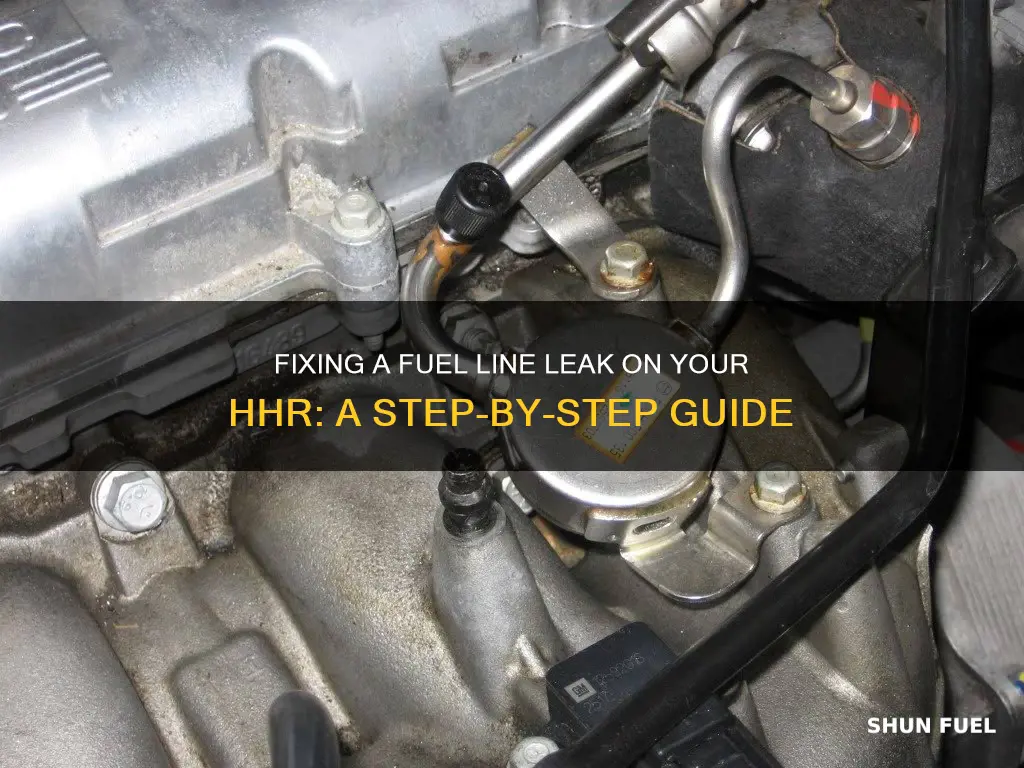

Fixing a fuel line leak on a HHR (Hummer HHR) can be a challenging task, but with the right tools and knowledge, it is definitely achievable. The HHR, a compact SUV known for its rugged design, may encounter fuel line issues due to its age or wear and tear. When a fuel line leaks, it poses a serious safety hazard as it can lead to engine misfires, reduced performance, and even potential fires. This guide will provide a step-by-step approach to identifying and repairing the leak, ensuring your HHR runs smoothly and safely.

What You'll Learn

- Locate the Leak: Identify the exact spot of the fuel line damage or break

- Prepare Tools: Gather necessary tools like fuel line connectors, tape, and a wrench

- Clean the Area: Ensure the leak site is clean and free of debris

- Replace the Section: Carefully cut out the damaged part and install a new section

- Test for Leaks: After reassembly, check for any remaining fuel leaks

Locate the Leak: Identify the exact spot of the fuel line damage or break

When dealing with a fuel line leak on an HHR (Hummer HHR), the first and most crucial step is to locate the exact source of the issue. This process requires a methodical approach to ensure you fix the problem effectively. Here's a detailed guide on how to identify the leak:

Step 1: Visual Inspection

Start by carefully examining the fuel lines under the hood and along the vehicle's frame. Look for any visible signs of damage, such as cracks, punctures, or tears. Fuel lines are typically made of rubber or plastic and can be susceptible to wear and tear over time. Inspect the lines for any discolored or softened areas, as these could indicate a breach. Pay close attention to the connections and fittings, as these are common points of failure.

