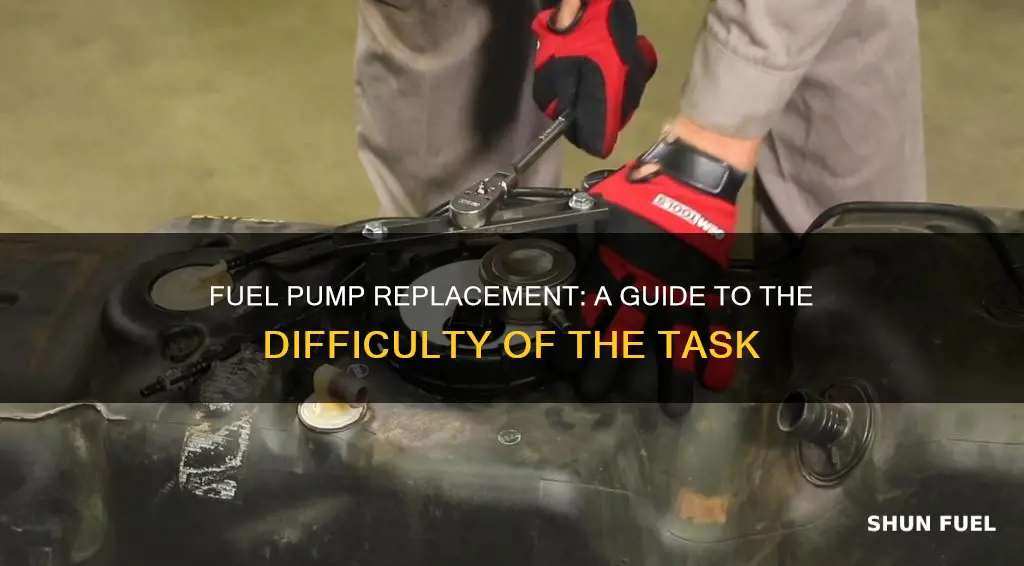

Fuel pump replacement can be a challenging task for car owners, as it often requires specialized tools and knowledge. The difficulty level depends on the vehicle's make and model, but generally, it's a complex process that demands patience and technical expertise. This guide will provide an overview of the steps involved, offering a comprehensive understanding of the process and the potential challenges one might face when replacing a fuel pump.

| Characteristics | Values |

|---|---|

| Complexity | Can vary depending on the vehicle model and the location of the fuel pump. Generally, it is considered a moderately difficult task for DIY enthusiasts. |

| Time Required | The time needed for the replacement can range from 1 to 4 hours, depending on the vehicle's make and model, and the mechanic's experience. |

| Tools Required | Basic tools like socket wrenches, screwdrivers, and a fuel pump removal tool may be necessary. More complex procedures might require specialized tools. |

| Common Issues | Potential problems include fuel leaks, difficulty in removing the old pump, and issues with the new pump not functioning properly. |

| Safety Precautions | It is important to drain the fuel tank and disconnect the battery before starting the replacement to avoid accidents and electrical issues. |

| Cost | The cost of parts and labor can vary widely. Parts can range from $50 to $200, while labor costs can be $100 to $300 or more, depending on the location and the mechanic's rates. |

| Vehicle Compatibility | The difficulty level may also depend on the vehicle's design and the accessibility of the fuel pump. Some cars might require more intricate procedures. |

| Expertise Level | While some experienced DIYers can handle it, it is recommended to have some mechanical knowledge or seek professional assistance for a successful replacement. |

What You'll Learn

- Accessing the Pump: Locate and remove the old fuel pump, often requiring engine disassembly

- Pump Selection: Choose a compatible replacement pump with the right specifications

- Installation Process: Carefully install the new pump, ensuring proper connections and alignment

- Testing and Diagnostics: Test the fuel system to ensure proper flow and pressure

- Safety Precautions: Follow safety guidelines to prevent fuel spills and electrical hazards during replacement

