Unclamping a fuel line is a crucial step in vehicle maintenance, especially when performing repairs or replacements. This process involves carefully disconnecting the fuel line from the fuel tank and engine to ensure a safe and efficient fuel supply. It requires a systematic approach, including identifying the correct tools and understanding the specific vehicle's fuel system. By following a step-by-step guide, you can safely unclamp the fuel line, preventing any potential fuel leaks and ensuring a smooth and successful repair process.

What You'll Learn

- Locate the Fuel Line: Identify the fuel line's position, often near the fuel tank or engine

- Inspect for Damage: Check for any cracks, leaks, or signs of wear

- Loosen Clamps: Use a wrench to carefully loosen and remove the fuel line clamps

- Replace or Repair: If damaged, replace or repair the fuel line

- Reattach Securely: Reattach the fuel line, ensuring it's clamped tightly and securely

Locate the Fuel Line: Identify the fuel line's position, often near the fuel tank or engine

Locate the fuel lines on your vehicle, as these are typically positioned close to the fuel tank or engine. The fuel lines are usually made of rubber or plastic and carry gasoline from the tank to the engine. They are often color-coded for identification, with the most common colors being red, blue, and black. These lines are designed to be flexible and durable, allowing them to withstand the movement of the vehicle and the varying temperatures it encounters.

When you locate the fuel lines, it's important to identify their exact positions. The primary fuel line, also known as the main line, connects the fuel tank to the engine's fuel injection system or carburetor. It is usually the largest and most visible line. There may also be smaller lines branching off from the main line, which supply fuel to different parts of the engine, such as the fuel pump or the carburetor. These smaller lines are often referred to as branch lines.

Near the fuel tank, you will typically find the main fuel line, which is the largest and most prominent. It runs from the tank to the engine's fuel system. Look for a sturdy, often thicker line, which may have a fuel filter attached. The fuel filter is an important component that helps ensure the cleanliness of the fuel before it reaches the engine.

In addition to the main line, there may be other fuel lines connected to the fuel pump, which is responsible for delivering fuel from the tank to the engine at the required pressure. These lines are usually smaller in diameter and can be found near the fuel pump, often with a small, cylindrical shape. It's crucial to identify these lines to ensure you don't accidentally disconnect the fuel pump during the unclamping process.

Remember, when working with fuel lines, it's essential to exercise caution. Fuel lines can be under pressure, and any damage or incorrect handling may result in fuel leaks or engine performance issues. Always refer to your vehicle's manual for specific instructions and safety guidelines when dealing with fuel system components.

Mastering Fuel Line and Steering Repairs: A Comprehensive Guide

You may want to see also

Inspect for Damage: Check for any cracks, leaks, or signs of wear

When inspecting a fuel line for damage, it's crucial to be thorough and methodical. Start by visually examining the line for any visible signs of wear and tear. Look for cracks, tears, or punctures along the length of the fuel line. These defects can be caused by various factors, such as age, corrosion, or physical damage. Pay close attention to the connections and fittings, as these areas are more susceptible to damage. Inspect the clamps and ensure they are intact and securely holding the fuel line in place. Check for any signs of rust or corrosion around the fittings, as this can indicate potential issues.

Next, perform a more detailed inspection by feeling the fuel line. Run your fingers along the length, checking for any soft spots or areas that feel compromised. This tactile inspection can help identify internal damage that may not be immediately visible. If you notice any areas that feel unusually soft or spongy, it could indicate a potential issue with the fuel line's integrity.

Leak testing is another critical step in the inspection process. Start by ensuring the fuel system is properly bled and that the fuel line is not under pressure. Then, apply a small amount of fuel or a suitable leak detection liquid along the length of the fuel line, paying particular attention to the connections and fittings. If a leak is present, you will typically see a small amount of the liquid or fuel appear at the point of the leak. This test is essential to identify any hidden damage or weaknesses in the fuel line that may not be immediately apparent.

Additionally, check for any signs of fuel contamination or degradation. Over time, fuel can break down, leading to the formation of varnish or sludge, which can damage the fuel line. Look for any discolouration or residue around the fittings and connections. If you notice any signs of contamination, it may indicate a need for a fuel system flush and treatment.

Remember, the goal of this inspection is to identify any potential issues before they become major problems. By carefully examining the fuel line for cracks, leaks, and signs of wear, you can ensure the safety and reliability of your fuel system. Regular maintenance and inspections are key to preventing costly repairs and ensuring the longevity of your vehicle's fuel system.

