Fuel line purging is a crucial process in maintaining the performance and longevity of your vehicle's fuel system. It involves removing air bubbles and contaminants from the fuel lines, ensuring that your engine receives clean, fresh fuel. This process is particularly important after fuel system repairs, when a vehicle has been sitting for an extended period, or when switching between different types of fuel. By following a systematic approach to fuel line purging, you can optimize your vehicle's performance, improve fuel efficiency, and prevent potential engine issues caused by contaminated fuel.

What You'll Learn

- Understanding Fuel Line Purging: Identify the purpose and process of purging fuel lines

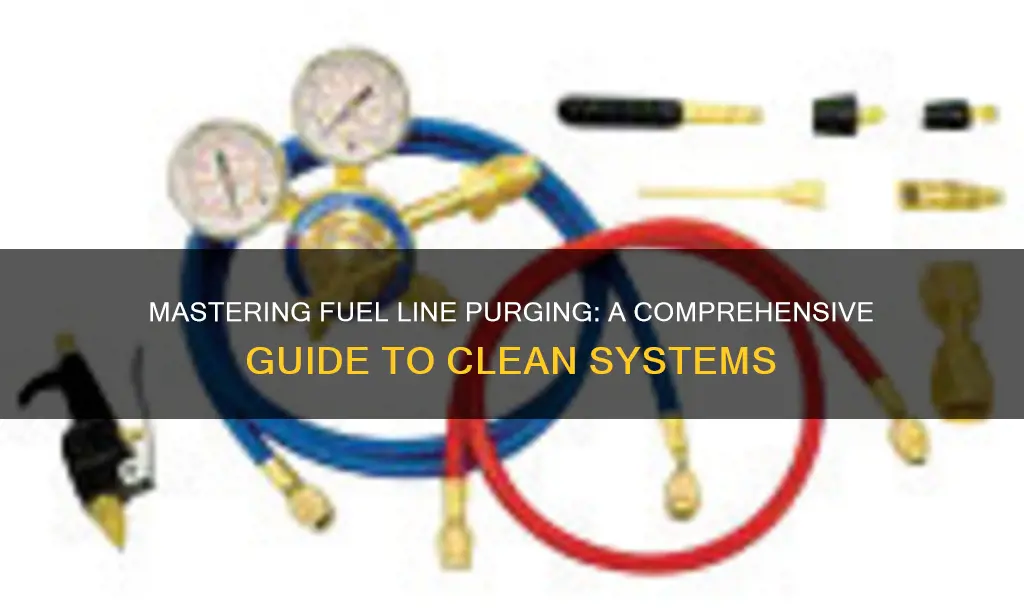

- Tools and Materials: Gather necessary tools like pressure gauges and fuel line cleaners

- Safety Precautions: Ensure safety by wearing protective gear and following manufacturer guidelines

- Purging Process: Follow a step-by-step procedure to purge fuel lines effectively

- Troubleshooting: Address common issues and errors during the purging process

Understanding Fuel Line Purging: Identify the purpose and process of purging fuel lines

Fuel line purging is a crucial maintenance procedure for vehicles, especially those with fuel injection systems. It serves the primary purpose of removing air bubbles and contaminants from the fuel lines, ensuring optimal fuel delivery to the engine. This process is essential to maintain engine performance, efficiency, and longevity. Over time, fuel lines can accumulate air pockets and impurities, leading to various issues such as poor fuel atomization, reduced power, and even engine misfires.

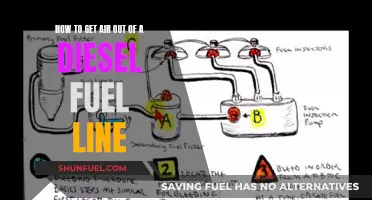

The process of fuel line purging involves a systematic approach to identify and eliminate these air bubbles. It typically begins with the driver or mechanic identifying potential problem areas, such as low-lying sections of the fuel lines or areas where air can easily enter, like fuel tanks or fuel pumps. The first step is to locate the fuel line's lowest point, often near the engine or the fuel tank, and open the fuel line at this point to allow air to escape. This can be done by removing a section of the fuel line or using a specialized tool to create an opening. As the fuel line is opened, air will be released, and it's important to monitor this process to ensure all air bubbles are expelled.

Once the initial purging is complete, the fuel lines need to be closed and sealed to prevent further air entry. This is achieved by carefully reconnecting the fuel line segments or using appropriate seals. After sealing, the system is then pressurized to force any remaining air bubbles through the fuel system. This step may require specialized equipment to control the pressure and ensure the fuel lines are thoroughly purged.

The final stage of fuel line purging involves monitoring the engine's performance during and after the process. Mechanics often use diagnostic tools to check for any error codes or unusual behavior, ensuring that the purging process has been successful. This step is critical as it helps identify any potential issues with the fuel system that may require further attention.

