Connecting dual vacuum lines on a Jeep fuel pump can be a challenging task, but with the right tools and knowledge, it is definitely achievable. This process involves understanding the intricate network of vacuum lines and their functions, as well as ensuring a secure and leak-free connection. By following a step-by-step guide, you can effectively link the two vacuum lines, ensuring optimal performance and safety for your Jeep's fuel system.

What You'll Learn

- Fuel Pump Location: Identify the fuel pump's position under the hood

- Line Routing: Plan the path for the vacuum lines to avoid obstructions

- Fittings and Adapters: Use appropriate fittings to connect the lines securely

- Vacuum Test: Ensure proper vacuum operation after connecting the lines

- Safety Precautions: Wear gloves and goggles, and work in a well-ventilated area

Fuel Pump Location: Identify the fuel pump's position under the hood

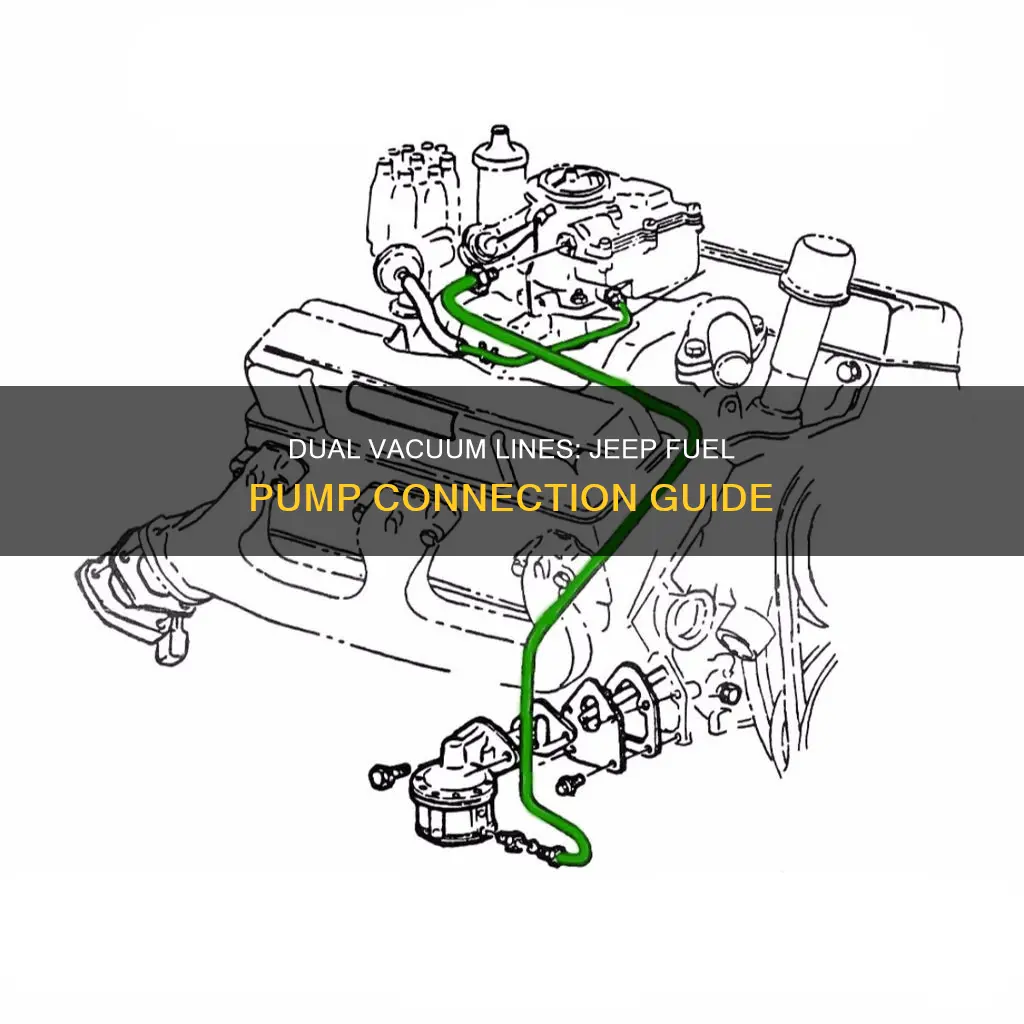

The fuel pump on a Jeep is typically located in the engine compartment, often under the hood. It is a crucial component of the fuel system, responsible for delivering fuel from the tank to the engine. Identifying the exact position of the fuel pump is essential before attempting any repairs or modifications, especially when dealing with a dual vacuum setup.

