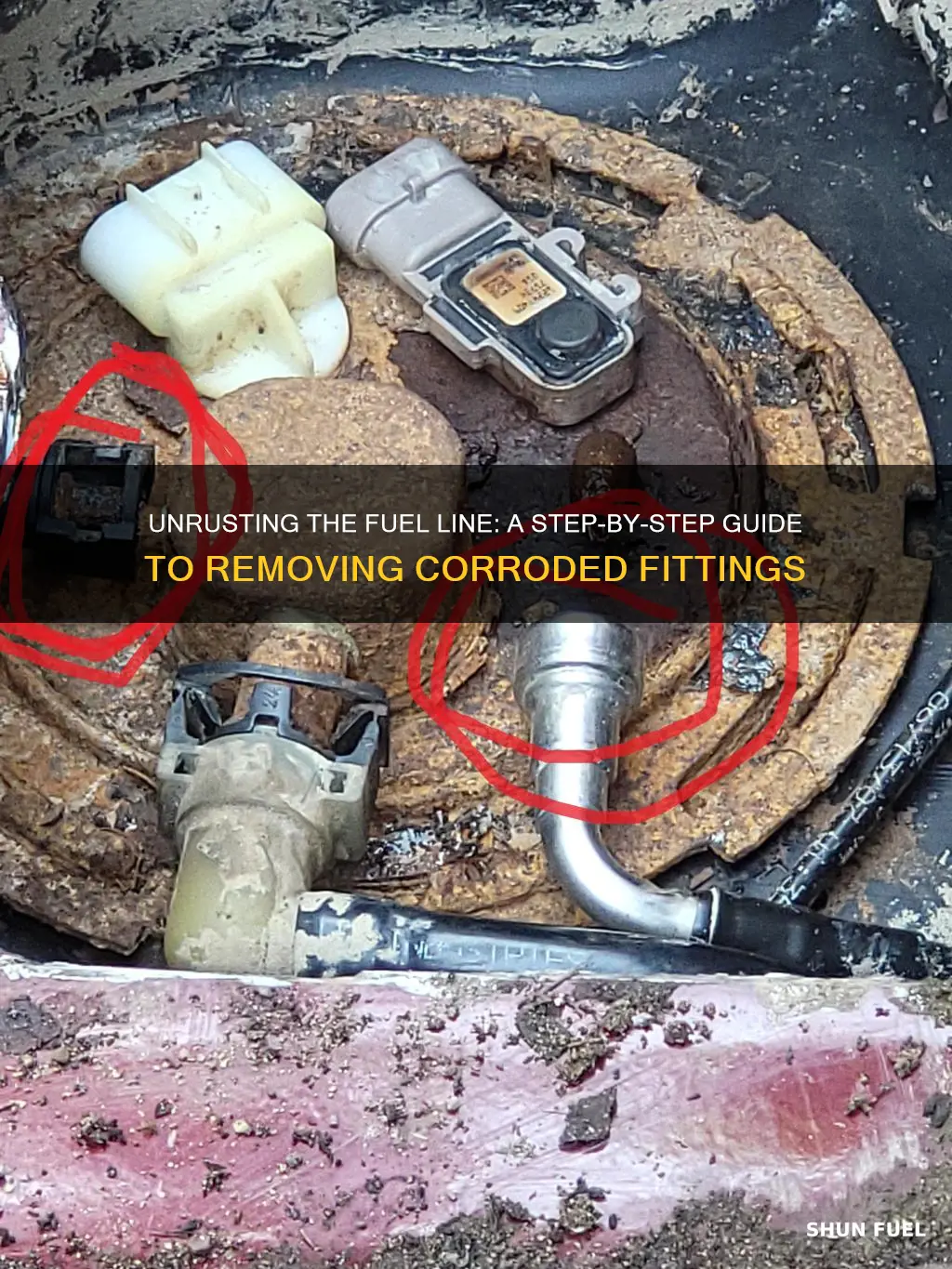

Removing a rusted fuel line fitting can be a challenging task, but with the right tools and techniques, it is certainly achievable. This guide will provide a step-by-step approach to safely and effectively tackle this issue, ensuring you can restore your fuel system without causing further damage. By following these instructions, you'll learn how to carefully disassemble the fitting, clean the components, and reattach them, all while minimizing the risk of fuel leaks and ensuring a secure connection.

