Fuel line leaks can be a serious issue for vehicle owners, leading to potential engine damage and safety hazards. When a fuel line leaks, it's crucial to address the problem promptly to prevent further complications. This guide will provide a step-by-step approach to identifying and stopping a fuel line leak, ensuring your vehicle remains safe and reliable. We'll cover essential tools and techniques, from inspecting the fuel system to using appropriate sealants and adhesives, offering a comprehensive solution to this common automotive problem.

What You'll Learn

- Identify the Source: Locate the damaged section of the fuel line and inspect for tears or cracks

- Prepare the Tools: Gather necessary tools like fuel line clamps, tape, and a solvent cleaner

- Clean the Area: Use a solvent to remove dirt and corrosion, ensuring a clean surface

- Apply Repair Material: Use a suitable fuel line repair tape or compound to seal the leak

- Test and Secure: Tighten the clamp and test for leaks, ensuring a secure and effective repair

Identify the Source: Locate the damaged section of the fuel line and inspect for tears or cracks

When dealing with a fuel line leak, it's crucial to pinpoint the exact source of the issue to effectively address it. Here's a step-by-step guide to help you identify and locate the damaged section of the fuel line:

Step 1: Visual Inspection

Start by thoroughly examining the fuel line system. Look for any visible signs of damage, such as tears, cracks, or bulges. These visual cues can provide valuable information about the extent of the leak. Pay close attention to areas where the fuel line connects to other components, such as the engine, fuel tank, or fuel pump.

Step 2: Follow the Fuel Line Path

Fuel lines are typically routed through the engine compartment, often in close proximity to other engine components. Carefully trace the path of the fuel line, following it from the fuel tank to the engine. This visual inspection will help you understand the layout and identify potential problem areas.

Step 3: Check for Leaks at Connections

Fuel lines often have various connections, including fittings, clamps, and hoses. Inspect these connections for any signs of damage or deterioration. Look for leaks at these points, as they could be the source of the issue. Ensure that all connections are secure and that there are no visible signs of corrosion or wear.

Step 4: Inspect for External Damage

Examine the fuel line for any external damage caused by road debris, impacts, or other factors. Small punctures or tears might not be immediately visible, so a careful inspection is essential. Look for any signs of discoloration or moisture around the fuel line, as these could indicate a leak.

Step 5: Use a Flashlight for Better Visibility

In low-light conditions or tight spaces, use a flashlight to illuminate the fuel line and its surroundings. This will help you identify any hidden damage or leaks that might not be apparent in normal lighting.

By following these steps, you can accurately locate the damaged section of the fuel line. Once the source is identified, you can then proceed with the necessary repairs or replacements to stop the fuel line leak and ensure the safe operation of your vehicle. Remember, a thorough inspection is key to resolving fuel line issues effectively.

Mastering the Art of Fuel Line Removal: A Step-by-Step Guide

You may want to see also

Prepare the Tools: Gather necessary tools like fuel line clamps, tape, and a solvent cleaner

When dealing with a fuel line leak, having the right tools and materials on hand is crucial to ensure a successful repair. Here's a step-by-step guide on preparing your toolkit:

Gather Fuel Line Clamps: Start by acquiring fuel line clamps specifically designed for the size and type of fuel line you are working with. These clamps are essential for creating a secure and tight seal around the damaged area. Ensure you have enough clamps to cover the entire length of the leak, allowing for proper coverage and support.

Prepare Adhesive Tape: Adhesive tape, such as duct tape or specialized fuel line repair tape, is another vital component. This tape is designed to adhere to the fuel line and provide a temporary fix until a more permanent solution can be implemented. Get a roll of this tape in a color that matches your fuel line to ensure a discreet repair.

Solvent Cleaner: A high-quality solvent cleaner is necessary to remove any dirt, debris, or old adhesive residue from the fuel line. This step ensures a clean and proper bond for the repair. Look for a solvent that is compatible with the material of your fuel line to avoid any potential damage.

Additionally, consider having some gloves and safety goggles for protection during the repair process. These simple tools will ensure a safe and efficient repair, allowing you to address the fuel line leak effectively. Remember, having the right tools ready beforehand can make the repair process much smoother.

2003 Trailblazer Fuel Line Location: A Comprehensive Guide

You may want to see also

Clean the Area: Use a solvent to remove dirt and corrosion, ensuring a clean surface

When dealing with a fuel line leak, it's crucial to start by cleaning the affected area thoroughly. This initial step is often overlooked but is essential for ensuring a successful repair. The goal is to remove any dirt, corrosion, or contaminants that might interfere with the sealing process.

