Hooking up a fuel cell to power a car is a complex process that involves integrating the fuel cell system with the vehicle's existing electrical infrastructure. This technology, which converts chemical energy from hydrogen into electricity, offers a promising alternative to traditional internal combustion engines. The process begins with the installation of a fuel cell stack, which is the heart of the system, and the necessary components such as a hydrogen storage system, air compressor, and control electronics. The fuel cell then needs to be connected to the car's battery, alternator, and other electrical systems to ensure efficient power distribution and management. This guide will provide a step-by-step overview of the installation and integration process, covering the technical aspects and considerations for a successful fuel cell-powered vehicle.

What You'll Learn

Fuel Cell Basics: Understand the components and their functions

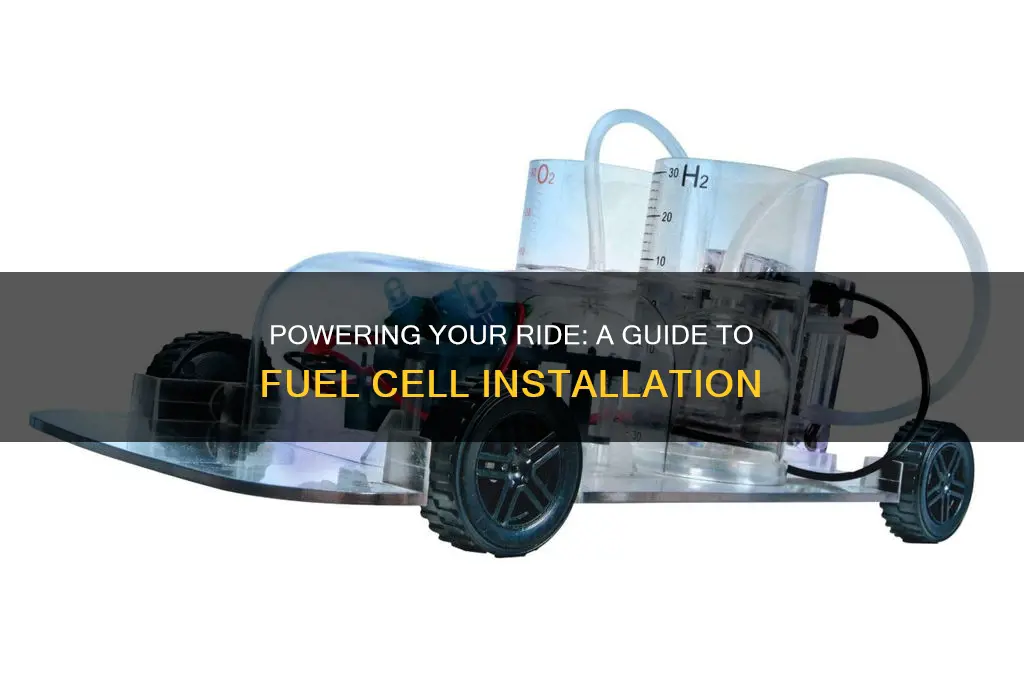

A fuel cell is a device that converts chemical energy from a fuel source, typically hydrogen, into electricity through a process called electrochemical reactions. This technology is a clean and efficient alternative to traditional internal combustion engines, offering a promising solution for powering vehicles with zero direct emissions. Understanding the basic components and their functions is essential to grasp the concept of how fuel cells work in automobiles.

The core of a fuel cell consists of an electrolyte, an anode, and a cathode. The electrolyte is a conductive material that facilitates the movement of ions between the anode and cathode while preventing the flow of electrons. This separation of charge carriers is crucial for the cell's operation. Typically, a polymer membrane, such as Nafion, is used as the electrolyte due to its ability to conduct protons (H+) while blocking electrons.

At the anode, the fuel, usually hydrogen gas, undergoes oxidation, releasing electrons and protons. The electrons flow through an external circuit, providing electrical power, while the protons migrate through the electrolyte to reach the cathode. In the cathode, oxygen from the air combines with the protons and electrons to form water, completing the reaction. This process is known as the fuel cell's electrochemical reaction, which generates electricity.

Other essential components include the fuel supply system, which delivers hydrogen gas to the anode, and the air supply system, which provides oxygen to the cathode. These systems ensure a continuous supply of reactants for the cell's operation. Additionally, fuel cells often incorporate a catalyst, typically made of precious metals like platinum, to lower the activation energy of the reactions, making the process more efficient.

