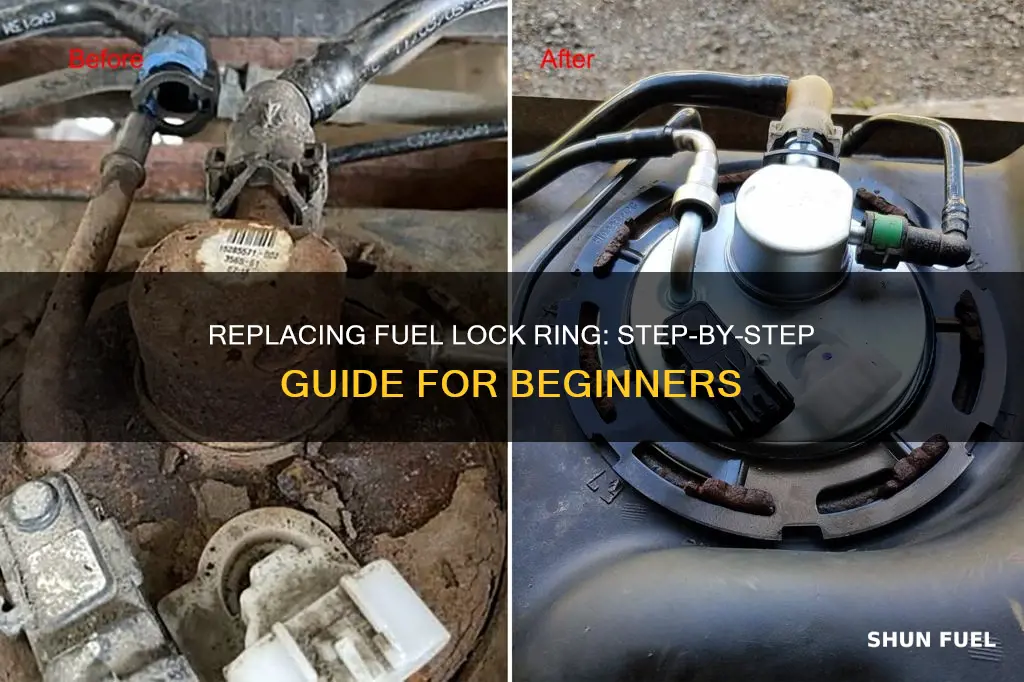

Replacing a fuel lock ring can be a challenging task, especially if the ring is rusty or corroded. The process typically involves removing the fuel pump and gasket, and then using a specialised tool or a pair of channel locks to twist and loosen the lock ring counter-clockwise. It is important to be cautious and avoid creating sparks when working with fuel system components. Some mechanics recommend using a rubber mallet or a hammer with a brass punch to apply force without causing damage. Before installing a new lock ring, it is essential to clean the area and ensure proper seating of the fuel pump and gasket.

What You'll Learn

Using a brass punch and hammer to knock the lock ring off

Step 1: Gather the Necessary Tools and Materials

You will need a brass punch, a hammer, safety goggles, and work gloves for this task. Brass punches come in various sizes, so ensure you select one that fits the lock ring dimensions. It is crucial to prioritize eye and hand protection during this process.

Step 2: Locate the Lock Ring

The lock ring is typically found on the fuel pump, securing it in place. Identify the lock ring's position and ensure you have unobstructed access to it.

Step 3: Position the Brass Punch

Place the tip of the brass punch at the edge of the lock ring. Ensure that the punch is firmly and accurately positioned before proceeding.

Step 4: Apply Controlled Force with the Hammer

Hold the hammer in your dominant hand and gently tap the end of the brass punch. The goal is to deliver controlled force to the lock ring without damaging the surrounding components. Strike the brass punch with moderate force, being careful not to hit the fuel pump or any other sensitive parts.

Step 5: Work Your Way Around the Lock Ring

Continue tapping the brass punch with the hammer in a clockwise or counterclockwise direction, depending on the lock ring's thread. Work your way around the lock ring, applying consistent force with each strike. This process will gradually loosen the lock ring, allowing you to unscrew it by hand or with a suitable tool.

