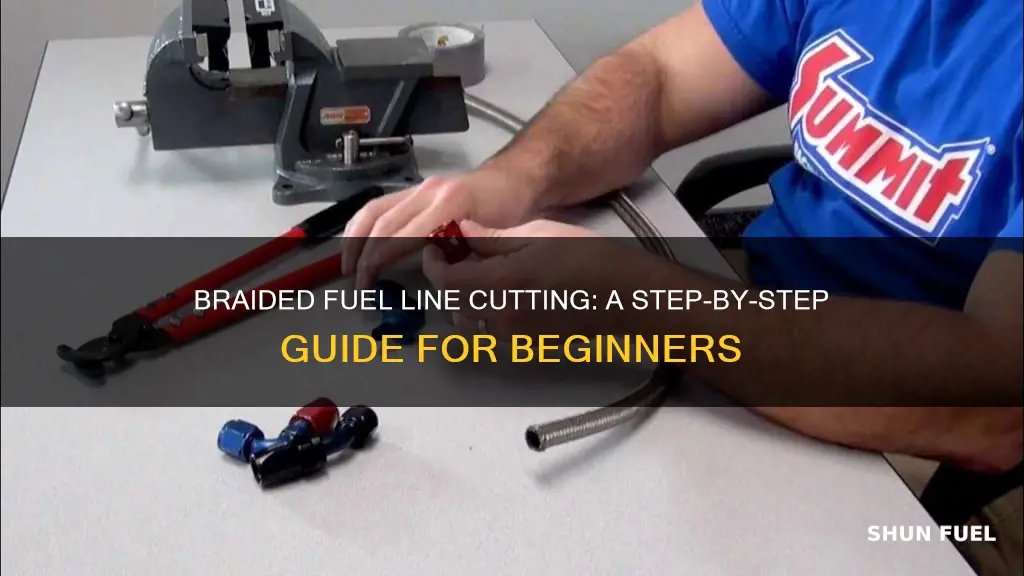

Cutting a braided fuel line requires precision and care to ensure a clean and secure connection. This process is essential when modifying or repairing fuel systems, as it allows for the replacement of damaged sections or the installation of new components. The key to a successful cut is using the right tools and following a step-by-step approach. First, identify the correct cutting tool, such as a fuel line cutter or a sharp, clean blade. Then, locate the desired cut point, ensuring it is free of any obstructions or bends that could compromise the line's integrity. With the line secured, make a precise cut, taking care to avoid any damage to the inner fuel-carrying tube. Proper preparation and technique will result in a clean, straight cut, facilitating a seamless repair or modification.

What You'll Learn

- Prepare the Tools: Gather necessary tools like a fuel line cutter, safety gear, and a clean workspace

- Locate the Braided Line: Identify the braided fuel line, often found under the hood or near the fuel tank

- Cut with Precision: Use the cutter to make a clean, straight cut, avoiding damage to surrounding components

- Secure the Line: Wrap the cut end with a ferrule or tape to prevent fuel leakage

- Test for Leaks: After cutting, inspect the line for any leaks and ensure proper connection

Prepare the Tools: Gather necessary tools like a fuel line cutter, safety gear, and a clean workspace

Before you begin the process of cutting a braided fuel line, it's crucial to ensure you have the right tools and safety measures in place. Here's a step-by-step guide on preparing your workspace and gathering the necessary equipment:

Gather the Tools:

- Fuel Line Cutter: This is the primary tool you'll need to make a clean and precise cut. Choose a cutter that is suitable for the diameter of your fuel line. There are various types available, including hand-held cutters and power tools, so select one that suits your preference and the job at hand.

- Safety Gear: Protecting yourself is essential when working with fuel lines. Wear safety goggles to shield your eyes from any potential debris or splashes. Additionally, consider wearing gloves to provide a better grip and an extra layer of protection. A respirator or dust mask can also be useful to avoid inhaling any fuel line material.

- Work Gloves: Opt for heavy-duty work gloves to protect your hands during the cutting process. This will prevent any potential cuts or burns and ensure a firm grip on the fuel line cutter.

- Safety Mask: A safety mask is recommended to prevent any inhalation of fuel line material, especially if you're working in a confined space.

