A fuel gauge sender is a device that transmits data from the fuel tank to the fuel gauge. The fuel gauge sender is located in the fuel tank and attached to the fuel pump. The sender has a base with a rod and float attached to it. The float is a device that is light and hollow to lay on top of the fuel without sinking. The rod is attached to the base and has a rheostat meter that registers the amount of fuel in the fuel tank. When the fuel gauge sender fails, the engine management system will record this event. A fuel level sensor will let the computer know of the level and resistance transmitted to the gauge.

| Characteristics | Values |

|---|---|

| Purpose of a fuel gauge sender | Transmits data from the fuel tank to the fuel gauge |

| Location of a fuel gauge sender | Inside the fuel tank |

| Fuel gauge sender failure signs | Fuel gauge registering overfull when the tank is full, gauge registering empty when the tank is not empty |

| Fuel rail pressure sensor function | Monitors the pressure inside the fuel rail, the metal tube that connects the fuel delivery system to the engine |

| Fuel rail pressure sensor symptoms | Engine start problems, erratic engine operation, engine cutting out during normal operation |

| Fuel sending unit faults | Fuel gauge reading full or empty all the time, erratic needle movement |

| Fuel sending unit tests | OBD-II scanner, fuel gauge self-test, multimeter test, sending unit wiring connections test, output voltage test |

| Fuel sending unit replacement steps | Release fuel tank pressure, disconnect fuel lines and electrical connections, clean the area, remove and replace the unit, reconnect electrical connectors and fuel lines |

What You'll Learn

Disconnect the fuel lines and electrical connections

Disconnecting the fuel lines and electrical connections is a crucial step when replacing a fuel sending unit or fuel gauge sender. Here is a detailed guide on how to perform this task safely and effectively:

Before beginning, ensure you have the necessary tools and safety equipment. Wear fuel-resistant gloves and safety glasses to protect yourself from fuel and debris. It is also recommended to keep a fire extinguisher nearby as a safety precaution when working with fuel-related components.

Locate the fuel tank and identify the fuel sending unit or fuel gauge sender. Refer to your vehicle's repair manual for specific instructions on accessing this component. In some cases, you may need to lower the fuel tank or remove it completely. Make sure to place a container under the tank to catch any spilled fuel.

Once you have accessed the fuel sending unit, carefully disconnect the fuel lines. These lines supply fuel to the engine, so it is important to be cautious and avoid any spills. Use a fuel hose quick-disconnect tool or a similar device to safely release the pressure in the fuel lines and detach them from the unit.

After disconnecting the fuel lines, focus on the electrical connections. Disconnect the harness or wiring from the fuel sending unit. Again, refer to your vehicle's repair manual for the exact location of the harness and specific disconnection instructions. Be gentle with the wires to avoid any damage.

As you work, pay attention to the condition of the components. Look for any signs of damage, corrosion, or debris accumulation. Clean the connectors and the area around the plug to ensure no contaminants fall into the tank. Use a lint-free cloth and electrical cleaner to wipe down the connections and remove any residue or moisture.

Finally, before removing the old fuel sending unit, compare it with the replacement unit to ensure they are compatible. This includes checking the gasket or O-ring to make sure it is properly aligned and in good condition.

By following these steps, you can safely and effectively disconnect the fuel lines and electrical connections when replacing a fuel sending unit or fuel gauge sender. Remember to work cautiously and refer to your vehicle's repair manual for specific instructions pertaining to your make and model.

Replacing Fuel Injectors in a 2001 Ford Focus: Step-by-Step Guide

You may want to see also

Clean the area around the plug

To clean the area around the plug, you will need to prepare the work area first. Park your vehicle on a flat, hard surface, preferably indoors, and engage the parking brake. Make sure that the transmission is in park (for automatics) or in first gear (for manuals). Place wheel chocks around the tires.

Next, open the vehicle's hood and disconnect the battery. Take the ground cable off the battery's negative post, disabling the power to the fuel pump and sending unit. If you have one, install a nine-volt battery saver into your cigarette lighter to keep your computer live and maintain your current settings.

Now, you can begin to clean the area around the plug. First, locate the fuel tank and remove the fuel filler cap cable from the fuel neck. Place this aside and open the fuel door to gain access to the fuel filler neck. Remove the mounting screws or bolts attached to the cutaway.

Go under the vehicle and locate the fuel tank. You may need to lower the fuel tank slightly to access the plug. Be sure to use a transmission jack or similar to support the fuel tank. Loosen and remove the straps to the fuel tank.

