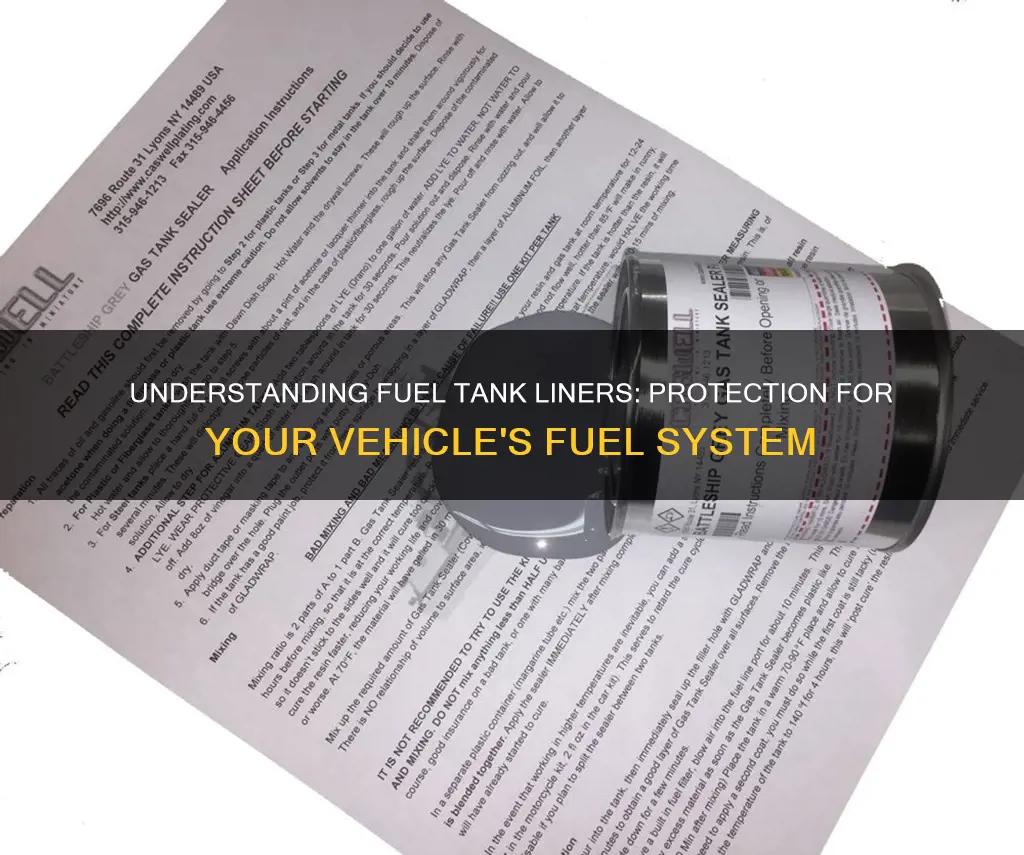

A fuel tank liner is a crucial component in the automotive industry, designed to protect the inner surface of a fuel tank from corrosion and damage. It acts as a protective barrier, ensuring the fuel remains clean and free from contaminants that could affect engine performance and longevity. This liner is typically made of durable materials such as rubber or plastic and is installed inside the fuel tank to provide an additional layer of defense against wear and tear. The primary purpose of a fuel tank liner is to maintain the integrity of the fuel system, prevent fuel leaks, and enhance the overall efficiency and reliability of the vehicle's engine.

What You'll Learn

- Material: Fuel tank liners are made from durable materials like rubber or plastic

- Function: They protect the fuel tank from corrosion and fuel contamination

- Installation: Liners are installed inside the tank to line the interior surface

- Compatibility: Liners are designed to fit specific vehicle models and tank sizes

- Maintenance: Regular inspection and replacement are essential for optimal performance

Material: Fuel tank liners are made from durable materials like rubber or plastic

Fuel tank liners are an essential component of any vehicle's fuel system, designed to protect the inner surface of the fuel tank from corrosion, wear, and potential damage caused by fuel contaminants. These liners are typically made from high-quality, durable materials that can withstand the harsh conditions within a fuel tank. The primary materials used for manufacturing fuel tank liners are rubber and plastic, both of which offer excellent resistance to chemical degradation and mechanical stress.

Rubber is a popular choice for fuel tank liners due to its inherent flexibility and resilience. It can absorb vibrations and shocks that occur during driving, ensuring a smoother and more stable fuel supply. Natural rubber, in particular, is known for its ability to withstand the corrosive effects of gasoline and diesel, making it an ideal material for fuel tank protection. The rubber liners are often reinforced with fibers to enhance their strength and durability, ensuring they can handle the constant expansion and contraction of the fuel tank.

Plastic, another common material for fuel tank liners, offers several advantages. It is lightweight, making it easier to install and replace compared to rubber. High-density polyethylene (HDPE) and polypropylene are the most commonly used plastics for this application. These plastics are resistant to impact, chemicals, and UV radiation, ensuring long-lasting protection for the fuel tank. Additionally, plastic liners are often more cost-effective, especially for larger fuel tanks, and can provide an excellent barrier against rust and corrosion.

