Outboard motors rely on a network of fuel lines to deliver gasoline from the tank to the engine. Over time, these lines can develop issues that lead to poor performance or even prevent the engine from starting. This guide will help you identify and troubleshoot common problems with the fuel lines in your outboard motor, ensuring you can get back on the water quickly and safely.

| Characteristics | Values |

|---|---|

| Fuel Line Issues | Clogged, cracked, kinked, or damaged fuel lines can cause problems with an outboard motor. |

| Symptoms | Engine misfires, stalls, or fails to start; poor performance; reduced power; rough idling; fuel leaks; engine overheating. |

| Visual Inspection | Check for any visible signs of damage, such as cuts, punctures, or discolouration. Inspect for kinks, bends, or twists in the fuel line. |

| Pressure Test | Use a fuel pressure gauge to measure the pressure at the fuel pump and injectors. Low pressure may indicate a clogged or damaged fuel line. |

| Fuel Flow | Listen for the sound of fuel flowing through the line when the engine is running. A lack of sound or a weak flow could suggest a problem. |

| Engine Diagnostics | Use an engine diagnostic tool to check for error codes related to fuel system issues. |

| Fuel Pump Check | Ensure the fuel pump is functioning correctly by testing it with a multimeter or a fuel pump tester. |

| Fuel Filter | Inspect and replace the fuel filter if it appears clogged or dirty, as this can restrict fuel flow. |

| Professional Help | If issues persist, consult a marine mechanic or outboard motor specialist for a thorough diagnosis and repair. |

What You'll Learn

- Visual Inspection: Check for cracks, leaks, or damage to the fuel line

- Pressure Test: Use a gauge to measure pressure and identify potential leaks

- Fuel Flow: Monitor fuel flow rate and pressure to detect blockages

- Engine Performance: Observe engine behavior for stalling, hesitation, or poor performance

- Fuel Pump: Inspect the pump for proper operation and fuel delivery

Visual Inspection: Check for cracks, leaks, or damage to the fuel line

A visual inspection is a crucial step in identifying potential issues with the fuel line on an outboard motor. This simple yet effective method can help you detect problems early on, preventing costly repairs and ensuring the motor's optimal performance. Here's a detailed guide on how to perform this inspection:

