Removing a rubber fuel line can be a necessary step during vehicle maintenance or repairs, but it requires careful execution to avoid spills and ensure safety. This process involves identifying the correct tools and techniques to disconnect the line from the fuel tank and engine, which may vary depending on the vehicle's make and model. Understanding the specific steps and safety precautions for your particular vehicle is essential to ensure a successful and safe removal process.

What You'll Learn

- Prepare the Vehicle: Ensure the car is parked, cooled down, and the fuel line is accessible

- Locate the Line: Identify the rubber fuel line, often found under the car near the fuel tank

- Release Pressure: Loosen the fuel line clamp and release pressure to prevent spillage

- Remove the Line: Carefully pull the rubber fuel line away from the connections, being cautious of sharp edges

- Clean and Inspect: Clean the area and inspect for any damage before reinstalling or replacing the line

Prepare the Vehicle: Ensure the car is parked, cooled down, and the fuel line is accessible

To safely and effectively remove a rubber fuel line, it's crucial to start with the right preparation. Begin by ensuring your vehicle is in a secure and controlled environment. Park it on a level surface, preferably in a well-ventilated area, to avoid any potential hazards. Allow the engine to cool down completely; working on a hot engine can be dangerous and may cause burns.

Once the vehicle is parked and cooled, locate the fuel line you intend to remove. Rubber fuel lines are typically found running from the fuel tank to the engine or other components that require fuel. Identify the specific line you want to take off, as there may be multiple fuel lines connected to the engine. It's important to know which line is associated with the component you're working on to avoid any unintended consequences.

Before proceeding, ensure you have the necessary tools and safety equipment. You'll likely need a fuel line removal tool or a similar device designed for this purpose. Additionally, have a container ready to catch any fuel that may spill during the process. Safety gear, such as gloves and eye protection, is also essential to safeguard yourself from potential fuel splashes or spills.

With the vehicle in a safe position and the necessary tools at hand, you're now ready to proceed with the removal process. Remember to work carefully and methodically to avoid any damage to the vehicle or injury to yourself.

Air in Paperstroke Return Fuel Line: A Cause for Concern?

You may want to see also

Locate the Line: Identify the rubber fuel line, often found under the car near the fuel tank

To begin the process of removing a rubber fuel line, you must first locate it. The fuel line is typically positioned under the vehicle, close to the fuel tank. It is an essential component of the fuel system, responsible for transporting fuel from the tank to the engine. Here's a step-by-step guide to help you identify and access the rubber fuel line:

Start by examining the undercarriage of your vehicle. Look for a flexible, rubber-like tube that runs along the frame, often near the driver's side. This line is usually black or dark in color and can vary in thickness depending on the vehicle model. It may be secured in place with clips, brackets, or ties to keep it in position.

The fuel line can be found in various locations, but it often runs from the rear of the fuel tank, along the frame, and towards the engine compartment. It might pass through the firewall, which is the metal barrier separating the engine bay from the passenger compartment. If you have a lift gate or a vehicle with a removable panel, you might be able to access the line more easily.

When you locate the fuel line, take note of its position relative to other components. It is essential to understand the layout of your vehicle to ensure you do not damage any other parts during the removal process. Rubber fuel lines are often color-coded or marked with a small identifier to help with identification.

If you are unsure about the exact location, consult your vehicle's manual or a trusted online resource specific to your car model. These sources will provide detailed diagrams and instructions tailored to your vehicle, making the identification process more accurate.

Once you have identified the rubber fuel line, you can proceed with the removal process, ensuring you have the necessary tools and safety precautions in place.

Visual Guide: Sleeved Fuel Lines Explained

You may want to see also

Release Pressure: Loosen the fuel line clamp and release pressure to prevent spillage

To safely remove a rubber fuel line, it's crucial to release the pressure within the line to avoid any spills or mess. Here's a step-by-step guide to help you through this process:

Step 1: Locate the Fuel Line Clamp

Start by identifying the fuel line clamp, which is typically a metal or plastic bracket that secures the fuel line to the vehicle's engine or fuel tank. It is usually located near the point where the fuel line connects to the fuel source.

Step 2: Loosen the Clamp

Use a suitable tool, such as a wrench or a specialized fuel line removal tool, to loosen the clamp. Turn it counterclockwise to release the tension. Be cautious and apply gentle force to avoid forcing the tool, as this can damage the fuel line. The goal is to create enough slack to allow for the release of pressure.