Step 2: Check for Spills and Stains

Fuel spills and stains can provide valuable clues about the leak's location. Get under the vehicle and inspect the ground for any recent fuel leaks. Look for dark, oily stains or puddles around the fuel tank, engine, and under the car's body. These stains might indicate a breach in the fuel line or a faulty fuel pump. If you find any, mark the approximate location to ensure you don't miss it during the inspection.

Step 3: Listen for Fuel Sounds

Fuel lines can sometimes make a hissing or gurgling sound when there is a leak. Get under the vehicle and listen carefully near the fuel tank and engine bay. A fuel leak might produce a distinct sound that can help you pinpoint the problem area. This method is especially useful if you suspect a small, hard-to-see leak.

Step 4: Use a Fuel Leak Detector

Consider using a fuel leak detector spray, which is a useful tool for identifying fuel line issues. These sprays contain a chemical that reacts with fuel vapor, causing it to turn a specific color when a leak is present. Apply the spray along the fuel lines, following the manufacturer's instructions. If a leak is present, the affected area will turn the specified color, indicating the location of the breach.

Step 5: Remove Panels and Inspect

If you suspect a leak in a hard-to-reach area, you might need to remove certain panels or components. This could include the engine bay cover, fender panels, or even the inner fender wells. Carefully remove the necessary panels and inspect the fuel lines for any damage or breaches. Ensure you have the required tools and knowledge to reassemble the vehicle properly after the inspection.

By following these steps, you can accurately locate the fuel line leak on your HHR, enabling you to proceed with the necessary repairs or replacements. Remember, a thorough inspection is key to ensuring the issue is resolved effectively.

Understanding B1 Fuel Line: A Comprehensive Guide

You may want to see also

Prepare Tools: Gather necessary tools like fuel line connectors, tape, and a wrench

Before you begin any repair work on your HHR, it's crucial to gather the right tools to ensure a successful fix. Here's a step-by-step guide on preparing the necessary tools:

Fuel Line Connectors: Start by sourcing the appropriate fuel line connectors that match the size and type of your HHR's fuel lines. These connectors are designed to securely attach the fuel lines, ensuring a tight seal. Look for high-quality connectors that are compatible with your vehicle's specifications. Having the right connectors will make the repair process much smoother.

Fuel Line Tape: In addition to connectors, you'll need fuel line tape, also known as fuel line sealant tape. This tape is specifically designed to provide an extra layer of protection and insulation around the fuel lines. It helps prevent leaks by creating a barrier against fuel vapor and moisture. Ensure you get a tape that is compatible with your fuel type and has a strong adhesive to ensure it stays in place.

Wrench: A wrench is an essential tool for any vehicle repair. You'll need a wrench to tighten the fuel line connectors and ensure they are securely fastened. Choose a wrench that fits the size of your fuel line fittings. It's important to have a good grip and leverage to tighten the connections properly. Consider getting a set of wrenches in different sizes to accommodate various fuel line sizes.

Other Basic Tools: Besides the specific tools mentioned above, it's always a good idea to have a basic toolkit for any car repair. This may include items like a screwdriver set, pliers, a hammer, and a utility knife. These general tools can be useful for various tasks during the repair process, such as removing old connections or trimming excess fuel line.

By gathering these tools, you'll be well-prepared to tackle the fuel line leak on your HHR. Remember, having the right equipment will make the repair process more efficient and effective, ensuring your vehicle is running smoothly again.

Choosing the Right Fuel Line for Your Side-by-Side Adventure

You may want to see also

Clean the Area: Ensure the leak site is clean and free of debris

When dealing with a fuel line leak on your HHR, the first crucial step is to ensure the area around the leak is thoroughly cleaned. This process is essential for several reasons. Firstly, it helps to identify the exact source of the leak, making it easier to pinpoint the necessary repairs. Secondly, a clean surface allows for better adhesion of any materials used to seal the leak, ensuring a more effective and long-lasting fix. Lastly, removing debris and contaminants from the area minimizes the risk of further damage or contamination during the repair process.

