Replacing a fuel pump can be a challenging task, and the process may vary depending on the year, make and model of your vehicle. In some cases, it may be necessary to drop the fuel tank in order to access the fuel pump, while in other cases, it may be possible to replace the fuel pump from inside the car. It is important to take safety precautions when working with fuel, and to refer to a trusted repair manual or seek the assistance of a qualified mechanic if you are unsure about the procedure.

| Characteristics | Values |

|---|---|

| Vehicle Make | Chevy, Ford, Honda, Nissan, Mercury |

| Vehicle Model | Avalanche, Cougar, Explorer, Accord, Altima, Mustang |

| Vehicle Year | 2002 |

What You'll Learn

Disconnecting the fuel tank

Step 1: Safety First

Before starting any work on your vehicle, it's crucial to prioritize your safety. Make sure to wear protective gear, including safety glasses and gloves. Work in a well-ventilated area away from any open flames or potential sources of sparks, such as pilot lights or incandescent light bulbs. Keep a fire extinguisher nearby as an added precaution.

Step 2: Prepare the Vehicle

The next step is to prepare the vehicle for the fuel pump replacement. If possible, reduce the amount of fuel in the tank to minimize the risk of spills. Relieve the fuel system pressure by running the engine and then pulling the fuel pump relay, or by pressing the Schrader valve momentarily to release the pressure.

Step 3: Lift the Vehicle and Access the Fuel Tank

Use a jack to lift the vehicle and securely support it. This will provide you with access to the underside of the vehicle and the fuel tank. If your vehicle has an access panel or port, you may be able to access the fuel pump without fully removing the tank. However, if a full tank removal is necessary, proceed to the next step.

Step 4: Disconnect Fuel Lines and Electrical Connections

Before removing the fuel tank, it's important to disconnect the fuel lines and electrical connections associated with the fuel pump. Carefully detach the fuel lines and take note of their connections for reassembly. Disconnect the electrical connectors to the fuel sender and fuel pressure sensor.

Step 5: Remove the Fuel Tank

Now, you can proceed to remove the fuel tank. Loosen and remove the fuel tank strap bolts and carefully lower the rear of the fuel tank. You may need an assistant to help support the tank during this process. Be cautious not to bend or damage the fuel tank straps. Once the tank is lowered, you can access the fuel pump for replacement.

Step 6: Drain and Clean the Fuel Tank

Before removing the fuel sender assembly, it's important to drain the fuel from the assembly into an approved container to reduce the risk of fire and personal injury. Never store drained fuel in an open container. After draining the fuel, clean the fuel sender sealing surfaces to ensure no dirt or debris enters the tank.

By following these steps, you can safely disconnect the fuel tank and proceed with the fuel pump replacement process. Remember to work cautiously and refer to your vehicle's service manual or online tutorials for specific instructions pertaining to your vehicle's make and model.

Best Fuel Tank Replacement Options for Your Briggs & Stratton Engine

You may want to see also

Removing the fuel pump

Step 1: Prepare your vehicle

Before you begin, make sure you have the necessary tools and equipment, including a new fuel pump, fuel filter, and any other components specific to your vehicle. It is also important to reduce the amount of fuel in the tank to minimise the risk of spillage and make the tank easier to handle.

Step 2: Safety first

Fuel is flammable and toxic, so ensure you are wearing safety gear, including gloves and safety glasses. Work in a well-ventilated area, away from any open flames or potential sources of ignition, such as pilot lights and incandescent light bulbs. Have a fire extinguisher on hand.

Step 3: Lift the vehicle

Use a jack to lift your vehicle and remove the tank. If there is fuel in the tank, drain it into an approved container.

Step 4: Remove the fill lines

Remove the clamps from the fill lines and then remove the fill lines as you prepare to drop the gas tank. Use a rag to keep dirt out of the tank.

Step 5: Lower the gas tank

Support the tank as you remove the straps and carefully lower it.

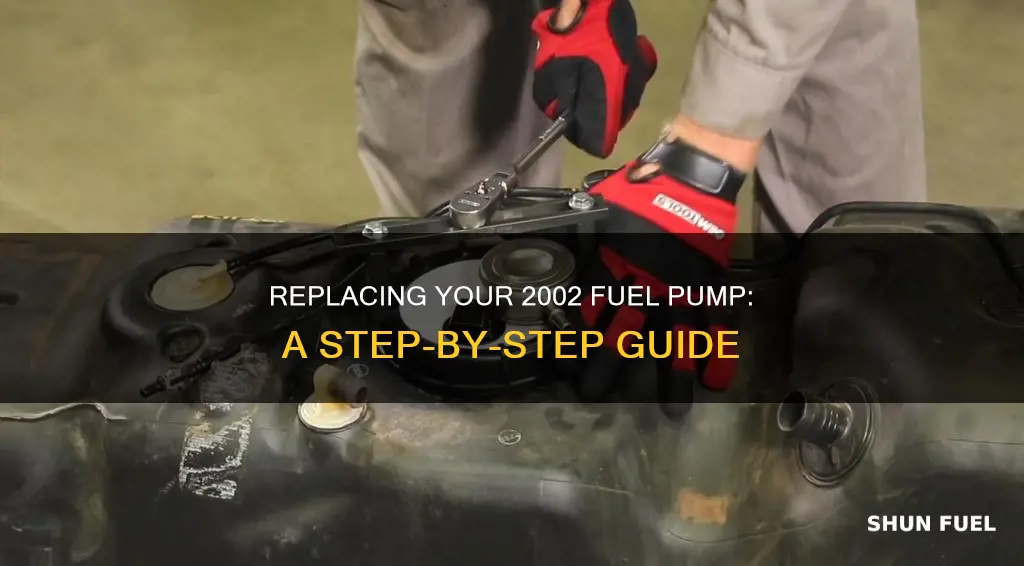

Step 6: Remove the pump assembly

Remove the pump assembly so you can replace it with a new part. Keep in mind that some fuel pumps require parts to be transferred from the old unit.

