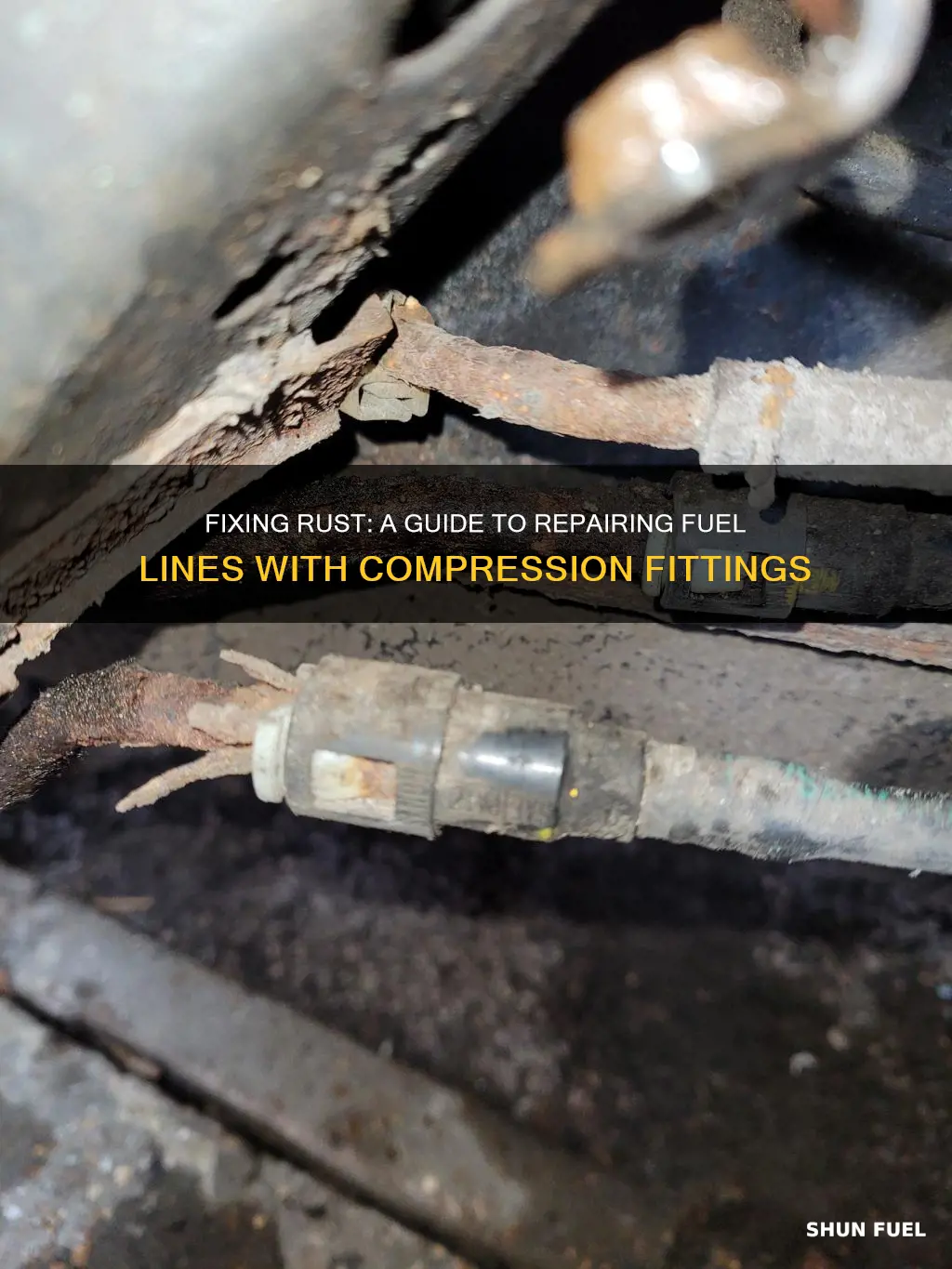

Repairing a rusted fuel line with a compression fitting is a practical solution for restoring the functionality of your vehicle's fuel system. This method involves using a compression fitting to seal the damaged area, ensuring a secure and leak-free connection. By following a few simple steps, you can effectively address rust-related issues and restore the integrity of your fuel line, allowing for safe and efficient operation of your vehicle.

What You'll Learn

- Prepare Tools: Gather necessary tools: wrench, compression fitting, fuel line, and cleaning supplies

- Clean Rust: Scrub fuel line with wire brush to remove rust and debris

- Cut and Prepare: Carefully cut the fuel line and prepare the ends for the fitting

- Install Fitting: Slide the fitting over the fuel line, ensuring a snug fit

- Test and Secure: Tighten the fitting securely, then test for leaks and secure with clamps

Prepare Tools: Gather necessary tools: wrench, compression fitting, fuel line, and cleaning supplies

Before you begin the process of repairing a rusted fuel line with a compression fitting, it's crucial to gather the right tools and materials. This ensures a smooth and effective repair. Here's a detailed guide on preparing the necessary tools:

- Wrench: A wrench is an essential tool for any fuel line repair. You'll need a wrench that fits the size of the fuel line you're working with. It should be able to provide a firm grip and allow you to tighten or loosen the fitting securely. Consider using a adjustable wrench, which can accommodate different sizes.