To locate the fuel pump, start by opening the hood of your Jeep. You will likely find it positioned near the front of the engine bay, often towards the driver's side. The pump is usually a small, rectangular or cylindrical component with a few electrical connections and a fuel line attached. It might be mounted on a bracket or directly on the engine block.

Jeeps with a dual vacuum system often have two fuel pumps, one for each cylinder head. These pumps are strategically placed to ensure an even fuel supply to all parts of the engine. Each pump will have a distinct fuel line and electrical connection, making it easier to identify. Look for the fuel lines that run from the tank to the engine, as these will lead you to the pumps.

When dealing with a dual vacuum setup, it's important to understand the layout. The pumps might be positioned side by side or one above the other, depending on the Jeep model. Some Jeeps may have a single pump with a divider to create two separate fuel sources. In such cases, you'll need to carefully inspect the pump and its connections to determine which part is responsible for each cylinder head.

If you're having trouble finding the pumps, consider consulting the Jeep's service manual or online resources specific to your vehicle model. These sources will provide detailed diagrams and instructions, ensuring you can accurately identify the fuel pump location and proceed with the necessary connections for your dual vacuum setup.

Mastering Fuel Line Shrink Techniques: A Comprehensive Guide

You may want to see also

Line Routing: Plan the path for the vacuum lines to avoid obstructions

When connecting dual vacuum lines to a Jeep fuel pump, proper line routing is crucial to ensure optimal performance and avoid potential issues. Here's a detailed guide on how to plan the path for these vacuum lines:

- Understand the Jeep's Engine Bay Layout: Familiarize yourself with the Jeep's engine bay and the locations of various components. Identify the fuel pump, which is typically located near the engine's front side. Note the positions of other critical parts like the air filter, intake manifold, and any existing vacuum lines. This understanding will help you visualize the best routes for the new vacuum lines.

- Route to Avoid Obstructions:

- Keep the lines as short and direct as possible to minimize the risk of damage or interference. Avoid routing the lines through areas where they might come into contact with moving parts or hot surfaces.

- For the primary vacuum line, consider running it along the firewall, where it can be protected by the engine's structure. This line should connect the fuel pump to the engine's intake manifold or a suitable vacuum source.

- The secondary vacuum line, if required, should be routed similarly, ensuring it doesn't interfere with other components. You might need to use rubber or plastic sleeves to protect the lines from sharp edges or heat sources.

- Consider Flexibility and Adjustability: Depending on the Jeep model and engine configuration, you might need to allow for some flexibility in the line routing. This could be achieved by using flexible vacuum hoses that can bend without kinking. This flexibility is especially important if the engine bay has limited space or if the lines need to accommodate slight engine movement during operation.

- Secure the Lines: Properly secure the vacuum lines to prevent them from coming loose over time. Use appropriate clamps or ties to attach the lines to the firewall, fender, or other suitable mounting points. Ensure that the lines are taut and not rubbing against any sharp edges.

- Test and Adjust: After routing and securing the lines, start the engine and check for any unusual noises or vacuum leaks. Adjust the line positions if necessary to optimize performance. Proper line routing will contribute to a smooth and efficient vacuum system, ensuring your Jeep's fuel pump operates correctly.