Step 6: Remove the Lock Ring

Once the lock ring is sufficiently loose, use your fingers or a pair of pliers to remove it carefully. If you encounter significant resistance, stop and re-evaluate your technique. Forcing the lock ring may result in damage to the threads or the fuel pump itself.

Step 7: Clean and Inspect the Components

With the lock ring removed, clean and inspect the exposed components for any signs of damage or corrosion. This step is crucial to ensure that no debris or residue interferes with the proper seating of the new fuel pump.

Step 8: Install the New Fuel Pump

Follow the manufacturer's instructions to install the new fuel pump, ensuring it is securely seated and aligned correctly. This process may involve placing a new gasket or O-ring and reinstalling the lock ring, but be sure to tighten it by hand to avoid over-tightening.

Step 9: Test the Fuel Pump

After installing the new fuel pump, test it to ensure it functions correctly. Depending on your vehicle, you may need to turn on the ignition or perform a specific sequence of steps to prime the fuel pump. Consult your vehicle's manual or a mechanic if you are unsure about the testing procedure.

Replacing Fuel Injectors in Your Dodge Charger: Step-by-Step Guide

You may want to see also

Applying force to the lock ring

When applying force to the lock ring, it is important to exercise caution and employ the correct tools to avoid injury or damage to the lock ring. The process of applying force will depend on whether you are installing or removing the lock ring.

Removing the Lock Ring:

If you are removing a lock ring from a fuel tank, it is recommended to use a specialized tool designed for this purpose, such as a lock ring wrench or a pair of channel locks. These tools can grip the lock ring securely, allowing you to apply force and twist counter-clockwise to loosen and remove it.

Installing the Lock Ring:

When installing a new lock ring, it is important to ensure that all components are properly aligned and seated. Begin by threading the lock ring onto the wheel or module by hand. Lock rings are typically reverse-threaded, so you will need to turn it to the left to tighten it.

Next, use a lock ring wrench to securely grip the lock ring. Apply force and turn the wrench to the left to further tighten the lock ring in place. It is crucial to tighten the lock ring as much as possible to prevent it from loosening during use.

In some cases, you may need assistance from another person to apply additional force or to ensure that all components are properly aligned. Additionally, lubricants or adhesives, such as Loctite, can be used to aid in the installation process and prevent the lock ring from coming loose.

It is worth noting that the amount of force required to tighten the lock ring will depend on the specific application and the tools being used. In general, it is important to follow the manufacturer's instructions and recommendations for the specific lock ring and tools being used.

Replacing the Fuel Tank on a Santa Fe: Step-by-Step Guide

You may want to see also

Using a wrench to tighten the lock ring

To tighten the lock ring on a fuel tank, you will need a wrench or spanner that fits the lock ring. This may be a special fuel tank lock ring wrench, which can be purchased or rented, or a more general tool such as a pair of channel locks or a flat-head screwdriver.

Before attempting to tighten the lock ring, ensure that the area is free of debris and that there are no open flames or sparks nearby. If the lock ring is corroded, you may need to apply a penetrating lubricant and allow it to sit before attempting to tighten it.

To tighten the lock ring, align the wrench with the teeth or ribs on the outside of the lock ring. Apply firm, even pressure and turn the wrench clockwise to tighten the lock ring. If necessary, use a longer tool or breaker bar to increase your leverage. Ensure that the wrench is tight on the lock ring to prevent slipping. If possible, have a second person apply their weight to the tool while you tighten the lock ring.

If the lock ring is difficult to turn, you can try tapping it lightly with a rubber mallet while turning it. Alternatively, use a hammer to gently tap a flat-head screwdriver or punch against the lock ring as you turn it. It is important to avoid using excessive force, especially if you are using metal tools, as this could damage the lock ring or create sparks.

Replacing Fuel Line on Echo Trimmer: A Step-by-Step Guide

You may want to see also

Using a rubber safe lubricant to seat the seal when installing

When installing a fuel lock ring, a rubber-safe lubricant can be used to seat the seal. This is done to ensure that the seal sits properly when installing the lock ring.

