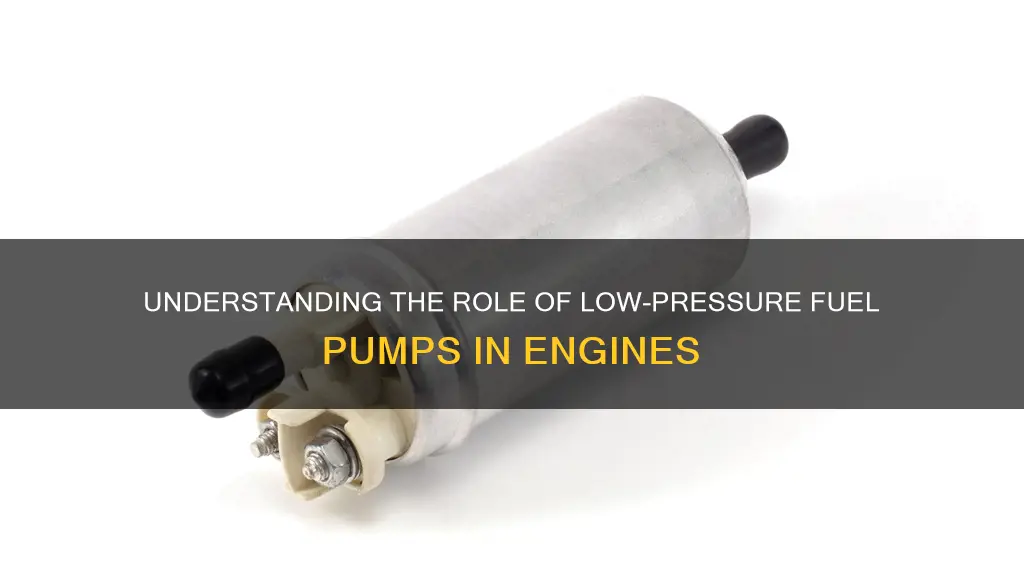

A low-pressure fuel pump is a crucial component of an engine's fuel system, responsible for delivering fuel from the tank to the injectors or the engine. It ensures a steady supply of fuel at the required pressure, rate of flow, and temperature for the engine to function optimally. The low-pressure fuel pump plays a vital role in preventing issues like vapor locking and cavitation of the fuel. Additionally, it works in tandem with filters, regulators, and other components to ensure the fuel is free of contaminants and maintained at the correct pressure. While it may not generate extremely high pressures, it is essential for the engine's overall performance and fuel efficiency.

What You'll Learn

Supplies fuel to the injectors for combustion

The low-pressure fuel system is responsible for supplying fuel from the fuel tank to the injectors for combustion, cooling, and removing air from the fuel system. This system plays a crucial role in ensuring that the injectors have the necessary fuel to facilitate combustion.

The primary function of a low-pressure fuel pump is to deliver fuel from the tank to the injectors, maintaining a steady supply for combustion. This process involves pulling fuel from the tank and passing it through a series of filters and pumps to ensure clean and consistent fuel delivery.

The fuel first passes through a primary fuel filter or water separator, which removes large debris and separates water from the fuel. It then flows into a transfer pump, also known as a low-pressure fuel pump. This pump plays a critical role in ensuring the fuel reaches the injectors. It creates a low-pressure system that forces the fuel toward the engine or injectors.

The transfer pump, often a gear pump, contains a pressure relief valve to regulate fuel pressure. The fuel exits the pump through an outlet port and passes through a secondary fuel filter, which removes smaller abrasive contaminants that could damage the injectors. This multi-stage filtration process ensures that the fuel is clean and free of debris that could hinder combustion or damage engine components.

Additionally, the low-pressure fuel system includes a fuel pressure regulator valve, which helps maintain the desired fuel pressure. This regulator ensures that the fuel pressure remains within an optimal range for the injectors to function effectively.

In summary, the low-pressure fuel pump plays a vital role in supplying fuel to the injectors for combustion. It achieves this by creating a low-pressure system, transferring fuel from the tank, filtering it, and regulating its pressure to meet the requirements of the injectors for efficient combustion.