Unveiling the Mystery: Where Fuel Lines Originate from the Internal Pump

You may want to see also

Fittings and Adapters: Use appropriate fittings to connect the lines securely

When dealing with the vacuum lines on a Jeep fuel pump, it's crucial to use the right fittings and adapters to ensure a secure and reliable connection. The goal is to create a tight seal that can withstand the vacuum pressure and prevent any leaks, which could lead to performance issues. Here's a step-by-step guide on how to approach this task:

Choose the Right Fittings: Select fittings that are compatible with the vacuum lines and the Jeep's fuel pump system. Typically, you'll need two types of fittings: one for the intake manifold and one for the fuel pump. The intake manifold fitting will have a larger diameter to accommodate the vacuum port, while the fuel pump fitting will be smaller to match the line leading to the pump. Common types include barbed fittings, which are easy to install and provide a strong seal when used with the appropriate O-rings or seals.

Prepare the Lines: Ensure that the vacuum lines are clean and free of any debris or old fittings. Cut the lines to the desired length, leaving a small excess for fitting installation. Smooth the ends of the lines to prevent damage to the fittings. It's essential to use a sharp, clean cutting tool to avoid any burrs that could compromise the seal.

Install the Fittings: Start by inserting the larger intake manifold fitting onto the line, ensuring it is aligned properly. Secure it using the appropriate clamp or band to hold it in place. Then, take the smaller fuel pump fitting and slide it onto the line, again ensuring it is centered. Tighten the fitting securely, being careful not to overtighten, as this can damage the line. Use a wrench or pliers if needed, but be gentle to avoid stripping the threads.

Use Adapters for Compatibility: In some cases, you might need to use adapters to ensure the fittings match the vacuum lines. Adapters can be used to convert different sizes or types of fittings. For example, if you have a non-standard vacuum port, an adapter can help you connect the appropriate fitting. Always check the compatibility of adapters with your specific Jeep model and vacuum system.

Test for Leaks: After installing the fittings and adapters, it's crucial to test for any leaks. Apply vacuum pressure to the system and inspect all connections for any signs of leakage. If you detect a leak, carefully remove the fitting and re-evaluate the installation, ensuring a tight seal. Consider using a vacuum gauge to measure the pressure and identify any weak points.

By following these steps and paying close attention to the use of fittings and adapters, you can ensure a secure and reliable connection for the dual vacuum lines on your Jeep fuel pump, contributing to the overall performance and efficiency of the vehicle's vacuum system.

Mastering the Art of Top Fuel Line Hose Removal: A Step-by-Step Guide

You may want to see also

Vacuum Test: Ensure proper vacuum operation after connecting the lines

Before you begin the vacuum test, it's crucial to understand the principles of vacuum operation in the context of a Jeep fuel pump system. The fuel pump relies on a vacuum source to draw fuel from the tank and deliver it to the engine. When connecting dual vacuum lines, you're essentially creating a system that utilizes two vacuum sources to enhance the fuel delivery process. This setup requires careful testing to ensure optimal performance.

The first step in the vacuum test is to identify the vacuum sources. In a Jeep, these sources could be the intake manifold vacuum or the engine's crankcase vacuum. You'll need to locate the vacuum ports on the fuel pump and the associated vacuum lines. Typically, there will be a primary vacuum line and a secondary one, each connected to a different vacuum source.

Now, you can proceed with the test. Start the engine and allow it to idle. Use a vacuum gauge to measure the vacuum levels at both ports. The gauge should read a consistent vacuum value at each port, indicating that the lines are connected correctly and are functioning as intended. If the readings differ significantly, it suggests a potential issue with the vacuum sources or the lines themselves.

Pay close attention to the behavior of the fuel pump during this test. The pump should activate and deliver fuel when the engine is running, responding to the vacuum created by the connected lines. Listen for any unusual noises and check for any leaks or blockages in the lines. Proper vacuum operation ensures that the fuel pump operates efficiently, providing the necessary pressure to deliver fuel to the engine.

After the initial test, it's beneficial to simulate different driving conditions. Rev the engine to higher RPMs and observe the vacuum gauge's response. The vacuum should hold steady or slightly increase, indicating that the dual vacuum lines are compensating for the higher engine demand. This test will help identify any potential issues that may arise under varying load conditions. Remember, a well-functioning vacuum system is vital for optimal fuel delivery and engine performance.

