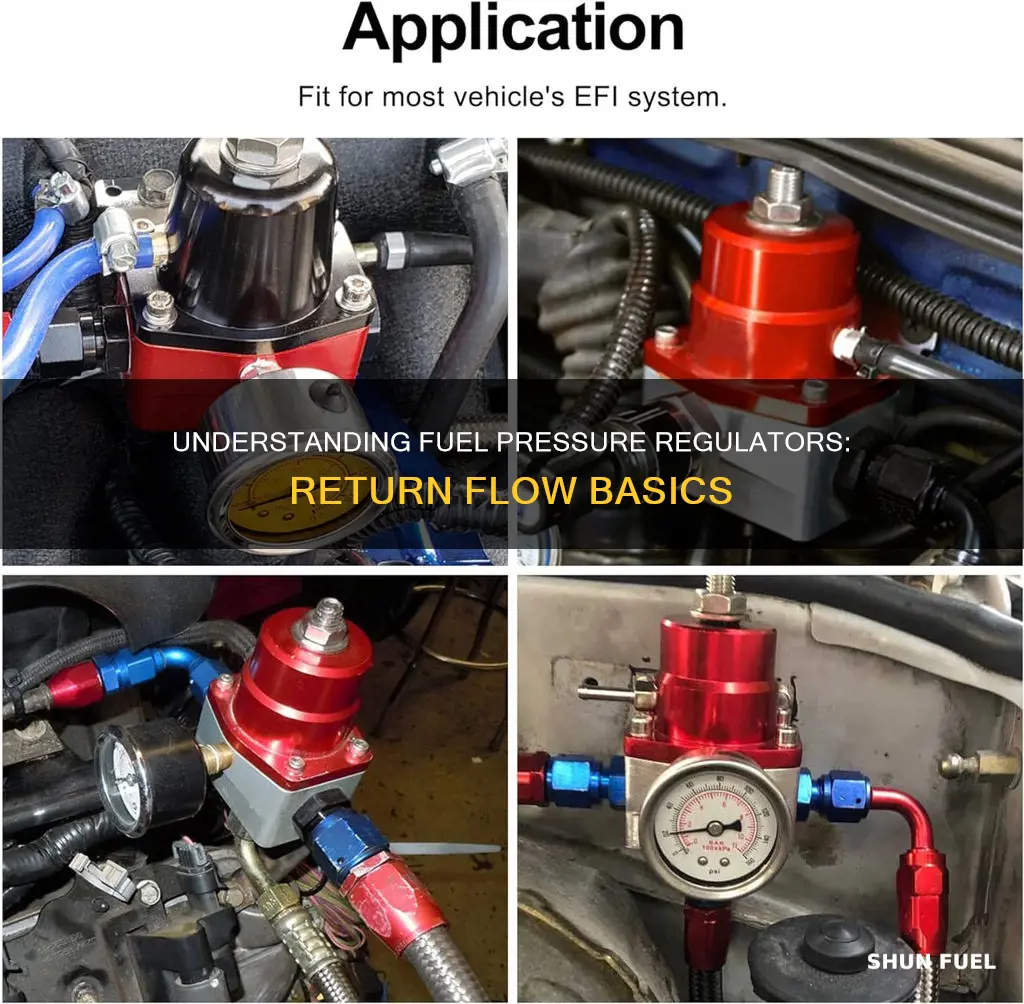

A fuel pressure regulator is an important component of a vehicle's fuel system, ensuring optimal engine performance, fuel efficiency, and emissions control. There are two main types of fuel systems: return-style (or bypass) and returnless-style. Return-style fuel pressure regulators feature a return port, which allows excess fuel to be redirected back to the fuel tank, maintaining proper fuel pressure and preventing overpressure. This type of regulator typically has a pair of inlet/outlet ports on opposite sides, with the return port at the bottom. On the other hand, returnless-style fuel systems do not circulate fuel back to the tank and have a simpler design with fewer components. When choosing a fuel pressure regulator, it is important to consider the specific requirements of the engine and fuel delivery system to ensure optimal performance, fuel efficiency, and longevity.

