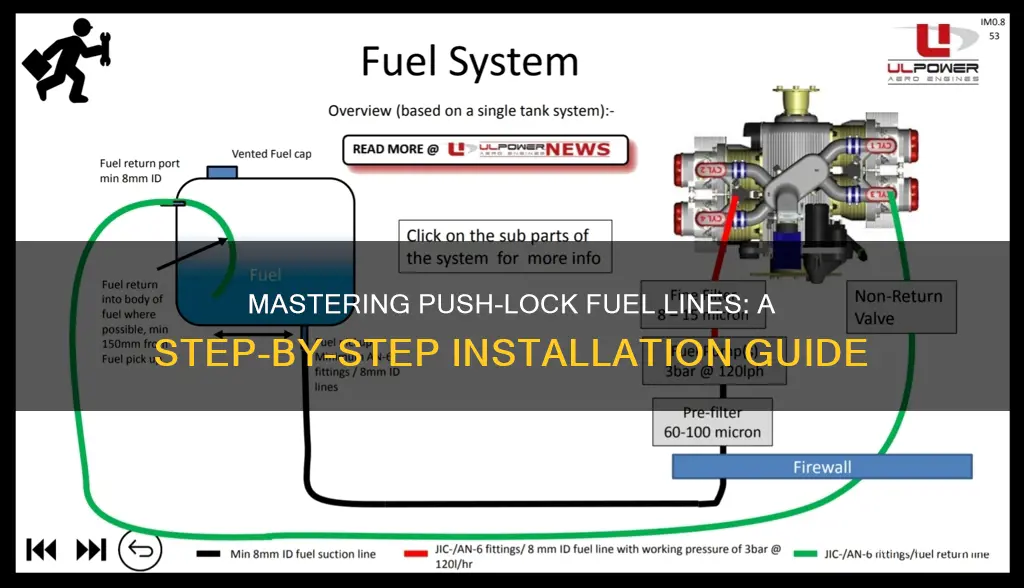

Installing a push lock fuel line to a fitting is a straightforward process that ensures a secure and leak-free connection. This method is commonly used in automotive applications to connect fuel lines to various components, such as fuel tanks or fuel pumps. The push lock design provides a quick and easy way to attach the line, making it a popular choice for mechanics and DIY enthusiasts. By following a few simple steps, you can ensure a tight and reliable connection, which is crucial for maintaining the integrity of your vehicle's fuel system. This guide will provide a step-by-step approach to help you master this installation technique.

What You'll Learn

- Prepare Tools: Gather necessary tools: wrench, fuel line, fitting, and cleaning supplies

- Clean Fitting: Ensure fitting is clean and free of debris for a secure connection

- Cut Fuel Line: Measure and cut fuel line to fit the fitting, using a sharp blade

- Slide onto Fitting: Slide the fuel line onto the fitting, ensuring a snug fit

- Tighten Securely: Tighten the connection with a wrench, but be careful not to over-tighten

Prepare Tools: Gather necessary tools: wrench, fuel line, fitting, and cleaning supplies

To begin the installation of a push-lock fuel line to a fitting, it is crucial to ensure you have the right tools and materials ready. Start by gathering a set of essential tools and supplies. Firstly, you will need a wrench, preferably a adjustable spanner or a fuel line wrench, which is specifically designed for working with fuel lines. This tool will help you tighten and secure the connections. Next, procure a length of fuel line that matches the size and type required for your specific application. Ensure it is compatible with the existing fuel system and has the necessary fittings at both ends.

In addition to the fuel line, you should have a suitable fitting that is designed to connect the fuel line to the engine or fuel tank. This fitting should be compatible with the fuel line material and have a secure locking mechanism, such as a push-lock, to ensure a tight and leak-proof connection. Make sure you have the appropriate size and type of fitting for your fuel line. Along with these components, it is essential to have cleaning supplies. This includes a fuel line cleaner, which will help remove any contaminants or old fuel residue from the existing fuel lines, ensuring a clean and proper connection. You might also need a brush or a small cleaning tool to assist in the cleaning process.

Having all these tools and supplies prepared beforehand will make the installation process much smoother and efficient. It ensures that you have everything readily available, allowing you to focus on the task at hand without interruptions. By gathering these items, you are setting the foundation for a successful and secure fuel line installation.

