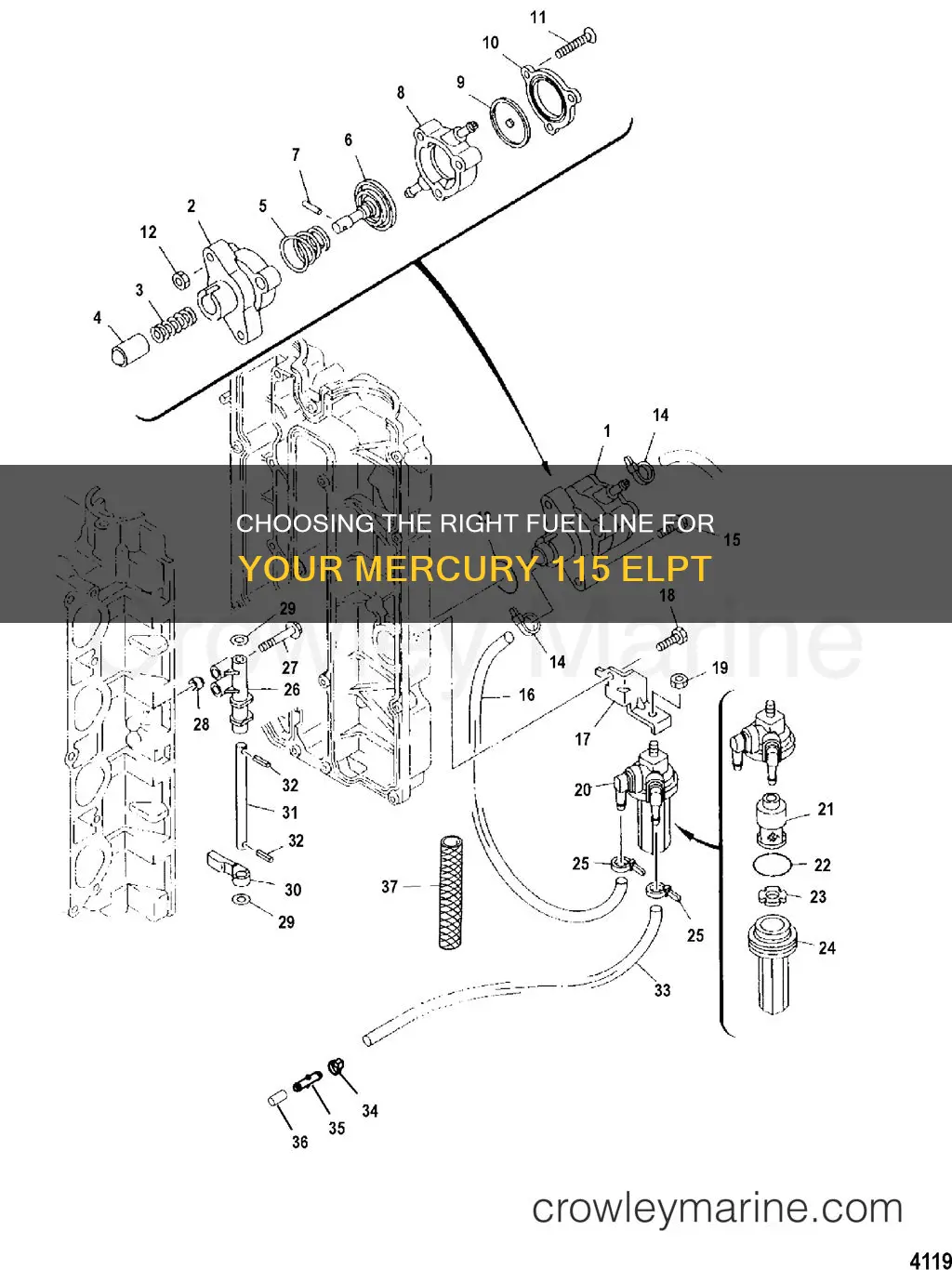

When it comes to maintaining your 115 ELPT Mercury engine, one crucial aspect is ensuring that the fuel line is the right size. The fuel line is responsible for delivering fuel from the tank to the engine, and using the correct size is essential for optimal performance and safety. In this guide, we'll explore the recommended fuel line size for your 115 ELPT Mercury engine, helping you make informed decisions about your vehicle's maintenance.