What You'll Learn

- Return-style regulators are also called bypass regulators

- Return-style regulators have a dedicated return port

- Return-style regulators are normally closed until the pressure limit is reached

- Deadhead regulators are normally open, and fuel flow is restricted when the pressure reaches its pre-set limit

- Return-style regulators are better for engines that produce an additional 100-200 hp

Return-style regulators are also called bypass regulators

Return-style regulators, also called bypass regulators, are a common choice for a performance fuel system. They are designed to control fuel system pressure using a spring and diaphragm that is either adjustable or preset. Fuel from the pump enters the inlet, flowing past the "bypass valve", which is closed by a spring. As the pressure increases, it pushes against the spring through a diaphragm, and when the pressure is high enough, the bypass valve opens, redirecting some fuel back to the tank. This reduces the pressure in the system.

Return-style regulators are typically installed between the fuel pump and carburetor or throttle body, but they can also be at the end of a fuel injection rail. They are an important part of the fuel system as they provide the correct fuel pressure to either the carburetor or fuel injection system. Maintaining the correct fuel pressure is crucial for achieving optimal engine performance, fuel efficiency, and emissions control.

Return-style regulators offer several benefits over blocking regulators. They react faster to changes in engine load, provide more consistent and accurate fuel pressure, and are easier on electric fuel pumps. Additionally, they keep the entire system cooler by constantly circulating fuel, which also reduces the risk of vapor lock and can increase power output.

However, there are also some drawbacks to using return-style regulators. They require extra plumbing, including additional hoses and fittings for the return line. They also cannot be used in some fuel systems, such as a nitrous system with multiple regulators set at different pressures. In such cases, the entire system will be limited by the regulator with the lowest setting.

Understanding the Role of Fuel Injector Pressure Dampers

You may want to see also

Return-style regulators have a dedicated return port

Return-style regulators, also known as "bypass" regulators, are a common choice for performance fuel systems. They are designed to maintain the correct fuel pressure, which is crucial for achieving optimal engine performance, fuel efficiency, and emissions control.

The inlet and outlet ports on a return-style regulator are interchangeable, allowing fuel to flow from the fuel pump into the inlet and exit through the outlet towards the carburetor or fuel injection system. As fuel enters the regulator, it flows past the bypass valve, which is held closed by a spring. When the fuel pressure increases, it pushes against the spring through a diaphragm, causing the bypass valve to open and redirecting excess fuel back to the tank through the return port. This reduces the pressure in the system.

Return-style regulators offer several benefits over blocking or deadhead regulators. They react faster to changes in engine load, provide more consistent and accurate fuel pressure, reduce lean condition spikes, and are easier on electric fuel pumps. By bleeding off excess pressure, the pump only maintains the set pressure, resulting in reduced heat, noise, and longer pump life. Additionally, the constant circulation of fuel keeps the entire system cooler and reduces the risk of vapor lock.

However, return-style regulators also have some drawbacks. They require additional plumbing and fittings, such as a return line with hoses and fittings. They also cannot be used in all fuel systems, such as those with multiple regulators set at different pressures.

Understanding Diesel Fuel Pressure Regulators: Their Critical Function Explained

You may want to see also

Return-style regulators are normally closed until the pressure limit is reached

Return-style fuel pressure regulators, also known as "bypass" regulators, are a common choice for performance fuel systems. They are designed to maintain the correct fuel pressure, ensuring optimal engine performance, fuel efficiency, and emissions control. Unlike non-return or "deadhead" regulators, return-style regulators are normally closed until the pressure limit is reached.

In a return-style regulator, fuel from the pump enters the inlet and flows past the "bypass valve," which is held closed by a spring. As the pressure increases, it pushes against the spring through a diaphragm. When the pressure reaches a certain level, the bypass valve starts to open, redirecting excess fuel back to the tank through the "return" port, which is usually marked as such. This reduces the pressure in the system. As the pressure drops, the spring closes the valve again, allowing the pressure to rise. This continuous adjustment ensures that the fuel pressure remains consistent and prevents it from exceeding or falling below the recommended levels.

The return-style regulator offers several advantages over blocking regulators. It reacts faster to changes in engine load, provides more consistent and accurate fuel pressure, and reduces Lean Condition spikes. Additionally, it is easier on electric fuel pumps as it only maintains the set pressure, resulting in less heat, noise, and longer pump life. The constant circulation of fuel also keeps the entire system cooler and reduces the risk of Vapor Lock, potentially increasing power output.

However, there are also some drawbacks to using return-style regulators. They require additional plumbing, including a Return Line with extra hoses and fittings. They also have limited compatibility and cannot be used in certain fuel systems, such as a nitrous system with multiple regulators set at different pressures.

