Replacing a fuel sending unit is a crucial task for maintaining the performance and safety of your vehicle. This process involves replacing the component responsible for measuring and sending fuel level information to the engine control unit. It's important to understand the specific steps and requirements for your vehicle model, as the process can vary depending on the make and year of your car. This guide will provide a step-by-step overview of how to replace a fuel sending unit, ensuring you have the necessary knowledge to complete the task safely and effectively.

| Characteristics | Values |

|---|---|

| Vehicle Model Compatibility | Specific to the vehicle model and year |

| Fuel Type | Gasoline or diesel |

| Fuel Sending Unit Location | Usually in the fuel tank or near the engine |

| Tools Required | Wrenches, screwdrivers, fuel pump relay tester, multimeter |

| Safety Precautions | Turn off the engine, disconnect the battery, drain fuel, use safety gear |

| Diagnosis | Check for fuel pressure, inspect for leaks, test the sending unit with a multimeter |

| Replacement Steps | 1. Drain fuel and remove the old unit. 2. Install the new sending unit, ensuring proper alignment. 3. Reattach fuel lines and secure. |

| Testing | Start the car and check for fuel pressure and sending unit functionality using a scan tool. |

| Common Issues | Malfunctioning fuel pumps, clogged fuel lines, faulty sensors |

| Maintenance | Regularly check for corrosion and ensure proper fuel system maintenance. |

What You'll Learn

- Preparation: Gather tools, safety gear, and a replacement unit before starting

- Location: Identify the fuel sending unit's location under the hood or tank

- Removal: Disconnect electrical connections and release clips to remove the old unit

- Installation: Align the new unit, secure it, and reconnect wiring

- Testing: Check for proper function with a multimeter and start the engine

Preparation: Gather tools, safety gear, and a replacement unit before starting

Before you begin the process of replacing a fuel sending unit, it's crucial to prepare and gather the necessary tools, safety equipment, and a replacement part to ensure a smooth and efficient repair. Here's a step-by-step guide to help you get ready:

Tools and Equipment: Start by making a list of the tools you'll need. This process requires precision and the right equipment to avoid any complications. You'll likely need a wrench or a socket set to loosen and remove the fuel sending unit. A new fuel sending unit, compatible with your vehicle's make and model, is essential. Additionally, consider getting a fuel filter and a fuel pump if your old unit is faulty or if you plan to replace multiple components. Other tools might include a fuel gauge tester, a multimeter, and various sizes of screwdrivers or hex keys for any additional fasteners.

Safety Gear: Protecting yourself is paramount during any automotive repair. Safety gear includes gloves to protect your hands from sharp edges and potential fuel leaks. Safety goggles are essential to shield your eyes from any debris or fuel that may spray during the process. Additionally, consider wearing old clothing that you don't mind getting dirty or damaged.

Replacement Unit: Ensure you have a replacement fuel sending unit that is compatible with your vehicle. Check the specifications and dimensions of the old unit to find an exact match. You can purchase this from an auto parts store or online retailer, ensuring you have the correct part for your specific car or truck. Having the replacement unit ready will save time and prevent any delays during the installation process.

Work Area Preparation: Choose a suitable work area, preferably a well-lit and clean garage or driveway. Ensure you have a stable surface to work on, and consider using a jack and jack stands if your vehicle requires lifting. A well-organized workspace will make the repair process more efficient and safer.

By gathering these items and preparing your work area, you'll be well-equipped to tackle the fuel sending unit replacement. This preparation phase is crucial to ensure you have everything you need to complete the job successfully and safely.