The choice of material for a fuel tank liner depends on various factors, including the type of fuel used, the climate conditions, and the specific requirements of the vehicle. Rubber liners are often preferred for their ability to absorb vibrations, while plastic liners excel in providing a lightweight, durable solution. Both materials are engineered to meet strict industry standards, ensuring they can effectively seal the fuel tank and prevent any leaks or contamination.

In summary, fuel tank liners are a critical component of vehicle maintenance, and their choice of material is crucial for their performance and longevity. The use of durable rubber or plastic materials ensures that the fuel tank remains protected, providing a reliable and safe fuel supply for the vehicle's operation. Understanding the properties of these materials is essential for vehicle owners and mechanics alike to make informed decisions regarding fuel tank maintenance.

Fuel Line for Your 96 Civic: A Guide to Finding the Right Fit

You may want to see also

Function: They protect the fuel tank from corrosion and fuel contamination

A fuel tank liner is a crucial component designed to safeguard the internal surface of a fuel tank, offering a protective barrier against various detrimental factors. Its primary function is to shield the tank from the corrosive effects of fuel and prevent contamination, ensuring the longevity and optimal performance of the vehicle's fuel system.

The fuel tank, being a critical part of any vehicle, is susceptible to corrosion and degradation over time due to the constant exposure to fuel. This corrosion can lead to a range of issues, including fuel leaks, reduced engine performance, and even structural damage to the tank itself. The liner acts as a protective layer, creating a barrier between the fuel and the tank's interior, thus preventing direct contact and potential corrosion.

In addition to corrosion protection, fuel tank liners also play a vital role in preventing fuel contamination. Fuel, especially when exposed to air, can absorb moisture and other impurities, leading to the formation of sludge and varnish. These contaminants can clog fuel filters, reduce engine efficiency, and even cause engine damage. By lining the tank's interior, the liner creates a sealed environment, minimizing the exposure of fuel to air and moisture, and thus preventing the absorption of contaminants.

The design and material of the fuel tank liner are carefully considered to ensure optimal performance. Liners are typically made from durable materials such as rubber, plastic, or composite materials, chosen for their ability to withstand the corrosive nature of fuel and the harsh operating conditions. These materials are engineered to be resistant to fuel degradation, ensuring that the liner remains effective over the long term.

Proper installation of the fuel tank liner is essential to maximize its protective capabilities. It should be securely fitted to the tank's interior, ensuring complete coverage to provide an effective barrier. Regular inspection and maintenance of the fuel tank and its liner are also recommended to identify and address any potential issues promptly, ensuring the continued protection of the fuel system.

Thawing Frozen Fuel Lines: A Guide to Winter Car Care

You may want to see also

Installation: Liners are installed inside the tank to line the interior surface

The installation process of fuel tank liners is a crucial step in ensuring the longevity and performance of your vehicle's fuel system. These liners are designed to provide an additional layer of protection between the fuel and the tank's interior surface, offering several benefits.

When installing a fuel tank liner, the primary goal is to create a seamless and secure interior lining for the tank. This process typically involves the following steps: First, ensure that the fuel tank is empty and has been properly drained to avoid any safety hazards during the installation. Then, carefully inspect the tank's interior to identify any existing damage or imperfections that might affect the liner's adherence. Cleaning the tank's interior is essential; any debris or contaminants must be removed to ensure a proper bond between the liner and the tank.

The next step is to measure and cut the liner to fit the tank's interior dimensions precisely. Liners are usually made of durable materials like rubber or plastic, and their design often includes features such as baffles or baffled baffles to optimize fuel flow and prevent sloshing. Once the liner is cut to size, it is carefully positioned inside the tank, ensuring that all interior surfaces are properly covered. The liner should be securely fastened using the appropriate fasteners provided by the manufacturer, such as screws, clips, or adhesive.

After the liner is in place, it is essential to inspect the installation for any gaps or imperfections. The liner must be tightly fitted to the tank's interior to provide optimal protection. Any gaps or uneven surfaces can lead to fuel leakage or reduced performance. Once the installation is complete, the fuel tank is refilled, and the vehicle's fuel system is restored to its normal operating condition.

Proper installation of fuel tank liners is a specialized task that requires attention to detail and adherence to manufacturer guidelines. It is recommended to consult the vehicle's manual or seek professional assistance to ensure a successful and safe installation. By following these steps, you can effectively protect your fuel tank and maintain the efficiency of your vehicle's fuel system.

Clogged Fuel Line: How It Affects Your Car's Performance

You may want to see also

Compatibility: Liners are designed to fit specific vehicle models and tank sizes

When it comes to fuel tank liners, compatibility is a crucial aspect that cannot be overlooked. These liners are specifically engineered to fit the unique dimensions and contours of different vehicle models and their respective fuel tanks. This precision in design ensures a seamless and secure installation process, providing optimal protection for the fuel tank's interior.

