Measuring a fuel line is a crucial step in ensuring the proper functioning of your vehicle's fuel system. Whether you're a car enthusiast or a professional mechanic, knowing how to accurately measure fuel lines is essential. This process involves using specific tools and techniques to determine the correct length and diameter of the fuel line, which is vital for optimal fuel delivery and engine performance. By following a step-by-step guide, you can ensure that your fuel lines are properly installed, preventing potential issues such as fuel leaks or reduced engine power. Understanding the measurement process will empower you to make informed decisions and maintain your vehicle's fuel system effectively.

What You'll Learn

- Fuel Line Length: Measure the total length of the fuel line from the tank to the engine

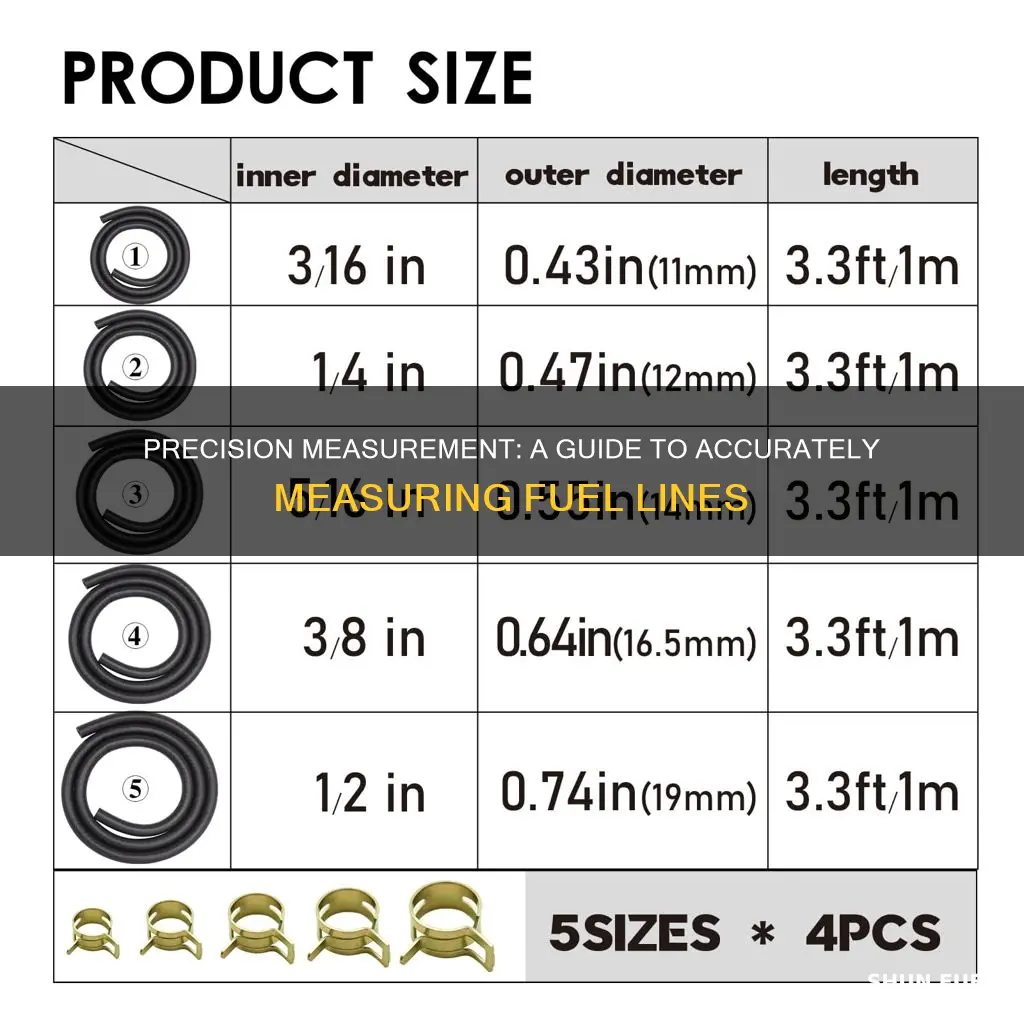

- Fuel Line Diameter: Use a caliper to determine the diameter of the fuel line

- Fuel Line Material: Identify the material of the fuel line (e.g., rubber, plastic, metal)

- Fuel Line Routing: Note the path and any bends or turns in the fuel line

- Fuel Line Connections: Inspect the connections and fittings for leaks or damage

Fuel Line Length: Measure the total length of the fuel line from the tank to the engine

To accurately measure the fuel line length, you need to inspect the entire route from the fuel tank to the engine. This measurement is crucial for ensuring the fuel line is the correct size and length to handle the required fuel flow efficiently. Here's a step-by-step guide:

- Locate the Fuel Tank and Engine: Start by identifying the fuel tank and the engine compartment in your vehicle. The fuel line typically runs from the bottom of the tank, often near the front of the vehicle, to the engine's fuel injection system or carburetor.