Replacing the Fuel Pump in Your 2004 Infiniti FX35

You may want to see also

Location: Identify the fuel sending unit's location under the hood or tank

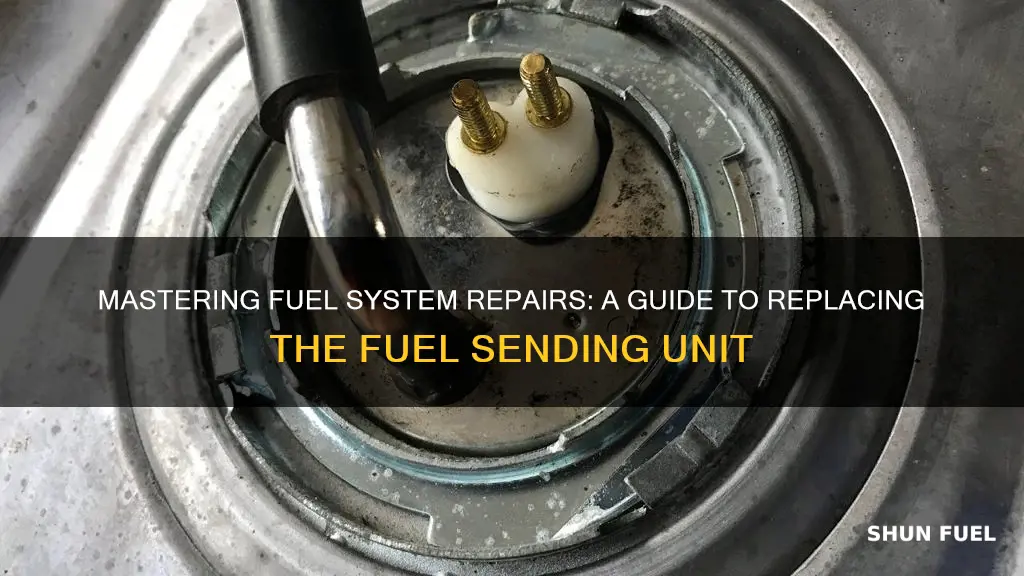

When it comes to replacing a fuel sending unit, locating it is the first crucial step. The fuel sending unit is a vital component of your vehicle's fuel system, responsible for measuring the fuel level and sending this information to the engine control unit (ECU). It is typically located either under the hood or inside the fuel tank.

Under the hood, it is usually positioned near the front of the engine compartment, often close to the firewall. It is designed to be easily accessible for maintenance and repairs. Look for a small, cylindrical-shaped component that is connected to the fuel tank by a rubber hose. This unit has a float inside it that rises and falls with the fuel level, allowing it to send the correct signal to the ECU.

If you can't find it under the hood, it's likely located inside the fuel tank. In this case, you will need to access the tank, which is usually done by removing the fuel filler cap and lifting the tank. The sending unit is often attached to the inside wall of the tank with brackets or clips. It may be a separate component or integrated into the fuel pump assembly.

Identifying the exact location can be made easier by referring to your vehicle's service manual, which will provide detailed diagrams and instructions specific to your make and model. This is especially important if your car has a complex fuel system or if the sending unit is located in a less accessible spot.

Once you've located the fuel sending unit, you can proceed with the replacement process, ensuring that you have the necessary tools and a clear understanding of the steps involved.

Replacing Fuel Pump in Chevy Trailblazer: Step-by-Step Guide

You may want to see also

Removal: Disconnect electrical connections and release clips to remove the old unit

To begin the process of replacing a fuel sending unit, you'll need to carefully disconnect the electrical connections and release any clips that secure the old unit in place. This step is crucial to ensure a smooth and safe removal process. Start by locating the electrical connections, which are typically found near the fuel tank. These connections are often in the form of small wires or connectors that attach to the sending unit. Carefully detach these wires, taking note of their positions and the order in which they are connected. This information will be essential when reconnecting the new unit.

Once the electrical connections are disconnected, you'll need to locate and release the clips that hold the sending unit in place. These clips are usually small metal or plastic fasteners that secure the unit to the fuel tank or surrounding structure. Carefully inspect the clips and identify their exact location. You may need to use a small screwdriver or a specialized tool to release the clips without causing any damage. Gently pry the clips open, being mindful of any nearby components that could be affected.

As you release the clips, you might notice that the sending unit starts to become loose. At this point, it's important to handle the unit with care to avoid any accidental damage. Gently pull the sending unit away from the fuel tank, ensuring that you don't force it. The unit should now be free from the tank, and you can set it aside for disposal or further inspection.

Remember, the key to a successful removal is patience and a gentle approach. Take your time to carefully disconnect the electrical connections and release the clips without causing any damage to the surrounding components. This detailed and methodical process will make the subsequent installation of the new fuel sending unit much easier and more efficient.

When to Replace Your Fuel Filter: Signs to Watch For

You may want to see also

Installation: Align the new unit, secure it, and reconnect wiring

When replacing a fuel sending unit, proper installation is crucial to ensure optimal performance and prevent potential issues. Here's a step-by-step guide for the installation process, focusing on aligning, securing, and reconnecting the new unit:

Alignment: Begin by carefully inspecting the fuel tank and locating the mounting points for the new sending unit. Most units have specific markings or notches to guide installation. Carefully lift the old sending unit (if present) to create space for the new one. Line up the new unit with the mounting holes, ensuring it is positioned correctly and aligned with the fuel tank's interior. Pay close attention to the orientation to guarantee accurate placement.

Securing the Unit: Once aligned, secure the new fuel sending unit in place. Use the appropriate fasteners provided with the unit. Typically, this involves tightening screws or bolts through the mounting holes. Ensure the unit is firmly attached and cannot move or shift under engine operation. Double-check the tightness of the fasteners to avoid any potential vibrations or dislodging during driving.