Step 3: Release Pressure

Once the clamp is loosened, you'll need to release the pressure inside the fuel line to prevent any fuel from spilling out. Here's how:

- Step 3.1: Locate the fuel line's pressure release point. This is often a small port or a dedicated valve on the fuel line itself. It might be marked with a small arrow or a specific symbol.

- Step 3.2: Using a clean rag or a small cloth, cover the pressure release point to catch any potential fuel that might leak.

- Step 3.3: Slowly and carefully turn the pressure release point counterclockwise or pull it to open it. This will allow the air and fuel to escape, reducing the pressure inside the line. Take your time to ensure you don't accidentally release too much fuel.

Step 4: Prevent Spillage

As you work on the fuel line, it's essential to take precautions to avoid any fuel spills:

- Containment: Place a suitable container or a bucket beneath the fuel line to catch any fuel that might leak during the removal process.

- Gloves and Clothing: Wear gloves and old clothing to protect yourself from potential fuel contact.

- Ventilation: Ensure you are working in a well-ventilated area to avoid inhaling any fuel vapor.

By following these steps, you can safely release the pressure from the fuel line, making the removal process cleaner and safer. Remember to always exercise caution when working with fuel to prevent any accidents or environmental hazards.

Understanding Fuel Line Sizes for Tahoe Ti 9000 Lxu Models

You may want to see also

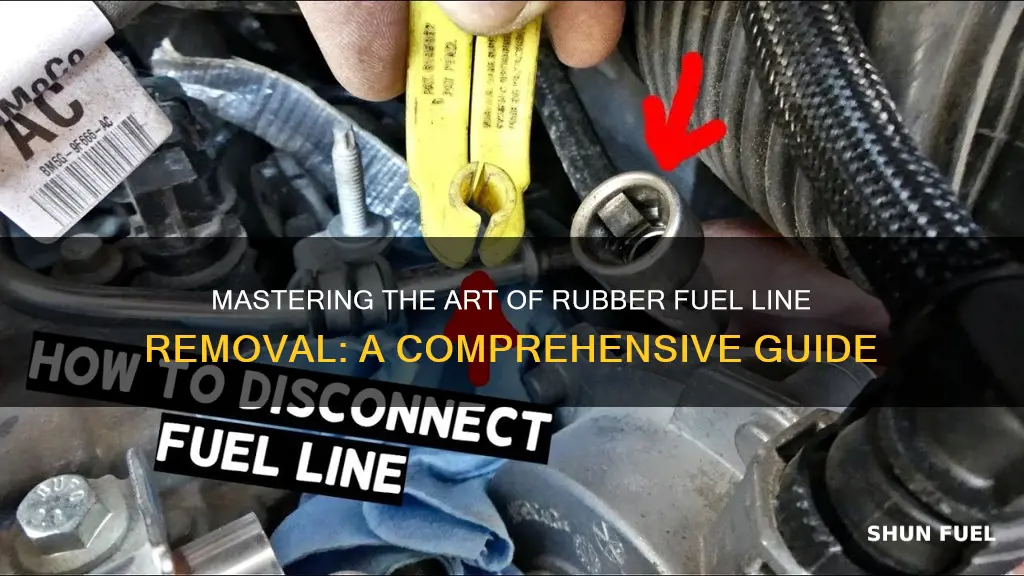

Remove the Line: Carefully pull the rubber fuel line away from the connections, being cautious of sharp edges

To safely remove a rubber fuel line, it's crucial to approach the task with care and precision. Start by identifying the specific connections where the fuel line is attached. These connections can vary depending on the vehicle's make and model, but they often involve fittings or clamps that secure the line. Once you've located these connections, carefully inspect the area to ensure you understand the layout and any potential hazards, such as sharp edges or protruding components.

Gently grasp the rubber fuel line and feel for any resistance or tension. This initial pull will help you assess the line's condition and identify any areas that might require extra attention. It's important to maintain a steady and controlled force to avoid sudden movements that could damage the line or nearby components. As you pull, be mindful of any connections or fittings that might come loose, and ensure you have a clear view of the work area to prevent any accidents.

When you've identified the connections, carefully detach the fittings or clamps. Use the appropriate tools for this step, such as a socket or wrench, to avoid damaging the connections. Take your time to ensure you remove the fasteners completely without forcing them, as this could lead to stripped threads or damaged components. Once the fasteners are removed, you should have access to the fuel line, allowing you to begin the process of removing it.

