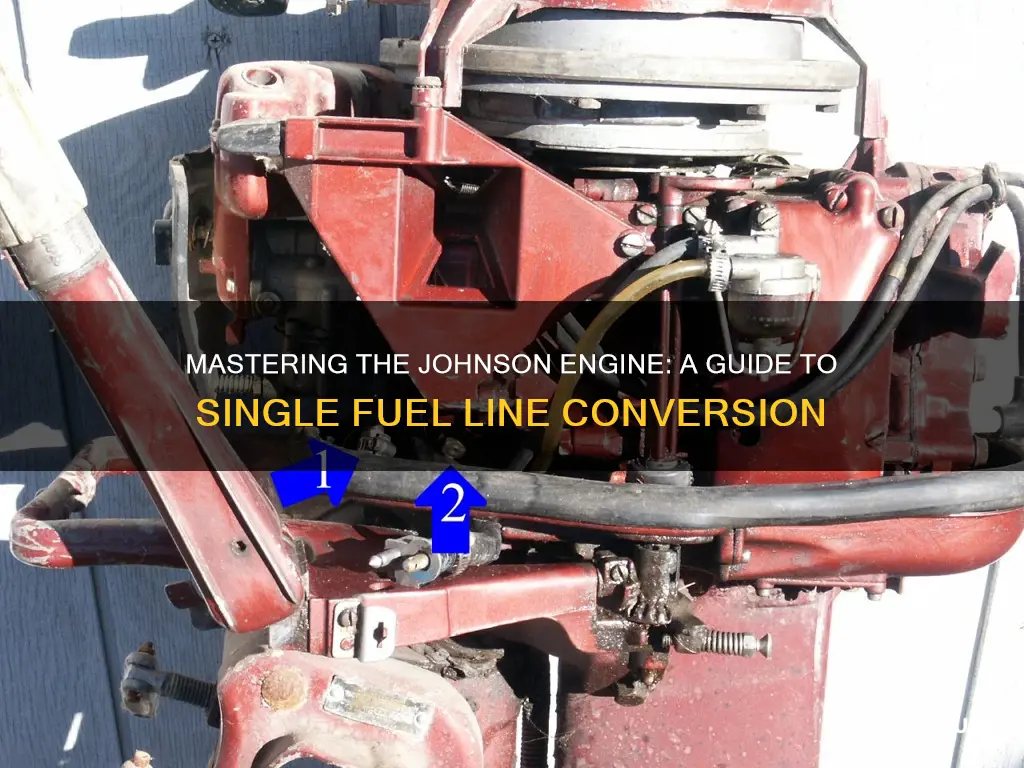

Converting a Johnson engine to a single fuel line can be a complex process, but it can offer significant performance improvements. This guide will provide a step-by-step approach to ensure a successful conversion, covering everything from selecting the right components to fine-tuning the engine for optimal performance. By following these instructions, you can achieve a more efficient and powerful engine, making the conversion process well worth the effort.

What You'll Learn

- Understanding Johnson Outboards: Familiarize yourself with Johnson's outboard motor design and fuel system

- Fuel Line Routing: Plan optimal routes for the single fuel line, considering engine placement and accessibility

- Fuel Filter Installation: Learn how to install a fuel filter to ensure clean fuel flow

- Fuel Pump Configuration: Explore different fuel pump setups for efficient single-line fueling

- Safety Measures: Implement safety protocols to prevent fuel leaks and ensure a secure conversion

Understanding Johnson Outboards: Familiarize yourself with Johnson's outboard motor design and fuel system

Understanding the intricate design of Johnson Outboards is essential for anyone looking to convert them to a single fuel line system. Johnson, a renowned name in the marine industry, has developed a unique outboard motor design that requires a specific approach to fuel management. The key to success lies in comprehending the motor's fuel system, which is designed to deliver gasoline efficiently to the engine while ensuring optimal performance and longevity.

Johnson Outboards typically feature a dual-fuel system, consisting of two separate fuel lines, one for the primary fuel supply and another for the carburetor. This design is intentional, as it allows for precise fuel-air mixture control, ensuring the engine operates at its peak. However, when converting to a single fuel line, it's crucial to understand the implications and potential challenges. The primary goal is to maintain the engine's performance while simplifying the fuel delivery process.

To begin the conversion, one must identify the primary fuel pump and the carburetor's fuel supply line. The primary fuel pump is responsible for delivering fuel from the tank to the carburetor and the secondary fuel system. By connecting the single fuel line to this pump, you ensure a continuous supply of gasoline to the engine. It's important to note that the secondary fuel system, which was originally designed for a dual-fuel setup, may not be required during the conversion.

When implementing the single fuel line, consider the fuel filter and its placement. Proper filtration is essential to prevent contaminants from entering the engine. The fuel filter should be positioned close to the primary fuel pump to ensure optimal flow and minimize pressure drops. Additionally, the fuel line should be routed carefully, avoiding sharp bends or kinks that could restrict fuel flow.

