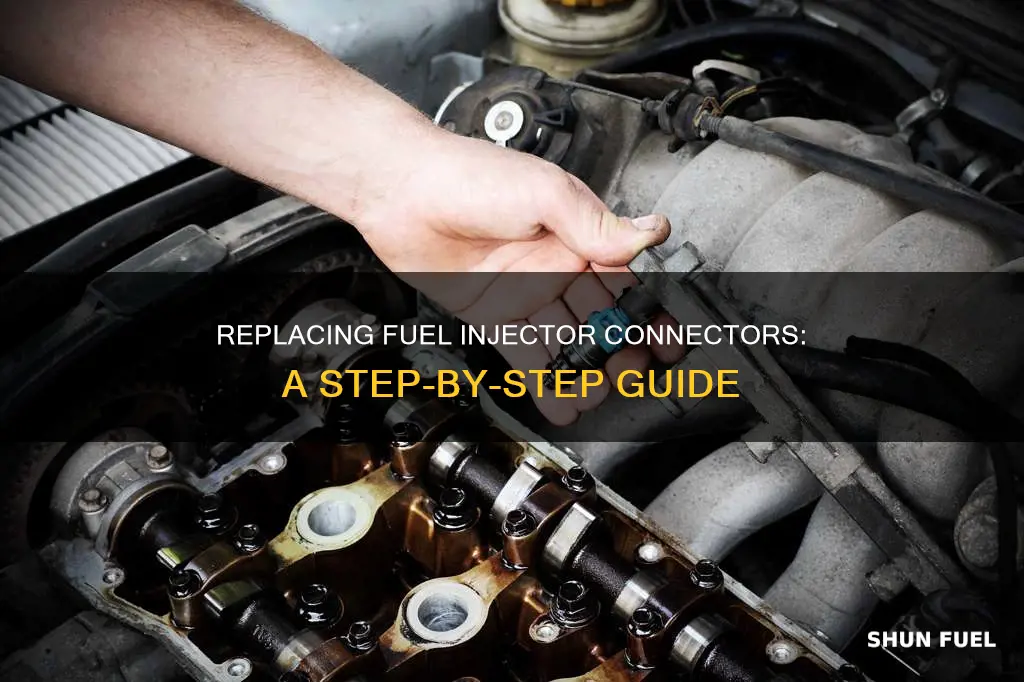

Replacing a fuel injector connector can be a tricky task, especially if the connector is old and brittle. The process may involve removing the fuel rail first to access the connector, using tools like a small flat-head screwdriver or a pick to release the metal clip holding the connector in place. It's important to be careful when handling the connector to avoid damaging the terminals or wires. In some cases, it may be necessary to cut the wires and solder new connectors. When replacing the connector, it's crucial to ensure that the wires are securely seated and that the correct type of connector is used for a proper fit.

What You'll Learn

Removing the old fuel injector connector

First, gather the necessary tools. In some cases, a terminal remover or a small flat-head screwdriver may be needed to release the connector. It is also recommended to have a pick tool or a small jeweler's flat-head screwdriver to help with the removal process.

Next, locate the fuel injector connector. If it is still connected to the fuel injector, you may need to remove the fuel rail first to access the connector more easily. This will provide more space to work on detaching the connector.

Once you have access to the connector, examine it for any release buttons or metal clips that need to be pressed or manipulated to release it. In some cases, there may be a locking tab on the backside of the connector that needs to be bent back with a small tool. Gently pry or lift the locking tab towards the centre of the connector to release it.

If the connector is brittle or cracked, exercise caution when attempting to remove it. In some cases, it may be necessary to cut the connector carefully to avoid damaging the wires or other components. Ensure that you cut as close as possible to the terminal to minimise wire loss.

After detaching the old connector, you may need to strip the insulation from the wires before installing the new connector. This can be done carefully with a suitable tool, such as a wire stripper or a small knife. Be cautious not to damage the wires during this process.

Finally, prepare the wires for the new connector by crimping on the new terminal. Ensure that the wires are inserted securely into the new connector until you hear a clicking sound. Gently pull on the wires to ensure they are properly seated.

Remember to take your time during the removal process and be gentle with the wires and components to avoid any damage. If you encounter any difficulties, it is always recommended to seek professional assistance or refer to vehicle-specific repair manuals for more detailed instructions.

Replacing Fuel Lines on Mercury Outboards: A Step-by-Step Guide

You may want to see also

Cutting the wires

When it comes to cutting the wires of a fuel injector connector, there are a few things to keep in mind to ensure a safe and effective replacement. Here is a step-by-step guide:

- Assess the Condition: Before cutting any wires, it is important to thoroughly inspect the fuel injector connectors. Look for any signs of damage, such as brittle or cracked connectors, which may hinder the removal process.

- Gather the Right Tools: Ensure you have the necessary tools on hand to make clean and precise cuts. A good pair of wire cutters or diagonal pliers can help you cut through the wires efficiently.

- Cut at the Tip: When cutting the wires, it is recommended to cut them as close as possible to the tip, near the terminal. This minimizes wire loss and makes it easier to attach the new connector.

- Strip the Insulation: Once you have cut the wires, use a wire stripper to carefully remove the insulation from the ends of the wires. This will expose the fresh wire, ready for the new connector.

- Measure and Cut New Wire: If you need to extend the wire length due to cutting, measure the amount of wire lost and cut a new piece of wire to match. Ensure you use the same gauge wire, which you can source from a junkyard or auto parts store.

