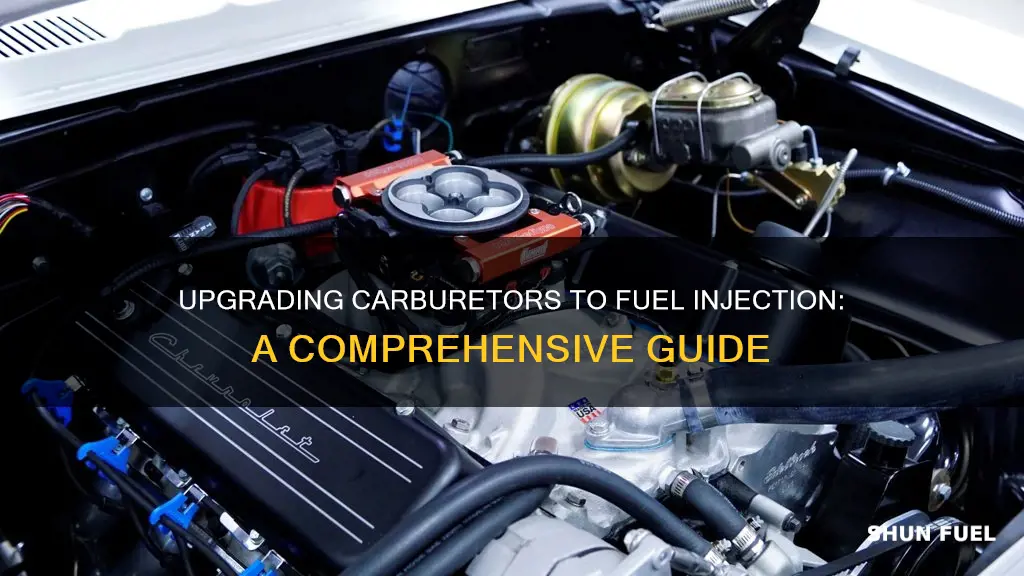

Replacing a carburetor with fuel injection is a modification that many car enthusiasts consider. Carburetors and fuel injection systems both perform the crucial task of combining fuel and air in the engine's combustion chamber, but their unique concepts and workings significantly impact vehicle design and operation. Carburetors played a crucial role in the development of internal combustion engines, but technological advancements have mostly replaced them with more accurate and economical substitutes such as fuel injection systems. Fuel injection in automobiles is a key innovation that has revolutionized how engines work by bringing about increased economy, higher performance, and lower emissions. It has replaced conventional carburetor systems, delivering fuel to the engine cylinders with more control and precision.

| Characteristics | Values |

|---|---|

| Reasons to convert | Fuel efficiency, improved performance, easier starting, better reliability, improved drivability in all weather and elevations, improved emissions, improved fuel economy, improved throttle response, reduced maintenance |

| Tuning the chip | One of the most difficult parts of the DIY fuel injection conversion |

| Removing the carburetor | Take off the fuel lines and hoses that come from the carburetor; it is mounted to the manifold by nuts, which can be removed with a wrench |

| Injector installation | Injectors need to be installed into the intake manifold, which may require welding and a machine shop |

| Throttle body installation | Bolt the throttle body on and hook it up at the throttle linkage, connected to the accelerator pedal; an idle air controller is also needed |

| Sensor installation | An oxygen sensor, manifold air pressure sensor, air temperature sensor, coolant sensor and throttle position sensor are needed |

| Distributor adjustment | The new EFI system controls the timing and advance of the ignition, so these will need to be locked out of the distributor |

| Electronics setup | The easiest way to install is to get an aftermarket system; all of the necessary components are programmed in and by connecting the computer to a laptop you can customise the different settings |

What You'll Learn

Removing the carburetor

Locate the Fuel Lines and Hoses: Begin by identifying all the fuel lines and hoses that are connected to the carburetor. These lines and hoses supply fuel to the carburetor and need to be disconnected before removing the carburetor.

Disconnect the Fuel Lines: Using appropriate tools, carefully disconnect the fuel lines and hoses from the carburetor. Make sure to place a container underneath to catch any spilled fuel and absorb it with a clean rag.

Loosen the Nuts: The carburetor is usually mounted to the manifold with nuts. Use a suitable wrench to loosen and remove these nuts. Keep them in a safe place as you may need them later.

Remove the Carburetor: Once the nuts are removed, carefully lift and detach the carburetor from the manifold. Be cautious as the carburetor may be heavy and you don't want to damage any nearby components.

Dispose or Sell the Carburetor: If the carburetor is in good condition, you can consider selling it as a used part. Alternatively, if it is beyond repair, take it to a junkyard for disposal.

Clean the Area: Before proceeding with the installation of the fuel injection system, it is essential to clean the area where the carburetor was mounted. Remove any dirt, debris, or residue that may have accumulated over time.

At this point, you have successfully removed the carburetor from your vehicle. The next steps would involve preparing for and installing the fuel injection system, which may include tasks such as welding, sliding in injectors, and installing injection fuel rails or a throttle body. Remember to refer to a reliable conversion kit manual or seek professional assistance if needed.

Trimmer Fuel Line Replacement: A Step-by-Step Guide

You may want to see also

Installing injectors in the intake manifold

Step 1: Choose the Right Injectors and Fuel Rails

Before you begin, it is crucial to select the appropriate injectors and fuel rails for your specific engine and desired power output. Injector sizing depends on the horsepower your engine produces and the type of fuel you intend to use. Additionally, ensure that your intake manifold can accommodate the fuel rails and injectors. Some manifolds may require modifications or adaptations to fit the injectors.