Now, carefully pull the rubber fuel line away from the connections, maintaining a gentle and steady force. Rubber can be quite flexible, but it's important to avoid excessive force that might cause the line to kink or twist. Pay close attention to the line's condition as you work, ensuring that you don't catch any sharp edges or protruding components that could damage the line. If you encounter any resistance or feel the line is stuck, inspect the area for any debris or obstructions that might be causing the issue.

Throughout the process, it's essential to work methodically and avoid rushing. Removing a fuel line requires patience and a careful approach to ensure the task is completed safely and effectively. By taking your time and being mindful of the line's condition, you can successfully detach the rubber fuel line without causing any damage or creating potential hazards.

Optimizing Performance: Choosing the Right Fuel Line for Your 3/8 ID Engine

You may want to see also

Clean and Inspect: Clean the area and inspect for any damage before reinstalling or replacing the line

When dealing with a rubber fuel line, it's crucial to follow a systematic approach to ensure a proper and safe installation. The first step is to clean the area where the fuel line will be reinstalled or replaced. This process is essential to remove any dirt, debris, or contaminants that could interfere with the line's performance and longevity. Start by using a mild detergent or a specialized fuel line cleaner, ensuring it is suitable for the material of your fuel line. Apply the cleaner to the affected area and use a soft-bristled brush or a clean cloth to gently scrub the surface, removing any grime. Rinse the area thoroughly with clean water to eliminate any residue.

After cleaning, it's vital to inspect the fuel line for any signs of damage or wear. Rubber fuel lines can degrade over time due to various factors, including exposure to fuel, heat, and mechanical stress. Carefully examine the line for cracks, tears, or any visible signs of deterioration. Check for any bulges or areas where the rubber has become soft or discolored, as these could indicate potential issues. Pay close attention to the connections and fittings, ensuring they are intact and securely attached. If any damage is detected, it is recommended to replace the fuel line to prevent potential leaks or performance problems.

During the inspection, also verify the compatibility of the fuel line with the vehicle's system. Ensure that the line's size, length, and fittings match the specifications required for your vehicle. This step is often overlooked but is critical to ensure optimal performance and safety. If the fuel line does not match the vehicle's requirements, it may need to be replaced with a compatible alternative.

Once the cleaning and inspection process is complete, you can proceed with reinstalling or replacing the fuel line. Ensure that all necessary tools and materials are available before beginning the task. This includes new fuel line fittings, seals, and any other components required for the installation. Properly secure the fuel line, following the manufacturer's guidelines, and double-check all connections to guarantee a leak-free system.

Optimizing Nitrous Performance: Choosing the Right Fuel Line Diameter

You may want to see also

Frequently asked questions

Removing a rubber fuel line requires careful handling to avoid any potential hazards. First, ensure you are in a well-ventilated area and wear protective gear, including gloves and safety goggles. Locate the fuel line and identify the connections or fittings. Use a fuel line cutter or a sharp tool to carefully cut through the line, making sure to cut at a slight angle to create a clean edge. Avoid cutting too close to the fuel source or any other components. Once cut, you can remove the section of the line by pulling it away from the connections.

Reusing a rubber fuel line is possible, but it depends on its condition. Inspect the removed line for any signs of damage, cracks, or deterioration. If the line is still in good shape and free from any leaks or punctures, it can be cleaned and reused. Clean the line by soaking it in a suitable solvent to remove any fuel residue. Rinse it thoroughly and allow it to dry completely before reinstalling. However, if the line shows significant wear and tear, it's best to replace it to ensure optimal performance and safety.

The tools needed for removing a rubber fuel line may include a fuel line cutter or a sharp knife, safety goggles, gloves, a rag or cloth for cleaning, and a suitable solvent (if required for cleaning). It's essential to have a steady hand and a good understanding of the fuel system to ensure a safe and successful removal process.

Absolutely! Safety should always be a top priority when working with fuel lines. Before starting, ensure the engine is off and the fuel supply is disconnected or blocked to prevent any accidental fuel release. Be cautious when cutting the line to avoid sharp edges that could cause injury. Keep children and pets away from the work area. If you're unsure or uncomfortable with the process, it's best to consult a professional mechanic to ensure the work is done safely and correctly.