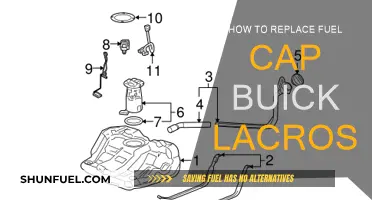

Accessing the Pump: Locate and remove the old fuel pump, often requiring engine disassembly

When it comes to replacing a fuel pump, accessing and removing the old one can be a challenging task, often requiring careful engine disassembly. Here's a step-by-step guide to help you navigate this process:

Locate the Fuel Pump: The first step is to identify the fuel pump's location. Fuel pumps are typically found near the fuel tank, often mounted on the engine's rail or bracket. Consult your vehicle's service manual or online resources to determine the exact position. The pump is usually connected to the fuel lines and may require some disassembly of the fuel system to gain access.

Prepare for Disassembly: Before you begin, ensure you have the necessary tools and safety equipment. You'll likely need a jack and jack stands to support the engine, especially if it's a rear-mounted fuel pump. Additionally, have a supply of new fuel filters and lines ready, as you may need to replace these during the process. It's crucial to drain the fuel tank and disconnect the fuel lines to prevent spills and ensure a safe working environment.

Engine Disassembly: Accessing the fuel pump often involves removing various engine components. Start by disconnecting the electrical connections to the pump. Carefully unplug the wires and set them aside. Then, locate and remove any screws or fasteners securing the pump's bracket or mounting plate. This may require removing other parts like the air filter housing or the intake manifold, depending on your vehicle's design. Take your time and be methodical to avoid losing any small components.

Remove the Old Pump: With the necessary components removed, you should now have access to the old fuel pump. Carefully lift the pump out of its mounting position. Be cautious as some pumps are heavy and may have delicate connections. If your vehicle has a pressure regulator or a check valve associated with the pump, remember to disconnect and set them aside as well. Once the old pump is out, inspect it for any signs of damage or wear that may have caused its failure.

Remember, each vehicle model is unique, so it's essential to consult specific repair manuals or online tutorials for your particular make and model. Proper preparation and a systematic approach will make the fuel pump replacement process more manageable.

Replacing Fuel Injector in Your 4Runner: Step-by-Step Guide

You may want to see also

Pump Selection: Choose a compatible replacement pump with the right specifications

When replacing a fuel pump, selecting the right replacement is crucial to ensure optimal performance and avoid potential issues. Here's a guide on how to choose a compatible and suitable pump:

Research and Compatibility: Begin by researching the specific make and model of your vehicle. Different car manufacturers use various fuel pump designs and specifications. Identify the exact year, make, and model of your car, as well as the engine type. This information will help you find a compatible replacement pump. Check vehicle manuals or online resources to understand the original equipment manufacturer (OEM) specifications for your car's fuel pump. This includes details such as the pump's flow rate, pressure requirements, electrical connections, and mounting dimensions.

Flow Rate and Pressure: One of the critical factors in pump selection is the flow rate and pressure requirements. The new pump should match or exceed the original pump's specifications. Flow rate is measured in gallons per minute (GPM) or liters per minute (LPM), indicating how much fuel the pump can deliver. Ensure you choose a pump with a flow rate suitable for your engine's needs. Higher-performance engines may require a pump with a higher flow rate to meet their demands. Additionally, check the pressure specifications. The pump should provide the necessary pressure to deliver fuel efficiently to the engine.

Electrical Compatibility: Fuel pumps are often electrically powered, so electrical compatibility is essential. Examine the electrical connections of the original pump and ensure the replacement pump uses the same wiring harness and connectors. This includes checking the voltage and current requirements to ensure the new pump can be powered correctly. Some vehicles may have specific electrical requirements, so consult the vehicle's manual or seek professional advice if needed.

Mounting and Size: Consider the physical dimensions and mounting style of the fuel pump. Ensure the replacement pump fits the designated space in your fuel tank or fuel module. Check the mounting holes and brackets to ensure they align with the existing setup. Some pumps may require modifications or additional brackets for installation, so plan accordingly.