Copper Line Sizing for Fuel Oil: A Comprehensive Guide

You may want to see also

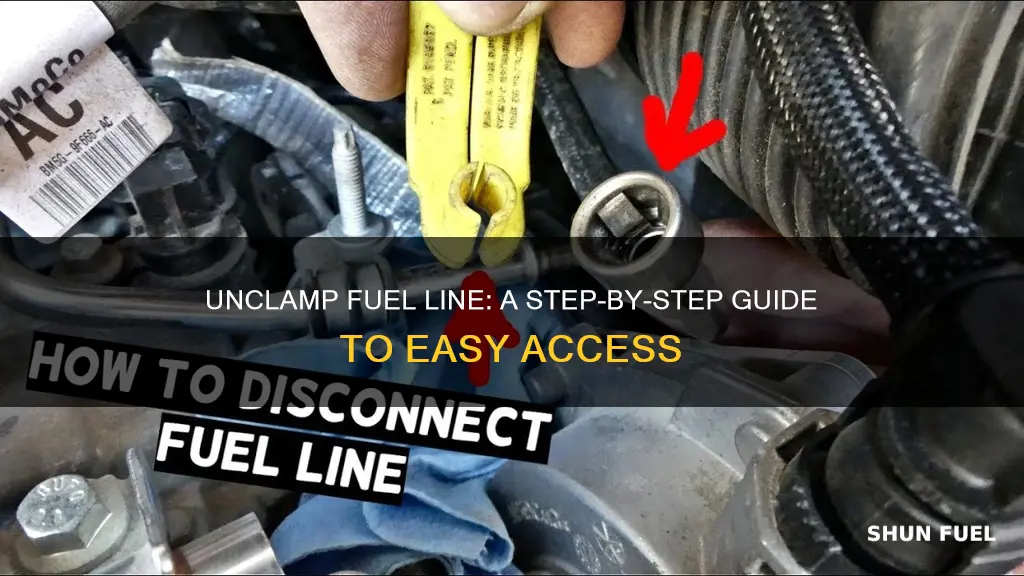

Loosen Clamps: Use a wrench to carefully loosen and remove the fuel line clamps

To safely and effectively unclamp a fuel line, it's crucial to follow a methodical approach. Here's a step-by-step guide to help you through the process:

Loosen the Clamps:

The first step is to carefully loosen the clamps that hold the fuel line in place. These clamps are typically made of metal or plastic and are designed to secure the fuel line to various components of the vehicle's fuel system. Use a wrench that fits the size of the clamp bolts. Wrenches come in various sizes, so choose one that provides a good grip without being too tight or too loose. Apply gentle force to loosen the clamp. You might need to apply some pressure, but be careful not to overtighten, as this can damage the fuel line or the surrounding components. Work in a controlled manner, turning the wrench counterclockwise to loosen the clamp.

Once the clamp is loosened, you should be able to see the fuel line and potentially access any connections or fittings that need further attention. Remember to keep the fuel line stable and secure during this process to avoid any accidental spills or damage.

Choosing the Right Fuel Line for Your Snowblower: A Guide

You may want to see also

Replace or Repair: If damaged, replace or repair the fuel line

If you notice any damage to the fuel line, it is crucial to address the issue promptly to prevent further complications. The fuel line is a critical component responsible for transporting fuel from the tank to the engine, and any damage can lead to fuel leaks, reduced engine performance, or even a complete breakdown. Here's a step-by-step guide on how to replace or repair a damaged fuel line:

Assessment and Safety: Before beginning any repair work, ensure you are in a well-ventilated area and take necessary safety precautions. Fuel lines can carry flammable substances, so it's essential to avoid sparks or open flames during the process. Inspect the fuel line for any visible signs of damage, such as cracks, punctures, or corrosion. Look for areas where the line may have been damaged by sharp edges, road debris, or previous repairs.

Gather Tools and Materials: You will need a few essential tools and materials to replace or repair the fuel line. This typically includes a new fuel line (if replacement is necessary), fuel line clamps, a fuel line cutter or saw, sandpaper or a file, and a fuel line inspection mirror (optional but useful for hard-to-reach areas). Ensure you have the correct size and type of fuel line that matches your vehicle's specifications.

Removing the Old Fuel Line: If the fuel line is damaged and needs replacement, start by disconnecting the fuel line from the fuel tank and the engine. Locate the fuel line clamps and carefully loosen them to release the tension. Be cautious not to damage the surrounding components. Carefully cut or sever the damaged section of the fuel line using the fuel line cutter or saw. Take note of the length and positioning of the cut to ensure an accurate replacement.