Now, clean the area around the plug. Use a lint-free cloth and electrical cleaner to wipe down the harness on the vehicle and the connector to the fuel pump or sending unit on the fuel tank. Ensure that the area is free of any contaminants that could fall into the tank.

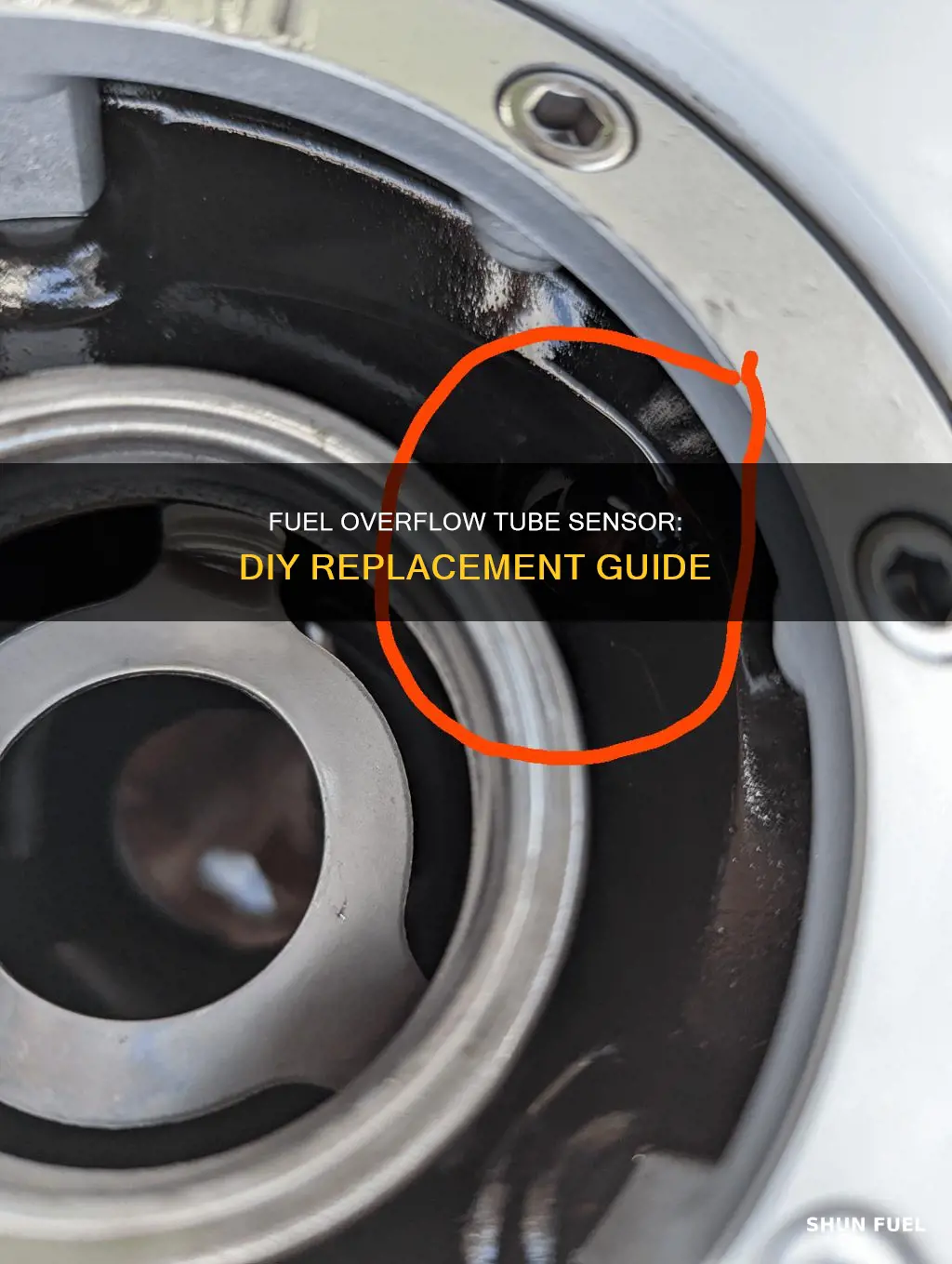

Once the area is clean, you can proceed with the next steps of replacing the fuel overflow tube sensor.

Oxygen Sensor Replacement: Tahoe Fuel Mileage Fix?

You may want to see also

Remove the old fuel sending unit

To remove the old fuel sending unit, you'll need to park your vehicle on a flat, hard surface. Make sure that the transmission is in park (for automatics) or in 1st gear (for manuals). Place wheel chocks around the front tires and engage the parking brake to prevent the vehicle from moving.

