When it comes to maintaining a carburetor, one common question that arises is whether to permatex the fuel line. Permatex, a silicone-based sealant, is often used to ensure a tight and leak-free connection. However, its application to the fuel line is a topic of debate among mechanics and car enthusiasts. Some argue that permatex can provide a reliable seal, especially in high-temperature environments, while others caution against its use due to potential long-term effects on fuel quality and engine performance. This paragraph aims to explore the pros and cons of permatex for fuel lines, offering insights into the best practices for carburetor maintenance.

| Characteristics | Values |

|---|---|

| Advantages | - Helps prevent fuel leaks due to its adhesive properties. - Can provide a temporary seal for small punctures or cracks. - May improve fuel flow by removing air bubbles. |

| Disadvantages | - Not a permanent solution for major fuel line issues. - May not be suitable for high-pressure fuel systems. - Can be difficult to remove once applied, potentially causing damage. |

| Considerations | - Always refer to the vehicle's manual for specific recommendations. - Use Permatex sparingly and only as a temporary measure. - Consider professional repair for significant damage. |

| Alternatives | - For minor leaks, temporary fixes like rubber tape or electrical tape can be used. - For major issues, replacing the fuel line is often necessary. |

What You'll Learn

- Fuel Line Material: Permatex is suitable for rubber and vinyl fuel lines, not for metal or plastic

- Application Technique: Apply Permatex in a thin, even layer, avoiding excess buildup

- Curing Time: Allow sufficient time for Permatex to cure before reassembling the carburetor

- Cleanliness: Ensure the fuel line is clean and dry before applying Permatex to prevent adhesion issues

- Safety Precautions: Wear gloves and work in a well-ventilated area when using Permatex to avoid inhalation risks

Fuel Line Material: Permatex is suitable for rubber and vinyl fuel lines, not for metal or plastic

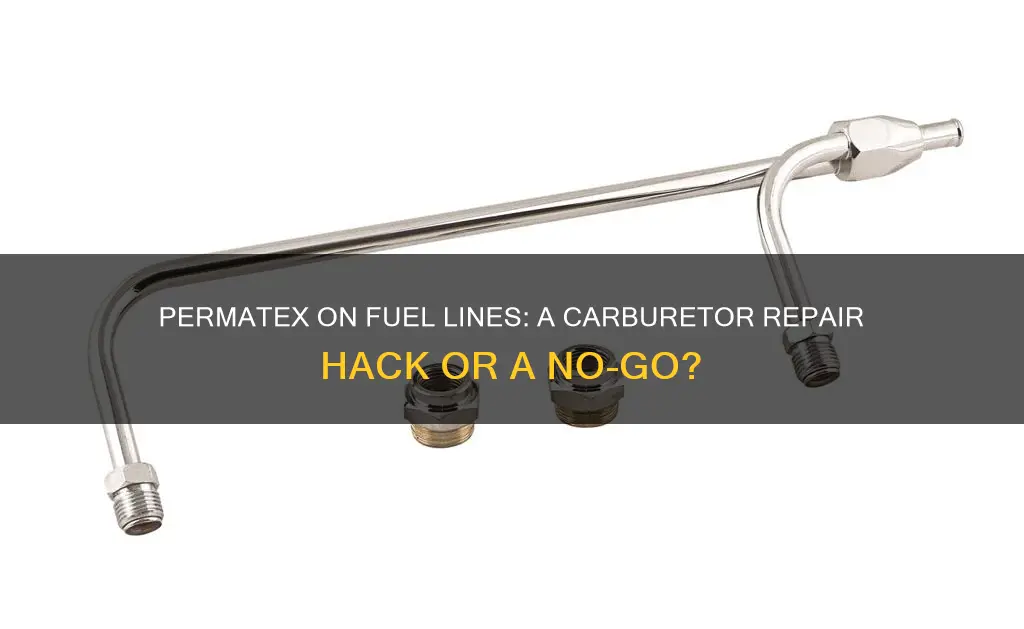

Permatex is a well-known brand of silicone-based lubricant and sealant that is commonly used in various automotive applications, including fuel line maintenance. When it comes to the fuel lines on a carburetor, the choice of material is crucial for ensuring optimal performance and longevity. Here's a detailed explanation of why Permatex is suitable for rubber and vinyl fuel lines but not for metal or plastic:

Suitable for Rubber and Vinyl Fuel Lines:

Rubber and vinyl fuel lines are prevalent in older vehicles and classic cars, as they were commonly used for their flexibility and durability. Over time, these lines can dry out, crack, or become brittle, leading to fuel leaks and potential engine issues. Permatex, with its silicone-based formula, is an excellent choice to rejuvenate and protect these fuel lines. It provides a flexible and durable seal, ensuring that the fuel lines remain intact and leak-free. The product's ability to adhere to rubber and vinyl surfaces makes it ideal for repairing and maintaining these fuel lines, especially in vintage or classic car restoration projects.