Fixing a Clogged Fuel Line: A Step-by-Step Guide to Lawn Mower Repair

You may want to see also

Clean Fitting: Ensure fitting is clean and free of debris for a secure connection

When installing a push-lock fuel line to a fitting, ensuring a clean and debris-free connection is crucial for a secure and reliable setup. This process might seem straightforward, but taking the time to properly prepare the fitting can prevent potential issues down the line. Here's a step-by-step guide to achieving a clean and precise connection:

Step 1: Gather the Necessary Tools and Materials

Before you begin, ensure you have all the required tools and materials. This includes the push-lock fuel line, a suitable solvent or cleaner, a rag or cloth, and possibly a small brush for more delicate cleaning. Having everything ready will make the process smoother and more efficient.

Step 2: Prepare the Fitting

Start by inspecting the fitting you intend to connect. Use a rag or cloth to wipe down the fitting's surface, removing any visible dirt, grease, or debris. Pay close attention to the threads and the area where the fuel line will be inserted. Ensure that the fitting is free from any contaminants that could interfere with the connection.

Step 3: Clean the Fitting Thoroughly

If the fitting is particularly dirty or greasy, you may need to use a solvent or cleaner. Apply the cleaner to the fitting and allow it to work for a few minutes to dissolve any stubborn grime. Then, use a small brush or your fingers (gloved if preferred) to scrub the threads and the insertion point thoroughly. Rinse the fitting with clean water to remove any residue, ensuring it is completely dry before proceeding.

Step 4: Inspect for Final Cleanliness

After cleaning, inspect the fitting once more to ensure it is free from any debris or contaminants. You can use a magnifying glass or a bright light to help with this inspection. If any residue or dirt is present, repeat the cleaning process until the fitting is spotless. A clean fitting will ensure a tight and secure connection when you insert the fuel line.

By following these steps, you'll create an optimal environment for a successful push-lock fuel line installation. Remember, taking the time to clean the fitting is an essential part of the process, as it guarantees a reliable and long-lasting connection.

Mastering the Art of Fuel Line Bending: Tips for a Tight Fit

You may want to see also

Cut Fuel Line: Measure and cut fuel line to fit the fitting, using a sharp blade

When installing a push-lock fuel line to a fitting, one crucial step is accurately measuring and cutting the fuel line to ensure a proper fit. This process requires precision and attention to detail to avoid any potential issues during the installation. Here's a step-by-step guide on how to measure and cut the fuel line:

Measuring the Fuel Line:

Start by carefully examining the fuel line and the fitting you are connecting it to. Measure the length of the fuel line required to connect the two points. Use a flexible measuring tape or a ruler to get an accurate measurement. Take note of any bends or curves in the line, as these will influence the cutting process. It's essential to measure twice to ensure you get the correct length, as cutting the line too short can lead to installation difficulties.

Preparing the Cutting Tools:

Before you begin cutting, ensure you have a sharp blade specifically designed for cutting fuel lines or similar materials. A sharp blade will make a clean cut and prevent damage to the fuel line. You can use a utility knife or a dedicated fuel line cutter, which often has a serrated edge for easier cutting. Additionally, consider wearing safety gloves to protect your hands during the process.

Cutting the Fuel Line:

Place the fuel line on a stable surface, ensuring it is straight and aligned with the desired cut point. Using your sharp blade, carefully cut along the measured length. Apply steady pressure and make a clean, straight cut. Avoid applying excessive force, as it may cause the blade to skip or damage the fuel line. If you're using a dedicated fuel line cutter, follow the manufacturer's instructions for the best cutting technique.

Finishing the Cut:

Once the initial cut is made, inspect the edges to ensure they are smooth and straight. If the cut is not precise, it may affect the installation process. Consider using a file or sandpaper to smooth any rough edges, especially if you're using a utility knife. Take your time with this step to ensure a professional finish.

Remember, accurate measurement and a sharp, precise cut are key to a successful installation. By following these steps, you can ensure that the fuel line is cut to the correct length, making the push-lock installation process smoother and more efficient.

Unveiling the Magic: How Fuel Line Primer Bulbs Work

You may want to see also

Slide onto Fitting: Slide the fuel line onto the fitting, ensuring a snug fit

When installing a push-lock fuel line to a fitting, one crucial step is ensuring a secure and snug connection. This process involves sliding the fuel line onto the fitting, creating a tight seal that prevents fuel leaks and ensures optimal performance. Here's a detailed guide on how to achieve this:

Start by preparing the fuel line and fitting. Ensure the fitting is clean and free of any debris or contaminants. Inspect the fuel line for any damage or wear, replacing it if necessary. The key to a successful installation lies in the preparation and alignment of the components.

