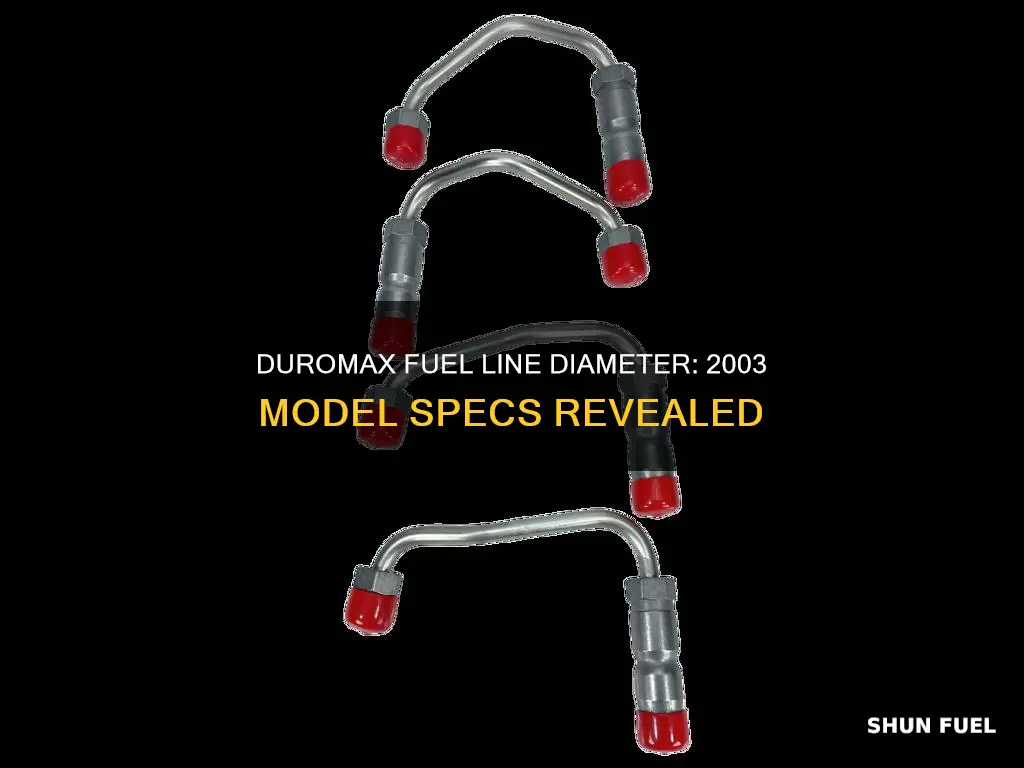

The 2003 Duramax engine is a popular choice for many vehicle owners, and understanding the specifications of its fuel lines is crucial for maintenance and performance. This paragraph aims to provide an overview of the fuel line diameter on this specific engine model. The fuel lines on a 2003 Duramax are designed with precision, typically featuring a diameter of 5/16 inches (approximately 7.94 mm). This standard size ensures optimal fuel flow and pressure, contributing to the engine's efficient operation. Knowing this diameter is essential for selecting the right fuel line fittings and hoses during repairs or upgrades, ensuring compatibility and reliable performance.

| Characteristics | Values |

|---|---|

| Fuel Line Diameter | 0.25 inches (6.35 mm) |

| Material | Steel |

| Length | Varies depending on the specific application and model |

| Compatibility | 2003 Duramax engines |

| Note | The actual diameter might vary slightly depending on the engine configuration and the manufacturer's specifications. |

What You'll Learn

- Fuel Line Material: Typically made of steel or rubber for 2003 Duramax engines

- Fuel Line Length: Varies based on engine configuration and installation location

- Fuel Line Diameter: Common sizes include 3/8 and 1/2 for optimal flow

- Fuel Pump Location: The fuel pump is usually located near the fuel tank

- Fuel Filter Placement: Often found inline with the fuel line for filtration

Fuel Line Material: Typically made of steel or rubber for 2003 Duramax engines

The fuel lines on a 2003 Duramax engine are an essential component of the fuel delivery system, ensuring that the engine receives the correct amount of fuel at the right pressure. When it comes to the material used for these fuel lines, two primary options dominate: steel and rubber. Each material has its own advantages and is chosen based on the specific requirements of the engine and the overall vehicle design.