Not Recommended for Metal or Plastic Fuel Lines:

While Permatex is effective for rubber and vinyl, it is not suitable for metal or plastic fuel lines. Metal fuel lines are typically found in modern vehicles and are designed to withstand high temperatures and pressure. These lines are often made of materials like steel or aluminum and require specific lubricants and sealants that can withstand the harsh conditions of the engine bay. Plastic fuel lines, on the other hand, are less common but can be found in some vehicles. Plastic lines are more flexible and lightweight but may not require the same level of sealing as rubber or vinyl. In these cases, using Permatex might not provide the necessary protection and could potentially damage the fuel lines.

When working on a carburetor, it is essential to consider the material of the fuel lines to ensure the right maintenance or repair techniques are applied. For rubber or vinyl lines, Permatex can be a game-changer, providing a long-lasting solution to potential fuel line issues. However, for metal or plastic lines, other specialized products should be considered to avoid any adverse effects on the fuel system's performance. Always refer to the vehicle's manual or consult with automotive experts to determine the appropriate materials and products for your specific car's fuel line system.

Air in Paperstroke Return Fuel Line: A Cause for Concern?

You may want to see also

Application Technique: Apply Permatex in a thin, even layer, avoiding excess buildup

When it comes to maintaining and repairing fuel lines on a carburetor, one popular product that often comes up is Permatex. This product is a silicone-based grease that is commonly used to lubricate and protect various components in engines. While it is primarily designed for these purposes, some enthusiasts and mechanics also use it to coat fuel lines, which has sparked the question: "Should you permatex the fuel line on a carburetor?"

The application technique is crucial to ensure the effectiveness and longevity of the repair. Here's a detailed guide on how to apply Permatex correctly:

Application Technique:

- Prepare the Surface: Before applying Permatex, ensure the fuel line is clean and free of any debris or old grease. Use a cloth or a brush to wipe down the surface, creating a smooth and dry environment for the application.

- Thin and Even Layer: The key to successful application is using a thin, even layer of Permatex. Squeeze a small amount of the product onto a clean cloth or your fingertips. Then, carefully apply it along the length of the fuel line, ensuring you cover the entire surface. Avoid excessive buildup, as it may lead to performance issues.

- No Over-Coating: It's important to resist the urge to apply a thick layer of Permatex. Over-coating can result in a sticky residue, which might interfere with the carburetor's operation. Instead, focus on a thin, uniform layer that provides the necessary protection without affecting performance.

- Let it Dry: After application, allow the Permatex to dry completely. This process might take a few hours, depending on the ambient temperature and humidity. Ensure the engine is off during this time to prevent any accidental activation of the grease.

By following this application technique, you can effectively use Permatex to protect and lubricate the fuel line, potentially extending the life of your carburetor and improving overall engine performance. Remember, the goal is to provide a subtle layer of protection without altering the fuel flow or causing any unwanted side effects.

Outboard Motor Fuel Line: To Disconnect or Not to Disconnect?

You may want to see also

Curing Time: Allow sufficient time for Permatex to cure before reassembling the carburetor

When working on a carburetor, one common question that arises is whether to use Permatex, a silicone-based thread seal tape, on the fuel lines. The answer is yes, it can be beneficial, but only if applied correctly and with consideration for the curing time. Permatex helps create a secure and leak-free connection between the carburetor and the fuel lines, ensuring optimal performance. However, the process requires patience and attention to detail.

After applying Permatex to the threads of the fuel line and carburetor, it's crucial to allow ample time for it to cure. The curing process is essential to ensure the adhesive properties of Permatex are fully activated. Rushing this step might lead to inadequate bonding, potentially causing leaks or reduced performance. The curing time can vary depending on the specific Permatex product used and the ambient temperature.

For most silicone-based thread seal tapes, including Permatex, a curing period of at least 24 hours is recommended. During this time, the adhesive properties of the tape will develop, creating a strong bond between the surfaces. It's important to avoid reassembling the carburetor or handling the fuel lines during this curing period to ensure the best results.

In some cases, especially in high-temperature environments, a longer curing time of 48 hours or more might be necessary. This extended curing period allows the Permatex to fully set and provide optimal sealing. Always refer to the product instructions for specific curing time guidelines, as different brands may have slightly varying requirements.

Once the curing time has passed, you can confidently reassemble the carburetor, knowing that the Permatex has done its job effectively. This simple yet crucial step ensures that your carburetor remains leak-free and performs as intended, providing a reliable source of power for your engine. Remember, taking the time to cure the Permatex is an essential part of the process for a successful repair.

Winterizing Outboard: Fuel Line Disconnect: A Wise Move?