Understanding the intricacies of Johnson Outboards' fuel system is a crucial step in the conversion process. By familiarizing yourself with the dual-fuel setup and identifying the key components, you can make informed decisions during the conversion. This knowledge ensures that the single fuel line system is designed to meet the engine's requirements, providing efficient fuel delivery and maintaining the performance standards Johnson engines are known for.

Fuel Line for Power Steering: A Viable Option?

You may want to see also

Fuel Line Routing: Plan optimal routes for the single fuel line, considering engine placement and accessibility

When converting a Johnson engine to a single fuel line system, proper routing is crucial for optimal performance and longevity. Here's a step-by-step guide to planning the fuel line route:

- Engine Placement and Accessibility: Begin by understanding the engine's position and the available space around it. Single fuel line conversions often involve moving the engine closer to the center of the vessel or modifying its placement for better access. Ensure the engine is easily accessible for maintenance and repairs. Consider the vessel's overall design and layout to choose a suitable location for the fuel line.

- Identify Fuel Sources and Tanks: Locate the fuel tanks and sources on your vessel. Determine the primary fuel tank that will supply the engine and identify any additional fuel tanks or sources that might be used for backup or different engine compartments. Understanding the fuel distribution system is essential for proper routing.

- Route Planning: Map out the path the fuel line will take from the fuel source(s) to the engine. Consider the following:

- Start at the fuel tank(s) and identify the closest access points.

- Plan a route that minimizes bends and sharp turns to reduce pressure on the fuel line.

- Avoid areas with potential obstructions or vibrations that could damage the fuel line.

- Ensure the route is long enough to provide sufficient length for any necessary fittings and connections.

- Consider the engine's orientation and any existing plumbing or wiring to avoid interference.

- Material Selection: Choose a suitable fuel line material that can withstand the engine's operating conditions and the vessel's environment. Common materials include rubber, vinyl, or braided steel. Ensure the fuel line has the appropriate diameter to handle the fuel flow rate and pressure.

- Fittings and Connections: Plan the locations of fittings, such as elbows, tees, and unions, to make the fuel line route more flexible and adaptable. Ensure these connections are secure and sealed properly to prevent fuel leaks. Consider using fuel-resistant adhesives or tape for added security.

- Testing and Inspection: After routing the fuel line, thoroughly test the system for any leaks or blockages. Inspect the entire route, including connections, for any signs of damage or potential issues. This step is crucial to ensure the safety and efficiency of the converted system.

Mastering Fuel Line Press Fitting: A Comprehensive Guide

You may want to see also

Fuel Filter Installation: Learn how to install a fuel filter to ensure clean fuel flow

Fuel filters are essential components in any vehicle's fuel system, ensuring that the engine receives clean and contaminant-free fuel for optimal performance and longevity. When it comes to converting a Johnson engine to a single fuel line setup, installing a fuel filter is a crucial step to maintain the engine's health. Here's a step-by-step guide on how to install a fuel filter for a clean fuel flow:

Step 1: Gather the Tools and Materials

Before you begin, ensure you have the necessary tools and materials. You will need a new fuel filter, suitable for your engine model, a wrench or fuel filter adapter, a rag or cloth, and some fuel line connectors. It's also a good idea to have a fuel pump primer and a container to catch any spilled fuel.

Step 2: Locate the Fuel Tank and Pump

Identify the fuel tank and the fuel pump on your Johnson engine. The fuel pump is typically located near the tank, and you might need to remove some panels or access panels to get to it. Locate the existing fuel lines connected to the pump and the tank.

Step 3: Disconnect the Old Fuel System

Carefully disconnect the old fuel lines from the fuel pump and the tank. Take note of the positions and orientations of the lines to ensure proper reconnection later. If there are any clamps or fittings, use your wrench to loosen them and set them aside.

Step 4: Install the New Fuel Filter

Now, it's time to install the new fuel filter. Cut the new fuel line to the appropriate length and attach it to the fuel filter. Use the rag to wipe away any excess fuel or debris from the lines. Slide the fuel filter into place, ensuring it is securely mounted. Connect the other end of the fuel line to the fuel pump and tighten the fittings.

Step 5: Test and Secure the System

With the fuel filter installed, prime the fuel pump using the primer bulb. Hold the bulb and release the fuel slowly to ensure the pump is functioning correctly. Check for any leaks at the connections. If everything is secure, you can permanently mount the fuel filter and lines using the appropriate fasteners.

Step 6: Final Checks and Maintenance

After installation, start the engine and check for any unusual noises or vibrations. Ensure that the fuel gauge reads correctly and that the engine runs smoothly. Regularly inspect and replace the fuel filter as recommended by the manufacturer to maintain optimal engine performance.

By following these steps, you can effectively convert your Johnson engine to a single fuel line setup and ensure a clean fuel flow, promoting a healthier and more efficient engine operation. Remember, proper maintenance and regular filter changes are key to keeping your vehicle's fuel system in top condition.

Fuel Line Repair: A Simple Fix or a Tricky Task?

