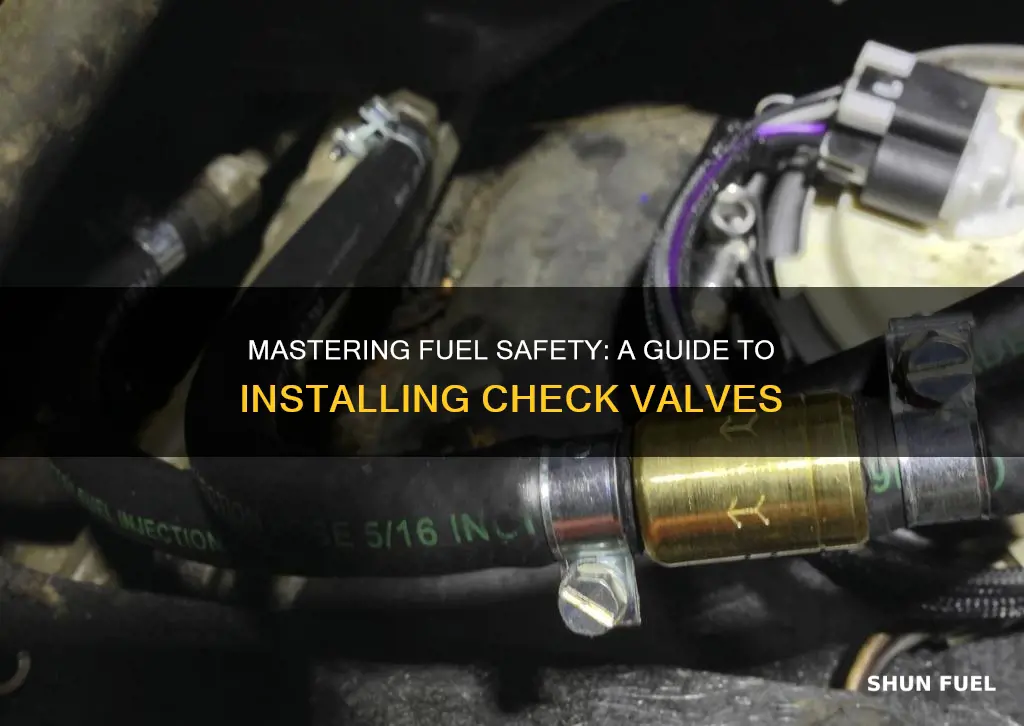

Installing a fuel line check valve is a crucial step in ensuring the safety and efficiency of your vehicle's fuel system. This valve acts as a safeguard, preventing fuel from flowing back into the engine when the vehicle is turned off, which can cause engine damage and fuel wastage. The process involves connecting the valve to the fuel line, typically near the fuel pump, and securing it with appropriate fasteners. This guide will provide a step-by-step overview of the installation process, ensuring that you can effectively protect your vehicle's engine and fuel system.

What You'll Learn

- Location and Routing: Identify optimal placement and plan fuel line path

- Valve Selection: Choose the right check valve size and material

- Installation Tools: Gather necessary tools for a successful installation

- Assembly Steps: Follow a step-by-step guide for valve assembly

- Testing Procedures: Learn how to test the valve's functionality post-installation

Location and Routing: Identify optimal placement and plan fuel line path

When installing a fuel line check valve, careful consideration of its location and routing is crucial to ensure optimal performance and reliability. The primary goal is to place the check valve in a position that allows it to effectively regulate fuel flow while minimizing potential issues.

Start by identifying the fuel source, which could be a fuel pump, tank, or reservoir. The check valve should be positioned immediately after the fuel source to control the flow from the primary supply. This placement ensures that any potential issues with the valve itself do not affect the overall fuel system. Consider the fuel line's path and choose a location that is easily accessible for maintenance and potential future modifications.

The routing of the fuel line is another critical aspect. Aim for a straight and direct path from the fuel source to the check valve, minimizing any unnecessary bends or twists. This approach reduces the risk of fuel line damage and ensures efficient fuel flow. Avoid crossing over other components or running the line too close to heat sources, as this can lead to potential issues over time.

Optimal placement often involves mounting the check valve near the fuel source, allowing for a shorter and more direct connection. This proximity reduces the length of the fuel line, which in turn minimizes the potential for leaks and pressure drops. Additionally, consider the orientation of the valve; it should be positioned to allow for easy access during inspections and potential future adjustments.