- Compression Fitting: This is the key component for sealing the fuel line. Choose a compression fitting that matches the diameter of your fuel line. Compression fittings are designed to create a tight seal by compressing the fuel line into the fitting. Ensure you select the correct size to avoid any leaks.

- Fuel Line: If you need to replace a damaged fuel line, ensure you have a new one that is compatible with your vehicle's specifications. The new fuel line should be the same diameter as the old one and made of a suitable material, typically rubber or a flexible plastic.

- Cleaning Supplies: Rust and debris can accumulate around the fuel line, so it's important to clean the area thoroughly. Gather cleaning supplies such as a degreaser or fuel line cleaner, a wire brush, and a cloth. These will help remove any corrosion and ensure a proper seal.

Having all these tools and materials ready will make the repair process more efficient. It's always a good practice to double-check the compatibility of the compression fitting and fuel line with your vehicle's system to ensure a successful repair.

Nylon Fuel Line: Choosing the Right Material for Optimal Performance

You may want to see also

Clean Rust: Scrub fuel line with wire brush to remove rust and debris

Before you begin the repair process, it's crucial to ensure a clean and safe working environment. Start by disconnecting the fuel line from the fuel tank and any other connected components. This step is essential to prevent any accidental fuel leaks or spills. Once disconnected, use a suitable solvent or fuel line cleaner to remove any remaining fuel or debris from the line. This initial cleaning step is vital to avoid any contamination during the repair.

Now, grab a sturdy wire brush and get to work. Carefully scrub the interior of the fuel line, paying close attention to any areas where rust has formed. The wire brush will help dislodge and remove the rust particles, ensuring a thorough clean. Be thorough and persistent in your scrubbing, as rust can be stubborn and may require multiple passes to fully eliminate. As you work, you might also notice other debris or contaminants; remove these as well to ensure a smooth and clean interior surface.

For optimal results, consider using a wire brush specifically designed for fuel lines or one with a flexible handle to navigate the twists and turns of the line. Apply moderate pressure while brushing to ensure effective cleaning without causing damage to the line's inner surface. Remember to work in a well-ventilated area or outdoors to avoid inhaling any potential fumes from the cleaning process.

After completing the scrubbing process, rinse the fuel line thoroughly with clean water to remove any remaining debris or cleaning agents. Ensure that all traces of rust and cleaning products are washed away. You can use a garden hose or a pressure washer for this step, but be cautious not to exert excessive pressure that could damage the fuel line.

Once the fuel line is thoroughly cleaned, allow it to air dry completely before reassembling and reconnecting it to the fuel tank and other components. Proper drying is essential to prevent any moisture-related issues in the future. With these steps, you'll effectively remove rust and debris, setting the stage for a successful fuel line repair using a compression fitting.

Understanding Fuel Lines: The Vital Link in Your Engine's Fuel Supply

You may want to see also

Cut and Prepare: Carefully cut the fuel line and prepare the ends for the fitting

Before you begin the repair, it's crucial to ensure you have the right tools and materials. You'll need a pair of sharp, clean shears or a fuel line cutter, a file or emery cloth, and a compression fitting suitable for your fuel line material. It's also a good idea to have some fuel line adhesive or tape to secure the connection.

Now, carefully locate the damaged section of the fuel line. Use a fuel line inspection tool or a bright flashlight to identify any signs of corrosion or damage. Once you've identified the issue, mark the spot with a permanent marker or a piece of tape. This will help you cut the line at the right place.

With the damaged section identified, it's time to cut the fuel line. Using your shears or cutter, make a clean, straight cut at the marked location. Ensure the cut is smooth and free of any burrs, as these can cause damage to the fitting and the fuel line. If the fuel line is particularly thick, you may need to use a file or emery cloth to smooth the edges and create a precise cut.

Next, prepare the ends of the fuel line for the compression fitting. Carefully deburr the ends to remove any sharp edges. You can use a small file or sandpaper for this task, taking care not to damage the inner surface of the fuel line. The goal is to create a smooth, even surface for the fitting to grip onto.

Finally, inspect the prepared fuel line ends and the compression fitting. Ensure they are free of any debris or contaminants. If necessary, use a small brush or compressed air to clean the areas where the fitting will be attached. This step is crucial to ensure a secure and leak-free connection.