There are a few options for lubricants that can be used. A thin film of engine oil will not cause any harm. If using a silicon-based material, it is important to ensure that there is no excess that could get inside the tank. Grease should not be used.

Another option is to use a synthetic oil, such as Redline or Stihl Ultra. A small amount of this oil can be wiped onto the seal. Two-stroke oil can also be used, although it should be noted that this type of oil may cause the O-rings to roll out, so extra care should be taken when installing them.

If you are looking for a lubricant that will not dissolve and will not cause Neoprene rubber to swell, DC4 (Dow Corning) compound is a good option. This product is a silicone-based grease that is compatible with gasoline and will not dissolve or cause swelling.

Finally, a small amount of Windex or spit can also be used as a lubricant. While these may not be as effective as some of the other options, they can work in a pinch.

Fuel Filter Replacement Guide for 2008 Toyota 4-Runners

You may want to see also

Measuring the ring and tank openings to find faults

When replacing a fuel lock ring, measuring the ring and tank openings to find faults is a crucial step to ensure a proper fit and prevent leaks. Here is a detailed guide on how to approach this task:

Gather the Necessary Tools:

Before beginning the measurement process, ensure you have the required tools on hand. You will need a caliper, which is a precision measuring instrument used to accurately measure the dimensions of the ring and tank openings.

Inspect the Fuel Lock Ring:

Begin by carefully examining the fuel lock ring. Look for any signs of damage, warping, or deformation. Pay close attention to the ring's overall flatness and the condition of its edges. Any irregularities or deviations from its original shape can affect its ability to seal properly.

Measure the Fuel Lock Ring:

Using the caliper, take measurements of the fuel lock ring's inner and outer diameters. Ensure that the caliper's jaws are firmly but gently clamped onto the ring to obtain accurate readings. Take measurements at multiple points along the ring to check for any inconsistencies or variations in its dimensions. Compare these measurements against the specifications provided by the manufacturer or a trusted source. This will help you determine if the ring is the correct size and has not been distorted during installation or removal.

Inspect the Tank Opening:

Proceed to inspect the tank opening where the fuel lock ring sits. Ensure that the opening is free from debris, corrosion, or any damage that could affect the seal. Look for any signs of deformation or irregularities that might hinder the proper seating of the fuel lock ring.

Measure the Tank Opening:

Using the caliper, carefully measure the inner diameter of the tank opening. Take measurements at several points along the circumference to verify consistency. Compare these measurements to the specifications provided by the manufacturer or vehicle's service manual. This will help identify if there are any discrepancies that could impact the fuel lock ring's fit.

Compare Measurements and Identify Faults:

By comparing the measurements of the fuel lock ring and tank opening, you can identify any faults or incompatibilities. If the ring's dimensions fall significantly outside the specified range, it may be the wrong size or damaged. Additionally, if the tank opening measurements deviate from the expected values, there could be an issue with the fuel tank itself, such as warping or damage.

Address Identified Faults:

If faults are identified during the measurement process, take appropriate corrective actions. This may involve sourcing a new fuel lock ring that conforms to the specified dimensions or addressing any issues with the tank opening, such as removing debris, repairing damage, or seeking professional assistance if the tank is deformed.

Measuring the fuel lock ring and tank openings is a critical step in ensuring a proper seal and preventing fuel leaks. By following the outlined steps, you can identify and address any faults, ensuring a secure and reliable installation.

Replacing the Fuel Filter in Your GLK250: When and Why

You may want to see also

Frequently asked questions

You can use a rubber hammer and a plastic-handled screwdriver, or a brass punch. You can also use a real hammer and something that won't create a spark, like a short length of copper pipe.

Try using a lubricant to help the seal seat properly. You can also try using a metal hammer and hitting harder.

Check that the pump is sitting in the tank correctly. If it is, then the issue may be with the O-ring. Try using the old O-ring if you have it, or check that the new O-ring is compatible with your vehicle.

You may need to replace the tank. Check if the threads on the ring and the tank are faulty. If there is no fault, you will need to measure each opening and compare until you find the issue.

You may need to replace the O-ring.