Preparing the New Fuel Line: If you are replacing the fuel line, ensure the new line is the correct size and length. Use sandpaper or a file to smooth any sharp edges or burrs on the new line. This step is crucial to prevent damage to the fuel line and the engine during installation. If repairing an existing line, clean the damaged area and ensure it is free from debris or corrosion.

Installing the New or Repaired Fuel Line: Carefully feed the new fuel line through the appropriate openings, ensuring it is routed correctly to reach the engine. Secure the new line with the fuel line clamps, tightening them firmly but being careful not to overtighten, as this can cause damage. Double-check the connections and ensure there is no excessive movement or rubbing between the line and other components.

Testing and Final Checks: After installing the new fuel line or repairing the damaged one, start the engine and check for any leaks. Ensure that the fuel line is securely attached and that there is no fuel escaping. Test-drive the vehicle to confirm that the fuel system is functioning correctly and that there are no performance issues.

Remember, working with fuel lines requires precision and caution. If you are unsure or uncomfortable with any part of the process, it is best to consult a professional mechanic to ensure the job is done safely and correctly.

John Deere Fuel Line Size 72: What You Need to Know

You may want to see also

Reattach Securely: Reattach the fuel line, ensuring it's clamped tightly and securely

Reattaching a fuel line securely is a crucial step in ensuring the proper functioning of your vehicle's fuel system. When you've unclamped the fuel line for any reason, whether it's for maintenance, repairs, or modifications, the process of reattachment requires careful attention to detail. Here's a step-by-step guide to help you reattach the fuel line securely:

Prepare the Components: Before you begin, ensure you have the necessary tools and components ready. You'll need a new fuel line clamp (if you need to replace the old one) and a wrench or socket that fits the clamp's bolt. Inspect the fuel line for any signs of damage or wear, especially if it was previously unclamped. If there are any issues, address them before proceeding.

Locate the Clamp: Identify the location of the fuel line clamp. This clamp is typically found where the fuel line connects to the fuel tank, engine, or other components. Carefully inspect the clamp and the fuel line to ensure there are no obstructions or interference that might prevent a secure connection.

Remove Old Clamp (if applicable): If you're replacing an old clamp, carefully remove it by loosening the bolt with the appropriate tool. Take note of the bolt's position and orientation to ensure you can reattach it correctly. Clean the fuel line and the clamp's surface to remove any dirt or debris that might interfere with the connection.

Reattach the Fuel Line: Now, carefully slide the new fuel line into the clamp, ensuring it is aligned properly. Tighten the clamp bolt by hand first to secure the fuel line in place. Use the wrench or socket to tighten the bolt further, applying firm pressure to ensure a tight seal. Make sure the clamp is snug and there is no movement or play in the connection.

Final Check: After reattaching the fuel line, perform a final inspection. Check for any leaks around the clamp by gently pressing on the connection and observing for any fuel escaping. Ensure that the fuel line is not pinched or kinked, as this can lead to potential issues. Verify that all connections are secure and that the fuel line is functioning correctly.

Remember, a secure and tight connection is essential to prevent fuel leaks and ensure the efficient operation of your vehicle's fuel system. Take your time during the reattachment process, and if you're unsure, consult a professional mechanic for guidance.

XR80 Fuel Line Sizes: A Comprehensive Guide

You may want to see also

Frequently asked questions

Unclamping a fuel line is a necessary step when replacing or repairing a fuel pump, filter, or any component in the fuel system. It allows for easy access to the affected area, ensuring a proper and safe repair process.

Before starting, ensure you have the correct tools, including a fuel line disconnect tool or a pair of adjustable pliers. Locate the fuel line clamp, typically made of metal or plastic, and use the tool to carefully pry it open, being mindful of any fuel pressure. Avoid using excessive force to prevent damage to the fuel line.

Absolutely. When working with fuel lines, it is crucial to prevent fuel spillage. Always drain the fuel tank or ensure the vehicle's fuel system is properly bled to release any pressure. Wear protective gear, such as gloves and safety goggles, to safeguard against potential fuel splashes.

If the fuel line is damaged, it is essential to replace it immediately. Inspect the line for any cracks, holes, or signs of corrosion. Use a suitable fuel line replacement kit, ensuring the new line is the correct size and type for your vehicle. Properly clamp and secure the new line to maintain a safe and efficient fuel supply.

It is generally not recommended to reuse old clamps as they may have deteriorated over time. Fresh clamps provide a secure seal and ensure the fuel line is properly contained. Always use new clamps for optimal performance and safety.