Understanding the purpose and process of fuel line purging is essential for vehicle owners and mechanics alike. It ensures that the fuel system operates efficiently, delivering clean, pressurized fuel to the engine, which in turn improves performance and extends the life of the vehicle's fuel system components. Regular maintenance, including fuel line purging, is a proactive approach to vehicle care.

Toyota Sienna Fuel Line Clip Removal: A Step-by-Step Guide

You may want to see also

Tools and Materials: Gather necessary tools like pressure gauges and fuel line cleaners

To effectively purge fuel lines, you'll need a set of specialized tools and materials to ensure a thorough cleaning process. Here's a detailed breakdown of the essential items you should gather:

Pressure Gauges: These are crucial for monitoring the pressure within the fuel system during purging. You'll need a gauge that can accurately measure fuel pressure in the range typically found in automotive applications. Look for gauges with a good range, preferably with a digital display for precise readings. Having multiple pressure gauges can be beneficial if you're working on multiple vehicles simultaneously.

Fuel Line Cleaners: Cleaning agents are the core of the purging process. You'll require a fuel line cleaner that is effective in dissolving and removing contaminants. There are various types available, including chemical cleaners and solvent-based options. Choose a cleaner specifically designed for fuel lines to ensure it can penetrate and clean the internal surfaces effectively. Follow the manufacturer's instructions for application and contact time to achieve optimal results.

Fuel Line Brushes: These brushes are essential for physically cleaning the fuel lines. Look for stiff, bristled brushes with a flexible shaft that can navigate the twists and turns of the fuel lines. The brush should be long enough to reach deep into the lines, ensuring a thorough clean. Consider getting a set with different brush sizes to accommodate various fuel line diameters.

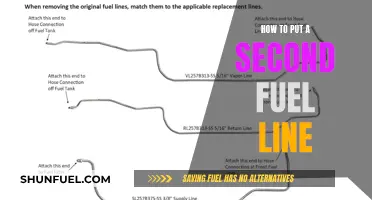

Hose Clamps and Fittings: You'll need hose clamps to secure the fuel lines temporarily during the purging process. Opt for high-quality clamps that can withstand fuel pressure without leaking. Additionally, have a variety of fuel line fittings on hand, such as tees, elbows, and couplings, to reconnect the fuel lines after cleaning.

Safety Gear: While not directly related to the purging process, safety gear is essential. Wear gloves to protect your hands from chemicals and potential fuel spills. Safety goggles are also recommended to shield your eyes from any splashes or fumes.

By gathering these tools and materials, you'll be well-prepared to tackle fuel line purging effectively. Remember to always follow safety protocols and manufacturer guidelines when working with fuel systems to ensure a safe and successful outcome.

Unplugging Fuel Lines: A Step-by-Step Guide to a Smooth Process

You may want to see also

Safety Precautions: Ensure safety by wearing protective gear and following manufacturer guidelines

When performing fuel line purging, it is crucial to prioritize safety to prevent any potential hazards. Here are some essential safety precautions to keep in mind:

Protective Gear: Before beginning the purging process, ensure you are adequately protected. Wear appropriate personal protective equipment (PPE) such as gloves, safety goggles, and a respirator mask. Fuel lines can contain volatile substances, and proper ventilation is essential. Gloves will protect your hands from potential splashes or burns, while safety goggles shield your eyes from any debris or splatters. A respirator mask is vital to avoid inhaling harmful fumes.

Manufacturer's Guidelines: Always refer to the manufacturer's instructions and guidelines specific to your vehicle or equipment. Different makes and models may have unique requirements and procedures. These guidelines often include detailed steps, recommended tools, and safety protocols. Following the manufacturer's recommendations ensures you are using the correct methods and tools, reducing the risk of errors or damage.

Ventilation and Containment: Set up a well-ventilated workspace to minimize the inhalation of fumes. If working in a confined area, consider using a fume hood or working outdoors. Proper ventilation helps disperse fumes and reduces the risk of inhalation. Additionally, contain the purging process to prevent fuel from spreading. Use a catch basin or a suitable container to collect any fuel that may spill or drip.

Fire Safety: Fuel line purging involves working with flammable substances, so fire safety is critical. Ensure there are no open flames or sparks in the vicinity. Keep a fire extinguisher nearby, specifically rated for fuel or chemical fires. In case of a fire emergency, have a clear plan and know how to respond promptly.

Training and Supervision: If you are not familiar with the process, consider seeking guidance from a professional or someone with experience. Proper training ensures you understand the potential risks and know how to handle the task safely. Supervision is also beneficial, especially for complex purging procedures, to ensure all safety measures are followed.

Remember, safety should always be the top priority when working with fuel lines. By adhering to these precautions and guidelines, you can minimize risks and ensure a safe purging process.