Understanding these basic components and their roles is fundamental to the process of hooking up a fuel cell in a car. It involves ensuring the proper connection of these elements to create a functional power source for the vehicle, offering a sustainable and environmentally friendly driving experience.

The Science of F1 Fuel: Powering the Ultimate Race Cars

You may want to see also

System Integration: Connect fuel cell to car's power system

When integrating a fuel cell into a vehicle's power system, it's crucial to understand the specific requirements and compatibility of the fuel cell system and the car's existing electrical architecture. The process involves connecting the fuel cell to the car's power grid, which typically includes the battery, inverter, and other electrical components. Here's a detailed guide on how to achieve this integration:

- Electrical Compatibility Assessment: Begin by evaluating the electrical specifications of both the fuel cell system and the vehicle. Ensure that the voltage, current, and power output of the fuel cell align with the car's electrical system. This assessment is vital to prevent damage to the fuel cell or the vehicle's components. Check the fuel cell's operating range and the car's electrical system's capabilities to ensure a safe and efficient connection.

- Power Inverter Installation: In many cases, a power inverter is necessary to convert the direct current (DC) output of the fuel cell into alternating current (AC) that the car's electrical system can use. Install the inverter in a location that provides easy access for maintenance and ensures it is securely mounted within the vehicle's engine compartment or designated electrical bay. Follow the manufacturer's instructions for wiring connections and ensure proper grounding to minimize electrical interference.

- Fuel Cell Mounting and Wiring: Securely mount the fuel cell unit within the vehicle, ensuring it is positioned away from heat sources and potential hazards. Connect the fuel cell's positive and negative terminals to the corresponding terminals on the inverter or directly to the car's battery, depending on the system design. Use high-quality wiring harnesses and terminals to ensure a reliable and safe connection. Proper insulation and routing of wires are essential to prevent damage and maintain a clean installation.

- System Integration and Control: Integrate the fuel cell system with the car's existing power management and control systems. This may involve programming the fuel cell controller to communicate with the vehicle's onboard computer. Ensure that the system can monitor and control fuel cell operation, including start-up, shutdown, and power output adjustments. The integration should also include safety mechanisms, such as over-current protection and temperature monitoring, to safeguard the fuel cell and the vehicle.

- Testing and Calibration: After the installation, conduct thorough testing and calibration. Check the system's performance, voltage, and current levels to ensure they meet the required specifications. Calibrate the fuel cell controller and any associated sensors to optimize power delivery and efficiency. This step is critical to ensure the fuel cell operates seamlessly with the vehicle's power system.

Remember, the specific steps and components required may vary depending on the fuel cell technology, vehicle model, and manufacturer's guidelines. It is essential to consult the fuel cell system's documentation and seek professional assistance when performing such complex integrations.

The Grinding, Sputtering Sound: When Your Car's Fuel Pump Fails

You may want to see also

Fuel Supply: Manage hydrogen storage and delivery

The efficient management of hydrogen storage and delivery is a critical aspect of integrating fuel cells into vehicles. Hydrogen, being a highly flammable gas, requires careful handling to ensure the safety and reliability of the fuel cell system. Here's an overview of the key considerations for managing hydrogen storage and delivery in a fuel cell vehicle:

Storage Systems: Hydrogen storage in vehicles can be achieved through various methods, each with its own advantages and challenges. One common approach is the use of compressed hydrogen gas tanks. These tanks are typically made of lightweight, high-strength materials like aluminum or composite materials to withstand the high pressure required for storage. The pressure in these tanks can range from 350 to 700 bars (5,000 to 10,000 psi), allowing for sufficient hydrogen storage while maintaining a compact vehicle design. Another storage method involves the use of metal hydrides or chemical hydrides, which store hydrogen through chemical reactions. These systems offer higher energy densities but may require more complex storage and release mechanisms.

Hydrogen Delivery: The delivery of hydrogen to the fuel cell stack is a crucial process. In a typical fuel cell vehicle, hydrogen is supplied from the storage system to the fuel cell stack through high-pressure pipelines or hoses. These pipelines must be carefully designed to minimize hydrogen leakage and ensure efficient delivery. The system should include pressure regulators to control the hydrogen flow and maintain the required pressure for the fuel cell stack. Additionally, filters and separators may be employed to remove any impurities or contaminants from the hydrogen stream, ensuring optimal performance and longevity of the fuel cell.