- Connect the New Wire: Solder or crimp the new wire onto the existing wire, ensuring a secure connection. This will create an extended wire that can reach the new connector.

- Attach the New Connector: With the new wire in place, attach the new fuel injector connector according to the manufacturer's instructions. This may involve crimping or soldering, depending on the type of connector.

- Test the Connection: Once the new connector is in place, test the fuel injector to ensure a proper connection. Refer to your vehicle's manual to verify the correct procedure for testing.

Remember to take all necessary safety precautions when working with fuel injectors and wires. It is important to work with care and precision to avoid any damage to the engine or electrical system. Always refer to your vehicle's repair manual for specific instructions pertaining to your make and model.

Replacing the Fuel Pump in a '97 Mazda MPV

You may want to see also

Sourcing a replacement connector

First, it is important to know that there are different types of fuel injector connectors available in the market. The most common types are EV1 and EV6 connectors, which are also known as Jetronic or Minitimer connectors. These connectors are typically used in automotive, truck, and marine applications. When sourcing a replacement connector, it is crucial to visually identify the type of connector you need by comparing it to detailed pictures available online or in product catalogues.

You can find replacement fuel injector connectors at various retailers, including online stores and automotive parts stores. Here are some specific options for sourcing a replacement connector:

- Online Stores: Websites such as Amazon, Injector Repair LLC, and O'Reilly Auto Parts offer a wide range of fuel injector connectors for different vehicle makes and models. They provide detailed product descriptions, customer reviews, and often have helpful resources for identifying the correct connector for your vehicle.

- Automotive Parts Stores: Local auto parts stores, such as Oreilly Auto Parts, can be a great resource for sourcing replacement connectors. Their staff can help you identify the correct connector for your vehicle and provide advice on the installation process.

- Manufacturer Websites: If you own a Volvo, for example, you can visit the official Volvo website or authorised dealers to source replacement connectors specifically designed for your vehicle. This ensures compatibility and can provide peace of mind.

- Salvage Yards: While not ideal, salvage yards can be a last resort for sourcing replacement connectors. You may be able to find used connectors that can be reused or modified to fit your vehicle. However, this option may require more time and effort.

When sourcing a replacement connector, it is essential to consider the quality and compatibility of the part. Always opt for high-quality connectors made from durable materials, such as heat-resistant nylon and metal terminals. Additionally, ensure that the connector you choose is specifically designed for your vehicle's fuel injector system to ensure a proper fit and reliable performance.

Replacing the Fuel Filter in Your 1999 Toyota Sienna

You may want to see also

Disassembling the new connector

Step 1: Using a 90-degree pick tool, carefully insert it under the red locking piece of the connector. This piece locks the wires in place, and you will need to push it straight up to release it. Be gentle to avoid accidentally prying or breaking any parts.

Step 2: Once the red locking piece is removed, you will expose the inner workings of the connector. Look for the two small plastic prongs that hold the metal connector in place. These prongs are delicate, so be cautious when handling them.

Step 3: Using a small flat-head screwdriver or a similar tool, carefully pry down on one of the plastic prongs. You will need to apply just enough force to release the wire without breaking the prong. Repeat this step for the other prong if necessary.

Step 4: With the prongs released, you can now gently pull out the wires from the connector. Take care not to damage the wires or the surrounding components. If the wires seem stuck, gently wiggle them back and forth while pulling to release them.

Step 5: At this point, the new connector should be fully disassembled. Set the individual parts aside in a safe place, making sure to keep them oriented correctly for easier reassembly.

Step 6: Before proceeding, take a moment to inspect the old connector that you will be replacing. It is recommended to replace all the connectors at once, as they will eventually wear out. Practice disassembling and reassembling the new connectors until you feel confident in your technique.

Remember to work with patience and precision, as fuel injector connectors are delicate and crucial for the proper functioning of your vehicle's fuel system.

Replacing the Fuel Pump in Your 1996 Buick Regal: Step-by-Step Guide

You may want to see also

Reassembling the new connector

To reassemble the new connector, you will need to have a pick tool, ideally a 90-degree pick, to avoid accidentally stabbing your fingers.

Firstly, you will notice a small notch under the red piece of the connector. This is where you need to insert the pick tool and push the piece straight up. This will release the red piece, which can then be removed.

Next, look inside the connector. You should see two small plastic prongs that hold the metal connector in place. Carefully pry down on these plastic prongs, just enough to be able to pull the wire out.

Now, take the old connector and remove both wires, ensuring you insert them both into the new connector at the same time. This will ensure the correct wire length and a secure fit. You do not need to hold the little black plastic prong out of the way when installing the wires. Simply push them in until you hear a click, and then double-check by pulling on the wires to ensure they are seated correctly.

Finally, reinstall the red hold-down piece that was removed earlier, and your new connector is now assembled and ready to be installed.

Refueling Non-Athletes: Healthy Energy Sources for Everyday People

You may want to see also

Frequently asked questions

You have to pull the metal clip to the side. Use a small flat screwdriver to pull the end of the clip to release it.

There is no off-the-shelf mainstream parts list for the wiring harness. You can either force yourself to splice better factory-used connections or go to a junkyard and cut some wires to extend the connection.

From the open end, on the back side, use the opposite side from the picture. Get in there and bend back the locking tab.

Use a Dremel with a teensy-toothed cutoff, score down close to the terminals, then prise the cut pieces apart with a flat-blade screwdriver.