- Inspect the Fuel Line Route: Carefully examine the path the fuel line takes. It may follow a complex route, passing through various components like the firewall, engine bay, and even under the vehicle in some cases. Look for any bends, kinks, or obstructions that could affect the line's length.

- Measure with a Tape Measure: Use a flexible measuring tape to determine the total length of the fuel line. Start from the point where the fuel line exits the tank and carefully measure along the entire route to the engine. Ensure you measure both the straight and curved sections of the line. Take note of any fittings or connectors and include their length in your measurement.

- Consider the Fuel Pump: The fuel pump, which is often located near the tank, is also an important part of the fuel system. Measure the distance from the pump outlet to the engine's fuel rail or carburetor. This measurement is essential to ensure the fuel line can accommodate the required fuel flow rate.

- Document the Measurement: Record the total length of the fuel line, including any additional lengths from fittings or connectors. This measurement will help you choose the appropriate fuel line replacement or ensure that any modifications to the fuel system comply with the vehicle's requirements.

Accurate measurement of the fuel line length is a critical step in maintaining a vehicle's fuel system. It ensures proper fuel delivery, prevents engine performance issues, and helps identify potential problems that may arise from a poorly fitted or damaged fuel line.

Marine Fuel Line Valves: When and Why to Replace

You may want to see also

Fuel Line Diameter: Use a caliper to determine the diameter of the fuel line

To accurately measure the diameter of a fuel line, you'll need a caliper, a precision measuring tool that can provide highly accurate measurements. Here's a step-by-step guide on how to use a caliper to determine the diameter of your fuel line:

Step 1: Prepare Your Tools

- Ensure you have a caliper with a jaw size suitable for the fuel line. The jaws should be able to enclose the fuel line without excessive pressure or movement.

- Choose a caliper with a resolution of at least 0.001 inches (0.0254 mm) for accurate measurements.

Step 2: Position the Caliper

- Carefully place the caliper's jaws around the fuel line, ensuring they are snugly fitted and aligned with the fuel line's center.

- Make sure the caliper is positioned perpendicular to the fuel line to get an accurate measurement.

Step 3: Take the Measurement

- Close the caliper's jaws until they touch the fuel line.

- Read the measurement on the caliper's scale. This reading will be the diameter of the fuel line.

Step 4: Record the Data

- Note down the diameter measurement in inches or millimeters, whichever your reference material uses.

- If you're comparing different fuel lines or troubleshooting an issue, record this measurement along with other relevant data, such as the fuel line's length and material.

Step 5: Repeat for Accuracy

For best results, measure the fuel line at multiple points to ensure consistency. Measure at least three different locations along the length of the fuel line.

Important Considerations:

- Cleanliness: Ensure the fuel line is clean and free of debris before taking measurements. Dirt or contaminants can skew the results.

- Consistency: Measure at the same point on the fuel line each time to ensure comparable data.

- Safety: When using a caliper, always exercise caution to avoid injury.

By following these steps and using a caliper accurately, you can determine the diameter of your fuel line, which is crucial for ensuring proper fuel flow, compatibility with fuel injectors or pumps, and overall engine performance.

Fixing a Fuel Line Leak: Cost Breakdown and Tips

You may want to see also

Fuel Line Material: Identify the material of the fuel line (e.g., rubber, plastic, metal)

To identify the material of your fuel line, you'll need to inspect it carefully. Here's a step-by-step guide:

- Visual Inspection: Start by visually examining the fuel line. Look for any visible signs of wear, damage, or discoloration. Different materials have distinct appearances. For example, rubber fuel lines often have a smooth, flexible texture, while metal fuel lines might appear rigid and metallic.

- Feel the Material: Carefully touch the fuel line if you can safely do so. Rubber fuel lines will feel flexible and pliable, while metal fuel lines will be rigid and potentially cold to the touch. Plastic fuel lines might feel slightly more flexible than metal but less so than rubber.

- Consider the Application: Think about the vehicle's age and the specific area where the fuel line is located. Older vehicles might have rubber fuel lines, while newer ones could have plastic or metal lines. Additionally, fuel lines in high-temperature areas might be made of materials that can withstand heat better.

- Check for Manufacturers' Marks: In some cases, the material might be indicated by a manufacturer's mark on the fuel line itself. This could be a small label or engraving that specifies the material used. Look for any such markings that could provide clues about the fuel line's composition.

- Consult Vehicle Manuals: If you're unsure, consult your vehicle's owner's manual. It should provide information about the fuel system, including the type of materials used for various components, including the fuel lines.