Reliability and Quality: Opt for a reputable brand that offers high-quality replacement pumps. Well-known automotive suppliers often provide reliable and durable pumps that meet or exceed OEM standards. Reading reviews and seeking recommendations can help ensure you choose a pump known for its longevity and performance.

Remember, proper research and compatibility checks are essential to a successful fuel pump replacement. Taking the time to select the right pump will contribute to a smoother and more efficient operation of your vehicle's fuel system.

Dodge Nitro Fuel Filter Replacement: A Step-by-Step Guide

You may want to see also

Installation Process: Carefully install the new pump, ensuring proper connections and alignment

The installation process for replacing a fuel pump can be a challenging task, but with careful attention to detail, it is certainly achievable. Here's a step-by-step guide to ensure a successful replacement:

Step 1: Preparation and Safety

Before you begin, ensure you have the necessary tools and a well-lit, clean workspace. Fuel pump replacement often requires removing various components, so have your tools ready. Additionally, it's crucial to drain the fuel tank to prevent spills and ensure safety. Locate the drain valve and open it to release any residual fuel. This step is essential to avoid any messy situations during the installation.

Step 2: Locate and Remove the Old Pump

Identify the old fuel pump's location. It is typically mounted near the engine or in the fuel tank. Carefully disconnect the electrical connections and hoses attached to the pump. Take note of the connections' positions to ensure proper reattachment later. Carefully lift and remove the old pump, setting it aside for inspection or disposal.

Step 3: Prepare the New Pump

Lay out all the components of the new fuel pump. Ensure you have the pump, any necessary gaskets or seals, and the appropriate tools for installation. Check the manual or specifications for your vehicle to ensure you have the correct parts. Inspect the new pump for any signs of damage or defects before proceeding.

Step 4: Installation

Carefully position the new fuel pump in the designated location. Ensure it is aligned correctly and securely mounted. Reattach the electrical connections and hoses, making sure they are properly connected and tightened. Use the appropriate torque settings for the connections to avoid over-tightening. Double-check the alignment and security of the pump to ensure it won't shift during operation.

Step 5: Final Connections and Testing

Once the pump is installed, make any necessary final connections, such as securing hoses or adding any required seals. Refill the fuel tank and close the drain valve. Start the engine and monitor for any leaks or unusual noises. Check the fuel gauge to ensure the pump is functioning correctly and refilling the tank as expected. If everything is in order, you've successfully replaced the fuel pump.

Remember, fuel pump replacement requires patience and attention to detail. Take your time during each step, and if you encounter any specific issues, consult the vehicle's manual or seek guidance from an experienced mechanic.

Corvette Fuel Pump Replacement: Step-by-Step Guide for 2001 Models

You may want to see also

Testing and Diagnostics: Test the fuel system to ensure proper flow and pressure

When it comes to testing and diagnosing the fuel system for a fuel pump replacement, it's crucial to ensure that the system is functioning correctly to avoid any potential issues. Here's a step-by-step guide to help you through the process:

Step 1: Gather the Right Tools and Equipment

Before you begin, make sure you have the necessary tools and equipment. You'll need a fuel pressure gauge, a fuel system tester, a set of wrenches, and possibly a fuel system cleaner. These tools will help you measure pressure, test the system, and clean any debris or contaminants.

Step 2: Locate the Fuel Pump and Lines

Identify the fuel pump and its associated lines. The fuel pump is typically located near the engine and is responsible for supplying fuel to the engine. Locate the fuel lines, which carry fuel from the tank to the pump and then to the engine. Ensure you have easy access to these components for testing.

Step 3: Test Fuel Pressure

Use the fuel pressure gauge to measure the pressure at the fuel rail or the point where the fuel pump connects to the engine. Compare the reading to the manufacturer's specifications. If the pressure is significantly lower than the recommended range, it may indicate a faulty pump or restricted fuel lines.

Step 4: Inspect Fuel Flow

To test the flow, you can use a fuel system tester or a simple method by starting the engine and monitoring the fuel delivery. Listen for any unusual noises and check for consistent fuel flow. If the flow is inconsistent or there are any leaks, it could suggest a problem with the pump or the fuel lines.