Understanding the Role of Fuel Pressure Relief Valves

You may want to see also

Supplies fuel to the injectors for cooling

The low-pressure fuel pump is an integral part of a vehicle's fuel system, ensuring the engine receives a steady supply of fuel to keep running. One of its key functions is to supply fuel to the injectors for cooling.

The low-pressure fuel pump plays a crucial role in maintaining the performance and longevity of the engine. By supplying fuel to the injectors, the pump helps regulate the temperature of the injectors, preventing overheating. This cooling function is essential for the injectors to function optimally and avoid thermal damage.

The process of supplying fuel for cooling involves the fuel being drawn from the fuel tank by the low-pressure pump and delivered to the injectors. This fuel flow helps absorb and dissipate excess heat generated during the combustion process, ensuring the injectors maintain a safe operating temperature.

The low-pressure pump's role in injector cooling is particularly important in high-performance engines or vehicles operating in demanding conditions. These engines tend to generate more heat, and the low-pressure fuel pump's ability to provide a continuous supply of fuel for cooling becomes critical in preventing overheating and potential engine damage.

Additionally, the low-pressure fuel pump's contribution to injector cooling enhances the overall efficiency of the fuel system. By maintaining optimal injector temperatures, the pump helps improve fuel atomization, resulting in more complete combustion and better engine performance. This, in turn, can lead to improved fuel economy and reduced emissions.

Understanding the Role of Fuel Injector Pressure Dampers

You may want to see also

Removes air from the fuel system

A low-pressure fuel pump is a crucial component of an engine's fuel system, ensuring the smooth and efficient delivery of fuel from the tank to the engine. One of its key functions is to remove air from the fuel system, maintaining optimal engine performance.

The process of removing air from the fuel system is essential to prevent issues such as vapour lock and cavitation. Vapour lock occurs when air or vapour accumulates in the fuel lines, creating pockets that disrupt the consistent flow of fuel. Cavitation, on the other hand, refers to the formation of vapour cavities in the fuel, typically caused by rapid changes in pressure or temperature. By effectively removing air, the low-pressure fuel pump helps prevent these issues, ensuring that fuel flows smoothly and efficiently to the engine.

In a typical setup, the low-pressure fuel pump pulls fuel from the tank and delivers it to the primary fuel filter or water separator. This filter plays a critical role in removing large debris and contaminants from the fuel before it proceeds further in the system. From there, the fuel moves to the transfer pump, which is often equipped with a pressure relief valve. This valve opens when the pressure reaches a certain threshold, typically around 60 to 125 psi.

Additionally, the low-pressure fuel system may include a secondary fuel filter, also known as a micron filter. This filter is designed to capture smaller abrasive contaminants that can cause damage to the injectors. By removing these contaminants, the low-pressure fuel pump ensures that the fuel injectors remain clear and functional, facilitating the precise delivery of fuel into the engine's cylinders.

The low-pressure fuel pump also works in conjunction with other components, such as the fuel pressure regulator, to maintain the optimal fuel pressure required for efficient engine operation. This regulator ensures that the fuel pressure remains within a suitable range, preventing issues like fuel starvation or excessive fuel pressure that could lead to engine damage.

In summary, the role of the low-pressure fuel pump in removing air from the fuel system is vital to prevent performance issues and potential engine damage. By maintaining a consistent and uninterrupted fuel supply, engines can operate smoothly, and the risk of vapour lock and cavitation is significantly reduced.

Diagnosing Faulty Fuel Pumps: Sounds and Solutions

You may want to see also

Supplies fuel to the engine at a suitable pressure, flow rate and temperature

The low-pressure fuel pump is an essential component of an engine's fuel system, ensuring the smooth and efficient delivery of fuel. One of its critical functions is to supply fuel to the engine at the appropriate pressure, flow rate, and temperature. Here's a detailed overview of this aspect:

Suitable Pressure

The low-pressure fuel pump plays a vital role in maintaining the correct fuel pressure. It draws fuel from the tank and delivers it to the engine at a lower pressure compared to a high-pressure pump. This pressure differential is crucial for the engine's performance. The low-pressure pump ensures that the fuel is supplied at a consistent and controlled pressure, preventing issues like vapor locking and cavitation. This pressure regulation helps maintain the engine's overall performance and fuel efficiency.