The process of selecting the right fuel tank liner begins with identifying the vehicle's make, model, and year. Each vehicle has a specific fuel tank configuration, and the liner must match this layout to ensure a proper fit. For instance, a fuel tank liner designed for a Toyota Camry's tank will have the same dimensions and shape as the one installed in that particular model. This compatibility is essential to guarantee that the liner covers all critical areas of the tank, providing comprehensive protection against wear and tear, corrosion, and fuel contamination.

Furthermore, fuel tank liners come in various sizes to accommodate different tank capacities. Whether it's a compact car, a full-size SUV, or a heavy-duty truck, there is a liner available that fits the vehicle's fuel tank perfectly. This customization ensures that the liner doesn't interfere with other components or the vehicle's overall performance. Properly sized liners also contribute to a secure installation, minimizing the risk of movement or shifting within the tank.

In summary, the compatibility of fuel tank liners is a critical feature that ensures their effectiveness and longevity. By being designed to fit specific vehicle models and tank sizes, these liners provide a tailored solution for protecting the fuel system. This level of customization allows for a precise fit, maximizing coverage and minimizing potential issues during installation and long-term use.

Scooter Fuel Lines: Powering the Engine's Heart

You may want to see also

Maintenance: Regular inspection and replacement are essential for optimal performance

Fuel tank liners are an essential component of vehicle maintenance, especially for those who frequently carry heavy loads or operate in harsh environments. These liners are designed to line the interior of the fuel tank, providing a protective barrier between the fuel and the tank's interior surface. Over time, the fuel tank's interior can corrode, leading to various issues such as fuel contamination, reduced fuel efficiency, and even engine damage. This is where the fuel tank liner comes into play, offering a crucial layer of protection.

Regular maintenance and inspections are vital to ensure the longevity and optimal performance of fuel tank liners. Here's why: Firstly, fuel tanks are exposed to various contaminants, including water, dirt, and corrosive substances present in fuel. Over time, these contaminants can accumulate and damage the tank's interior, compromising the liner's integrity. Regular inspections allow for the early detection of any signs of wear, tear, or damage to the liner. This includes checking for cracks, punctures, or any unusual wear patterns that may indicate a compromised barrier.

During these inspections, it is crucial to look for any signs of fuel leakage or contamination. Even a small breach in the liner can lead to significant issues. Fuel leakage not only poses a safety hazard but can also result in engine misfires, reduced performance, and increased emissions. Regular checks help identify any potential leaks early on, allowing for prompt replacement of the liner if necessary. Additionally, inspecting the fuel tank's overall condition is essential. This includes checking for any signs of corrosion on the tank walls, as this can affect the liner's ability to provide adequate protection.

The replacement of fuel tank liners is a critical maintenance task. Over time, liners can degrade, especially in vehicles with high mileage or those exposed to extreme temperatures. When an inspection reveals significant wear, tears, or damage, it is imperative to replace the liner promptly. Delaying replacement can lead to further contamination and potential engine damage. Modern vehicles often have indicators or warning lights that signal the need for a fuel tank inspection or replacement, so staying vigilant and addressing these issues promptly is key.

In summary, regular maintenance and inspections are vital to the proper functioning of fuel tank liners. By identifying and addressing any issues early on, vehicle owners can ensure their engines run efficiently and avoid costly repairs. It is a simple yet crucial aspect of vehicle care that should not be overlooked, especially for those who want to maximize the lifespan of their vehicles and maintain optimal performance. Remember, proper maintenance can save you from potential headaches and expenses in the long run.

Emergency Fuel Line Fixes: Quick Solutions for Leaks & Clogs

You may want to see also

Frequently asked questions

A fuel tank liner is a protective layer or coating applied to the interior surface of a fuel tank. It is designed to prevent corrosion, rust, and leaks, ensuring the tank's longevity and maintaining the quality of the fuel.

The liner acts as a barrier between the tank's metal surface and the fuel, preventing direct contact. This reduces the risk of metal degradation and fuel contamination. Liners can be made from various materials, such as rubber, plastic, or metal-coated materials, depending on the specific application and requirements.

Fuel tank liners are crucial for several reasons. They help prevent fuel leaks, which can cause environmental damage and safety hazards. Liners also protect the tank's interior from corrosion, especially in vehicles or equipment exposed to harsh weather conditions or saltwater environments. Additionally, they can improve fuel efficiency by ensuring a clean and smooth interior surface for the fuel to flow through.

Replacing a fuel tank liner is a complex process and is generally recommended to be done by professional mechanics. It requires specialized tools and knowledge to ensure proper installation. Attempting it without proper expertise may lead to further issues and potential safety risks.

The frequency of inspection and replacement depends on various factors, including the vehicle's age, usage, and environmental conditions. It is advisable to have the fuel tank inspected regularly, especially if the vehicle is used in corrosive environments or has a history of fuel leaks. Professional mechanics can assess the liner's condition and provide recommendations for maintenance or replacement.