Identifying the material is crucial for ensuring you use the correct replacement parts and maintenance procedures. Different materials have varying levels of flexibility, temperature resistance, and durability, so choosing the right material for your fuel line replacement is essential for optimal vehicle performance and longevity.

1987 F150 Fuel Line: What You Need to Know

You may want to see also

Fuel Line Routing: Note the path and any bends or turns in the fuel line

Fuel line routing is a critical aspect of any fuel system installation or repair, ensuring optimal performance and safety. When measuring and routing a fuel line, it's essential to pay close attention to the path it takes and any bends or turns it encounters. This attention to detail will help ensure a smooth and efficient flow of fuel throughout the system.

Start by identifying the source of the fuel, such as a fuel tank or a fuel pump, and determine the destination, which could be an engine or a fuel-injected system. Visualize the path that the fuel needs to take to reach its destination. This initial step is crucial as it sets the foundation for the entire routing process.

Now, carefully examine the fuel line's path. Note any bends, turns, or changes in direction. Fuel lines should be routed in a way that minimizes stress and potential damage. Avoid sharp bends or kinks that could restrict fuel flow or cause the line to burst. The ideal routing should allow the line to move freely without any sharp angles.

Consider the vehicle's structure and available space when planning the route. Fuel lines should be positioned away from hot engine components, exhaust systems, and other potential sources of heat or damage. Ensure that the line is not routed through tight spaces or under heavy components that could cause damage over time.

Additionally, take into account any necessary connections, such as fuel filters, regulators, or injectors. These components should be easily accessible for maintenance and should not restrict the fuel line's movement. Properly secure all connections to prevent any leaks or disconnections during operation.

By carefully documenting the fuel line's path and making precise measurements, you can ensure a well-organized and efficient fuel system. This attention to detail will contribute to the overall performance and longevity of the vehicle's fuel-related components.

Fuel Line Flush: Essential Maintenance for Optimal Engine Performance

You may want to see also

Fuel Line Connections: Inspect the connections and fittings for leaks or damage

When inspecting the fuel line connections, it's crucial to ensure they are secure and free from any potential issues that could lead to fuel leaks or system malfunctions. Start by locating all the connections along the fuel line, including the fittings where the line connects to the fuel tank, pump, and engine. These connections are often made using various types of fittings, such as quick-release clips, screws, or clips, depending on the vehicle's make and model.

The first step is to visually inspect each connection for any signs of damage or wear. Look for cracks, corrosion, or any visible deterioration in the fittings and hoses. Over time, fuel lines can develop small punctures or leaks due to the corrosive nature of fuel or the stress of movement during engine operation. Inspect the hoses for any bulging or softening, as these could indicate internal damage. If you notice any damage, it's essential to replace the affected section of the fuel line immediately to prevent further issues.

Next, you should check for tightness and proper alignment. Ensure that all fittings are securely tightened according to the manufacturer's specifications. Loose connections can lead to fuel leaks and may even cause the line to disconnect under pressure. Use a wrench or the appropriate tool to tighten the fittings, but be careful not to overtighten, as this can also cause damage. Additionally, verify that the fuel line is correctly positioned and not rubbing against any moving parts or sharp edges that could cause further damage.

Leak detection is a critical part of this process. You can use a simple method to check for leaks by applying a small amount of diesel fuel or soapy water to the connections and fittings. If you notice any bubbles forming or soap suds appearing, it indicates a leak. Bubbles are a clear sign of air entering the system, which can cause engine misfires or stalling. For soapy water, any bubbles or persistent foam suggests a fuel leak. If you identify a leak, it's best to have the fuel line repaired or replaced by a professional to ensure the safety and reliability of your vehicle's fuel system.

Remember, regular maintenance and inspection of fuel line connections are vital to prevent costly repairs and ensure your vehicle's engine runs efficiently. By following these steps, you can identify and address potential issues before they become major problems, keeping your vehicle's fuel system in optimal condition.

Mastering Push-to-Connect Fittings: A Step-by-Step Guide to Fuel Line Installation

You may want to see also

Frequently asked questions

To accurately measure a fuel line, you will need a flexible measuring tape or a ruler, preferably with metric and imperial units. Additionally, a pen or pencil to mark the measurements can be useful.

Start by ensuring the fuel line is straight and coiled as little as possible. Then, use the measuring tool to extend along the entire length of the fuel line, noting the starting and ending points. Take multiple measurements if necessary to ensure accuracy, especially if the line is curved or has multiple sections.

If the measured length does not match the required specifications, you may need to adjust the fuel line. For a longer line, consider trimming it carefully with a sharp blade or cutting tool. For a shorter line, you might need to extend it by adding a suitable length of fuel line or finding an alternative solution, ensuring all connections are secure and leak-free.