Step 7: Reassemble

Get the new pump installed and the pump retaining ring back in place. Raise the tank close to the vehicle so you can reconnect the wire connectors and fuel lines. Reconnect the straps and fill lines with the tank properly positioned.

Step 8: Test

Partially fill the tank and run the vehicle to inspect for any leaks.

Fuel Pump and Harness: Why Replace Both?

You may want to see also

Installing the new fuel pump

First, make sure you have a new fuel pump that matches the one you removed. Then, clean the area around the pump access hole to prevent dirt and debris from entering the tank. Next, install the new seal ring and new pump assembly in the tank.

Now, use a transmission jack or equivalent to raise the tank just enough to reconnect the fuel hoses, electrical connections, and emissions hoses. Then, raise the tank into place and reinstall the fuel tank straps. Torque the mounting bolts to the specification listed in the factory repair manual.

After that, safely remove the jack stands and lower the vehicle. Reconnect the negative battery cable. Finally, fill the fuel tank as needed and start the vehicle to double-check your work, looking for leaks.

Replacing Fuel Line on Troy Bilt Leaf Blower: Step-by-Step Guide

You may want to see also

Reattaching the fuel tank

When reattaching the fuel tank, it is important to follow the correct safety procedures and manufacturer guidelines. Here is a step-by-step guide:

Firstly, ensure the fuel tank is supported securely. This can be done with the aid of an assistant. It is important not to bend the fuel tank straps as this may cause damage.

Next, reconnect the fuel lines and electrical connectors to the new fuel pump. Use appropriate tools, such as fuel line disconnect tools, to safely reattach the fuel lines. Ensure all connections are secure to prevent leaks.

Then, carefully lift the fuel tank back into position. Reattach the fuel tank straps and bolts, ensuring they are tightened correctly.

Once the fuel tank is in place, reconnect the EVAP vent pipe at the fuel tank clip and the vent hose and filler hose to the pipe.

Finally, check all connections and components for tightness and security. This includes hoses, clamps, and fittings. A small leak can lead to a dangerous situation, so it is important to be thorough.

Once you have completed these steps, you can proceed to test the fuel pump system as outlined in the previous section.

Replacing the Fuel Pump on a Bobcat 440B: Step-by-Step Guide

You may want to see also

Testing the new fuel pump

Electrical Test:

- Check the fuel pump fuse: Locate the fuse box and identify the fuse associated with the fuel pump. Inspect the fuse for any signs of failure, such as burning or breakage. If the fuse appears damaged, replace it with one of the proper amp rating.

- Check voltage at the pump: Ensure that the power is reaching the pump by checking the voltage as per your vehicle's service manual.

- Test for source voltage: Determine if the charge leaving the fuse is reaching the pump. If there is no power, check the fuel pump relay circuit for any issues.

- Perform a drop test with a voltmeter: Check the power wire for full voltage and verify that the grounding wire is properly grounded. If this test doesn't reveal any issues, the problem is likely with the fuel pump, and it may need replacement.

Fuel Pressure Test:

- Eliminate the filter: Remove the filter and drain excess fuel. Use a rubber hose on the filter inlet and blow through it, checking for resistance. Inspect the screen for debris and replace the filter if necessary.

- Use a fuel pressure gauge: Purchase or borrow a fuel pressure gauge and hook it up to the fuel pump test point, usually located near the fuel injectors or the fuel pump's connection to the filter injector rail.

- Rev the engine: With the engine slightly warmed up, check the pressure at idle speed and the rated speed specified in your pump specifications. If the needle doesn't move or moves below specifications, it indicates a problem with the fuel pump, and it may need to be replaced.

- Check fuel trim with a scan tool: If your engine is running, use a scan tool to check the short-term fuel trim (STFT) parameter. Typically, fuel trim readings should be between -10 and 10, but refer to your vehicle's specifications. If the fuel trim is above 10, it suggests a lean-running engine, which could be due to a faulty fuel pump.

Remember to consult your vehicle's repair manual for specific instructions and safety precautions when performing these tests.

Replacing Fuel Line on John Deere LT150: A Step-by-Step Guide

You may want to see also

Frequently asked questions

Replacing a fuel pump can take anywhere from 2 hours to 6 hours depending on your expertise and the type of car.

There are several signs that indicate a bad fuel pump. These include a car that won't start, a car that stalls after starting, a check engine light turning on, or a whirring sound coming from your fuel tank.

You can access the fuel pump either by removing the fuel tank or through an access panel in the passenger compartment.

The tools required to replace a fuel pump vary depending on the car model. However, some common tools include a jack, jack stands, a screwdriver, and a hammer.

It is recommended to replace the fuel pump strainer, fuel filter, and fuel sender assembly at the same time as the fuel pump.