Next, open the hood and disconnect the negative battery cable to disable the power to the fuel pump and sending unit. Then, locate a jacking point under the vehicle and use a jack to lift it until the wheels are off the ground. Place jack stands under the vehicle for support.

Go underneath the vehicle and locate the fuel tank. You may need to lower the fuel tank slightly to access it. Disconnect the harness from the connector attached to the fuel tank. This may involve reaching up to the top of the fuel tank.

Now, you can begin to remove the fuel tank. First, disconnect the vent hose by removing the clamp and small vent hose. Then, twist and pull out the fuel filler neck from the rubber hose. Guide the fuel filler neck out of the way and remove the clamp on the rubber hose.

At this point, you should be able to remove the fuel tank from the vehicle. Be sure to transfer any remaining fuel from the tank to a safe container. Inspect the rubber hose for any cracks, and replace it if necessary.

With the fuel tank out of the vehicle, it's time to remove the old fuel sending unit. Clean any dirt or debris from the mounting area. Remove the mounting bolts securing the fuel pump and sender to the fuel tank. You may need to rotate the fuel sender to get the float out of the tank. Once the bolts are removed, pull out the fuel pump and sender, along with the rubber seal.

Now, you have successfully removed the old fuel sending unit! The next step would be to install a new fuel sending unit, following the manufacturer's instructions and torque specifications.

Replacing the Fuel Filter in Your GLK250: When and Why

You may want to see also

Install the new fuel sending unit

To install the new fuel sending unit, follow the steps outlined below:

Firstly, ensure that you have purchased the correct level sending unit for your tank. Measure the distance from the inside bottom to the outside top of the tank to determine the appropriate sending unit length. It is imperative to maintain a minimum clearance of 1" between the tank bottom and the float retaining collar.

Once you have the correct unit, begin by sliding the gasket over the down tube. Then, align the screw-hole pattern to fit flush against the underside of the mounting plate. Remember that the screw hole pattern is not symmetrical, so there is only one way to align the gasket correctly.

Position the new level sending unit above the tank, ensuring that the screw hole pattern in the mounting plate aligns with the hole pattern at the top of the tank. This step is crucial to ensure the proper placement of the sending unit.

Next, install the level sending unit by inserting the down tube into the tank. Make sure that the tank is empty and free of any fuel or fumes before proceeding with the installation.

Secure the level sending unit to the tank by tightening the mounting screws in a star-shaped pattern. Be careful not to over-tighten the screws, as this can weaken the seal and reduce the service life of the gasket.

After the level sending unit is secured, conduct a leak test to ensure it is properly installed. Pressurize the tank to 3 PSI and inspect for bubbles using soapy water around the seal. If bubbles are present, tighten the screws further in a star-shaped pattern and repeat the leak test until no bubbles are visible.

Finally, connect the level sending unit to a gauge. Connect the ground (pink) wire from the sending unit to a common grounding hook-up, and then connect the black wire to the gauge hook-up. Turn on the power to the level sending unit and gauge, and adjust the float to ensure proper functionality.

If you are unsure about any of these steps or feel uncomfortable performing them, it is always best to seek professional assistance.

Replacing Your Fuel Gauge Sender: A Step-by-Step Guide

You may want to see also

Reconnect electrical connectors and fuel lines

To reconnect the electrical connectors and fuel lines, follow these steps:

- Clean the connectors: Use a clean rag to wipe down the connectors on the fuel tank and the engine. Remove any dirt or debris that may interfere with the connection.

- Apply fuel line lubricant (optional): Applying a small amount of fuel line lubricant to the connectors can help prevent leaks.

- Insert the fuel line: Carefully insert the fuel line into the connectors. Ensure the line is fully seated.

- Tighten the connectors: Use pliers to tighten the connectors. Do not overtighten, as this could damage the fittings.

- Reconnect the battery: Once the fuel line is reconnected, reconnect the battery's negative terminal.

- Start the engine and check for leaks: Start the engine and allow it to run for a few minutes. Check for any fuel leaks around the connectors. If you notice any leaks, tighten the connectors further.

It is important to note that working with fuel lines can be hazardous, so it is crucial to prioritise safety. Always wear safety glasses and gloves to protect your eyes and skin from potential fuel spills. Additionally, park your vehicle on a level surface and engage the parking brake. Allow the engine to cool down completely before starting any work, and disconnect the battery's negative terminal to prevent electrical sparks.

Fuel Lines: Replacing Them Before They Become a Problem

You may want to see also