Now, slide the fuel line onto the fitting. Begin at one end of the fitting and carefully guide the fuel line over the threads or the fitting's surface. Apply gentle, even pressure as you slide the line onto the fitting. The goal is to create a smooth, continuous motion without forcing the line, as this can damage the fitting or the line itself. Take your time and ensure the line is properly aligned with the fitting's opening.

As you slide the fuel line onto the fitting, pay close attention to the fit. The line should feel snug against the fitting, with no gaps or loose areas. If you encounter resistance or feel the line is not seated properly, stop and re-evaluate your technique. Ensure that the fuel line is not kinked or twisted, as this can affect the seal and lead to potential issues.

To ensure a tight seal, consider using a fuel line clamp or a push-lock fitting, depending on your preference and the application. These accessories provide an additional layer of security, locking the fuel line in place and preventing it from coming loose. When using a clamp, ensure it is the correct size and securely fastened to avoid any movement or leakage.

By following these steps and paying attention to detail, you can effectively slide the fuel line onto the fitting, creating a secure and reliable connection. This process is essential for maintaining the integrity of your fuel system and ensuring the safe and efficient operation of your vehicle or equipment. Remember, a proper installation contributes to the overall performance and longevity of your fuel-related components.

Mastering Carburetor Fuel Flow: A Guide to Running Return Lines

You may want to see also

Tighten Securely: Tighten the connection with a wrench, but be careful not to over-tighten

When installing a push-lock fuel line to a fitting, ensuring a tight and secure connection is crucial to prevent fuel leaks and maintain the integrity of your fuel system. Here's a step-by-step guide on how to tighten the connection securely:

Start by ensuring you have the right tools, including a wrench that fits the size of the fitting. It's important to use the correct tool to avoid damage to the fitting or the fuel line. Locate the push-lock fuel line and the fitting it needs to connect to. Position the fuel line so that the push-lock mechanism aligns with the fitting. This mechanism is designed to create a secure seal when engaged. Apply firm pressure to the fuel line, ensuring it is fully inserted into the fitting. This initial pressure will help create a tight seal.

Now, it's time to tighten the connection. Take the wrench and place it on the fitting, ensuring it is positioned correctly to turn the fitting in a clockwise direction. Apply a steady and firm force to the wrench, turning it in a clockwise motion. The goal is to tighten the fitting without applying excessive force. You should feel resistance as the fitting starts to tighten, but it should not feel forced or difficult. Use your judgment and stop when the fitting is snug and secure.

Over-tightening can lead to several issues. It may damage the fuel line or the fitting, causing potential fuel leaks. Additionally, over-tightening can strip the threads or damage the internal components of the fitting. Always be mindful of the amount of force you apply. A secure connection is achieved when the fitting is tight enough to prevent movement but not so tight that it causes damage.

After tightening the connection, give the fuel line a gentle test by applying slight pressure. Ensure there is no movement or play in the connection. If everything feels secure, you've successfully tightened the push-lock fuel line to the fitting. Remember, a careful and measured approach is key to ensuring a reliable and leak-free fuel system.

Unveiling the Power of 8AN Fuel Lines: A Comprehensive Guide

You may want to see also

Frequently asked questions

A push lock fuel line fitting is a type of connector used in fuel systems to join fuel lines to fuel tanks, pumps, or other components. It is designed with a locking mechanism that allows for a secure and leak-free connection without the need for nuts, bolts, or screws.

Installation is generally straightforward and can be done by following these steps: First, ensure you have the correct size and type of push lock fitting for your fuel line. Then, cut the fuel line to the desired length, deburr the ends if necessary, and insert the line into the fitting. Align the locking mechanism and push the fitting onto the fuel line until it is fully seated. You should feel a distinct 'click' or 'snap' when the fitting is properly locked in place.

Yes, removing a push lock fitting is possible, but it requires a bit more effort compared to regular fittings. You will need a special tool or a pair of pliers to release the locking mechanism. Carefully insert the tool into the fitting's locking groove and apply gentle force to unlock it. Once unlocked, you can remove the fitting by pulling it straight off the fuel line. Make sure to clean the fitting and fuel line thoroughly before reinstalling or reusing them.