What You'll Learn

- Prepare the Tools: Gather necessary tools: wrench, pipe cutter, sandpaper, safety gear

- Loosen the Fitting: Use a wrench to loosen the rusted fuel line fitting

- Cut and Remove: Carefully cut the rusted section with a pipe cutter

- Clean and Inspect: Clean the area, inspect for damage, and replace if necessary

- Reinstall and Test: Reinstall the new fitting, test for leaks, and ensure proper functionality

Prepare the Tools: Gather necessary tools: wrench, pipe cutter, sandpaper, safety gear

To tackle a rusted fuel line fitting, you'll need the right tools and safety gear to ensure a safe and effective process. Here's a breakdown of what you should gather:

Wrench: A wrench is essential for loosening and removing the rusted fitting. Choose a wrench that matches the size of the fitting. Wrenches come in various types, including open-end, box, and adjustable wrenches. For fuel lines, an adjustable wrench is often the most versatile. Ensure it's made of durable materials like chrome vanadium steel to withstand the force required to break free the rusted connection.

Pipe Cutter: In some cases, the rusted fitting might be tightly sealed, making it difficult to remove with a wrench alone. A pipe cutter can be a valuable addition to your toolkit. This tool allows you to carefully cut through the fuel line, providing a clean and precise cut. Look for a high-quality pipe cutter with adjustable cutting wheels to accommodate different pipe sizes.

Sandpaper: While not a primary tool for removal, sandpaper is crucial for smoothing any rough edges after the fitting is removed. It helps prevent damage to the surrounding fuel line and ensures a clean, professional finish. Choose a fine-grit sandpaper, such as 400 or 600 grit, to gently remove any remaining rust or debris.

Safety Gear: Prioritize your safety by wearing appropriate gear. Safety goggles are essential to protect your eyes from any potential debris or sparks during the removal process. Additionally, consider wearing gloves to safeguard your hands from sharp edges and potential cuts. A dust mask can also be useful to minimize inhaling any dust or fumes that might be released during the operation.

Having these tools and safety gear ready will ensure you're well-prepared to tackle the removal of a rusted fuel line fitting effectively and safely. Remember to always work in a well-ventilated area and take the necessary precautions to protect yourself and those around you.

Yamaha 250XTRS Oatboard Fuel Line: Size Guide

You may want to see also

Loosen the Fitting: Use a wrench to loosen the rusted fuel line fitting

To tackle a rusted fuel line fitting, it's crucial to approach the task with the right tools and techniques. One of the initial steps is to loosen the fitting itself, a process that requires patience and the right approach. Here's a detailed guide on how to do it:

Start by ensuring you have a wrench that fits the size of the fuel line fitting. Wrenches come in various sizes, and it's essential to choose the right one to avoid damaging the fitting or the surrounding components. Place the wrench over the fitting, ensuring it is positioned correctly and securely. Apply a steady amount of force to begin turning the wrench counterclockwise. The goal is to loosen the fitting, not to remove it entirely. You might need to apply significant force, especially if the rust has created a tight seal. If you encounter resistance, don't force it; instead, use a combination of turning and applying pressure to break the rust's grip.

As you turn the wrench, you should feel the fitting start to move. It's important to work slowly and steadily to avoid stripping the threads or damaging the fitting. If the fitting is extremely rusted, you might need to use a lubricant to reduce friction. A small amount of penetrating oil or white lithium grease can be applied to the threads of the fitting and the wrench to make the process easier. Allow a few minutes for the lubricant to work its magic, and then try turning the wrench again.

Remember, the key is to loosen the fitting, not to remove it. Once you've loosened it sufficiently, you can move on to the next steps, such as cleaning the fitting and potentially replacing it if necessary. Always take your time and use the appropriate tools to ensure a safe and effective repair.

