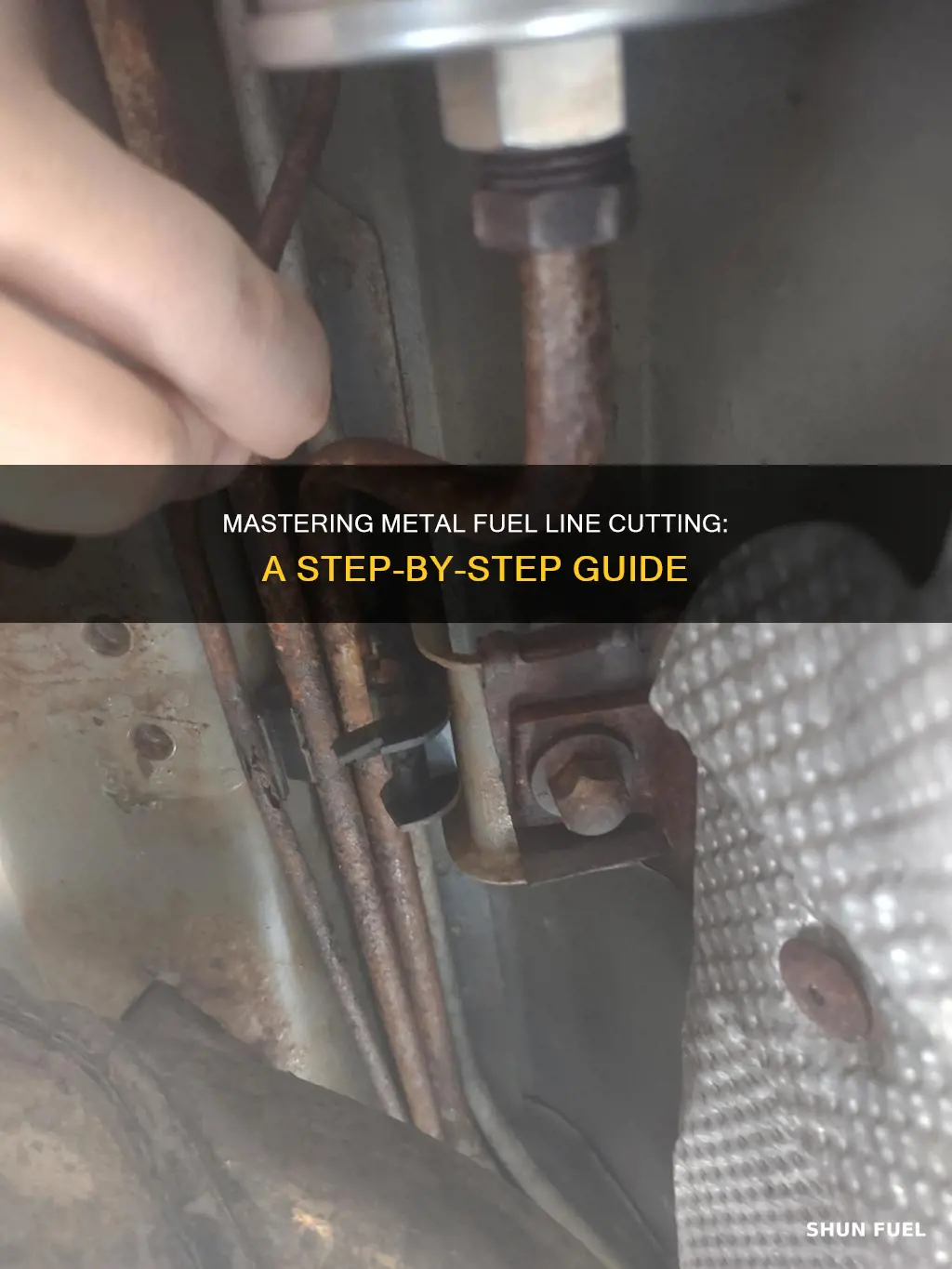

Cutting a metal fuel line is a precise task that requires careful planning and the right tools to ensure safety and efficiency. It's important to understand the specific requirements of your vehicle and the type of fuel system you're working with before attempting any modifications. This guide will provide a step-by-step process for safely and effectively cutting a metal fuel line, including the necessary safety precautions and tools required to complete the job.

