a tight and secure seal, preventing fuel leaks and ensuring that the fuel flows smoothly to the engine. These fittings are typically made of durable materials such as brass or stainless steel, which offer excellent corrosion resistance and longevity. The primary purpose of using inboard fittings is to establish a robust connection between the fuel tank and the carburetor, allowing for optimal fuel delivery.

The process of fitting inboard fittings involves several steps. Firstly, you need to ensure that the fuel lines are properly sized and cut to the appropriate length. This is essential to allow for a snug fit and to avoid any unnecessary strain on the fittings. Once the lines are prepared, you can slide the inboard fitting over the end of the fuel line. These fittings often feature a threaded or barbed connection, which securely fastens the line in place. Tightening the fitting securely ensures a leak-free seal.

It is important to use the correct type of inboard fitting for the specific fuel line diameter and application. Different engines may require varying sizes and types of fittings, so consulting the manufacturer's guidelines or seeking expert advice is recommended. Proper installation and regular maintenance of these fittings are vital to guarantee a consistent and reliable fuel supply, especially in high-performance or marine applications where fuel efficiency and security are critical.

By utilizing inboard fittings, engine owners can ensure that their fuel systems are well-connected and protected from potential leaks, contributing to a more efficient and reliable engine performance. This simple yet effective fitting system plays a significant role in maintaining the overall health and functionality of the engine's fuel delivery mechanism.

Fuel vs. Oil: Automotive Fluids Demystified

You may want to see also

Compatibility: Check engine manual for compatible fuel line sizes and types

When working on an outboard engine, ensuring the correct compatibility of fuel lines is crucial for optimal performance and longevity. The first step in this process is to consult the engine's manual, which is a comprehensive guide specific to your engine model. This manual will provide detailed information about the standard fuel line sizes and types required for your particular engine. It is essential to follow the manufacturer's recommendations to avoid any potential issues.

The engine manual will typically include a diagram or a list of part numbers for the compatible fuel lines. These specifications are designed to match the engine's fuel system perfectly. Using the wrong size or type of fuel line can lead to fuel leaks, reduced performance, or even engine damage. For example, if your engine requires a 3/8-inch fuel line, using a 1/4-inch line will not provide the necessary capacity to handle the fuel flow, potentially causing issues during operation.

Checking the compatibility is a critical step that should not be overlooked. Many engine problems can be traced back to using incorrect fuel lines, which can be costly to fix. By taking the time to refer to the manual, you can ensure that you select the right fuel lines for your engine, saving potential headaches and expenses down the line.

In some cases, you might find that the engine manual provides different recommendations for various engine models or years. This is because fuel line requirements can vary across different generations of the same engine type. Therefore, it is essential to identify the specific model and year of your engine to access the most accurate information.

Additionally, if you are unsure about any aspect of the fuel line installation or compatibility, it is advisable to consult a professional mechanic or the manufacturer's support team. They can provide expert guidance and ensure that your engine receives the correct fuel lines, contributing to its overall reliability and performance.

Choosing the Right Diameter Fuel Line for Your Yamaha Outboard

You may want to see also

Frequently asked questions

A standard outboard primer fuel line is a type of fuel line used in small engines, typically in boats or other recreational vehicles. It is designed to deliver fuel from the fuel tank to the engine's carburetor or fuel injection system, ensuring a steady supply of gasoline for combustion.

The standard outboard primer fuel line is usually a specific diameter and length, which can vary depending on the engine model and year. You can check the manufacturer's specifications or consult the engine's manual to determine the correct dimensions. Often, these fuel lines are made of durable materials like rubber or vinyl and feature a primer bulb or a built-in primer pump to facilitate easy starting.

While it is possible to use an alternative fuel line, it is generally recommended to stick with the standard specifications provided by the engine manufacturer. Non-standard fuel lines may not fit perfectly, leading to potential issues with fuel delivery and engine performance. Using the correct type ensures compatibility, proper functionality, and adherence to the engine's design requirements.