Step 2: Prepare the Injectors and Fuel Rails

Inspect the injectors and fuel rails for any debris or residue. Clean them if necessary to ensure there is no dirt or grease that could hinder the performance of the injectors. You can use motor oil or silicone grease on the rubber O-rings of the injectors to help with sealing and prevent damage during installation.

Step 3: Install the Injectors

There are two common methods for installing the injectors:

- Injector-First Method: Insert the injectors into the intake manifold first, ensuring they are properly seated and aligned. Then, install the fuel rail by dropping it down over the injectors and securing it in place.

- Fuel Rail-First Method: Lubricate the O-rings of the injectors and insert them into the fuel rail. Carefully lower the assembled fuel rail and injectors into the intake manifold, ensuring that the injectors are correctly seated in the manifold.

Step 4: Secure the Fuel Rail

Once the injectors and fuel rail are in place, tighten the bolts that secure the fuel rail to the intake manifold. Ensure that the bolts are adequately tightened to prevent leaks and ensure a firm connection.

Step 5: Test and Adjust

After installation, it is crucial to test the injectors and fuel system for any leaks. Check all connections and O-rings for signs of leakage. If leaks are detected, retighten the connections and ensure all O-rings are properly seated. Additionally, fine-tuning the injectors' position and spray pattern may be necessary to achieve optimal performance.

Step 6: Finalize the Installation

Once you are satisfied with the injectors' performance and there are no leaks, finalize the installation by securing any remaining components and ensuring that all connections are tight and secure.

It is important to note that this process may vary depending on the specific engine and fuel injection system you are working with. Always refer to the manufacturer's instructions and seek expert advice if needed.

Fuel Pump Replacement Guide for Dodge Charger Owners

You may want to see also

Installing the throttle body

The installation of a throttle body injection system is a straightforward process, especially if your engine is already equipped with a four-barrel carburetor, as the throttle body will simply take the place of the carburetor. However, there are a few additional components and considerations necessary for an EFI setup that are not required for a standard carburetor system.

Firstly, a return line must be used with EFI kits, and the ease of this addition will depend on your specific application. If you are building a truck from scratch, it is advisable to order a tank with a bung already installed for this purpose. For those retrofitting an old tank, it is a more involved process but can still be achieved by manipulating a later-model sending unit to accommodate a return line.

Secondly, consider the addition of electrical draws from a switched key source. Older trucks may not have sufficient fuse panel outlets to accommodate the components of a fuel injection system, so ensure you have a proper source to draw power.

Once these considerations have been addressed, it is a straightforward process to install the necessary components and replace your carburetor with a modern fuel injection system. Remember to refer to the specific instructions provided with your chosen EFI kit, as different kits may have unique requirements or installation processes.

It is also important to note that EFI systems require a good fuel pump and clean wiring for optimal performance. The fuel pump should be able to flow at least 255 liters per hour, and the EFI system should be wired directly to the battery with clean power, ensuring that the engine block and chassis are grounded.

Replacing the Fuel Pump in Your 370Z: Step-by-Step Guide

You may want to see also

Installing the sensors

In order for the EFI system to monitor and adjust the injection, several measurements need to be taken. If they are not already in place, several sensors need to be installed. These include an oxygen sensor, manifold air pressure sensor, air temperature sensor, coolant sensor, and throttle position sensor.

The sensors are fairly easy to install, as most simply screw into the engine. The kit should contain everything you need, but there are also sensor packages available if not.

The oxygen sensor is particularly important for fine-tuning the EFI system. It provides the ECU with information about how the engine is performing, allowing the system to add or subtract fuel as needed to meet the target air-fuel ratio.

The manifold air pressure sensor measures the air pressure in the intake manifold, which is crucial for determining the amount of fuel needed for the air-fuel mixture.

The air temperature sensor and coolant sensor monitor the temperature of the air and coolant, respectively, which helps the EFI system adjust the fuel injection to maintain optimal engine performance.

The throttle position sensor measures the position of the throttle valve, which indicates how much air is entering the engine. This information is used by the EFI system to adjust the fuel injection accordingly.

By installing these sensors, the EFI system will be able to collect the necessary data to optimise the engine's performance, improve fuel efficiency, and reduce emissions.

Replacing Fuel Vapor Canister Filter: Step-by-Step Guide

You may want to see also

Setting up the electronics

It is important to ensure that the wiring is of good quality. As Holley EFI engineer, Matt Lunsford, points out, "Good wiring is just as important as the fuel system... Grounds are a big deal – you have to make sure that the engine block is grounded directly to the battery, that the chassis is grounded directly to the battery, and that you have ‘clean’ power – you can’t have the power split between a bunch of fuses and that sort of thing."

Once everything is tuned to the desired performance, the vehicle is ready to go.

Replacing Fuel Pump in 225 Slant Six Engines: Step-by-Step Guide

You may want to see also

Frequently asked questions

Fuel injection offers greater fuel efficiency, improved performance, and lower emissions. It also provides better throttle response, a smoother acceleration, and higher power output.

The easiest way to convert from a carburetor to fuel injection is to use a fuel injection conversion kit. These kits are DIY-friendly and can be purchased from companies like FiTech, Holley, and MSD.

One of the most difficult parts of a fuel injection conversion is tuning the chip that runs the electronic fuel injection (EFI).

To remove a carburetor, you will need a wrench to remove the nuts that mount it to the manifold. You may also need machining tools, depending on the specific conversion.

For a fuel injection system to function properly, you will need an oxygen sensor, manifold air pressure sensor, air temperature sensor, coolant sensor, and throttle position sensor.