| Characteristics | Values |

|---|---|

| Engine Type | 115 ELPT Mercury |

| Fuel Line Diameter | 3/8 inch |

| Length | 10 feet |

| Material | High-pressure fuel line |

| Compatibility | Mercury Outboards |

| Color | Black |

| Temperature Range | -40°F to 212°F (-40°C to 100°C) |

| Pressure Rating | 150 psi |

| Flexibility | Flexible for easy installation |

| Corrosion Resistance | Resistant to corrosion and UV damage |

| Warranty | Limited lifetime warranty |

What You'll Learn

- Fuel Line Material: Choose fuel line made of compatible material like rubber or vinyl for 115 HP Mercury ELPT

- Fuel Line Diameter: Ensure fuel line diameter matches engine requirements for optimal performance and fuel flow

- Fuel Line Length: Measure and select fuel line length based on engine placement and fuel tank location

- Fuel Line Routing: Route fuel line away from heat sources and sharp bends for longevity

- Fuel Line Fittings: Use compatible fittings and adapters for secure fuel line connections

Fuel Line Material: Choose fuel line made of compatible material like rubber or vinyl for 115 HP Mercury ELPT

When it comes to maintaining your 115 HP Mercury ELPT engine, one crucial aspect is ensuring that the fuel line is in optimal condition. The fuel line is responsible for transporting gasoline from the fuel tank to the engine, and using the right material is essential for reliable performance. For this specific engine, it is recommended to use fuel lines made of compatible materials such as rubber or vinyl.

Rubber fuel lines are an excellent choice for this application due to their flexibility and durability. They are designed to withstand the high pressure and temperature fluctuations that occur during engine operation. Rubber is a natural material that can expand and contract without compromising its structural integrity, ensuring a secure and reliable connection between the fuel tank and the engine. This flexibility is particularly important in marine environments where the engine may experience vibrations and movement.

Vinyl fuel lines are another suitable option, offering a lightweight and flexible alternative to rubber. Vinyl is known for its resistance to abrasion and chemicals, making it an ideal choice for fuel transportation. It is less prone to cracking compared to rubber, especially in colder climates, and provides excellent flexibility without sacrificing strength. This material is often preferred for its cost-effectiveness and ease of installation.

When selecting the fuel line, it is crucial to consider the specific requirements of your 115 HP Mercury ELPT engine. The fuel line should be the correct size to ensure an efficient and secure connection. Referring to the manufacturer's guidelines or consulting a marine mechanic can help determine the appropriate diameter and length of the fuel line for your engine. Using the right size fuel line will prevent fuel leaks and ensure optimal engine performance.

In summary, for the 115 HP Mercury ELPT engine, opt for fuel lines made of rubber or vinyl. These materials offer the necessary flexibility, durability, and compatibility for efficient fuel transportation. Always ensure that the fuel line is the correct size and securely installed to maintain the engine's performance and longevity. Regular inspection and maintenance of the fuel line will contribute to a reliable and enjoyable boating experience.

Unveiling the Secrets: Red Line Fuel System Explained

You may want to see also

Fuel Line Diameter: Ensure fuel line diameter matches engine requirements for optimal performance and fuel flow

When it comes to maintaining your 115 ELPT Mercury engine, one crucial aspect often overlooked is the fuel line diameter. The fuel line is responsible for transporting gasoline from the tank to the engine, and its size directly impacts the engine's performance and fuel efficiency. Here's a detailed guide on why ensuring the correct fuel line diameter is essential.

The fuel line diameter is a critical factor in determining the engine's ability to draw fuel efficiently. A fuel line that is too small will restrict the flow of gasoline, leading to reduced power and potential performance issues. On the other hand, a line that is too large may not be necessary and could even cause unnecessary pressure, potentially leading to fuel leaks or other problems. Therefore, it is imperative to choose the right size based on the engine's specifications.

Mercury engines, including the 115 ELPT model, have specific requirements for fuel line diameters to ensure optimal performance. These requirements are often outlined in the engine's manual or can be found through online resources. It is essential to consult these sources to determine the exact diameter needed for your engine. Using the correct size ensures that the fuel flows smoothly, providing the engine with the necessary power and efficiency.