Begin by gathering the necessary supplies: a suitable solvent, such as a fuel line cleaner or a mixture of white vinegar and water, and a clean cloth or rag. Ensure you have adequate ventilation in the workspace to avoid inhaling any fumes.

Apply the solvent generously to the leak area and the surrounding surfaces. Allow it to sit for a few minutes, giving it time to penetrate and loosen any debris or corrosion. The solvent will help dissolve and remove built-up dirt and corrosion, making the surface more receptive to repairs.

Use the cloth to wipe down the area, ensuring you cover the entire length of the fuel line where the leak occurred. Be thorough and patient, as multiple passes with the cloth might be needed to effectively remove all contaminants. Rinse the area with clean water after cleaning to ensure no residue remains.

Finally, allow the area to dry completely before proceeding with any further repairs. This step is vital as it ensures a clean, dry surface, which is essential for the adhesion and effectiveness of any sealing materials used. By taking the time to clean the area properly, you set the foundation for a successful repair, minimizing the chances of the leak recurring.

Fuel Line or Coolant: Which Works Better for Your Engine?

You may want to see also

Apply Repair Material: Use a suitable fuel line repair tape or compound to seal the leak

When dealing with a fuel line leak, it's crucial to act quickly and effectively to prevent further damage and potential safety hazards. One of the most common and reliable methods to stop a leak is by applying a suitable repair material, such as a fuel line repair tape or compound. This approach is often preferred due to its ease of use and effectiveness in sealing small to moderate-sized leaks.

Choosing the Right Repair Material:

Before proceeding, ensure you have the appropriate repair tape or compound. These materials are specifically designed to withstand the harsh conditions of fuel lines, including high temperatures and pressure. Look for products that are compatible with the type of fuel your vehicle uses to avoid any adverse reactions. Common options include rubber-based tapes and epoxy-based compounds, each with its own advantages.

Preparation:

Start by cleaning the area around the leak. Remove any dirt, debris, or old repair material to ensure a clean and stable surface for the new repair. Use a small brush or cloth to gently wipe the area, taking care not to damage the fuel line further. If the leak is minor, you might be able to clean and reattach the fuel line without needing to cut it.

Application Process:

- Tape Application: For small leaks, a repair tape is often the quickest solution. Cut a piece of tape slightly larger than the leak area and ensure it has a good adhesive backing. Carefully align the tape over the leak, pressing it firmly to create a seal. For larger leaks, multiple tapes may be required, overlapping them slightly for added strength.

- Compound Application: If the leak is more extensive or the fuel line is damaged, a repair compound might be necessary. Follow the manufacturer's instructions for application. Typically, you'll need to apply a thin layer of the compound to the leak area, ensuring it covers the entire affected section. Use a small brush or your fingers (after wearing gloves) to spread the compound evenly, allowing it to cure according to the product's guidelines.

Post-Application Care:

After applying the repair material, it's essential to avoid any further stress on the fuel line. Do not drive the vehicle or apply any additional pressure to the area. Allow the repair to cure completely, which may take several hours or even overnight, depending on the product used. Once cured, test the vehicle's fuel system to ensure the leak has been successfully stopped.

Remember, while this method can be highly effective, it is a temporary fix. It's always best to consult a professional mechanic for a more permanent solution, especially if the leak is recurring or the fuel line shows significant damage.