Mastering the Art of Tying into Metal Fuel Lines

You may want to see also

Purging Process: Follow a step-by-step procedure to purge fuel lines effectively

The process of purging fuel lines is an essential maintenance task to ensure optimal engine performance and longevity. It involves removing contaminants and air bubbles from the fuel system, which can cause issues such as poor fuel atomization, engine misfires, and reduced power. Here's a step-by-step guide to effectively purge your fuel lines:

- Preparation: Begin by locating the fuel tank and identifying the fuel lines that need purging. Typically, this includes the lines connecting the fuel tank to the engine and any lines that run along the frame or under the vehicle. Ensure you have the necessary tools, such as a fuel pump primer bulb or a small hand pump, and a container to collect any purged fuel.

- Fuel Pump Operation: Start by running the engine and allowing it to idle. Turn the ignition to the 'on' position, but do not start the engine. This step is crucial as it activates the fuel pump, which will help in the purging process. Listen for the fuel pump's operation, ensuring it is functioning correctly.

- Purging the Lines: With the engine idling, locate the fuel lines you want to purge. Use the primer bulb or hand pump to apply gentle pressure to the fuel line near the tank. This action forces fuel through the lines, pushing out any air bubbles or contaminants. Work your way along the lines, applying pressure and releasing it periodically to allow fuel to flow back into the tank. Be thorough and ensure all sections of the lines are purged.

- Collection and Inspection: As you purge, collect any fuel that comes out of the lines in the container. This collected fuel may contain contaminants or air, so it's important to dispose of it properly or use it for other purposes, such as cleaning the fuel filter. Inspect the collected fuel for any signs of contamination, such as discoloration or sediment. If you notice any issues, consider replacing the fuel filter to ensure clean fuel reaches the engine.

- Engine Operation: After purging, start the engine and allow it to run for a few minutes. Listen for any unusual noises or vibrations, and check for any changes in engine performance. The engine should now be running smoothly, free from the previous issues caused by contaminated fuel.

- Post-Purging Maintenance: Regularly perform this purging process, especially after long periods of inactivity or when switching between different fuel types. This maintenance routine will help keep your fuel system clean and ensure optimal engine performance. Additionally, consider using a fuel system cleaner during long storage periods to prevent the buildup of contaminants.

Finding the Perfect Fuel Line for Your NX250

You may want to see also

Troubleshooting: Address common issues and errors during the purging process

When purging fuel lines, you might encounter various issues that can hinder the process and potentially lead to incomplete purging. Here's a guide to troubleshooting common problems:

Air Locks: One of the most frequent issues during fuel line purging is the presence of air locks. Air bubbles can form in the fuel lines, especially if the fuel has been stagnant for a while. To address this, start by running the fuel pump for a few minutes to ensure it circulates the fuel. You can also try using a fuel line cleaner or a dedicated fuel system flush to help dissolve any contaminants and air bubbles. If the issue persists, consider removing the fuel filter and cleaning it, as a clogged filter can restrict fuel flow and contribute to air locks.

Clogged Fuel Lines: Over time, fuel lines can become clogged with dirt, debris, or varnish, especially if the fuel contains impurities. This can be a significant challenge during purging. To tackle this, use a fuel line cleaner and a high-pressure air or water jet to flush out the lines. Ensure you follow the manufacturer's guidelines for the correct cleaning procedure. In some cases, you might need to disassemble the fuel lines and clean them manually, especially if they are hard-to-reach areas.

Leaking Connections: Leaks at fuel line connections can occur due to corrosion, damage, or improper installation. These leaks can make the purging process ineffective. Inspect all connections and look for signs of corrosion or damage. Tighten any loose connections and consider using thread seal tape or fuel-resistant tape to ensure a secure seal. If a connection is severely damaged, it may require replacement to prevent further issues during purging.

Incorrect Fuel Type: Using the wrong type of fuel can lead to various problems, including engine misfires and reduced performance. Always refer to the vehicle's manual to ensure you're using the correct fuel grade and type. If you suspect using the wrong fuel, stop the purging process immediately and consult a professional mechanic for guidance.

Engine Control Module (ECM) Issues: In some cases, the ECM may not recognize the purging process, leading to engine misfires or poor performance. This could be due to a faulty sensor or a programming issue. If you encounter such problems, it's best to consult a professional mechanic who can diagnose and address the ECM-related issues. They might need to update the ECM software or replace specific components to ensure proper fuel line purging.

Fuel Line Routing: LS Swap Guide for 1984 C10

You may want to see also

Frequently asked questions

Fuel line purging is a process used to remove air bubbles and contaminants from the fuel system of an engine. It ensures that the fuel is clean and free-flowing, which is crucial for optimal engine performance and longevity.

The frequency of purging depends on various factors, including the age of the vehicle, driving conditions, and fuel system maintenance. As a general guideline, it is recommended to purge the fuel lines every 30,000 to 50,000 miles or as per the manufacturer's instructions. Regular maintenance can prevent issues caused by accumulated contaminants.

Fuel line purging can be done at home with the right tools and knowledge. However, it requires some technical skills and access to specific equipment like a fuel pressure gauge and a fuel line cleaning tool. If you're unsure or uncomfortable with the process, it's advisable to consult a professional mechanic who can ensure the job is done correctly and safely.