Removing a nylon fuel line can be a straightforward process if you follow the right steps. This guide will provide a step-by-step approach to safely and effectively disconnect and replace the fuel line, ensuring your vehicle's engine operates efficiently and safely. It's important to take the necessary precautions, such as draining the fuel tank and disconnecting the battery, before beginning the process. With the right tools and a bit of patience, you can successfully remove the nylon fuel line and address any issues it may be causing.

What You'll Learn

- Preparation: Gather tools: wrench, fuel line cutter, safety gear

- Location: Identify fuel line, often under hood or near engine

- Cutter: Use fuel line cutter to carefully sever old line

- Connection: Disconnect fuel line from engine and tank securely

- Replacement: Install new fuel line, ensuring proper connections and routing

Preparation: Gather tools: wrench, fuel line cutter, safety gear

Before you begin the process of removing a nylon fuel line, it's crucial to ensure you have the necessary tools and safety equipment. Here's a detailed guide on what you need to prepare:

Wrench: A wrench is an essential tool for any fuel line removal process. You'll need a wrench that fits the size of the fuel line's connection. Wrenches come in various types, such as open-end or box-end, and different sizes. For nylon fuel lines, a standard adjustable wrench or a combination wrench is often sufficient. Make sure you have the appropriate size to comfortably grip and turn the fuel line connection.

Fuel Line Cutter: Removing the fuel line requires precise cutting. A fuel line cutter is a specialized tool designed for this purpose. It allows you to cut the nylon fuel line without damaging it further. There are various types of fuel line cutters available, including manual and power-driven options. For this task, a manual cutter with a sharp, adjustable cutting wheel is recommended. Ensure it has a comfortable grip and a cutting wheel that can handle the thickness of your fuel line.

Safety Gear: Working with fuel lines can be hazardous, so personal protective equipment (PPE) is vital. Here's what you should consider:

- Gloves: Wear heat-resistant gloves to protect your hands from any potential heat or chemicals in the fuel. Leather or heat-resistant fabric gloves are suitable choices.

- Safety Goggles: Protect your eyes from any potential fuel splashes or debris. Ensure the goggles fit well and provide clear vision.

- Respiratory Protection: If you're working in a poorly ventilated area, consider a respirator to avoid inhaling fuel fumes.

- Clothing: Wear long sleeves and pants to minimize skin exposure to fuel and potential hazards.

Having these tools and safety gear ready will ensure you're well-prepared for the removal process, allowing you to work efficiently and safely. It's always better to be over-prepared when dealing with potentially dangerous fuel lines.

Vacuum Line Fuel Spill: Unraveling the Mystery

You may want to see also

Location: Identify fuel line, often under hood or near engine

When it comes to removing a nylon fuel line, the first step is to locate it. This line is typically found under the hood of your vehicle or near the engine bay. It is an important component of your car's fuel system, responsible for transporting fuel from the tank to the engine. Identifying the correct line is crucial to ensure you don't damage other parts during the removal process.

Start by inspecting the engine bay. Look for any visible fuel lines that appear to be made of nylon or a similar flexible material. These lines often have a distinct color, such as black or blue, to differentiate them from other hoses. Nylon fuel lines are commonly used in modern vehicles due to their flexibility and resistance to fuel-related chemicals. They are usually located close to the engine, running along the frame or hanging from the engine bay.

If you can't find the line immediately, consult your vehicle's manual. It will provide detailed diagrams and illustrations of the fuel system, helping you identify the correct line. The manual will also offer specific instructions on how to safely remove the line without causing any damage to the surrounding components. Look for the section related to the fuel system or engine components for the most accurate information.

Once you've identified the nylon fuel line, it's time to prepare for the removal process. Ensure you have the necessary tools, such as a fuel line cutter or a hose cutter, designed for cutting fuel lines. These tools are essential to make a clean cut without causing any fuel leaks. Additionally, have a container ready to catch any spilled fuel, as a small amount may remain in the line.

Remember, when working with fuel lines, safety should be a top priority. Always wear protective gear, such as gloves and safety goggles, to prevent any potential injuries. It's also a good practice to drain the fuel tank and disable the fuel pump before attempting any fuel line work to minimize the risk of accidents. By following these steps and taking the necessary precautions, you can successfully remove the nylon fuel line from your vehicle.