Step 5: Check for Leaks and Contaminants

Inspect the fuel lines and connections for any signs of leaks or damage. Over time, fuel lines can develop cracks or become brittle, leading to fuel leaks. Additionally, use a fuel system cleaner to flush out any contaminants that may have accumulated in the system, ensuring optimal performance.

Step 6: Verify Pump Operation

With the engine running, listen for the pump's operation. It should produce a distinct humming or whirring sound. If the pump is not audible or operates erratically, it may need replacement.

By following these diagnostic steps, you can ensure that the fuel system is functioning correctly before proceeding with the replacement. Proper testing will help identify potential issues, making the fuel pump replacement process more efficient and effective.

Replacing Direct Fuel Injectors in Your 2010 MB: Step-by-Step Guide

You may want to see also

Safety Precautions: Follow safety guidelines to prevent fuel spills and electrical hazards during replacement

Before you begin the fuel pump replacement process, it's crucial to prioritize safety to avoid any potential hazards. Here are some essential safety precautions to follow:

Prepare the Workspace: Ensure you have a well-lit and spacious area to work on the vehicle. Cover the ground with a drop cloth or old newspapers to catch any potential spills. This simple step can help prevent fuel from damaging your workspace and the surrounding environment. Additionally, make sure to park the vehicle on a level surface to avoid any unexpected movement during the replacement process.

Fuel System Isolation: Locate the fuel pump and disconnect the fuel lines carefully. It is imperative to isolate the fuel system to prevent any accidental spills or leaks. Turn off the engine and allow it to cool down if it has been running. Release the fuel pump's pressure by opening the fuel tank vent or using a pressure release valve, following the manufacturer's instructions. This step is critical to avoid fuel spraying out when you remove the old pump.

Grounding and Electrical Safety: Fuel pumps are often connected to the vehicle's electrical system. When working on the fuel pump, it is essential to disconnect the battery to eliminate the risk of electrical shocks or short circuits. Proper grounding is crucial during this process to prevent static electricity discharge, which can ignite flammable fuel vapors. Use an appropriate grounding strap and ensure it is securely attached to the vehicle's metal body.

Personal Protective Equipment (PPE): Wear appropriate PPE, including gloves and safety goggles, to protect your hands and eyes from potential fuel splashes or debris. Consider wearing a respirator mask to avoid inhaling any harmful fumes that may be present in the fuel or during the removal process.

Follow Manufacturer's Guidelines: Each vehicle model may have specific instructions for fuel pump replacement. Refer to the vehicle's manual or the manufacturer's guidelines for detailed procedures and safety recommendations. These resources will provide valuable insights into the specific safety measures required for your particular vehicle.

By adhering to these safety precautions, you can significantly reduce the risks associated with fuel pump replacement, ensuring a safer working environment and minimizing the chances of accidents or damage to the vehicle. Remember, taking the time to follow these guidelines is essential for a successful and safe repair process.

Fuel Filter Replacement: What, Why, and How?

You may want to see also

Frequently asked questions

Fuel pump replacement can be a challenging task, especially for those without prior mechanical experience or knowledge. It requires a certain level of technical skill and access to the necessary tools and equipment. The process often involves removing various components, such as the fuel tank, to access the pump, which can be time-consuming and intricate.

Fuel pump issues can arise due to several factors. Common causes include wear and tear, contamination of the fuel system, electrical problems, or mechanical failures. Over time, the pump's internal components may degrade, leading to reduced performance or complete failure. Contaminated fuel, such as water or debris, can also cause pump damage.

DIY fuel pump replacement is possible for some vehicle owners with the right skills and resources. However, it's essential to have a good understanding of the vehicle's anatomy and the specific pump's location. Complex fuel systems and limited access in certain models might make it more feasible to seek professional assistance.

Yes, several specialized tools and equipment are required for fuel pump replacement. This may include fuel pump removal tools, fuel system pressure relief valves, fuel filters, and various sizes of sockets and wrenches. Additionally, having a good quality fuel pump tester can help ensure the correct pump is installed.