In summary, the key to successful installation is a thoughtful approach to location and routing. By placing the check valve close to the fuel source and following a straight path, you ensure efficient fuel regulation and minimize the chances of system-related problems. This detailed planning will contribute to a reliable and well-maintained fuel system.

Understanding the Husqvarna YTH20B42T Fuel Pump Line Connections

You may want to see also

Valve Selection: Choose the right check valve size and material

When selecting a check valve for your fuel line installation, it's crucial to consider both the size and material of the valve to ensure optimal performance and longevity. The size of the check valve should match the diameter of your fuel line to allow for smooth and efficient fuel flow while preventing backflow. A common rule of thumb is to choose a check valve with a diameter that is at least 1/4 inch larger than the fuel line to accommodate potential pressure variations and ensure reliable operation. For instance, if your fuel line is 1/2 inch in diameter, a check valve with a 3/4-inch diameter would be a suitable choice.

The material of the check valve is another critical factor. Different materials offer varying levels of durability and compatibility with different fuels. For fuel lines, it is generally recommended to use materials that are resistant to corrosion and degradation caused by fuel chemicals. Common materials for check valves in fuel lines include brass, stainless steel, and certain types of plastic, such as PVDF (polyvinylidene fluoride). Brass is a popular choice due to its affordability and good corrosion resistance, while stainless steel provides excellent durability and is ideal for high-pressure applications. PVDF is often used in fuel systems where compatibility with various fuels is essential.

Consider the operating conditions and the specific requirements of your fuel system. If your fuel line is exposed to extreme temperatures or operates under high-pressure conditions, you might need a more robust material like stainless steel to ensure the valve can withstand these challenges without compromising performance. Additionally, check the manufacturer's guidelines and specifications for your fuel line and valve to ensure compatibility and proper sizing.

In summary, selecting the right check valve size and material involves matching the valve's dimensions to the fuel line diameter and choosing a material that can withstand the fuel's properties and the operating environment. This ensures that the check valve effectively prevents backflow while maintaining the integrity of the fuel system. Always refer to the manufacturer's recommendations and consult with experts if needed to make an informed decision.

Mastering RV-12 Fuel Line Bending: A Comprehensive Guide

You may want to see also

Installation Tools: Gather necessary tools for a successful installation

Before you begin the installation process, it's crucial to gather the right tools to ensure a smooth and efficient job. Here's a list of essential tools you'll need:

- Wrenches and Pliers: These are fundamental tools for any automotive repair. You'll require a set of adjustable wrenches to tighten and loosen various nuts and bolts. Pliers are also handy for gripping small components and turning valves. Ensure you have different sizes to accommodate various fasteners.

- Fuel Line Tools: Since you're working with a fuel line, specialized tools are necessary. A fuel line cutter or a set of fuel line cutting tools will help you make precise cuts. Additionally, consider getting a fuel line crimping tool to ensure a secure connection. These tools will make the installation process cleaner and more accurate.

- Screwdrivers: Having a variety of screwdrivers is essential. Phillips and flathead screwdrivers are common, but you might also need star (Torx) drivers for certain fasteners. This ensures you can access and secure all the necessary components during the installation.

- Tapes and Seals: Don't forget the small but crucial items like tape and seals. You'll need fuel line tape to secure and protect the new check valve connection. Additionally, consider getting a small amount of rubber or silicone sealant to ensure a watertight seal, especially if there are any existing leaks.

- Safety Gear: Safety should always be a priority. Wear gloves to protect your hands and ensure a clean installation. Safety goggles are also recommended to shield your eyes from any potential debris or fuel splashes.

By gathering these tools, you'll be well-prepared to tackle the installation of the fuel line check valve. Having the right equipment will make the process more manageable and help you achieve a professional-looking result. Remember, proper preparation is key to a successful automotive repair or modification.

Mastering the Art of Fuel Line Hook-Up: A 4-Wheeler Guide

You may want to see also

Assembly Steps: Follow a step-by-step guide for valve assembly

Before you begin the assembly process, ensure you have the necessary tools and components, including the check valve, fuel line, and any additional fittings or adapters required for your specific vehicle. It is crucial to follow the manufacturer's instructions or a trusted online guide tailored to your car's make and model. Here's a step-by-step guide to help you through the assembly:

- Prepare the Work Area: Start by setting up a clean and well-lit workspace. Lay out all the components and tools you'll need to avoid any confusion during the process. Ensure you have a flat surface to work on, and consider using a vise or clamp to hold the fuel line securely in place while you work.