Wiring Reconnection: After securing the unit, carefully reconnect the wiring harness. Locate the wiring connections on the sending unit and match them with the corresponding terminals on the fuel pump and the vehicle's wiring harness. Ensure that all wires are properly connected and secured to prevent any interference or damage. Tighten any connectors securely, but be mindful not to overtighten, as this can damage the wiring.

Final Checks: Before starting the engine, perform a few crucial checks. Ensure all connections are secure and there are no visible signs of damage or interference. Verify that the fuel gauge reads zero when the tank is empty and rises correctly as fuel is added. Test the fuel pump operation by starting the engine and monitoring the fuel flow. If everything functions as expected, you've successfully replaced the fuel sending unit.

Remember, each vehicle model may have slight variations in the installation process, so always refer to the manufacturer's instructions or consult a professional mechanic for specific guidance tailored to your vehicle.

Fuel Line Maintenance: Replacing Vital Lines on 944 Turbos

You may want to see also

Testing: Check for proper function with a multimeter and start the engine

Before you begin the replacement process, it's crucial to test the fuel sending unit to ensure it's the culprit for any issues. This step will help you avoid unnecessary replacements and save time and resources. Here's a detailed guide on how to test the fuel sending unit using a multimeter:

Step 1: Prepare the Vehicle and Tools

Ensure the vehicle is parked on a level surface and the engine is off. Disconnect the negative battery terminal to prevent any accidental electrical discharges. Gather the necessary tools, including a multimeter, a set of wrenches, and a fuel pump primer (if needed).

Step 2: Locate the Fuel Sending Unit

Locate the fuel sending unit, which is typically mounted near the fuel tank. It is connected to the fuel line and has electrical connections for power and ground. Carefully inspect the unit for any signs of damage or corrosion.

Step 3: Multimeter Testing

- Set your multimeter to the ohms (Ω) or continuity mode. This will allow you to check for electrical continuity and resistance.

- Locate the electrical connections of the fuel sending unit. There should be two wires: one for power (usually red) and one for ground (usually black).

- Touch the multimeter's probes to the fuel sending unit's electrical connections. The multimeter should display a low resistance reading (typically below 1 ohm) if the unit is functioning properly. This indicates a good electrical connection.

- If the multimeter shows an open circuit or high resistance, it suggests a faulty sending unit. However, it's essential to consider other potential issues, such as a broken wire or a faulty fuel gauge.

Step 4: Starting the Engine

- Reconnect the negative battery terminal and ensure all electrical connections are secure.

- Start the engine and allow it to idle.

- Check the fuel gauge on the dashboard. It should be functioning correctly, indicating the fuel level accurately.

- If the fuel gauge is unresponsive or erratic, it may indicate a faulty sending unit. However, other issues like a faulty gauge or gauge wiring should be considered.

Step 5: Verify the Results

After testing, carefully observe the fuel gauge's behavior and the multimeter readings. If the fuel sending unit is functioning correctly, the fuel gauge should respond accurately, and the multimeter should show low resistance at the electrical connections. If any issues persist, further investigation is required to identify the root cause.

Remember, this testing process is a crucial step in diagnosing fuel sending unit problems. It helps narrow down the potential causes and ensures that the replacement is performed only when necessary. Always exercise caution when working with electrical systems and consult the vehicle's manual for specific instructions related to your make and model.

Fuel Rail Replacement: When is the Right Time?

You may want to see also

Frequently asked questions

A fuel sending unit, also known as a fuel level sensor, is a crucial component in a vehicle's fuel system. It is responsible for measuring the fuel level in the tank and sending this information to the engine's computer, which then displays the fuel level on the dashboard. Over time, this unit can malfunction due to wear and tear, corrosion, or damage from contaminants in the fuel. Common issues include inaccurate fuel readings, sensor failure, or electrical problems.

There are several signs that may indicate a faulty fuel sending unit. These include erratic or inaccurate fuel gauge readings, difficulty starting the engine, stalling, or the check engine light coming on. If you notice a sudden drop in fuel efficiency or if the fuel gauge reads lower than the actual fuel level, it could be a sign of a failing sensor. It is recommended to have the vehicle inspected by a professional mechanic to diagnose the issue accurately.

Replacing a fuel sending unit can be a complex task and is generally not recommended for DIY enthusiasts. It requires specialized tools and knowledge of the vehicle's fuel system. If you decide to attempt it, ensure you have the necessary skills and equipment. Otherwise, it is best to consult a professional mechanic who can safely and accurately replace the unit, ensuring proper functionality and avoiding potential hazards associated with fuel system repairs.