Replacing Fuel Lines: A Step-by-Step Guide for Your 2007 Cadillac CTS

You may want to see also

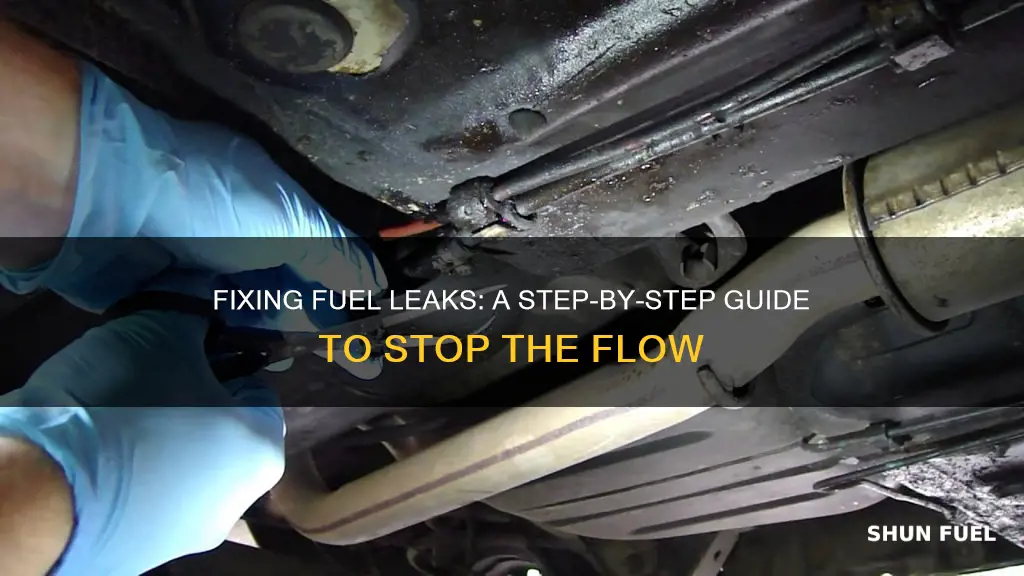

Test and Secure: Tighten the clamp and test for leaks, ensuring a secure and effective repair

When dealing with a fuel line leak, one of the most crucial steps is to ensure a secure and effective repair. This involves tightening the clamp and conducting a thorough test to verify that the leak has been successfully stopped. Here's a detailed guide on how to approach this process:

Tightening the Clamp: Start by ensuring that the clamp is properly positioned over the fuel line. Clamps can vary in design, so it's essential to use the correct type for your specific fuel line. Apply firm pressure to tighten the clamp, but be careful not to overtighten it. The goal is to create a snug fit that prevents any movement or looseness. Check the manufacturer's guidelines or consult a professional if you're unsure about the correct tightening torque. A secure clamp will provide a reliable seal, preventing any further leaks.

Visual Inspection: After tightening the clamp, perform a visual inspection to ensure there are no visible signs of leakage around the connection. Look for any wet spots, stains, or puddles of fuel near the clamp. If you notice any, it indicates that the repair is not complete, and further investigation is required.

Pressure Test: To ensure the integrity of the repair, a pressure test is essential. This test involves applying pressure to the fuel line and observing if any leaks occur. Here's how to do it:

- Locate the fuel pump and disconnect the fuel line from the pump.

- Securely attach a test gauge or pressure sensor to the fuel line.

- Start the engine and allow it to run for a few minutes to prime the fuel system.

- Gradually increase the pressure in the fuel line using the test gauge.

- Monitor the gauge for any drops in pressure, indicating a potential leak.

- If no leaks are detected, the repair is likely secure.

Leak Detection: If a leak is suspected during the pressure test, it's crucial to identify the source. This may involve further disassembly and inspection of the fuel line and its connections. Use a soapy water solution to perform a visual leak detection test. Apply the solution around the clamp and any other connections, and observe if any bubbles form, indicating a leak. If a leak is found, repeat the tightening and testing process until the issue is resolved.

Final Check: Once you've tightened the clamp and conducted the pressure test, it's essential to perform a final check. Start the engine and monitor it for any unusual noises or vibrations. Check the fuel gauge to ensure the fuel level is stable and that the engine is running smoothly. If everything appears normal, your fuel line leak should be effectively stopped.

Understanding Fuel Lines: The Vital Link in Your Engine's Fuel Supply

You may want to see also

Frequently asked questions

Fuel line leaks can occur due to various reasons, including age, wear and tear, damage from accidents or collisions, poor installation, or the use of substandard fuel. Over time, the fuel lines can deteriorate, develop cracks, or become brittle, leading to leaks.

For a temporary fix, you can use a fuel line clamp or a quick-fix kit designed for such leaks. These kits typically include a clamp and a sealing compound that can be applied to the leak area to create a temporary seal. However, it's essential to address the underlying issue promptly to prevent further damage and ensure safety.

When dealing with a fuel line leak, it is crucial to prioritize safety. Always ensure the engine is off and the vehicle is in a well-ventilated area. Avoid creating sparks or open flames as fuel is highly flammable. Wear protective gear, such as gloves and goggles, to prevent contact with fuel. If the leak is significant or you are unsure about the repair, it is best to consult a professional mechanic to ensure the issue is safely and effectively resolved.