Fuel Injector Cleaning: Unclogging Fuel Lines for Optimal Performance

You may want to see also

Cutter: Use fuel line cutter to carefully sever old line

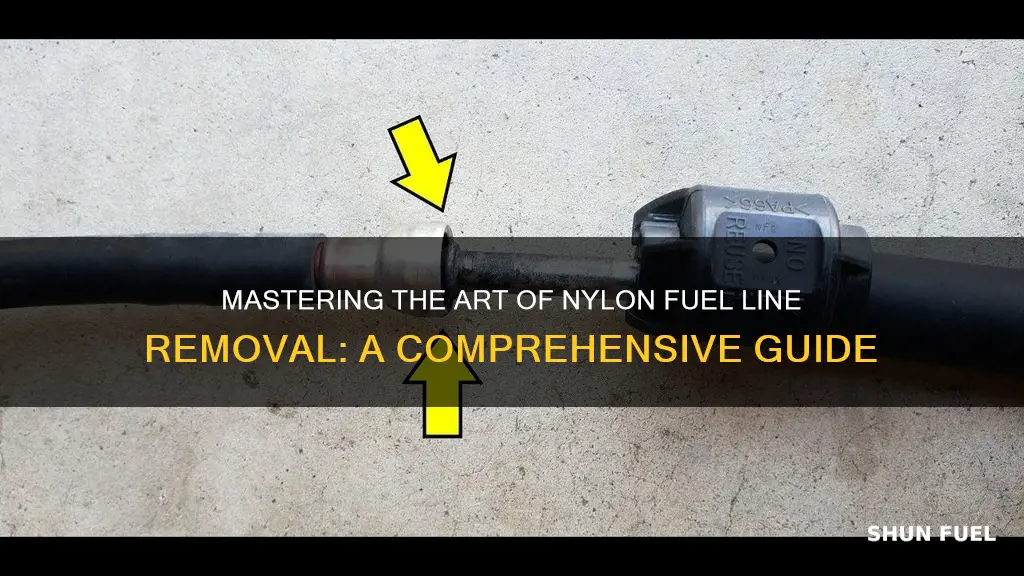

When it comes to removing a nylon fuel line, using a fuel line cutter is a precise and effective method. This tool is specifically designed to cut through fuel lines without causing damage to the surrounding components. Here's a step-by-step guide on how to use a fuel line cutter for this task:

Start by ensuring you have the right tools and safety equipment. Wear protective gloves and goggles to safeguard your hands and eyes during the process. Locate the nylon fuel line that needs to be removed. It is typically found running from the fuel tank to the engine, supplying fuel to the combustion chamber. Identify the point where the line needs to be severed; this could be due to a leak, damage, or the need for a new setup.

Position the fuel line cutter at the identified location. These cutters often have a serrated edge or a sharp blade designed to cut through the fuel line material. Apply firm pressure and make a clean, straight cut. It's crucial to be precise to avoid cutting into other components or causing further damage. Take your time and ensure the cut is neat and accurate.

After making the cut, inspect the area to ensure it is clean and free of any debris. Use a small brush or a wire brush to remove any remaining fuel line material or debris from the cut ends. This step is essential to ensure a proper connection for any new fuel line that might be installed.

Once the old fuel line is removed, you can proceed with the installation of a new one, ensuring a secure and leak-free connection. Remember, using a fuel line cutter is a precise technique that requires care and attention to detail to avoid any potential issues during the removal process.

Thawing Frozen Fuel Lines: A Guide to Winter Car Care

You may want to see also

Connection: Disconnect fuel line from engine and tank securely

To safely disconnect the nylon fuel line from both the engine and the fuel tank, follow these steps:

Step 1: Locate the Fuel Line Connections

Start by identifying the fuel line connections on both the engine and the fuel tank. The fuel line will typically have a quick-connect fitting or a clamp-style connection. Locate the fuel line that connects the fuel pump to the engine and the other end that connects to the fuel tank.

Step 2: Disconnect the Engine Connection

For the engine connection, locate the fuel line and use a fuel line disconnect tool or a pair of pliers to carefully release the quick-connect fitting or clamp. Ensure you have a container or rag ready to catch any residual fuel that may spill. Gently pull the fuel line away from the engine, being cautious not to damage any surrounding components.

Step 3: Disconnect the Fuel Tank Connection

On the fuel tank side, locate the fuel line connection. It might be a quick-connect fitting or a screw-on cap. If it's a quick-connect fitting, use the same tool as before to release it. If it's a screw-on cap, carefully remove the screws and lift the cap to disconnect the fuel line. Again, have a container or rag nearby to catch any fuel that may spill.

Step 4: Secure the Disconnected Lines

Once both connections are disconnected, it's essential to secure the fuel lines to prevent accidental tangling or damage. You can use fuel line ties or clips to bundle the lines together. Ensure they are tied securely but not so tightly that they restrict future reconnection.

