Installing a bead on a fuel line is a precise and delicate process that requires attention to detail. This guide will provide a step-by-step approach to ensure a successful and secure connection. By following these instructions, you can effectively attach a bead to the fuel line, ensuring a reliable and leak-free fuel supply for your vehicle or equipment.

What You'll Learn

- Prepare Tools: Gather necessary tools like fuel line cutters, crimping pliers, and a fuel line cleaner

- Cut and Prepare: Carefully cut the fuel line, clean the ends, and ensure a precise fit

- Crimp and Secure: Use crimping pliers to secure the bead tightly, following manufacturer instructions

- Test and Inspect: Check for leaks, ensure proper alignment, and verify the bead's integrity

- Dispose of Old Line: Properly dispose of the old fuel line to prevent environmental contamination

Prepare Tools: Gather necessary tools like fuel line cutters, crimping pliers, and a fuel line cleaner

Before you begin the process of adding a bead to your fuel line, it's crucial to ensure you have the right tools for the job. This will make the repair or modification much easier and more efficient. Here's a step-by-step guide on preparing your tools:

Gather the Essential Tools:

- Fuel Line Cutters: These specialized tools are designed to cut through fuel lines with precision. They often feature a sharp, durable blade that can cleanly sever the line, allowing for a secure connection. Look for cutters that can accommodate the diameter of your fuel line.

- Crimping Pliers: Crimping pliers are essential for creating a secure and leak-proof connection. They apply pressure to the fuel line's fittings, ensuring a tight seal. Choose pliers with adjustable jaws to accommodate different sizes of fittings.

- Fuel Line Cleaner: Cleaning the fuel line is an important step to ensure a successful bead installation. Use a fuel line cleaner to remove any contaminants, old fuel, or debris that might interfere with the bead's adherence. This step helps create a clean surface for the bead to bond effectively.

- Safety Gear (Optional): Depending on your work environment, consider wearing safety goggles to protect your eyes from any potential fuel splashes. Gloves can also provide a better grip and protect your hands during the process.

Having these tools ready will ensure you can tackle the task efficiently and effectively. It's always a good practice to inspect your tools before starting any project to ensure they are in good working condition. With the right preparation, you'll be well-equipped to handle the bead installation process.

Blower Fuel Lines: Location and Installation Guide

You may want to see also

Cut and Prepare: Carefully cut the fuel line, clean the ends, and ensure a precise fit