You may want to see also

Cleanliness: Ensure the fuel line is clean and dry before applying Permatex to prevent adhesion issues

When it comes to maintaining a carburetor, one might consider using Permatex, a popular silicone-based sealant and lubricant, to ensure a tight seal and prevent fuel leaks. However, before applying Permatex to the fuel line, it is crucial to prioritize cleanliness to avoid potential adhesion issues.

The fuel line plays a critical role in delivering fuel from the tank to the carburetor, and any contaminants or moisture can lead to performance problems. Before applying Permatex, ensure that the fuel line is thoroughly cleaned. Start by removing the fuel line from the carburetor and the fuel tank. Inspect the line for any signs of damage, cracks, or existing sealant residue. If any issues are found, address them accordingly before proceeding.

Cleaning the fuel line is essential to remove any dirt, grime, or old sealant. Use a mild detergent or fuel line cleaner to wash the line, ensuring you reach all areas, including the interior and any fittings. Rinse thoroughly with clean fuel or gasoline to eliminate any cleaning agent residue. Allow the line to dry completely in a well-ventilated area, ensuring no moisture remains, as this can affect the sealant's performance.

Once the fuel line is dry, inspect it again to ensure it is free from any debris or contaminants. If necessary, use a soft cloth or brush to gently remove any remaining dirt. This meticulous cleaning process ensures that the Permatex sealant adheres properly to the fuel line, creating a reliable and long-lasting seal.

By taking the time to clean and dry the fuel line, you create an optimal surface for the Permatex sealant, reducing the risk of adhesion problems. This simple yet crucial step can contribute to the overall success of the repair, ensuring a well-functioning carburetor and a reliable fuel supply. Remember, proper preparation is key to achieving the best results when working on any vehicle component.

Outboard Fuel Confusion: Diesel or Gasoline? Unraveling the Mystery

You may want to see also

Safety Precautions: Wear gloves and work in a well-ventilated area when using Permatex to avoid inhalation risks

When working with Permatex, a common sealant and adhesive, it is crucial to prioritize safety to ensure a healthy and accident-free environment. One of the primary safety precautions to consider is the use of personal protective equipment, specifically gloves. Gloves act as a barrier between your skin and the product, preventing direct contact and potential irritation or allergic reactions. Opt for gloves made from materials like nitrile or latex, which are durable and offer a good grip, allowing for a secure hold while working. This simple step can significantly reduce the risk of skin issues and ensure a comfortable experience during the task.

In addition to gloves, working in a well-ventilated area is essential. Permatex can release volatile organic compounds (VOCs) during application, which may pose health risks if inhaled. Proper ventilation helps to disperse these compounds, reducing their concentration in the air and minimizing the chances of inhalation. Ensure that the work area has adequate airflow, either by opening windows or using fans to create a continuous flow of fresh air. This simple measure can effectively lower the risk of respiratory issues and create a safer working environment.

The combination of gloves and a well-ventilated area is particularly important when dealing with fuel lines, as they can contain flammable substances. By wearing gloves, you protect your hands from potential burns or chemical exposure, and proper ventilation ensures that any released fumes are quickly dispersed, reducing the risk of fire or explosion. These precautions are especially critical when working in enclosed spaces or around other potential hazards.

Furthermore, it is advisable to read the product label and follow the manufacturer's instructions carefully. The label will provide specific guidelines on application techniques, drying times, and any potential hazards associated with the product. Understanding these instructions will enable you to work safely and effectively, ensuring that you are taking all necessary precautions.

In summary, when using Permatex, always wear gloves to protect your skin and work in a well-ventilated area to avoid inhaling potentially harmful fumes. These simple safety measures contribute to a safer and more enjoyable working experience, especially when dealing with fuel lines and other sensitive components. By prioritizing these precautions, you can ensure a healthy and accident-free environment while achieving the desired results.

Pipe Thread Sealant: Essential for Fuel Line Maintenance?

You may want to see also

Frequently asked questions

Permatex, also known as fuel line tape, is a protective coating applied to fuel lines to prevent fuel leaks and ensure a secure connection. It provides an extra layer of insulation and protection against corrosion, especially in high-temperature environments.

While it is not mandatory for all fuel lines, using permatex on carburetor fuel lines is highly recommended. Carburetor systems are more susceptible to fuel leaks due to the constant movement and vibration of the engine. Permatex helps secure the fuel lines and reduces the risk of leaks, ensuring optimal engine performance.

Applying Permatex is a straightforward process. Start by cleaning the fuel line to remove any dirt or debris. Then, cut a piece of Permatex tape slightly longer than the fuel line's length. Wrap the tape tightly around the fuel line, ensuring full coverage. Use your fingers or a tool to press the tape firmly against the line for a secure bond.

Yes, Permatex can be used on various engine components, including hoses, gaskets, and seals. It is a versatile product that provides excellent sealing and insulation properties. However, it's important to choose the appropriate type of Permatex for the specific component and follow the manufacturer's instructions for best results.