What You'll Learn

- Safety Gear: Wear gloves, goggles, and a respirator to protect yourself

- Line Location: Identify the metal fuel line using a fuel line locator tool

- Cutting Tools: Use a sharp metal-cutting saw or a metal-cutting blade

- Measure and Mark: Measure and mark the line, ensuring a precise cut

- Safety Precautions: Avoid high-heat sources and ensure proper ventilation during the cut

Safety Gear: Wear gloves, goggles, and a respirator to protect yourself

When cutting a metal fuel line, prioritizing safety is paramount. The process involves working with potentially hazardous materials and requires the use of specific protective gear to minimize risks. Here's a detailed guide on the essential safety gear you should consider:

Gloves: Protecting your hands is crucial to avoid direct contact with sharp metal edges and any potential fuel residue. Opt for heavy-duty gloves made from durable materials like leather or synthetic blends designed for industrial use. These gloves should provide a secure grip and offer protection against cuts and punctures. Ensure they are long enough to cover your wrists, providing an extra layer of defense.

Goggles: Eye protection is vital to shield your eyes from potential hazards. Metal fuel lines can generate sparks or small metal shards during the cutting process, which could cause severe eye injuries. Choose safety goggles that fit securely over your eyes, offering a clear field of vision. Look for goggles with impact-resistant lenses and side shields to provide comprehensive protection.

Respirator: Working with metal fuel lines may expose you to harmful fumes or vapors, especially if the fuel contains additives or is not pure. A respirator is essential to filter the air you breathe and prevent inhalation of these potentially dangerous substances. Select a respirator with a high-efficiency particulate air (HEPA) filter, which can capture small particles and provide better protection. Ensure it fits comfortably over your nose and mouth, allowing for easy breathing while effectively filtering the air.

Additionally, consider wearing a dust mask or a face shield to further protect your respiratory system and face from any debris or sparks. It is also advisable to work in a well-ventilated area or use a fume hood to minimize the inhalation of harmful substances. By wearing the appropriate safety gear, you significantly reduce the risks associated with cutting a metal fuel line, ensuring a safer working environment.

Optimizing Performance: Choosing the Right Fuel Line for Your TMAXX

You may want to see also

Line Location: Identify the metal fuel line using a fuel line locator tool

To locate the metal fuel line, you'll need to employ a fuel line locator tool, which is a specialized device designed to help identify the exact path of the fuel lines under the vehicle's body. This tool is particularly useful as fuel lines can be hidden beneath various components, making them difficult to access without the right equipment. Here's a step-by-step guide on how to use this tool effectively:

Start by ensuring your vehicle is parked on a level surface and securely supported on jack stands or a vehicle lift. This step is crucial for safety and stability during the process. Once the vehicle is secure, locate the fuel line locator tool, which typically consists of a flexible probe and a display unit. The probe is inserted into the vehicle's body, and the display unit provides real-time feedback on the location of the fuel lines.

Begin the process by inserting the probe into a small opening or access point on the vehicle's body. This opening is usually located where the fuel lines enter the vehicle's cabin or engine compartment. Press the probe gently into the opening, ensuring it makes contact with the fuel line. The tool will then start to scan and identify the metal fuel line. You may need to adjust the probe's position slightly to get a clear signal.

As you move the probe along the suspected path of the fuel line, the display unit will provide visual or auditory feedback, indicating when the tool is in close proximity to the metal line. This feedback could be in the form of a beep, a visual indicator on the display, or a change in the tool's sensitivity. Follow the tool's guidance to accurately pinpoint the location of the fuel line.

Once you've identified the metal fuel line using the locator tool, you can proceed with the cutting process, ensuring you have a clear view of the line and its surroundings to avoid any damage to other components. Remember, the key to success here is precision and the use of the right tools for the job.

Fuel Line to Injector Rail: The Right Connectors Explained

You may want to see also

Cutting Tools: Use a sharp metal-cutting saw or a metal-cutting blade

When it comes to cutting a metal fuel line, using the right tools and techniques is crucial to ensure a clean and precise cut. One of the most effective methods is to employ a sharp metal-cutting saw or a specialized metal-cutting blade. These tools are designed to handle the hardness and thickness of metal, providing a clean and accurate cut.

A metal-cutting saw, such as a hacksaw or a tin snip, is a versatile and commonly used tool for this task. It features a fine-toothed blade that allows for a smooth and controlled cut. To use a metal-cutting saw, start by positioning the blade at the desired cut location. Ensure that the saw is firmly held and that the blade is aligned with the line you want to cut. Apply steady pressure and move the saw in a smooth, continuous motion, following the path of the fuel line. Take your time and be patient, as rushing can lead to an uneven cut.

Alternatively, a metal-cutting blade attached to a power tool like a circular saw or a jigsaw can be highly efficient. These power tools offer more power and speed, making them ideal for cutting through metal fuel lines. When using a power tool, it's essential to prioritize safety. Always wear appropriate personal protective equipment, including safety goggles and gloves, to protect yourself from any potential debris or sparks. Additionally, ensure that the tool is properly grounded and that you are working on a stable surface to maintain control.