Craftsmen's Guide: Choosing the Right Fuel Line for Riding Lawnmowers

You may want to see also

Cut and Remove: Carefully cut the rusted section with a pipe cutter

When dealing with a rusted fuel line fitting, it's crucial to approach the removal process with care and precision. One of the most effective methods is to carefully cut the affected section using a pipe cutter. This technique allows for a clean and controlled break, ensuring that you don't damage the surrounding components. Here's a step-by-step guide to help you through this process:

Gather the Tools and Materials: Before you begin, ensure you have the necessary tools. A pipe cutter, also known as a pipe-cutting tool or a tube cutter, is essential for this task. These tools are designed to cut through pipes and tubes without causing damage to the material. You'll also need a pair of pliers or a wrench to grip the fitting securely. Additionally, have some replacement fittings and hoses ready, as you'll need to replace the damaged section.

Locate the Rusted Section: Carefully inspect the fuel line to identify the section that is heavily rusted or corroded. Rust often accumulates at the connections and bends, so pay close attention to these areas. Mark the spot with a piece of tape or a small piece of chalk to ensure you cut at the right location.

Prepare the Pipe Cutter: Pipe cutters come in various sizes, so choose one that is suitable for the diameter of your fuel line. Ensure the cutter is sharp and in good condition. If it's not, consider sharpening it or replacing it with a new one. Position the cutter's cutting wheel against the marked section of the fuel line, ensuring it is aligned properly.

Cut the Rusted Section: Now, it's time to make the cut. Apply firm pressure to the handle of the pipe cutter and guide it along the length of the fuel line. Keep the cutter straight and true to ensure a clean cut. Apply steady pressure and use controlled movements to avoid any accidental damage to the surrounding area. The pipe cutter should glide smoothly through the rusted section, creating a precise cut.

Remove the Cut Section: Once the cut is complete, carefully pull the rusted section of the fuel line away from the rest of the line. Inspect the cut ends for any damage and ensure they are clean and smooth. If necessary, use a file or sandpaper to smooth any rough edges. This step is crucial to ensure a proper seal when reconnecting the new fitting.

Install the Replacement Fitting: With the rusted section removed, it's time to replace it. Take your replacement fitting and align it with the cut end of the fuel line. Use the pliers or wrench to secure the fitting in place, following the manufacturer's instructions for proper torque specifications. Ensure the fitting is tight and secure, but be careful not to overtighten it, as this can damage the fuel line.

Perfect Fuel Line Fit: 97 Sea-Doo GTX Guide

You may want to see also

Clean and Inspect: Clean the area, inspect for damage, and replace if necessary

To effectively address a rusted fuel line fitting, it's crucial to follow a systematic approach that involves cleaning, inspection, and necessary replacement. Here's a detailed guide on how to tackle this issue:

Cleaning the Area:

Start by ensuring the work area is clean and well-lit. Use a wire brush or a specialized rust remover to scrub the affected area of the fuel line fitting. This step is essential to remove loose rust and debris. For stubborn rust, consider using a rust-dissolving solvent or a vinegar-based cleaner, ensuring you follow safety guidelines and wear appropriate protective gear. Rinse the area thoroughly with water to eliminate any remaining cleaning agents.

Inspecting for Damage:

After cleaning, a thorough inspection is vital. Check for any signs of significant corrosion or damage. Look for pitting, flaking, or thickening of the metal, as these indicate advanced corrosion. Inspect the threads of the fitting for damage, as rusted threads can make removal difficult. If you notice any severe damage, it may be necessary to replace the entire fitting.

Replacing the Rusted Fuel Line Fitting (if necessary):

If the inspection reveals significant corrosion or damage, it's time to replace the fitting. Here's a simple process:

- Gather the necessary tools: You'll likely need a wrench or pliers, a new fuel line fitting, and possibly a fuel line cutter and a tube cutter.

- Disconnect the old fitting: Carefully remove the rusted fitting by unscrewing or cutting it off, ensuring you don't damage the surrounding fuel line.

- Prepare the new fitting: Clean the end of the fuel line and the new fitting to ensure a proper connection.

- Install the new fitting: Slide the new fitting onto the fuel line and secure it with the appropriate tools, ensuring a tight and leak-free connection.