To begin cleaning, start by disconnecting the fuel line from the vehicle's fuel tank or the affected component. This step is critical to prevent any further fuel spillage and to ensure your safety. Once disconnected, place a suitable container under the line to catch any remaining fuel. Carefully remove the line and inspect it for any visible damage or signs of corrosion. If you notice any, make a note of the location for future reference.

Now, focus on the area where the leak is occurring. Use a fine-grit sandpaper or a similar abrasive tool to gently remove any loose debris or corrosion from the surface. Be thorough but careful not to damage the surrounding areas. After sanding, wipe the area with a clean cloth to remove any dust or loose particles. For stubborn stains or corrosion, consider using a mild acid cleaner, but always test it on a small, inconspicuous area first to avoid any unwanted damage.

Once the area is clean, rinse it thoroughly with water to remove any remaining cleaner or debris. Ensure that all traces of contaminants are gone, as these can interfere with the adhesion of any repair materials. After rinsing, allow the area to dry completely. You can speed up this process by using a hairdryer on a low setting, being cautious not to apply excessive heat.

Finally, inspect the cleaned area to ensure it is free from any debris or contaminants. If everything looks good, you're ready to proceed with the next steps of your repair, whether it's replacing a damaged section of the fuel line or applying a suitable sealant. Remember, taking the time to clean the area properly can significantly contribute to the success and longevity of your HHR's fuel line repair.

Does Fuel Line Size Affect Engine Performance?

You may want to see also

Replace the Section: Carefully cut out the damaged part and install a new section

To address a fuel line leak on your HHR, one of the most effective solutions is to replace the damaged section. This method ensures a long-lasting fix, as it involves removing the faulty part and installing a new, pristine section. Here's a step-by-step guide to help you through this process:

Step 1: Prepare Your Tools and Materials

Before you begin, ensure you have the necessary tools and materials. You'll need a fuel line repair kit, which typically includes a new section of fuel line, clamps, and any required adapters. Additionally, gather standard automotive tools like a wire brush, a utility knife, and a fuel line cutter. It's also a good idea to have a rag or cloth to cover the work area and protect your hands.

Step 2: Locate the Damaged Section

Carefully inspect the fuel lines under your HHR's hood. Identify the section that shows signs of damage, such as cracks, holes, or corrosion. Mark the starting and ending points of the damaged section with tape or a permanent marker to guide your cutting process.

Step 3: Cut Out the Damaged Part

Using the fuel line cutter, carefully cut through the damaged section, ensuring you cut at a 45-degree angle to create a clean, precise edge. Be cautious not to damage the surrounding areas or other fuel lines. If there is any debris or old fuel line material, use the wire brush to remove it, ensuring a smooth surface for the new connection.

Step 4: Prepare the New Section

Take the new section of fuel line from your repair kit and ensure it is the correct size and type for your HHR. If necessary, adapt the new line to fit the existing connections using the provided adapters. Clean the ends of the new fuel line to ensure a secure connection.

Step 5: Install the New Section

Carefully slide the new fuel line section into place, aligning it with the marked starting and ending points of the damaged section. Use the provided clamps to secure the new line, ensuring it is tight and won't come loose under pressure. Make sure the connection is snug and free from any kinks or bends that could cause future issues.

Step 6: Test and Verify

Once the new section is installed, start the engine and check for any leaks. Ensure that all connections are secure and that there is no fuel escaping. If no leaks are found, you've successfully replaced the damaged section and resolved the fuel line leak on your HHR.