Fuel Line Inspection: When to Check for Leaks and Damage

You may want to see also

Safety Precautions: Wear gloves and goggles, and work in a well-ventilated area

When working on any vehicle's fuel system, it's crucial to prioritize safety to prevent accidents and injuries. Here are the essential safety precautions to follow when connecting dual vacuum lines on a Jeep fuel pump:

Personal Protective Equipment (PPE): Always wear appropriate PPE to protect your skin and eyes. Gloves are essential to prevent direct contact with fuel and vacuum lines, which may contain harmful substances. Choose gloves made from durable materials like leather or synthetic blends to ensure they can withstand the rigors of the task. Additionally, safety goggles or glasses are a must to shield your eyes from potential splashes or debris.

Ventilation: Ensure you are working in a well-ventilated area to avoid inhaling harmful fumes. Fuel pumps and related components can release volatile organic compounds (VOCs) and other hazardous gases. Proper ventilation helps to disperse these fumes, reducing the risk of inhalation and potential health issues. If working in a confined space, consider using a portable air purifier or working outdoors if possible.

Fuel System Awareness: Before starting, understand the layout of the fuel system and the specific Jeep model you're working on. Familiarize yourself with the location of the fuel pump, vacuum lines, and any associated components. This knowledge will help you identify potential hazards and ensure you don't accidentally disconnect or damage critical parts.

Careful Handling: When handling vacuum lines, be extremely careful. These lines can be fragile and may have sharp bends or fittings. Avoid kinking or damaging the lines, as this can lead to reduced performance or leaks. Use appropriate tools and techniques to connect the lines securely, following the manufacturer's instructions or seeking guidance from a mechanic's manual.

Test and Verify: After connecting the dual vacuum lines, test the system to ensure it functions correctly. Check for any leaks or unusual noises. Verify that the fuel pump is operating as expected, and the vacuum system is providing the required pressure. This step is crucial to identify any potential issues before putting the vehicle back into service.

Remember, safety should always be the top priority when working on any vehicle. By following these precautions, you can minimize the risks associated with fuel system repairs and ensure a safe working environment.

Understanding Fuel Lines: The Vital Link in Your Engine's Fuel Supply

You may want to see also

Frequently asked questions

Connecting dual vacuum lines to the Jeep fuel pump involves a specific process to ensure proper functionality. First, locate the existing vacuum line connected to the fuel pump and identify the port where it connects. Then, using a suitable adapter or fitting, attach one end of the new dual vacuum line to this port. Ensure a secure and tight connection. The other end of the dual vacuum line should be connected to the appropriate vacuum source, such as the engine's intake manifold or a vacuum hose from another system. It's crucial to check the compatibility of the vacuum lines with the Jeep model and ensure they are of the correct size and material to handle the required vacuum levels.

While it is technically possible to use a single vacuum line for the Jeep fuel pump, it is not recommended for optimal performance. Dual vacuum lines provide redundancy and ensure that the fuel pump receives a consistent vacuum supply, which is essential for efficient fuel delivery. A single line may be more susceptible to leaks or damage, especially if it's a longer route, and could result in reduced pump performance or even failure. Using dual lines is a standard practice to maintain the reliability and efficiency of the fuel system in Jeeps.

Incorrectly connecting dual vacuum lines to the Jeep fuel pump can lead to several problems. One common issue is a loss of vacuum, causing the fuel pump to operate inefficiently or not at all. This can result in poor engine performance, hard starting, or even engine stall. Additionally, improper connections may lead to vacuum leaks, where air enters the system, reducing the overall vacuum and affecting fuel delivery. It's crucial to follow the manufacturer's guidelines and ensure that all connections are secure, tight, and compatible with the specific Jeep model to avoid these potential issues.

Yes, specific tools and adapters are necessary to ensure a proper connection. You will need a vacuum hose adapter that matches the port size and thread of your Jeep's fuel pump. It's essential to choose an adapter that is compatible with the vacuum line material and size. Additionally, a vacuum gauge can be useful to verify the vacuum levels and ensure the connection is secure. Having the right tools and adapters will make the installation process easier and help prevent potential issues related to incorrect connections.