Safety Measures: Given the hazardous nature of hydrogen, implementing robust safety measures is essential. This includes pressure relief valves in the storage tanks to prevent overpressure and potential hazards. Venting systems should be designed to safely release any excess hydrogen or byproducts during operation. Furthermore, hydrogen sensors can be installed to detect leaks and trigger alarms or safety protocols. Regular maintenance and inspections of the storage and delivery systems are vital to identify and rectify any potential issues.

On-Board Infrastructure: The vehicle's internal infrastructure plays a significant role in managing hydrogen supply. This includes the fuel cell stack, which is the heart of the system, and the associated control electronics. The stack's design should accommodate the specific hydrogen delivery requirements, ensuring a steady and controlled supply of hydrogen to each cell. Advanced control systems monitor and optimize the hydrogen flow, temperature, and pressure, maximizing efficiency and performance.

Effective management of hydrogen storage and delivery is essential for the successful implementation of fuel cell technology in automobiles. It requires a combination of innovative storage solutions, efficient delivery systems, and stringent safety measures to ensure a reliable and environmentally friendly transportation option. As research and development in this field progress, we can expect further advancements in hydrogen storage and delivery technologies, making fuel cell vehicles more accessible and practical for the general public.

Fuel Injector Cleaner: Pouring While Car Running?

You may want to see also

Power Generation: Convert hydrogen to electricity for the car

The process of converting hydrogen into electricity for a car's power generation involves a fuel cell, a device that harnesses the chemical energy of hydrogen to produce electrical power. This technology is a key component of the emerging electric vehicle (EV) market, offering a clean and efficient alternative to traditional internal combustion engines. Here's a detailed guide on how to set up and utilize a fuel cell for power generation in a car:

Fuel Cell Basics:

A fuel cell operates on the principle of electrochemical reactions. It consists of an anode and cathode, separated by an electrolyte membrane. When hydrogen gas is supplied to the anode, it undergoes a reaction, releasing electrons and forming protons. These electrons flow through an external circuit, providing the electrical current, while the protons move through the electrolyte to reach the cathode. At the cathode, oxygen from the air combines with the protons and electrons to form water, completing the reaction.

System Setup:

- Fuel Cell Stack: The core component is the fuel cell stack, which comprises multiple individual fuel cells. Each cell generates a small amount of electricity, and the stack is designed to produce the required power output. The stack is typically a thin, flat structure with a series of cells arranged in parallel or series to achieve the desired voltage and current.

- Hydrogen Supply System: Hydrogen is the fuel for the cell, and it needs to be supplied under pressure to the anode. This can be achieved through a high-pressure hydrogen tank or a reformer system. The latter is more common in automotive applications, as it generates hydrogen on-board by reforming natural gas or methanol. The reformer heats the fuel and water to produce hydrogen and carbon dioxide.

- Air Supply: Oxygen is required at the cathode for the electrochemical reaction. A compressor system is used to supply air to the cell stack, ensuring a steady flow of oxygen.

- Power Management Unit: This electronic control unit (ECU) regulates the entire process, monitoring the fuel cell's performance, adjusting the hydrogen and air flow rates, and managing the overall power output to match the car's requirements.

Power Generation Process:

- When the car's ignition is turned on, the ECU activates the fuel cell stack, allowing hydrogen to flow through the anode.

- The electrochemical reaction occurs, generating electricity and water as a byproduct.

- The electricity produced is then directed to the car's battery or directly to the electric motor, powering the vehicle.

- The water produced at the cathode is typically expelled as steam or condensed and recycled back into the system.

Advantages of Fuel Cell Power Generation:

- Zero direct emissions, making it an environmentally friendly power source.

- High energy efficiency, converting most of the hydrogen's chemical energy into electricity.

- Quiet operation, as there is no mechanical engine involved.

- Rapid refueling, similar to conventional gasoline or diesel vehicles.

This technology offers a promising solution for the future of sustainable transportation, providing efficient and clean power for electric vehicles.

Speeding: The Fuel-Consuming Truth: How Fast Driving Affects Your Car's Fuel Efficiency

You may want to see also

Emission Control: Ensure no harmful emissions are released

When integrating a fuel cell into a vehicle, it's crucial to prioritize emission control to ensure that the system operates efficiently and environmentally friendly. Here's a detailed guide on how to achieve this:

Design and Material Selection: Start by choosing materials and components that are compatible with the fuel cell's operating environment. Opt for corrosion-resistant materials to prevent any degradation of the fuel cell's performance over time. The fuel cell stack, for instance, should be designed to handle the corrosive nature of hydrogen and oxygen, ensuring its longevity.