Remember, when cutting metal, the sharpness of the tool is key. Dull blades can create jagged and uneven cuts, which may compromise the integrity of the fuel line. Regularly check the condition of your cutting tools and replace them if necessary. Keeping your tools sharp will not only make the cutting process easier but also ensure a safer and more professional finish.

Unclogging the Fuel Line: A Step-by-Step Guide to Removing Seized Lines

You may want to see also

Measure and Mark: Measure and mark the line, ensuring a precise cut

When it comes to cutting a metal fuel line, precision is key to ensure a safe and efficient repair. The first step in this process is to measure and mark the line accurately. This initial step is crucial as it sets the foundation for the rest of the cutting process.

Start by identifying the length of the fuel line that needs to be cut. Carefully measure the line, ensuring you account for any bends or twists in the pipe. Use a flexible measuring tape or a ruler to get an accurate length. Mark this measurement on the fuel line with a permanent marker or a piece of chalk. It's important to be precise here, as even a small deviation can lead to an improper fit during the cutting process.

Next, consider the type of cutting tool you will use. For metal fuel lines, a metal-cutting torch or a band saw is typically employed. Mark the chosen cutting point on the line, ensuring it aligns with your measured length. This marked spot will guide your cutting tool, providing a clear starting point for the cut.

Take your time with this step, as a careful measurement and mark will make the subsequent cutting process much easier and safer. A precise mark ensures that you start the cut in the right place, reducing the risk of cutting into other components or causing damage.

Remember, the goal is to create a clean, straight cut. Proper measurement and marking will contribute to achieving this, ensuring a professional-looking finish to your fuel line repair.

Lawn Mower Fuel Line Clean: A Step-by-Step Guide

You may want to see also

Safety Precautions: Avoid high-heat sources and ensure proper ventilation during the cut

When cutting a metal fuel line, it's crucial to prioritize safety to prevent accidents and potential hazards. One of the primary safety precautions is to avoid high-heat sources. Metal fuel lines can become extremely hot during operation, especially in engines or near exhaust systems. If you're working on a project that involves cutting a fuel line, ensure that the area is clear of any open flames, heat sources, or even hot surfaces. High temperatures can cause the fuel line to expand, making it more challenging to cut accurately and potentially leading to splashes or spills of flammable substances. Always use heat-resistant gloves and take extra care to maintain a safe distance from any potential heat sources.

Proper ventilation is another essential aspect of safety during this process. Fuel lines carry flammable substances, and any sparks or heat can create a dangerous situation. Ensure that the work area is well-ventilated to prevent the buildup of flammable vapors. Open windows or use exhaust fans to allow fresh air to circulate. This simple precaution significantly reduces the risk of explosions or fires, especially when using cutting tools that may generate sparks.

Additionally, it is advisable to wear protective gear, including safety goggles and a respirator, to shield your eyes and lungs from potential hazards. Keep a fire extinguisher nearby, specifically rated for flammable liquid fires, as a safety measure. By taking these precautions, you create a safer working environment and minimize the chances of accidents while cutting the metal fuel line. Remember, safety should always be the top priority in any project involving potentially hazardous materials.

Fixing a Rubber ATV Fuel Line: A Step-by-Step Guide

You may want to see also

Frequently asked questions

To cut a metal fuel line, you will need a few essential tools. A good pair of metal-cutting shears or a band saw with a fine-toothed blade designed for metal cutting is ideal. Additionally, have a pair of pliers for gripping and holding the line in place, and a wire brush or a small hammer to remove any burrs or sharp edges that may form after cutting.

Safety is crucial when working with fuel lines. Before you begin, ensure you are in a well-ventilated area and wear protective gear, including gloves and safety goggles. Identify the fuel line you want to cut and locate the nearest source of fuel. Turn off the fuel supply and allow sufficient time for the fuel to dissipate. Then, using your chosen cutting tool, carefully follow the line's path, making a clean cut.

While a regular saw might be sufficient for some materials, it is not recommended for metal fuel lines due to their thickness and strength. Metal-specific tools like shears or a band saw with fine teeth will provide a cleaner and more precise cut, reducing the risk of damage to the line or nearby components.

If the fuel line is damaged during the cutting process, it's essential to handle it with care. Use a small file or a wire brush to smooth any sharp edges or burrs. Ensure the cut ends are clean and free of debris. You can then use a fuel line repair kit to reconnect the ends or replace the damaged section if necessary.

When cutting metal fuel lines, avoid applying excessive force, as it may lead to line distortion or damage. Take your time and use steady, controlled movements. Additionally, be cautious not to cut too deeply, as this could compromise the line's integrity. Always measure and mark the cutting points accurately to ensure a precise and safe cut.