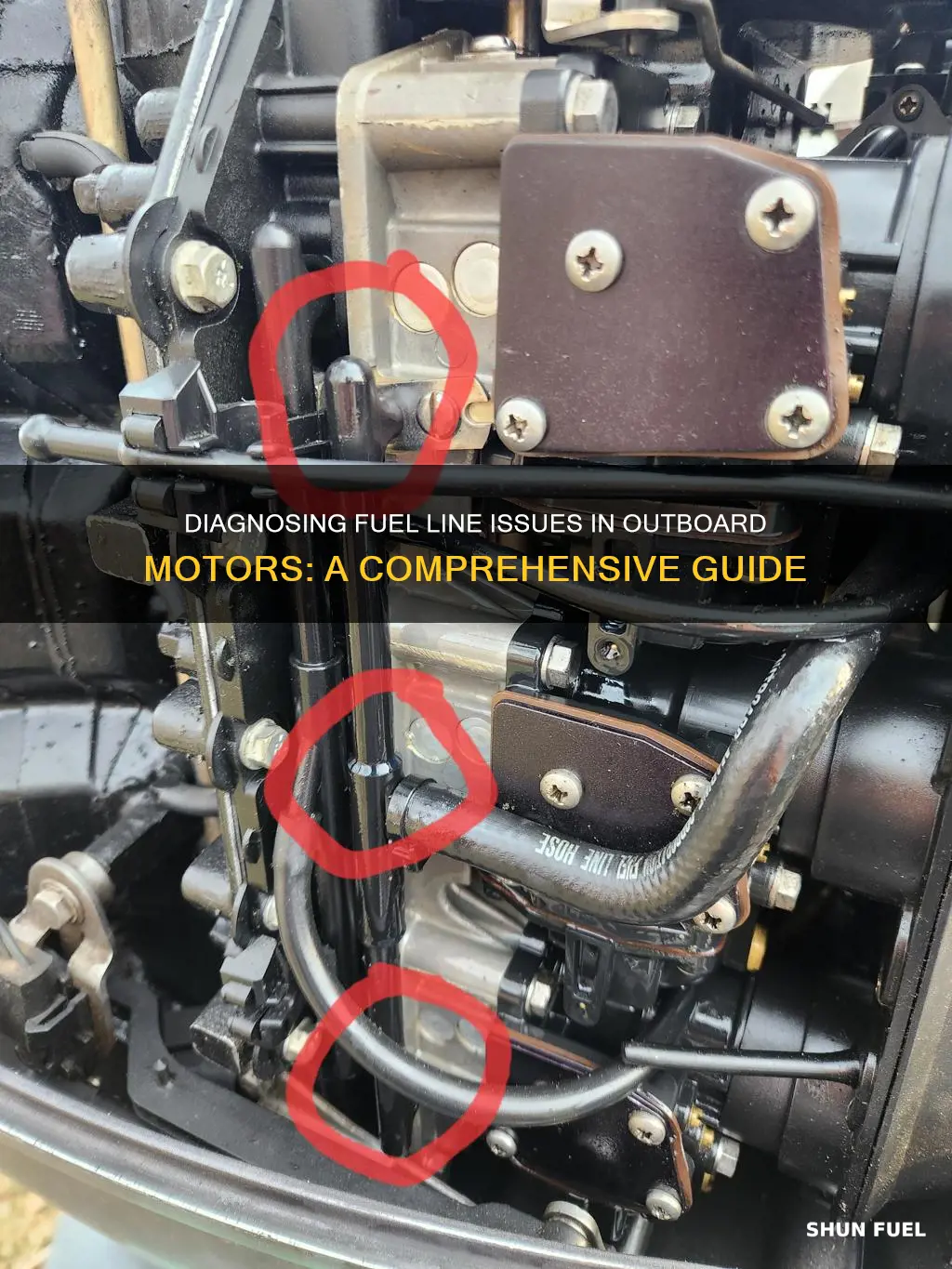

Start by locating the fuel line, which is typically a flexible tube connecting the fuel tank to the engine. It is often visible along the side or bottom of the motor. Carefully examine the fuel line for any visible signs of damage or deterioration. Look for cracks, splits, or punctures along the length of the line. Even small tears can lead to fuel leaks, which can cause significant engine issues. Check for any signs of corrosion or rust, especially if the fuel line is exposed to the elements. Over time, corrosion can weaken the line, making it more susceptible to damage. Inspect the connections between the fuel line and the motor, as well as the fuel tank. Ensure that all fittings are tight and secure. Leaky connections can result in fuel spillage, which can be dangerous and costly to clean up.

Look for any signs of fuel leakage around the fuel line. Even a small drip can indicate a potential problem. Check for wet spots or stains on the motor, deck, or nearby surfaces. If you notice any, it's essential to investigate further. Sometimes, a small leak can be contained, but if left unattended, it can lead to more significant issues. Pay attention to the condition of the fuel line's outer covering. If it appears worn or damaged, it might be a sign of underlying problems. Inspect the line for any signs of abrasion or damage caused by engine components, such as impellers or propellers.

In addition to visible damage, look for any signs of fuel contamination. Check the color and consistency of the fuel. If it appears discolored or has a strange odor, it might be contaminated with water or other substances, leading to engine problems. Contaminated fuel can cause engine misfires, reduced performance, and even permanent damage.

Remember, a thorough visual inspection can save you from potential engine trouble. If you notice any cracks, leaks, or damage during this process, it's advisable to consult a professional mechanic for further diagnosis and repair. Regular maintenance and inspections can help ensure your outboard motor's longevity and reliable performance on the water.

Ocean Outboard Fuel Line: Choosing the Right Type for Your Boat

You may want to see also

Pressure Test: Use a gauge to measure pressure and identify potential leaks

A pressure test is an essential diagnostic tool to identify potential issues with the fuel lines in an outboard motor. This method involves using a pressure gauge to measure the fuel system's pressure and detect any leaks or malfunctions. Here's a step-by-step guide on how to perform this test:

Start by ensuring the engine is cool and has been off for an extended period to avoid any safety hazards. Locate the fuel tank and identify the fuel lines leading to the engine. You'll need a pressure gauge with a range suitable for the fuel system's expected pressure. Connect the gauge to the fuel line, ensuring a secure and tight connection. Turn on the engine and allow it to idle for a few minutes to reach a stable operating temperature. This step is crucial as it simulates the engine's normal operating conditions.