Emission Control Systems: Implement a sophisticated emission control system tailored to the fuel cell's output. This system should include a catalyst that facilitates the conversion of harmful byproducts into less toxic substances. For instance, a platinum-based catalyst can efficiently reduce carbon monoxide (CO) and unburned hydrocarbons, which are common pollutants from fuel cell operation. Additionally, consider integrating a selective catalytic reduction (SCR) system to further minimize the release of nitrogen oxides (NOx), another harmful emission.

Hydrogen and Oxygen Management: Proper management of hydrogen and oxygen is essential. Ensure that the fuel cell system is designed to deliver a consistent and controlled supply of hydrogen while maintaining a precise oxygen-to-fuel ratio. This precision is critical to preventing the formation of harmful combustion products, such as carbon monoxide and nitrogen oxides. Advanced fuel injection systems and sensors can be employed to monitor and adjust these parameters in real-time.

Monitoring and Diagnostics: Develop a comprehensive monitoring system to keep track of the fuel cell's performance and emissions. This includes sensors to measure hydrogen and oxygen levels, temperature, and pressure. Real-time data analysis can help identify any deviations from optimal operation, allowing for immediate adjustments to maintain emission control. For instance, if a sensor detects a sudden increase in temperature, it could indicate a potential issue with the fuel cell or the emission control system, prompting further investigation.

Regular Maintenance and Calibration: Establish a maintenance schedule that includes regular checks and calibration of the emission control system. Over time, catalysts may lose their efficiency, and sensors might drift, affecting the overall emission control. Calibration ensures that the sensors provide accurate readings, and the emission control system functions optimally. Regular maintenance also involves inspecting the fuel cell stack for any signs of corrosion or damage, replacing worn-out components, and ensuring the overall system's reliability.

Fuel City Car Wash: Affordable Clean, Fast Service

You may want to see also

Frequently asked questions

A fuel cell is an electrochemical device that converts chemical energy from a fuel, typically hydrogen, directly into electricity through a reaction with oxygen in the air. In a car, it serves as a power source, replacing the internal combustion engine. The fuel cell generates electricity through a process called electrolysis, where hydrogen gas is split into protons and electrons. The electrons flow through an external circuit, providing power to the car's electrical systems, while the protons and oxygen combine to form water, which is a byproduct of the reaction.

Connecting a fuel cell to your car's electrical system involves several steps. First, ensure that the fuel cell system has the appropriate voltage and current ratings to match your car's requirements. You'll need to install a fuel cell stack, which is the core component that generates electricity, and connect it to the car's battery or alternator. This connection allows the fuel cell to power the vehicle's accessories and charge the battery simultaneously. It's crucial to follow the manufacturer's guidelines for wiring and installation to ensure safety and optimal performance.

Fuel cell technology is designed to be adaptable and can be integrated into various vehicle types. You can retrofit a fuel cell system into your existing car, but it may require modifications to accommodate the fuel cell stack and associated components. However, for a seamless and efficient installation, it is recommended to consider vehicles specifically designed for fuel cell technology, as they often have optimized systems and infrastructure to support the fuel cell's operation. These vehicles are engineered to provide a balanced power-to-weight ratio and efficient energy management.

Fuel cells offer several advantages over traditional internal combustion engines. Firstly, they produce zero tailpipe emissions, making them environmentally friendly. The only byproduct is water vapor and warm air, contributing to a cleaner and greener future. Secondly, fuel cells provide efficient energy conversion, resulting in higher energy density and longer driving ranges compared to batteries. This makes them suitable for long-distance travel. Additionally, fuel cells offer quick refueling times, similar to conventional vehicles, and have a longer lifespan, reducing maintenance costs.

While fuel cells present numerous benefits, there are some challenges to consider. One major limitation is the availability of hydrogen fuel infrastructure. The widespread distribution of hydrogen gas for refueling stations is still developing, which can restrict the practicality of fuel cell vehicles. Additionally, the initial cost of fuel cell systems can be high, making it a significant investment for consumers. Furthermore, the technology requires careful management of temperature and pressure to ensure optimal performance and safety, especially in varying environmental conditions.