- Locate the Installation Points: Identify the areas where the check valve will be installed. Typically, these are strategic points along the fuel line, often near the fuel pump or the engine. Mark these locations if necessary, so you can easily refer to them during assembly.

- Cut and Prepare the Fuel Line: Using a sharp, clean pair of cutting pliers or a fuel line cutter, carefully cut the fuel line to the desired length. Ensure the cut is clean and straight. Then, deburr the edges of the cut to prevent any sharp edges from causing damage or injury.

- Attach the Check Valve: Take the check valve and align it with the prepared fuel line. Securely fasten the valve to the fuel line using the appropriate fittings or adapters. Tighten the connections firmly, but be careful not to overtighten, as this can damage the fuel line or the valve itself.

- Test the Assembly: After completing the assembly, it's essential to test the check valve's functionality. Turn on the fuel pump and check for any leaks or unusual noises. Ensure that the valve is operating correctly, allowing fuel to pass when the engine is running and blocking it when the engine is off.

- Final Adjustments: If any adjustments are needed, make them carefully. Check for any tight spots or areas that require loosening. Ensure all connections are secure and that there are no obstructions that might prevent the valve from functioning optimally.

Remember, each vehicle may have unique requirements, so always refer to the specific instructions provided for your car. Following these detailed steps will help ensure a successful fuel line check valve installation.

Unraveling the Mystery: What's Beneath the Fuel Line in Elite: Dangerous

You may want to see also

Testing Procedures: Learn how to test the valve's functionality post-installation

After installing a fuel line check valve, it's crucial to test its functionality to ensure it's working correctly and preventing fuel leaks. Here's a step-by-step guide on how to test the valve:

Step 1: Prepare the Vehicle

Before testing, ensure the vehicle is parked on a level surface and the engine is cool. Turn off the ignition and disconnect the negative terminal of the battery to prevent any electrical interference during the test.

Step 2: Locate the Check Valve

Locate the fuel line check valve, which is typically installed near the fuel pump or in the fuel rail. It is often a small, cylindrical component with a built-in spring. Refer to your vehicle's manual if you're having trouble finding it.

Step 3: Inspect for Leaks

Start by visually inspecting the valve and the surrounding area for any signs of fuel leaks. Check for wet spots or fuel residue on the valve body and the fuel lines connected to it. If you notice any leaks, it may indicate a faulty installation or a pre-existing issue.

Step 4: Perform the Check Valve Test

- Remove the fuel line connections to the check valve.

- Temporarily block the fuel supply to the engine. You can do this by disconnecting the fuel line or using a fuel line clamp.

- Start the engine and listen for any unusual noises, especially hissing or roaring sounds, which could indicate a fuel leak.

- Check for any changes in engine performance. A properly functioning check valve should maintain the engine's performance without any noticeable changes.

- If the engine idles smoothly and there are no sounds of fuel escaping, the valve is likely functioning correctly.

Step 5: Re-test and Verify

After the initial test, it's essential to re-test the valve under different conditions. Try starting the engine with the fuel line disconnected and then reconnecting it. Observe the engine's behavior and listen for any fuel-related noises. If the valve is working correctly, the engine should start normally, and there should be no fuel leaks.

Step 6: Document and Monitor

Record your observations and any issues encountered during the testing process. If you notice any recurring problems, it may be necessary to consult a professional mechanic or refer to the vehicle's manual for further troubleshooting steps. Regularly monitoring the valve's performance can help identify potential issues early on.

Remember, proper testing ensures the check valve's effectiveness in maintaining a secure fuel system, preventing engine damage, and promoting overall vehicle reliability.

Sugar's Impact: How Fast Does It Affect Fuel Lines?

You may want to see also

Frequently asked questions

A fuel line check valve is a device installed in the fuel system of a vehicle to prevent fuel from flowing back into the engine when the vehicle is stationary. It is crucial to maintain fuel pressure and prevent engine damage caused by fuel contamination or loss of pressure.

Common signs that indicate a faulty check valve include engine misfires, reduced fuel efficiency, and the smell of gasoline inside the vehicle. If you notice any of these symptoms, it is advisable to have the valve inspected and replaced if necessary.

While some vehicles may allow for DIY installation, it is generally recommended to seek professional assistance. Fuel system repairs can be complex, and improper installation may lead to further issues. Automotive technicians have the expertise and tools to ensure a correct and safe installation.

The process typically involves draining the fuel tank, removing the old valve, and installing the new one. This requires disconnecting the fuel lines, using the right tools for removal and insertion, and ensuring proper torque specifications. It is a delicate process, and professionals can ensure the job is done correctly.