- Clean Workspace: Set up a dedicated workspace away from any potential hazards. Ensure the area is well-lit and has ample space to work comfortably. A clean and organized workspace will also help you identify and avoid any potential tripping hazards.

Organize Your Materials:

- Ensure you have the braided fuel line you intend to cut, along with any necessary replacement parts or connectors.

- Gather any additional tools you might need, such as a fuel line adapter or a fuel filter, depending on your specific project.

- Keep a supply of replacement fuel lines or components nearby, especially if you're working on a vehicle or machinery.

By having the right tools and safety gear ready, you'll be well-prepared to tackle the task of cutting a braided fuel line efficiently and safely. Remember, proper preparation is key to a successful and hazard-free project.

Nylon Fuel Line Swap: Rubber vs. Nylon - Pros and Cons

You may want to see also

Locate the Braided Line: Identify the braided fuel line, often found under the hood or near the fuel tank

To begin the process of cutting a braided fuel line, you must first locate the braided line itself. This line is an essential component of your vehicle's fuel system, responsible for transporting fuel from the tank to the engine. It is typically made of a durable, flexible material and is often braided or woven to provide strength and resistance to abrasion.

The braided fuel line is usually positioned in a strategic location to ensure easy access and protection. It can be found under the hood, where it connects to the fuel pump and injectors, or it may run along the side of the engine bay, providing a clear path for fuel delivery. In some cases, you might also find it near the fuel tank, where it connects to the tank's outlet port.

When locating the line, look for a bundle of hoses or a single, thicker hose that appears to be made of braided material. It may have a distinct color or pattern to differentiate it from other hoses in the engine bay. The line's path will often follow the contours of the engine and may be secured with clips or ties to keep it in place.

If you're having trouble identifying the braided line, consult your vehicle's manual or online resources specific to your car model. These sources will provide detailed diagrams and descriptions of the fuel system, making it easier to pinpoint the exact location of the line. Once you've identified the braided fuel line, you can proceed with the cutting process, ensuring you have the necessary tools and safety precautions in place.

Mastering Chainsaw Fuel Line Maintenance: A Step-by-Step Guide

You may want to see also

Cut with Precision: Use the cutter to make a clean, straight cut, avoiding damage to surrounding components

When it comes to cutting a braided fuel line, precision is key to ensuring a clean and safe cut. Here's a step-by-step guide to help you achieve this:

Start by identifying the specific section of the braided fuel line that needs to be cut. Carefully examine the line to locate the point where the cut is required. Look for any signs of damage, wear, or corrosion that might indicate the need for a replacement. It's crucial to make an accurate assessment to ensure you cut the right section.

Gather the necessary tools, including a sharp utility knife or a specialized fuel line cutter. These tools are designed to provide a clean and precise cut without causing damage to the surrounding components. Hold the fuel line firmly with one hand, ensuring it is taut and stable. This will help you maintain control and accuracy during the cutting process.

Now, carefully align the cutter with the identified cut point. Apply gentle pressure to guide the cutter along the length of the fuel line. Maintain a steady hand and a straight cutting motion to ensure a clean and precise cut. Avoid applying excessive force, as it may lead to damage to the surrounding fuel system components. Take your time and focus on precision to get a professional-looking result.

As you make the cut, keep the surrounding area clear of any potential hazards. Ensure that the cut is straight and avoids any contact with nearby sensors, wiring, or other fuel system components. A clean cut will prevent any potential leaks or damage to the fuel system. If you're unsure about the placement, consider marking the cut line with a temporary marker to ensure accuracy.

Once the cut is made, carefully remove the cutter and inspect the cut edge. Ensure it is smooth and free from any debris or damage. If necessary, use a fine-grit sandpaper to gently smooth the edges, creating a seamless finish. This attention to detail will contribute to a professional-grade repair or installation. Remember, taking the time to cut with precision will result in a safer and more reliable fuel system.

The Ultimate Guide to Propane Fuel Line Manufacturers

You may want to see also

Secure the Line: Wrap the cut end with a ferrule or tape to prevent fuel leakage

When you've carefully cut the braided fuel line to the desired length, it's crucial to secure the end to prevent any potential fuel leakage. This step is essential to maintain the integrity of your fuel system and ensure the safety of your vehicle. Here's a detailed guide on how to achieve this:

Using a Ferrules:

One effective method is to use a ferrule, which is a metal or plastic sleeve that slips over the end of the fuel line. Here's the process:

- Ensure you have the right size ferrule for your fuel line. Measure the diameter of the fuel line and choose a ferrule with a matching inside diameter.