Now, carefully observe the pressure gauge. The reading should remain stable, indicating that the fuel system is functioning correctly. If the pressure drops or fluctuates, it could be a sign of a leak or restriction in the fuel line. For instance, if the pressure drops significantly when the engine is idling, it may suggest a leak in the line or a problem with the fuel pump. In such cases, further investigation is required to pinpoint the exact issue.

To isolate the problem, you can perform a pressure test at different points along the fuel line. Start by testing the pressure at the fuel tank, then move to the engine's fuel inlet. This process helps determine if the issue is specific to a particular section of the fuel line. If the pressure drops at the tank but not at the engine, it could indicate a problem with the fuel pump or a restricted line. Conversely, a consistent pressure drop along the entire line might suggest a more extensive issue, such as a cracked fuel line or a faulty fuel pressure regulator.

Remember, this test requires careful observation and comparison of pressure readings. It is a valuable technique to diagnose fuel line problems and ensure the outboard motor's optimal performance and longevity. By identifying potential leaks or pressure variations, you can take the necessary steps to repair or replace the affected components, keeping your motor running smoothly.

American-Made Fuel Lines: Where to Find Quality Products

You may want to see also

Fuel Flow: Monitor fuel flow rate and pressure to detect blockages

Monitoring fuel flow rate and pressure is a crucial step in diagnosing potential fuel line issues in an outboard motor. By keeping a close eye on these parameters, you can quickly identify blockages or other problems that might be causing performance issues. Here's a detailed guide on how to approach this:

Understanding the Basics:

Fuel flow rate refers to the volume of fuel passing through the system per unit of time. It is typically measured in gallons per minute (GPM) or liters per minute (LPM). The ideal flow rate should be consistent and sufficient to meet the engine's requirements. On the other hand, fuel pressure indicates the force exerted by the fuel as it moves through the system. It is measured in pounds per square inch (PSI) or bars. Normal fuel pressure for an outboard motor usually ranges between 40-60 PSI.

Tools and Equipment:

To monitor fuel flow and pressure, you'll need a few essential tools. A fuel flow meter is a device specifically designed to measure the rate of fuel flow. It can be connected directly to the fuel line to provide accurate readings. Additionally, a fuel pressure gauge is necessary to measure the pressure. These gauges can be attached to the fuel lines, allowing you to monitor the fuel's journey through the system.

Step-by-Step Process:

- Isolating the System: Start by isolating the fuel system from the rest of the engine. This involves disconnecting the fuel lines at the engine's fuel supply and temporarily blocking the return line to prevent fuel from flowing back into the tank.

- Flow Rate Measurement: Connect the fuel flow meter to the isolated fuel line. Open the fuel supply valve and record the flow rate for a set duration (e.g., 1 minute). Compare this reading with the expected flow rate for your specific motor model. Any significant deviations may indicate a blockage or restriction in the fuel line.

- Pressure Check: Using the fuel pressure gauge, measure the pressure at the fuel supply and return lines. Note the readings and ensure they fall within the normal range for your motor. A sudden drop in pressure could suggest a blockage or a faulty fuel pump.

- Troubleshooting: If the flow rate or pressure readings are outside the expected range, it's time to troubleshoot. Check for any visible blockages in the fuel line, such as clogs or debris. Inspect the fuel filter and replace it if necessary. Ensure that the fuel pump is functioning correctly by checking its voltage and amperage.

By regularly monitoring fuel flow and pressure, you can promptly identify and address fuel line problems, ensuring optimal performance and longevity of your outboard motor. Remember, proper maintenance and timely issue detection can save you from potential breakdowns and costly repairs.

Understanding the 3 Gas Lines: Marine Fuel Pump Basics

You may want to see also

Engine Performance: Observe engine behavior for stalling, hesitation, or poor performance

When dealing with an outboard motor, one of the most critical aspects to monitor is its engine performance. Fuel lines play a vital role in delivering the necessary fuel to the engine, and any issues with these lines can lead to noticeable problems. Here's a guide on how to identify potential fuel line issues through engine behavior:

Stalling is a common symptom of a failing fuel line. If you notice that your engine stalls frequently, especially when you're trying to start it or during operation, it could be a sign of a restricted or damaged fuel line. Over time, fuel lines can develop cracks or become clogged with debris, leading to inadequate fuel supply. When the engine doesn't receive the required amount of fuel, it may stall, especially under load or when accelerating rapidly.