How Fuel Pressure Dampers Stabilize Your Engine

You may want to see also

Deadhead regulators are normally open, and fuel flow is restricted when the pressure reaches its pre-set limit

A deadhead regulator is a type of fuel pressure regulator that does not require a return line. Instead, it controls fuel pressure by restricting fuel flow when the pressure reaches its pre-set limit. This is in contrast to a bypass or return-style regulator, which bleeds off excess pressure through a return line back to the fuel tank. Deadhead regulators are normally open, allowing fuel to flow through until the pressure reaches the pre-set limit, at which point a spring closes a valve to restrict fuel flow and decrease the pressure after the regulator.

Deadhead regulators offer some advantages over return-style regulators, including simpler installation and compatibility with systems that have a single pump and multiple regulators. However, they also have some drawbacks. Deadhead regulators cannot be used with most EFI systems, and they can lead to an increase in fuel temperature and strain on the fuel pump.

Return-style regulators, on the other hand, offer improved performance and reliability. They react faster to changes in engine load, provide more consistent and accurate fuel pressure, and reduce lean condition spikes. Additionally, they are easier on electric fuel pumps and help keep the entire system cooler.

While deadhead regulators may be suitable for some carbureted engines, they may struggle to maintain steady fuel pressure in high-output engines, leading to pressure creep, inconsistent fuel pressure, and potential engine flooding. Return-style regulators, with their ability to bleed off excess fuel pressure, offer a more dynamic and efficient solution for fuel systems.

Fuel Pressure Woes: Bad Pressure, Bad Performance

You may want to see also

Return-style regulators are better for engines that produce an additional 100-200 hp

Return-style fuel pressure regulators are a common choice for performance fuel systems, especially for engines that produce an additional 100-200 hp. They are also known as "bypass" regulators. This type of regulator offers several benefits that make it a preferable choice for high-performance engines.

One key advantage of return-style regulators is their ability to react faster to changes in engine load. This is crucial for engines with increased horsepower, as they require a quick response from the fuel system to meet the demands of the engine. The regulator's design allows it to supply more consistent and accurate fuel pressure, reducing Lean Condition spikes and ensuring optimal engine performance.

Another benefit of return-style regulators is that they are easier on electric fuel pumps. By bleeding off excess pressure, the pump only needs to maintain the set pressure, resulting in less heat, reduced noise, and prolonged pump life. Additionally, the regulator helps keep the entire system cooler by constantly circulating fuel, reducing the risk of Vapor Lock and potentially increasing power output.

However, it is important to consider the drawbacks of return-style regulators. They require additional plumbing, including a Return Line with extra hoses and fittings. They may also not be compatible with certain fuel systems, such as nitrous systems with multiple regulators set at different pressures.

When choosing a return-style regulator, it is essential to ensure proper installation and attention to detail. The regulator should be placed near the engine to quickly react to pressure changes. Additionally, using appropriate fittings and fuel lines that can handle the pressure and flow requirements is crucial to prevent leaks or malfunctions.

In summary, return-style regulators are a popular choice for high-performance engines due to their ability to handle increased fuel demands, maintain consistent fuel pressure, and prolong pump life. However, they require additional plumbing and may not be compatible with all fuel systems. Proper installation and maintenance are key to ensuring optimal performance and avoiding potential issues.

Understanding Your Car: Fuel Pressure Gauges Explained

You may want to see also

Frequently asked questions

Return-style fuel pressure regulators, also called "bypass" regulators, are a common choice for a performance fuel system. Fuel from the pump enters the inlet, flowing past the "bypass valve" and exiting the outlet port to the fuel bowls or fuel rails. As pressure increases, it pushes against a spring through a diaphragm, opening the bypass valve and redirecting some fuel back to the tank.

A return-style regulator has a single port marked as "Return". They are typically designed with a pair of inlet/outlet (I/O) ports on opposite sides, with the return port on the bottom or opposite the inlet/outlets.

A return-style regulator is normally closed until the pressure limit is reached. Once the limit is reached, the regulator opens the bypass outlet to return excess fuel to the tank, reducing the pressure in the system.

Return-style regulators offer faster reaction to changes in engine load, more consistent and accurate fuel pressure, and reduced lean condition spikes. They are also easier on electric fuel pumps as they only need to maintain the set pressure.

Return-style regulators require additional plumbing, including a Return Line with extra hoses and fittings. They also cannot be used in some fuel systems, such as a nitrous system with multiple regulators set at different pressures.