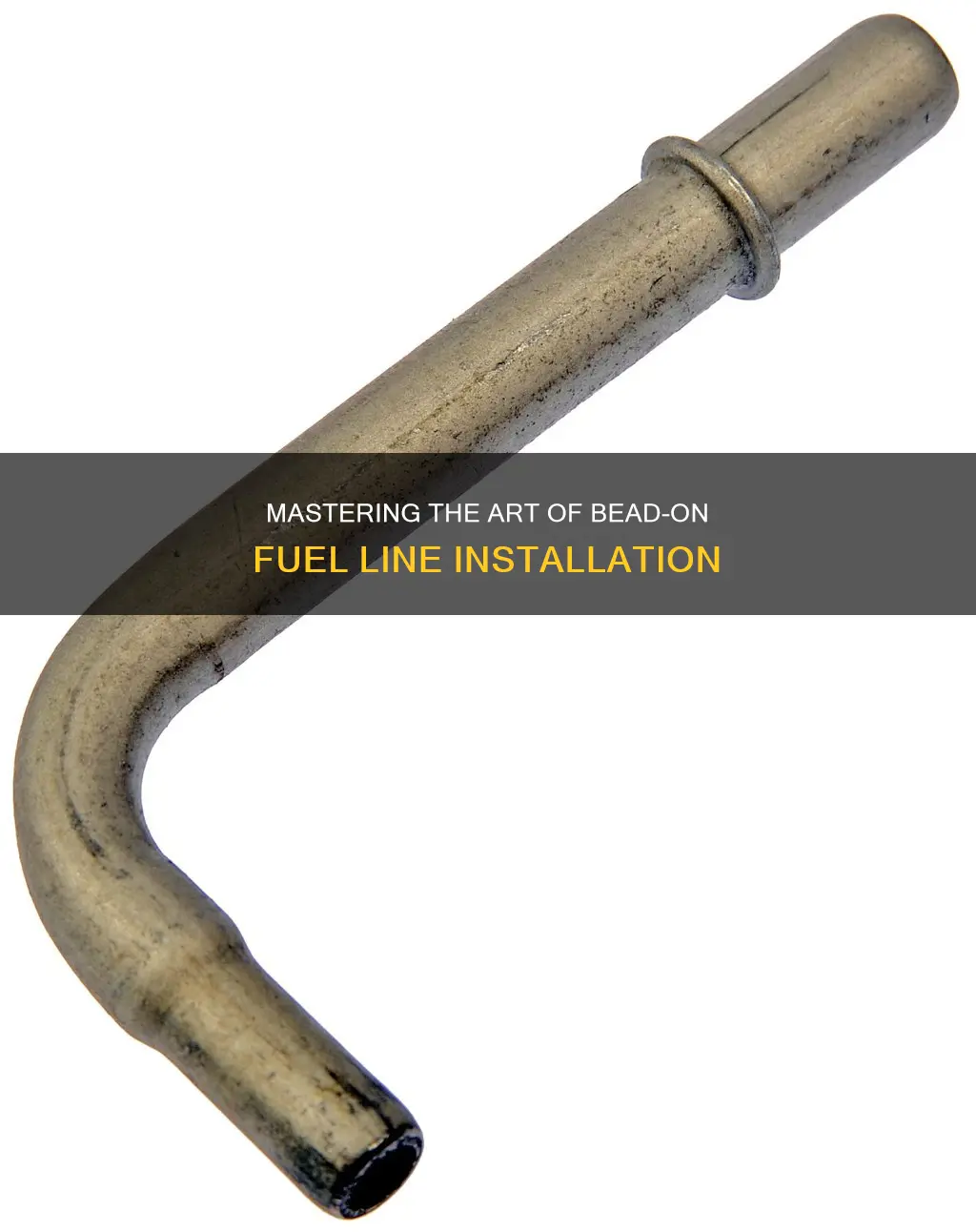

Before you begin, it's crucial to gather the right tools and materials. You'll need a fuel line, a bead (often a metal or plastic sleeve), a pair of sharp scissors or a fuel line cutter, a cleaning solution, and possibly a fuel line primer and adhesive. Ensure you have the correct size and type of bead for your fuel line to ensure a proper fit.

Carefully inspect the fuel line you intend to modify. Identify the section where the bead will be installed. Mark this area with a pen or a piece of tape to ensure you cut at the right spot. It's essential to make precise cuts to avoid any damage to the fuel line or the surrounding components.

Using your chosen cutting tool, carefully slice through the fuel line at the marked location. Take your time and apply steady pressure to ensure a clean cut. Avoid cutting too deeply, as this can compromise the integrity of the fuel line. Once cut, inspect the ends of the fuel line for any debris or damage.

Clean the ends of the fuel line thoroughly. Use a cleaning solution suitable for fuel lines to remove any dirt, corrosion, or old adhesive. Ensure the ends are free from any contaminants that could interfere with the bead's installation. Rinse the area with clean water and allow it to dry completely before proceeding.

Now, carefully slide the bead onto the fuel line. Ensure it is centered and aligned with the cut end. You may need to use a small tool or your fingers (gloved for protection) to gently push the bead onto the line. Take your time to ensure a precise fit, as any misalignment could lead to fuel leaks or damage. Once the bead is in place, check for any gaps or imperfections and make adjustments as necessary.

Mastering Fuel Line Removal: A Step-by-Step Guide for Car Enthusiasts

You may want to see also

Crimp and Secure: Use crimping pliers to secure the bead tightly, following manufacturer instructions

When working with fuel lines, it's crucial to ensure a secure connection to prevent any leaks or potential hazards. One effective method to achieve this is by using a crimping technique to secure a bead onto the fuel line. This process involves using crimping pliers to apply pressure and create a tight, reliable bond. Here's a step-by-step guide to help you master this technique:

Start by gathering the necessary tools and materials. You'll need crimping pliers specifically designed for the type of bead you're working with. Ensure you have the correct size and type of pliers to match the bead's specifications. Additionally, have the fuel line, bead, and any necessary cleaning supplies ready. It's essential to work with clean hands and surfaces to avoid any contaminants that could affect the crimping process.

Now, let's begin the crimping process. Take the fuel line and locate the section where you want to secure the bead. Clean the area to ensure a proper connection. Slide the bead onto the fuel line, ensuring it is centered and aligned with the desired connection point. The bead should have a slight overlap to create a secure bond.

Using the crimping pliers, apply firm pressure onto the bead. Follow the manufacturer's instructions for the specific crimping technique and force required. Typically, you'll need to apply a consistent and firm pressure for a few seconds to ensure the bead is securely fastened. Be cautious not to over-crimp, as it may damage the fuel line. The goal is to create a tight, reliable connection without compromising the integrity of the fuel line.

Once you've applied the necessary pressure, release the pliers and inspect the crimp. The bead should now be tightly secured to the fuel line, forming a strong bond. Repeat this process for any additional beads or connections required. Remember, practice and precision are key to mastering this technique. Always refer to the manufacturer's guidelines for specific instructions tailored to your bead and fuel line type.