Step 5: Clean and Inspect (Optional)

If you plan to reuse the fuel lines, consider cleaning them to remove any debris or fuel residue. You can use a fuel line cleaner and a brush to gently scrub the interior of the lines. Inspect the lines for any signs of damage or wear, and replace them if necessary before reinstalling.

Remember, when working with fuel lines, always prioritize safety. Wear protective gear, such as gloves and safety goggles, and ensure you are in a well-ventilated area to avoid inhaling fuel vapors.

Evo Fuel Line Size: Essential Guide for Optimal Performance

You may want to see also

Replacement: Install new fuel line, ensuring proper connections and routing

When replacing a nylon fuel line, it's crucial to follow a systematic approach to ensure a secure and reliable installation. Here's a step-by-step guide to help you through the process:

Step 1: Prepare the Necessary Tools and Materials

Before you begin, gather all the required tools and materials. You'll need a new fuel line that is compatible with your vehicle's specifications, along with fuel line connectors, a fuel line cutter or a sharp knife, a fuel line cleaner, and a rag or cloth for cleaning. Ensure you have the appropriate safety gear, such as gloves and safety goggles, to protect yourself during the process.

Step 2: Locate and Remove the Old Fuel Line

Start by identifying the old fuel line that needs to be replaced. Carefully trace the route of the fuel line from the fuel tank to the engine. Once located, use the fuel line cutter or a sharp knife to carefully cut the old fuel line, leaving a small excess length. Be precise and avoid damaging any surrounding components. If there are any clamps or fasteners holding the old fuel line in place, remove them carefully and set them aside.

Step 3: Clean the Fuel System

Before installing the new fuel line, it's essential to clean the fuel system to ensure optimal performance. Use the fuel line cleaner to flush out any contaminants or debris from the old fuel line. This step helps prevent any potential issues with the new fuel line. Rinse the fuel line thoroughly and ensure there are no remaining cleaner residues.

Step 4: Install the New Fuel Line

Now, you're ready to install the new fuel line. Start by connecting one end of the new fuel line to the fuel tank, ensuring a secure and tight fit. Use the appropriate connectors and make sure they are properly aligned. Then, carefully route the new fuel line along the same path as the old one, maintaining the correct angles and clearances. Secure the new fuel line with the appropriate clamps or fasteners, ensuring they are tightened to the manufacturer's specifications.

Step 5: Verify Connections and Routing

Once the new fuel line is installed, take the time to inspect all connections and routing. Ensure that the fuel line is securely attached to the fuel tank and engine, with no loose fittings. Check that the routing is neat, free from sharp bends, and does not interfere with any moving parts. Make any necessary adjustments to optimize the fuel line's performance and appearance.

Remember, proper connections and routing are critical to the efficient operation of your fuel system. Take your time during the installation process, and double-check your work at each step to ensure a successful replacement.

Mercury Verado Fuel Line Removal: A Step-by-Step Guide

You may want to see also

Frequently asked questions

Removing a nylon fuel line requires careful handling to avoid any fuel spills or damage. Start by identifying the fuel line's connection points and use the appropriate tools to loosen any fittings or clamps. Gently pull the line away from the fuel source, taking note of the path it follows. If the line is damaged or needs replacement, ensure you have the correct replacement part before proceeding with the removal.

Yes, applying heat can help soften the nylon material, making it easier to remove. Use a heat gun or a hairdryer on a low setting, holding it a few inches away from the fuel line. Heat the line for a few seconds, then use a tool like a flathead screwdriver to carefully pry it loose. Be cautious not to overheat the line, as it can melt or deform.

If the fuel line is stuck and won't budge, try using a lubricant like diesel fuel or a specialized fuel line cleaner. Apply a small amount to the line and let it sit for a few minutes. This can help reduce friction and make it easier to remove. Alternatively, you can use a wire brush or a small tool to carefully work the line loose, being mindful not to damage the surrounding components.

While you may use common tools like screwdrivers and wrenches, having the right tools can make the process smoother. Invest in a fuel line cutting tool or a fuel line removal kit, which often includes various-sized fittings and clamps to help with the removal process. These tools can provide a more precise and controlled approach, ensuring a clean break without damaging the fuel system.

When working with fuel lines, always prioritize safety. Wear protective gloves and goggles to shield your skin and eyes from potential splashes. Ensure you are in a well-ventilated area, and consider using a fume extractor if working in a confined space. Keep a bucket of water nearby to contain any spills, and double-check all connections and fittings to ensure they are secure and properly sealed after the removal process.