Mastering the Art of Fuel Line Installation: A Step-by-Step Guide

You may want to see also

Test for Leaks: After reassembly, check for any remaining fuel leaks

After you've reassembled the fuel system and ensured all components are properly connected, it's crucial to conduct a thorough test to identify and address any potential fuel leaks. This step is essential to prevent engine issues and ensure the vehicle's safety. Here's a detailed guide on how to perform this leak test:

Preparation: Before starting, ensure you have the necessary tools and materials, including a fuel system cleaner or a soapy water solution, a spray nozzle or a small pump sprayer, and rags or paper towels for cleaning. It's also a good idea to wear protective gear, such as gloves and safety goggles, to avoid any potential fuel-related hazards.

Step-by-Step Process:

- Fuel System Cleaning: Start by cleaning the entire fuel system, including the fuel tank, lines, and injectors. Use the fuel system cleaner or a soapy water solution to remove any dirt, debris, or old fuel that may have accumulated during the disassembly process. This step ensures that any potential leaks are not masked by contaminants.

- Pressure Test (Optional): For a more comprehensive test, consider using a fuel pressure gauge to check the system's pressure. This can help identify any restrictions or blockages in the fuel lines. Apply pressure to the system and observe for any leaks or unusual behavior. If you notice any issues, further investigation may be required.

- Visual Inspection: Visually inspect all connections and joints where fuel lines attach to the engine, fuel pump, and other components. Look for any signs of damage, corrosion, or deterioration. Check for any visible cracks, punctures, or discolored areas on the fuel lines. Even small leaks can lead to significant issues over time.

- Spray Testing: Using the spray nozzle or pump sprayer, apply a liberal amount of fuel system cleaner or soapy water to all fuel lines, connections, and suspected leak points. Pay close attention to areas where fuel lines bend, flex, or connect to other components. Watch for any bubbles forming on the surface, which indicates a fuel leak. If bubbles appear, it's a clear sign of a leak, and you should investigate further.

- Engine Operation: Start the engine and allow it to idle. Carefully observe for any signs of fuel escaping, such as hissing sounds or the presence of a cloud of vapor around the engine bay. If you notice any fuel escaping, it's a strong indicator of a leak that requires immediate attention.

- Drying and Re-inspection: After the test, ensure the area is well-ventilated and allow any spilled fuel to evaporate. Re-inspect the fuel system, especially the areas where leaks were suspected, to identify any permanent damage or further issues.

Troubleshooting: If you detect a leak, it's important to address it promptly. Refer to your vehicle's manual for specific repair procedures or consult a professional mechanic for guidance. Common causes of fuel leaks include damaged fuel lines, loose connections, or faulty fuel pumps. Addressing these issues will ensure the vehicle's optimal performance and safety.

Remember, regular maintenance and leak testing are vital to keeping your HHR in top condition. By following these steps, you can effectively identify and fix fuel line leaks, preventing potential engine problems and ensuring a reliable driving experience.

Mastering the Art of Bleeding Branson Fuel Lines: A Comprehensive Guide

You may want to see also

Frequently asked questions

Fuel line leaks can occur due to various reasons, including age, corrosion, damage from accidents, or improper installation. Over time, the fuel lines may degrade, develop cracks, or become brittle, leading to leaks.

For a temporary fix, you can use a fuel line clamp or a temporary repair kit. These kits provide a quick solution to contain the leak and prevent fuel from spilling. However, it's essential to address the issue permanently as soon as possible to avoid further damage.

To fix a fuel line leak, you'll need the following: fuel line repair tape or clamp, fuel line, crimping tool (if using a clamp), sandpaper or wire brush, cleaning supplies, and possibly a fuel line cutter. Ensure you have the appropriate size and type of fuel line that matches the damaged section.

Yes, with the right tools and knowledge, you can fix a fuel line leak yourself. However, it's crucial to have experience or guidance, especially when dealing with fuel lines, as improper repairs can lead to further complications. Always follow safety precautions and consider seeking professional assistance if you're unsure.

Driving with a fuel line leak is highly risky. Leaking fuel can lead to engine misfires, reduced performance, and potential engine damage. There's also a fire hazard due to the flammable nature of fuel. It is strongly recommended to address the leak promptly to ensure safe driving and prevent further issues.