- Test for leaks: After installation, start the vehicle and check for any signs of fuel leaks. If none are found, your work is complete.

Remember, regular maintenance and inspection of fuel line fittings can prevent such issues. If you're unsure about any step, consult a professional mechanic to ensure the job is done safely and effectively.

Saito 180 Fuel Line: Size Guide for Optimal Performance

You may want to see also

Reinstall and Test: Reinstall the new fitting, test for leaks, and ensure proper functionality

When dealing with a rusted fuel line fitting, the process of removing and replacing it requires careful execution to ensure a secure and leak-free installation. Once you've acquired the necessary tools and a new fitting, it's time to reinstall and test the system. Here's a step-by-step guide to help you through this process:

Start by ensuring you have the correct tools for the job. You'll need a wrench or socket that fits the size of the fitting, a new fuel line (if required), and possibly some thread seal tape or pipe compound. Locate the rusted fitting and prepare to remove it. Use the appropriate tool to loosen and remove the old fitting, being cautious not to damage the surrounding fuel line. If the fitting is severely rusted, you might need to cut it off using a utility knife or a fitting cutter. Take note of the orientation of the fitting to ensure proper alignment during reinstallation.

With the old fitting removed, it's time to prepare the new one. Clean the threads of the fuel line and the new fitting to ensure a tight seal. Apply a thin layer of thread seal tape or pipe compound to the threads, wrapping it clockwise for a secure bond. Insert the new fitting onto the fuel line, tightening it by hand first to avoid over-tightening. Use your wrench or socket to tighten the fitting securely, but be careful not to overtighten, as this can damage the fuel line.

After reinstalling the fitting, it's crucial to test for any potential leaks. Start by checking for visible signs of leakage around the fitting and along the fuel line. You can use a soapy water solution or a leak detection dye to identify any small leaks. If you notice any leaks, tighten the fitting further or reapply thread seal tape. Ensure that all connections are secure and tight.

Once you're confident that the fitting is leak-free, it's time to test the functionality of the fuel system. Start the vehicle and allow it to idle, monitoring for any unusual noises or vibrations. Check for any signs of fuel leakage around the engine and under the vehicle. If everything appears normal, you can drive the car for a short period to ensure the fuel system is operating correctly.

Remember, proper reinstallation and testing are essential to prevent future issues with rust or leaks. Regularly inspect your fuel system for any signs of deterioration and address any problems promptly to maintain optimal vehicle performance.

Locate the Fuel Injector Line on Your 2007 Impala SS

You may want to see also

Frequently asked questions

Removing a rusted fuel line fitting requires patience and the right tools to avoid any potential hazards. Start by soaking the area with a rust remover or a mixture of white vinegar and baking soda to loosen the rust. Allow it to sit for a while, then use a rust penetrant to further break down the corrosion. Once the rust is softened, insert a rust removal tool, such as a wire brush or a rust removal kit, into the fitting to carefully scrape away the rusted material. Take your time to avoid damaging the surrounding metal.

Using a wrench directly on a rusted fuel line fitting is not recommended as it can lead to damage to the fitting or the fuel line. Rust can make the fitting extremely tight, and applying force with a wrench might strip threads or crack the fitting. Instead, use a thread groove tool or a pipe wrench with a protective covering to grip the fitting without damaging it. Apply gentle, steady pressure to loosen the fitting.

If the fitting is stubbornly stuck, it's important to avoid forcing it to prevent damage. Try using a heat gun or a hairdryer to apply heat to the fitting, which will help expand the metal and loosen the corrosion. Allow the area to cool before attempting to remove it again. You can also consider using a lubricating compound or a thin layer of petroleum jelly to reduce friction and make the removal process easier.

Absolutely, safety is crucial when dealing with fuel line fittings. Always wear protective gear, including gloves and safety goggles, to protect your hands and eyes from any potential splashes or debris. Ensure the fuel source is turned off and the engine is cool before starting the removal process. Work in a well-ventilated area, and if possible, contain any potential fuel spills. Be cautious and patient throughout the process to ensure a safe and successful removal.