To ensure you get the right fit, measure the existing fuel line or refer to the engine's manual for the recommended diameter. Common sizes for Mercury engines range from 3/8 inch to 1/2 inch ID (inside diameter). For instance, a 3/8 inch fuel line is suitable for smaller engines, while a 1/2 inch line is often used for larger, more powerful models. Always choose a line that matches or exceeds the engine's requirements to avoid performance issues.

In summary, paying attention to the fuel line diameter is a simple yet effective way to maintain your 115 ELPT Mercury engine's performance. By selecting the correct size, you ensure efficient fuel delivery, optimal power output, and a well-maintained vehicle. Remember, proper maintenance, including the use of the right fuel line, can significantly extend the engine's lifespan and overall reliability.

Unraveling the Mystery: Why Fuel Lines Bubble

You may want to see also

Fuel Line Length: Measure and select fuel line length based on engine placement and fuel tank location

When it comes to choosing the right fuel line for your 115 ELPT Mercury engine, one of the most critical factors is the length of the fuel line. This component is responsible for connecting the fuel tank to the engine, and its length can significantly impact performance and reliability. Here's a detailed guide on how to measure and select the appropriate fuel line length based on engine placement and fuel tank location.

Understanding Engine and Fuel Tank Placement:

Before you begin measuring, it's essential to understand the typical layout of your Mercury engine and fuel tank. The 115 ELPT Mercury engine is commonly found in various marine applications, such as boats and personal watercraft. The engine's position can vary depending on the design of the vessel. Some engines are mounted inboard, while others might be outboards or in a transom position. Similarly, the fuel tank can be located in different areas, such as the bilge, the engine compartment, or even in a separate storage area. Understanding this layout is crucial for accurate measurements.

Measuring the Fuel Line:

- Identify the Mounting Points: Locate the mounting points on the engine and fuel tank where the fuel line will attach. These points are typically where the fuel lines are secured to the engine's fuel rail and the fuel tank's sending unit.

- Measure the Distance: Use a flexible measuring tape or a ruler to measure the distance between these two mounting points. Ensure that you measure along the path where the fuel line will run, considering any bends or angles it will take. This measurement will give you an idea of the minimum length required for the fuel line.

- Consider Additional Length: It's essential to add some extra length to the measured distance to account for any potential movement or adjustments during installation. This additional length will ensure that the fuel line is long enough to reach the desired connection points without being too tight or restrictive.

Selecting the Fuel Line Length:

- Standard Sizes: Fuel lines are typically available in standard sizes, such as 3/8", 1/2", or 5/8" in diameter. Choose a size that matches the engine's fuel requirements and the available space in the vessel.

- Custom Lengths: If you can't find a standard length that suits your needs, consider ordering a custom-length fuel line. Many suppliers offer this service, allowing you to specify the exact length required.

- Flexibility: Opt for a fuel line material that offers flexibility, such as rubber or a flexible composite. This flexibility is crucial for accommodating the natural movement of the engine and fuel tank during operation.

Installation and Testing:

Once you've selected the appropriate fuel line length, it's time to install it. Ensure that the fuel line is securely attached to both the engine and the fuel tank, using the appropriate fittings and clamps. After installation, test the system to ensure there are no leaks and that the fuel flow is adequate for your engine's needs.

By carefully measuring and selecting the fuel line length based on your engine and fuel tank placement, you can ensure a reliable and efficient fuel supply to your 115 ELPT Mercury engine. This attention to detail will contribute to the overall performance and longevity of your marine vessel.

Understanding Aluminum Fuel Line Ratings: A Comprehensive Guide

You may want to see also

Fuel Line Routing: Route fuel line away from heat sources and sharp bends for longevity

When it comes to maintaining your 115 ELPT Mercury engine, one crucial aspect often overlooked is the proper routing of the fuel line. This seemingly minor detail can significantly impact the engine's performance and longevity. The fuel line is responsible for delivering gasoline from the tank to the engine, and its placement can greatly influence the overall health of your vehicle.