Optimal Flow Rate

The flow rate of fuel supplied by the low-pressure pump is another critical factor. It ensures that the engine receives a steady and adequate supply of fuel. The pump is designed to deliver the required amount of fuel to the injectors or the fuel injection system. By providing the right flow rate, the low-pressure pump prevents issues such as fuel starvation, which can cause engine stalling or poor acceleration. A properly functioning low-pressure pump ensures that the engine receives a continuous stream of fuel, promoting smooth and efficient engine operation.

Appropriate Temperature

Maintaining the appropriate fuel temperature is another essential function of the low-pressure fuel pump. It helps prevent issues caused by extreme temperatures. For example, in cold conditions, the low-pressure pump can work in conjunction with a fuel heater to prevent the formation of ice crystals, ensuring that the fuel remains in a suitable state for combustion. Conversely, in high-temperature situations, the pump can be part of a cooling system to regulate the fuel temperature, preventing overheating issues.

The low-pressure fuel pump's ability to supply fuel at the right temperature helps maintain engine performance and protects the fuel system from potential damage caused by extreme temperatures.

In summary, the low-pressure fuel pump's role in supplying fuel at the suitable pressure, flow rate, and temperature is critical for engine performance and fuel efficiency. It ensures that the engine receives a consistent and properly conditioned fuel supply, contributing to a smooth and reliable driving experience.

Understanding Fuel Pressure Regulators: Return Flow Basics

You may want to see also

Prevents vapor locking and cavitation of the fuel

Vapor lock and cavitation are issues that can occur in fuel pumps, disrupting the operation of the fuel delivery system and causing loss of engine power or even complete engine stalling. Vapor lock occurs when liquid fuel changes state to vapour while still in the fuel delivery system, starving the engine of fuel. Cavitation occurs when the static pressure of the liquid fuel reduces below the fuel's vapour pressure, leading to vapour-filled cavities and bubbles that can cause shock waves and damage machinery.

Vapor lock is more common in older vehicles, particularly those with carbureted fuel systems and mechanical, engine-driven fuel pumps. In these systems, the fuel pump is located outside the fuel tank and higher than the fuel level, increasing the risk of vapour lock between the tank and the pump. Modern fuel-injected engines, on the other hand, have the fuel pump located inside the fuel tank, which helps prevent vapour lock as the entire fuel delivery system is under positive pressure and the fuel pump runs cooler.

Cavitation can occur in both mechanical and electronic fuel pumps and is the single most common failure in high-flow fuel systems. It is caused by a combination of too much heat and too much inlet restriction, leading to the liquid fuel boiling inside the fuel pump assembly. Cavitation can result in permanent damage to the fuel pump, reducing its capacity and efficiency. Eventually, the fuel system may completely fail to build or maintain pressure, leading to a loss of fuel delivery pressure and potential engine damage.

To prevent vapor lock and cavitation, it is important to ensure that fuel systems are properly designed and maintained. This includes ensuring that fuel lines are routed away from hot components, using appropriate fuel blends for the current weather conditions, and avoiding high inlet plumbing restrictions. Additionally, maintaining optimal fuel levels in the tank is crucial, as running the tank too low can lead to fuel pump issues and even prevent the engine from starting.

By understanding the causes and consequences of vapor lock and cavitation, preventative measures can be taken to ensure the reliable and efficient operation of fuel delivery systems.

Diagnosing Faulty Fuel Pressure Regulators by Listening for Symptoms

You may want to see also

Frequently asked questions

A low-pressure fuel pump is a device that moves fuel from the fuel tank to the engine, supplying the fuel at a constant pressure to ensure that the engine runs smoothly.

A low-pressure fuel pump ensures a regular stream of fuel to the engine, which is necessary for the engine to run.

A low-pressure fuel pump moves fuel around the aircraft, supplying volume.

Symptoms of a failing low-pressure fuel pump include jerking or sputtering at high speeds, losing power when accelerating, and losing power while driving uphill or towing a load.