Hesitation or lag in engine response is another indicator of a potential fuel line problem. If you feel that the engine takes a moment to react when you press the throttle, it might be due to a partially blocked fuel line. This hesitation can be noticeable when accelerating from a stationary position or when you need an immediate response from the engine. The engine may not reach its full power output, and you might experience a delay before it responds to your throttle input.

Poor performance, such as reduced power and speed, can also be attributed to fuel line issues. If your outboard motor doesn't perform as expected, it could be because the fuel line is not delivering fuel efficiently. This may result in a noticeable decrease in horsepower and overall engine power. You might find that the boat doesn't accelerate as quickly as it used to, and maintaining higher speeds may become challenging.

In addition to these symptoms, keep an eye out for other signs like rough idling, erratic behavior, or a noticeable change in the engine's sound. These indicators can further suggest that there is an issue with the fuel delivery system, including the fuel lines. Regularly inspecting the fuel lines for any visible damage or corrosion is essential, as it can help prevent sudden engine failures and ensure optimal performance.

Unveiling the Material Secrets of Metal Fuel Lines

You may want to see also

Fuel Pump: Inspect the pump for proper operation and fuel delivery

When dealing with an outboard motor that may have fuel line issues, it's crucial to inspect the fuel pump for proper operation and fuel delivery. Here's a step-by-step guide to help you with this process:

- Access the Fuel Pump: Start by locating the fuel pump, which is typically found near the engine's fuel tank or along the fuel lines. Carefully inspect the pump for any visible signs of damage, corrosion, or debris buildup. Ensure that all connections and wiring are secure and intact.

- Check for Fuel Delivery: With the engine off, listen to the fuel pump for a few seconds. It should produce a steady, continuous humming sound, indicating that it's drawing fuel from the tank. If you don't hear any sound or the humming is intermittent, it could suggest a problem with the pump's operation or a clogged fuel filter.

- Inspect for Leaks: Check for any fuel leaks around the pump and connections. Even a small leak can indicate a potential issue with the pump's integrity or the surrounding components. Inspect the fuel lines for any signs of damage, cracks, or kinks that might cause fuel leaks or restrict flow.

- Test the Pump's Pressure: Use a fuel pressure gauge to test the pump's output pressure. Connect the gauge to the fuel line, ensuring it's secure, and activate the engine. The pressure reading should be within the recommended range specified by the manufacturer. Low pressure might indicate a faulty pump or a clogged fuel filter, while extremely high pressure could suggest a blocked fuel line or pump malfunction.

- Check for Fuel Flow: Start the engine and observe the fuel flow. Ensure that the pump is delivering fuel to the engine's carburetor or fuel injection system. If the engine struggles to start or runs poorly, it may indicate a fuel delivery issue, which could be caused by a malfunctioning pump or clogged fuel lines.

Remember, proper maintenance and regular inspections can help prevent major issues with your outboard motor's fuel system. If you notice any problems during the inspection, it's advisable to consult a qualified marine mechanic for further diagnosis and repair.

Half-Inch Double Bead Fuel Line: Top Sources Revealed

You may want to see also

Frequently asked questions

Fuel line problems can often lead to symptoms like poor engine performance, stalling, or difficulty starting. If you notice a sudden drop in power, erratic behavior, or the engine idling inconsistently, it could be due to a clogged, cracked, or damaged fuel line.

Clogging can occur due to debris, dirt, or moisture. Symptoms may include reduced power, hesitation when accelerating, or the engine cutting out during operation. Inspecting the fuel line for any blockages or signs of contamination is essential.

Yes, fuel line leaks can be a significant problem. Leaks may result in fuel spilling onto hot engine components, potentially causing damage or fire hazards. Additionally, a leak can lead to reduced fuel pressure, affecting engine performance.

Visually inspect the fuel line for any visible cracks, punctures, or signs of deterioration. Feel for any soft spots or areas where the line might be damaged. It's also a good idea to check for any signs of corrosion or rust, especially if the motor has been used in saltwater environments.

If you suspect a fuel line problem, it's best to consult a qualified marine mechanic. They can perform a thorough inspection, pressure test the fuel system, and recommend the necessary repairs or replacements. Regular maintenance and fuel line inspections can help prevent potential issues.