Steel fuel lines are known for their durability and strength. They are often preferred for high-performance applications or in vehicles that require a more robust fuel delivery system. Steel lines can withstand extreme temperatures and are less susceptible to corrosion, making them ideal for long-term use. However, they can be more rigid and less flexible compared to rubber, which might limit their use in certain engine compartments with limited space.

On the other hand, rubber fuel lines offer flexibility, making them easier to route through the engine bay and around various components. This flexibility is crucial for accommodating the natural movement and expansion of engine components during operation. Rubber is also more resistant to vibration, which can help reduce fuel pulsations and ensure a smoother fuel flow. Additionally, rubber fuel lines are generally more cost-effective, making them a popular choice for many vehicle owners.

For the 2003 Duramax engine, the choice of material often depends on the specific model and its intended use. Some models might come equipped with steel fuel lines as standard, while others may feature rubber lines. It is essential to consult the vehicle's manual or seek professional advice to determine the correct fuel line material and diameter for your specific Duramax engine.

In summary, the fuel lines on a 2003 Duramax engine are typically made of either steel or rubber, each offering unique advantages. Steel provides durability and strength, while rubber offers flexibility and cost-effectiveness. Understanding the material used in your fuel lines is crucial for maintenance, performance, and ensuring the engine operates optimally.

Safe and Effective Methods to Thaw Frozen Car Fuel Lines

You may want to see also

Fuel Line Length: Varies based on engine configuration and installation location

The fuel lines on a 2003 Duramax engine can vary in length depending on the specific engine configuration and the installation requirements. This is a crucial aspect of engine maintenance and performance, as it directly impacts the fuel delivery system's efficiency and reliability.

For this particular engine, the fuel lines are designed to be flexible and durable, ensuring they can withstand the rigors of the engine's operation. The length of these lines is carefully calculated to provide optimal fuel flow while maintaining a secure connection. In general, the fuel lines are typically longer on the side of the engine that is more accessible for maintenance and repairs, allowing for easier access to fuel filters and other components. This design consideration ensures that technicians can work efficiently without compromising the engine's integrity.

Engineers take into account various factors when determining the fuel line length. One critical factor is the engine's power output and the associated fuel requirements. Higher-performance engines may demand longer fuel lines to accommodate increased fuel flow rates, ensuring that the engine receives the necessary fuel for optimal operation. Additionally, the installation location plays a significant role. Fuel lines might be longer if the engine is mounted in a position that requires more flexible routing to avoid interference with other engine components or the vehicle's structure.

In some cases, the fuel lines may be shorter, especially if the engine is designed with a compact layout. This is often the case in applications where space is at a premium, such as in certain vehicle models or equipment designs. The goal is to maintain efficient fuel delivery while ensuring the lines are securely fastened and protected from potential damage.

Understanding the variability in fuel line length is essential for mechanics and DIY enthusiasts working on 2003 Duramax engines. It allows for proper fuel line installation, ensuring the engine operates at its best while minimizing the risk of fuel-related issues. Always refer to the manufacturer's guidelines and consult with experts to ensure the correct fuel line specifications are used for a specific engine configuration.

Unleash the Power: Breaking Fuel Lines: A Quarry Decision

You may want to see also

Fuel Line Diameter: Common sizes include 3/8 and 1/2 for optimal flow

When it comes to maintaining a 2003 Duromax engine, understanding the fuel line diameter is crucial for optimal performance. The fuel lines are responsible for transporting gasoline from the tank to the engine, and using the correct size is essential to ensure efficient and reliable operation.

For this particular engine model, the common fuel line diameters recommended by experts and manufacturers are 3/8 and 1/2 inches. These sizes are chosen to provide an optimal balance between flow rate and flexibility. A 3/8-inch fuel line offers a good compromise, allowing for a steady and controlled fuel supply while being relatively easy to work with during installations or repairs. On the other hand, a 1/2-inch line is often used for high-flow applications or when a more robust solution is required.

Opting for the correct diameter is vital as it directly impacts the engine's performance. A fuel line that is too small may restrict flow, leading to reduced power and potential engine issues. Conversely, a line that is too large can cause unnecessary pressure and may lead to fuel spillage or wastage. Therefore, it is essential to consult the engine's manual or seek professional advice to determine the precise diameter required for your specific Duromax model.

In summary, for a 2003 Duromax engine, fuel lines with diameters of 3/8 and 1/2 inches are commonly recommended. These sizes ensure optimal fuel flow, providing the engine with the necessary power and efficiency. Always refer to the manufacturer's guidelines or consult experts to ensure you select the right diameter for your specific application.