Air in Diesel Fuel Line: Symptoms and Solutions

You may want to see also

Install Fitting: Slide the fitting over the fuel line, ensuring a snug fit

When repairing a rusted fuel line with a compression fitting, the installation process is crucial to ensure a secure and effective repair. Here's a step-by-step guide to help you through the process:

Start by gathering the necessary tools and materials. You'll need a compression fitting that is compatible with your fuel line size, a pair of pliers or a fuel line tool for tightening, and possibly some thread seal tape or pipe compound. Ensure you have the right fitting by checking the fuel line's diameter and any existing markings or labels.

Now, it's time to prepare the fuel line for the fitting. Clean the area around the rusted section to remove any dirt or debris. If the fuel line is severely corroded, you might need to cut it back to a smooth, clean surface. Use a file or sandpaper to create a rough surface for better grip.

With the fuel line prepared, slide the compression fitting over it. Ensure that the fitting is the correct size and shape for your fuel line. The fitting should have a smooth interior surface to allow for a snug fit. Take your time with this step to avoid any issues later.

Once the fitting is in place, it's crucial to secure it tightly. Use the pliers or fuel line tool to tighten the fitting onto the fuel line. Apply firm pressure, ensuring that the fitting is fully seated and there are no gaps or spaces between the fitting and the fuel line. You should feel a distinct click or hear a slight snap when the fitting is properly tightened.

Finally, check the tightness of the fitting by gently pulling on it. It should feel secure and not come loose easily. If you notice any movement or looseness, tighten it further. After ensuring a snug fit, you can test the repair by running the fuel line under water or using a pressure tester to confirm that there are no leaks.

Understanding Touareg Fuel Filter: Input vs. Output Lines

You may want to see also

Test and Secure: Tighten the fitting securely, then test for leaks and secure with clamps

Once you've tightened the compression fitting securely, it's crucial to test for any potential leaks. This step is essential to ensure the integrity of your fuel system and prevent any unwanted fuel loss. Here's a detailed guide on how to proceed:

Testing for Leaks:

- Start by applying a small amount of diesel fuel or a suitable fuel-safe product around the threads of the fitting and the surrounding area. Common choices include diesel fuel, white lithium grease, or a specialized thread seal tape. These substances will help identify any leaks.

- Use a rag or cloth to wipe the area, ensuring it's clean and dry. Then, re-tighten the fitting by hand, ensuring it's secure.

- Now, observe the area closely. If you notice any fuel seeping or dripping, it indicates a leak. Leaks can occur at the fitting, the fuel line, or even at the point where the fuel line connects to the engine.

Securing the Repair:

- If you detect a leak, immediately tighten the fitting further using a wrench. Ensure you don't overtighten to avoid damaging the threads or the fitting itself.

- After tightening, re-test for leaks by applying more fuel around the fitting and observing for any seepage.

- If no leaks are found, secure the fitting and fuel line with clamps. Clamps provide an additional layer of protection and ensure the fitting remains in place during operation.

- Ensure the clamps are tight enough to hold the fitting securely but not so tight that they restrict fuel flow.

Final Steps:

- Once you're confident there are no leaks, recheck the fuel line for any signs of damage or corrosion.

- If everything looks good, start the engine and monitor for any unusual noises or behavior.

- Let the engine run for a few minutes, then shut it off and recheck the fuel line for any signs of fuel leakage.

- If no issues are found, your fuel line repair is complete, and you can safely continue using your vehicle.

Remember, proper testing and securing of the compression fitting are critical to a successful repair. Always take your time and ensure each step is completed thoroughly to avoid any potential issues down the line.

The Dark Motives Behind Fuel Line Cuts: Uncovering Hidden Dangers

You may want to see also

Frequently asked questions

To repair a rusted fuel line with a compression fitting, start by cleaning the damaged area thoroughly. Remove any rust and debris using a wire brush or a rust remover. Ensure the surface is smooth and free of contaminants. Then, apply a thin layer of pipe compound or thread seal tape around the compression fitting and insert it into the fuel line. Tighten the fitting securely, but be careful not to overtighten to avoid damage. Use a wrench to tighten it, and check for any leaks.

Yes, you can use a compression fitting on a fuel line without modifications, but it's important to ensure a proper fit. Measure the inside diameter of your fuel line and choose a compression fitting with a matching diameter. The fitting should be slightly larger than the fuel line to create a tight seal. You can also consider using a ferrule or a compression nut to secure the fitting in place.

Preventing rust in fuel lines is crucial for maintaining a reliable fuel system. After the repair, you can apply a protective coating or a rust inhibitor to the fuel line. Consider using a fuel line protector or a specialized rust-inhibiting additive in the fuel. Regularly inspect the fuel line for any signs of corrosion and address any issues promptly. Keeping the fuel system clean and dry can also help prevent rust formation.

While you can use basic tools like a wrench and a wire brush for the repair, having a few specialized tools can make the process easier. A pipe reamer or a fuel line cutter can help ensure a precise fit. Additionally, a fuel line crimping tool can be useful for securing the compression fitting. These tools can provide more control and accuracy during the installation process.