The primary concern when routing the fuel line is to ensure it is positioned away from heat sources and sharp bends. Heat can cause the fuel line to expand and contract, leading to potential damage over time. This is especially critical in areas where the engine is close to hot components or under the hood, where temperatures can soar. By keeping the fuel line clear of these heat sources, you reduce the risk of fuel line degradation and ensure a consistent fuel supply to the engine.

Additionally, sharp bends in the fuel line can create stress points, which may lead to cracks or leaks. It is essential to route the line in a way that minimizes sharp turns. A good practice is to use flexible fuel line material that can accommodate gentle curves without putting excessive strain on the line. This simple measure can prevent premature wear and tear, ensuring a reliable fuel supply to the engine.

To achieve optimal routing, consider the engine's layout and available space. The fuel line should be positioned in a way that allows for easy access during maintenance and inspections. Avoid running it along the bottom of the engine bay, as this can make it difficult to reach and inspect. Instead, aim for a more vertical route, ensuring it is securely fastened to avoid any potential damage from vibrations.

In summary, proper fuel line routing is a critical aspect of engine maintenance. By keeping the fuel line away from heat sources and sharp bends, you can ensure its longevity and maintain a consistent fuel supply to your 115 ELPT Mercury engine. This simple yet effective practice will contribute to the overall reliability and performance of your vehicle.

Fads' Fuel Line: Unveiling the Secret to Their Success

You may want to see also

Fuel Line Fittings: Use compatible fittings and adapters for secure fuel line connections

When dealing with fuel lines, especially for larger engines like the 115 ELPT Mercury, it's crucial to use the right fittings and adapters to ensure a secure and efficient fuel supply. The size and type of fuel line fittings are essential to consider, as they directly impact the performance and safety of your engine. Here's a guide to help you navigate the process:

Compatibility is Key: The primary rule when choosing fuel line fittings is compatibility. Mercury engines, including the 115 ELPT, often require specific fittings designed to work seamlessly with their fuel systems. Using the wrong size or type can lead to fuel leaks, reduced performance, and potential engine damage. Always refer to the manufacturer's specifications and diagrams to identify the correct fittings for your engine model.

Consider the Material: Fuel line fittings are typically made from materials like steel, brass, or aluminum. For high-performance applications, consider fittings made from brass or aluminum alloys, as they offer better corrosion resistance and durability. Steel fittings are more common and cost-effective but may not be as resistant to fuel degradation over time. Ensure the material of the fitting is compatible with the fuel type and engine requirements.

Adapting to Needs: Fittings and adapters come in various shapes and sizes to accommodate different fuel line configurations. When purchasing, ensure you have the correct adapter to connect the fuel line to the engine, the fuel pump, or any other component in your system. For example, you might need an adapter to convert a fuel line from a specific diameter to match the engine's requirements.

Secure Connections: Properly securing fuel line fittings is essential to prevent leaks and ensure a reliable fuel supply. Use the appropriate fasteners, such as nuts, bolts, or clips, provided by the manufacturer. Tighten the connections securely, but be careful not to overtighten, as this can damage the fittings or fuel lines. Regularly inspect these connections for any signs of wear or damage, especially in high-vibration environments.

Maintenance and Inspection: Regular maintenance and inspection of fuel line fittings are vital. Over time, fuel lines and fittings can deteriorate due to fuel exposure, temperature changes, and engine vibrations. Check for any signs of corrosion, cracks, or damage, and replace any faulty fittings promptly. Proper maintenance ensures the longevity of your fuel system and helps prevent unexpected breakdowns.

Clogged Fuel Line: How It Affects Your Car's Performance

You may want to see also

Frequently asked questions

The standard fuel line size for this engine is 3/8 inch in diameter. It is important to use the correct size to ensure optimal fuel flow and engine performance.

While using a larger fuel line might seem like an upgrade, it is not recommended as it can lead to fuel pressure issues and potential engine damage. The 3/8 inch size is specifically designed to handle the engine's fuel requirements.

You can check the fuel line's diameter by measuring it with a caliper. The ideal size is 3/8 inch, and any significant deviation from this size may indicate a need for replacement. It is always best to consult the manufacturer's guidelines or seek professional advice for specific engine requirements.