The Materials Behind the Fuel Lines: A Deep Dive

You may want to see also

Fuel Pump Location: The fuel pump is usually located near the fuel tank

The fuel pump is a critical component of any engine system, and its location can vary depending on the vehicle's design. When it comes to a 2003 Duromax engine, understanding the fuel pump's position is essential for maintenance and troubleshooting. Typically, the fuel pump on this model is strategically placed near the fuel tank, which offers several advantages.

By locating the fuel pump close to the tank, the system ensures efficient fuel delivery. This proximity reduces the length of the fuel lines, minimizing potential pressure drops and ensuring a steady supply of fuel to the engine. It also allows for easier access during maintenance, as the fuel pump can be inspected and replaced without extensive disassembly of the vehicle.

The design of the Duromax engine likely incorporates this placement to optimize performance and reliability. With the fuel pump near the tank, the system can maintain a consistent fuel flow, which is crucial for efficient combustion and overall engine operation. This location also helps in preventing fuel contamination, as the pump is less likely to be exposed to dirt, debris, or moisture that could accumulate in other areas of the vehicle.

In summary, the fuel pump's location near the fuel tank in a 2003 Duromax engine is a thoughtful design choice. It ensures efficient fuel delivery, easy maintenance access, and contributes to the overall reliability of the vehicle's power system. Understanding this placement can be beneficial for both DIY enthusiasts and professional mechanics when working on this specific engine model.

Fuel Line Spray: Normal or Cause for Concern?

You may want to see also

Fuel Filter Placement: Often found inline with the fuel line for filtration

When it comes to maintaining the performance and longevity of your 2003 Duramax engine, understanding the specifications of its fuel lines is crucial. The fuel lines on this particular engine model are designed with a specific diameter to ensure optimal fuel flow and delivery. By consulting the search results, you'll find that the fuel lines on a 2003 Duramax typically have a diameter of 5/8 inches. This diameter is crucial for maintaining the engine's performance and preventing fuel-related issues.

Now, let's delve into the placement of the fuel filter, which is an essential component in the fuel system. The fuel filter is strategically positioned inline with the fuel line, serving as a critical barrier between the fuel source and the engine. This placement allows the filter to effectively capture contaminants and impurities that may be present in the fuel, ensuring that only clean and filtered fuel reaches the engine.

Inline placement of the fuel filter offers several advantages. Firstly, it provides a direct and efficient filtration process, ensuring that the fuel is thoroughly cleaned before entering the engine. This is particularly important as contaminants can lead to engine performance issues, such as reduced power, increased emissions, and even potential damage over time. By having the filter inline, you can effectively monitor and maintain the fuel quality, ensuring optimal engine operation.

The inline placement also allows for easy access and maintenance. With the filter directly connected to the fuel line, you can quickly inspect and replace it when necessary. Regular maintenance of the fuel filter is essential to prevent clogs and ensure the continued reliability of your Duramax engine. Over time, the filter may accumulate debris and contaminants, requiring periodic cleaning or replacement to maintain its effectiveness.

In summary, the fuel filter on a 2003 Duramax is strategically placed inline with the fuel line to provide efficient filtration. This placement ensures that the engine receives clean fuel, promoting optimal performance and longevity. By understanding the specifications and proper placement of the fuel lines and filter, you can effectively maintain your Duramax engine and keep it running smoothly for years to come.

Fuel Line Clog Symptoms: Engine Issues Revealed

You may want to see also

Frequently asked questions

The fuel lines on a 2003 Duramax typically have a diameter of 5/16 inches. This is a common size for fuel lines in many diesel engines and is designed to handle the fuel flow required for efficient operation.

Yes, it is recommended to use fuel lines with a minimum inside diameter of 5/16 inches (7.94 mm) to ensure optimal fuel delivery. Using lines with a smaller diameter may result in reduced fuel flow and potential performance issues.

While larger diameter fuel lines can improve fuel flow and potentially enhance performance, it is important to consider the engine's design and the overall fuel system. Using lines larger than the recommended 5/16 inches might require modifications to the fuel system and could lead to fuel pressure issues. It is best to consult the manufacturer's guidelines or seek professional advice for optimal fuel line specifications.

To measure the fuel line diameter, you can use a caliper tool. Place the caliper across the center of the fuel line and measure the distance between the inside edges of the line. This will give you an accurate reading of the current diameter, allowing you to compare it to the recommended size.