Artic Cat 650 V2 Fuel Line Routing: A Step-by-Step Guide

You may want to see also

Test and Inspect: Check for leaks, ensure proper alignment, and verify the bead's integrity

When you've completed the installation of the bead on the fuel line, it's crucial to thoroughly test and inspect the work to ensure it's secure and functional. Begin by applying a small amount of fuel or a suitable sealant to the bead and the surrounding area. This step helps to temporarily seal the area and makes it easier to identify any potential leaks. Then, use a rag or cloth to wipe away any excess sealant, leaving just a small amount around the bead.

The next step is to inspect the bead for any signs of damage or imperfections. Look for any cracks, chips, or deformities that might have occurred during the installation process. Proper alignment is essential, so check that the bead is centered and securely attached to the fuel line without any gaps or misalignments. Ensure that the bead's surface is smooth and free from any sharp edges that could cause damage to the fuel line or other components.

To check for leaks, start the engine and allow it to idle. Pay close attention to any unusual noises or smells, as these could indicate a leak. If you notice any fuel escaping or dripping around the bead, it's a clear sign of a problem. You can also use a soapy water solution and apply it to the bead and the fuel line connection. If bubbles appear, it confirms the presence of a leak. If any leaks are detected, carefully remove the bead and inspect the fuel line for any damage or wear.

Additionally, verify the bead's integrity by examining its flexibility and resilience. Try to gently deform the bead to ensure it can withstand the pressure and movement of the fuel line without permanent deformation. This test will help you understand the bead's ability to adapt to the fuel line's natural expansion and contraction.

Finally, consider using a fuel pressure tester to ensure that the fuel line is functioning correctly. This tool will help you measure the fuel pressure and ensure it meets the manufacturer's specifications. By following these detailed steps, you can confidently conclude that the bead is properly installed, leak-free, and capable of maintaining a secure connection between the fuel line and the tank.

1991 Mustang GT Fuel Line: Choosing the Right Size

You may want to see also

Dispose of Old Line: Properly dispose of the old fuel line to prevent environmental contamination

When dealing with old fuel lines, it is crucial to handle their disposal with care to prevent any potential environmental contamination. Here's a step-by-step guide on how to properly dispose of the old fuel line:

- Assess the Condition: Before disposal, inspect the fuel line for any visible damage or contamination. If the line is severely damaged, leaking, or shows signs of degradation, it is best to dispose of it immediately. Even small leaks can lead to environmental hazards, so don't underestimate the importance of this step.

- Contact Local Authorities: Dispose of hazardous materials, including old fuel lines, requires proper authorization and handling. Contact your local waste management authorities or environmental protection agency to understand the regulations and guidelines for disposing of such materials. They will provide you with the necessary instructions and may even offer specialized collection services.

- Contain and Seal: If you are disposing of the fuel line yourself, ensure you contain the old line in a suitable, leak-proof container. Use heavy-duty plastic bags or containers specifically designed for hazardous waste. Seal the container securely to prevent any fuel from leaking out during transportation. Label the container clearly with the words "Fuel Line" and any relevant warning symbols.

- Transportation: Transport the sealed container to an authorized disposal facility or a designated collection point. Follow all transportation guidelines provided by your local authorities to ensure the safe movement of the waste. Avoid transporting the waste over long distances unless absolutely necessary, as this can increase the risk of accidental spills.

- Professional Disposal: It is highly recommended to seek professional assistance for disposing of old fuel lines. Certified waste management companies have the expertise and equipment to handle hazardous materials safely. They will ensure that the fuel line is disposed of in an environmentally friendly manner, often through specialized treatment processes that neutralize or stabilize the waste.

- Documentation: Keep records of the disposal process, including any permits obtained, transportation details, and the name of the disposal facility. This documentation is essential for compliance with environmental regulations and can be useful in case of future audits or investigations.

Remember, proper disposal of old fuel lines is not just an environmental responsibility but also a legal obligation. By following these steps, you can contribute to a safer and more sustainable approach to fuel line maintenance and disposal.

Chevy Silverado Fuel Line: 2008 Model Size Guide

You may want to see also

Frequently asked questions

Adding a bead, often referred to as a fuel line bead, is a technique used to ensure a secure and leak-free connection between a fuel line and a fuel tank or other fuel system components. It helps create a tight seal, preventing fuel leaks and potential engine issues.

You might need to add a bead if you're replacing an old fuel line, making modifications to your fuel system, or simply want to ensure a reliable connection. Signs of a potential leak, such as fuel odors or engine performance issues, could also indicate the need for a bead.

The primary materials needed are fuel line beads (also known as fuel line ferrules or fuel line connectors), a fuel line, and a fuel line crimping tool. You might also require a fuel line cutter, sandpaper, and a fuel line primer for preparation.

It's important to use the correct type of bead for your specific fuel line material. Different fuels and line materials may require different bead types. Always refer to the manufacturer's guidelines or consult a professional to ensure compatibility.