- Slide the ferrule onto the cut end of the fuel line. Make sure it covers the entire cut surface, providing a secure seal.

- Use a pair of pliers or a special ferrule crimper tool to crimp the ferrule in place. Apply firm pressure to create a tight seal, ensuring the ferrule is securely attached.

- Test the connection by applying slight pressure to the ferrule and checking for any leaks. If no leaks occur, your fuel line is now safely sealed.

Taping the Cut End:

If you don't have access to ferrules, an alternative method is to use electrical tape or a specialized fuel line tape:

- Clean the cut end of the fuel line to remove any debris or contaminants.

- Wrap the cut end with a layer of electrical tape, ensuring complete coverage.

- Apply additional layers of tape, overlapping each layer slightly to create a secure seal.

- For extra protection, consider using a heat shrink sleeve over the taped connection. This will provide a more permanent and robust solution.

- Test the taped connection by applying pressure and checking for leaks. If no leaks are detected, the tape should effectively contain any potential fuel leakage.

Remember, proper sealing of the cut end is critical to maintaining the functionality and safety of your fuel system. By using either ferrules or tape, you can effectively secure the braided fuel line and prevent any unwanted fuel loss.

Fixing a Flooded Fuel Line: A Step-by-Step Guide

You may want to see also

Test for Leaks: After cutting, inspect the line for any leaks and ensure proper connection

After you've carefully cut the braided fuel line, it's crucial to inspect the line for any potential leaks and ensure that the connection is secure. This step is essential to prevent fuel loss and potential engine damage. Here's a detailed guide on how to test for leaks and ensure a proper connection:

- Visual Inspection: Start by visually examining the cut end of the fuel line. Look for any signs of fuel seepage or moisture. If you notice any liquid dripping or a cloudy appearance, it indicates a leak. Additionally, check for any visible damage to the line, such as tears or punctures, which could also lead to fuel leakage.

- Pressure Test: To further confirm the integrity of the connection, perform a pressure test. Attach a fuel pressure gauge to the line, ensuring it is securely connected. Turn on the fuel pump and monitor the gauge reading. A steady and consistent reading indicates a good seal. If the pressure drops or fluctuates, it suggests a potential leak, and you should investigate further.

- Bubble Test: Another effective method is to use a bubble test. Soak the cut end of the fuel line in a container of soapy water. If there are any leaks, you will see bubbles forming on the surface. This simple test can help identify small cracks or imperfections in the line that might not be visible to the naked eye.

- Tighten Connections: If you've identified any leaks, ensure that the connection is tightened securely. Use the appropriate tools to tighten the fittings, but be careful not to overtighten, as this can damage the line. Re-inspect the connections to ensure they are tight and secure.

- Final Check: Before reassembling the fuel system, give the line a final check for any remaining leaks. You can use a rag or paper towel to wipe the cut ends and observe if any fuel is absorbed. If no leaks are detected, you can proceed with reconnecting the line to the fuel pump and tank.

Remember, proper testing and inspection are critical to maintaining a safe and efficient fuel system. Always take the time to thoroughly check your work to avoid potential issues down the line.

Understanding Fuel Crossovers: A Comprehensive Guide to Efficient Systems

You may want to see also

Frequently asked questions

To cut a braided fuel line, you will need a good quality fuel line cutter or a sharp utility knife. It's important to have a tool that can easily slice through the braided material without causing damage to the underlying fuel line.

Measuring the required length is crucial. You can use a tape measure or a length of string to determine the exact amount of fuel line needed. Ensure you measure the length of the braided section, not the overall length of the line.

Absolutely! When working with fuel lines, safety is paramount. Always wear protective gloves and eye protection to shield yourself from any potential fuel splashes. It's also a good practice to work in a well-ventilated area and to have a fire extinguisher nearby as a precaution.

Reusing the braided fuel line is not recommended. Cutting the line will compromise its integrity, and it may not function properly or safely. It's best to replace the cut section with a new braided fuel line to ensure optimal performance and safety.