You may want to see also

Fuel Pump Configuration: Explore different fuel pump setups for efficient single-line fueling

When converting a Johnson engine to a single fuel line system, optimizing the fuel pump configuration is crucial for efficient operation. Here's an in-depth look at various fuel pump setups to consider:

- In-Line Fuel Pump: This is the most common and straightforward approach. The fuel pump is mounted directly in the fuel line, typically near the engine. This setup offers simplicity and ease of installation. The pump draws fuel from the tank and delivers it directly to the engine's intake. For single-line systems, a small, high-pressure pump is ideal, ensuring a steady fuel supply without excessive pressure that could lead to fuel vaporization.

- Remote Fuel Pump: In this configuration, the fuel pump is located away from the engine, often in the fuel tank or a nearby compartment. This setup can be beneficial for larger engines or those with limited space under the hood. A remote pump allows for the use of a larger, more powerful pump to ensure sufficient fuel flow. However, it requires careful consideration of fuel lines and potentially additional components like a fuel filter and pressure regulator.

- Electric Fuel Pump: Electric pumps offer precise control over fuel pressure, making them suitable for single-line systems. These pumps are often used in conjunction with an in-line or remote setup. By using an electric pump, you can regulate fuel pressure electronically, ensuring optimal performance and fuel efficiency. This is especially useful for engines that require precise fuel delivery, such as those in marine applications.

- Mechanical Fuel Pump: Traditional mechanical pumps, driven by the engine's camshaft, are another option. While they provide reliable fuel delivery, they may not be as efficient as electric pumps in terms of pressure control. For a single-line system, a mechanical pump can be an excellent choice, especially if you're restoring a classic Johnson engine. It requires careful calibration to ensure proper fuel flow.

When choosing a fuel pump configuration, consider factors like engine size, power requirements, and the desired fuel efficiency. Each setup has its advantages, and the right choice will depend on your specific application and preferences. Remember to consult the Johnson engine's manual and seek expert advice for the most accurate and safe conversion process.

Braided Fuel Line Lifespan: Unraveling the Mystery

You may want to see also

Safety Measures: Implement safety protocols to prevent fuel leaks and ensure a secure conversion

When converting a Johnson engine to a single fuel line system, implementing robust safety measures is paramount to prevent fuel leaks and ensure a secure conversion process. Here are some critical safety protocols to follow:

- Fuel System Inspection: Begin by thoroughly inspecting the existing fuel system. Identify all fuel lines, injectors, and components that will be modified or replaced. Look for any signs of damage, cracks, or corrosion. Replace any faulty parts immediately to avoid potential leaks during the conversion.

- Fuel Line Routing and Protection: Proper routing of the new fuel line is essential. Route the line away from hot surfaces, vibrations, and potential impact areas. Use protective sleeves or heat shields to safeguard the fuel line from damage. Ensure the line is securely fastened to the engine block and frame to prevent movement and potential leaks.

- Fuel Tank and Pump Maintenance: Inspect the fuel tank for any signs of contamination or damage. Clean and replace the fuel filter to ensure clean fuel flow. Check the fuel pump for proper operation and consider replacing it if it's an older unit. A well-maintained fuel system reduces the risk of leaks and ensures efficient fuel delivery.

- Grounding and Bonding: Proper grounding is crucial to prevent static electricity buildup, which can ignite fuel vapor. Bond all metal components of the fuel system together and ground them to the engine block. This simple step significantly reduces the risk of sparks and potential fuel leaks.

- Leaks and Cracks: Pay close attention to any potential leak points. Ensure all connections are tight and secure. Use high-quality fuel line connectors and seals to prevent fuel seepage. Regularly check for cracks or damage to the fuel lines and promptly address any issues.

- Testing and Verification: After the conversion, conduct thorough testing. Start the engine and monitor for any fuel-related issues. Check for leaks, unusual noises, or vibrations. Verify that the fuel system operates efficiently and safely. This testing phase is crucial to identify and rectify any potential problems before final use.

By adhering to these safety measures, you can ensure a successful conversion while minimizing the risks associated with fuel handling and system modifications. Remember, safety should always be the top priority when working with fuel systems.

Optimal Thickness for Metal Fuel Lines: A Comprehensive Guide

You may want to see also

Frequently asked questions

Converting a Johnson engine to a single fuel line is a process that can improve performance and simplify the fuel system. It involves combining the two fuel lines into one, which can reduce fuel pressure and improve the engine's overall efficiency.

Not all Johnson engines are created equal, and the suitability of the conversion depends on the specific engine model and year. It's essential to consult the engine's manual or seek expert advice to ensure the conversion is compatible with your engine.

The conversion typically requires basic automotive tools such as wrenches, sockets, and a fuel line cutter. You'll also need replacement fuel lines, fittings, and possibly a fuel pressure regulator, depending on the engine and your desired setup.

Yes, it's important to carefully follow the conversion instructions and take note of any specific requirements for your engine. Common challenges include ensuring proper fuel pressure, avoiding fuel leaks, and maintaining the engine's performance after the conversion. It's recommended to seek professional help or refer to detailed guides to minimize potential problems.