Bleed Kubota fuel injector lines is a crucial process to ensure optimal engine performance and longevity. This procedure involves removing air bubbles from the fuel lines, which can cause engine misfires, reduced power, and other issues. By following a systematic approach, you can effectively bleed the lines, ensuring a smooth and efficient fuel supply to the engine. This guide will provide a step-by-step process to help you through the process, ensuring your Kubota engine operates at its best.

What You'll Learn

- Prepare the Equipment: Gather tools like a fuel pump primer, bleed valve, and a clean container

- Locate the Injector: Identify the specific fuel injector line to be bled

- Remove the Line: Carefully disconnect the line from the injector and fuel tank

- Prime the Pump: Use the primer to create a vacuum, drawing fuel into the line

- Bleed the Line: Open the bleed valve to release air and ensure fuel flow

Prepare the Equipment: Gather tools like a fuel pump primer, bleed valve, and a clean container

To begin the process of bleeding the fuel injector lines on your Kubota machine, it's crucial to have the right tools and equipment ready. Here's a step-by-step guide on preparing the necessary items:

Fuel Pump Primer: This tool is essential for the bleeding process as it helps to prime the fuel system. It works by creating a vacuum that draws fuel into the lines, allowing you to remove any air bubbles. You can find fuel pump primers at hardware stores or online, and they are typically designed for use with diesel engines.

Bleed Valve: A bleed valve is used to release air or gas from the fuel lines. It is usually located near the fuel tank or the fuel filter. When you connect the bleed valve to the fuel line, it provides a path for air to escape, ensuring a smooth flow of fuel. Make sure to get the correct size and type of bleed valve that fits your Kubota model.

Clean Container: You will need a container to collect the fuel that is released during the bleeding process. It should be clean and dry to avoid any contamination. A plastic bucket or container with a capacity suitable for your fuel lines is ideal. Ensure it is labeled or marked to avoid confusion with other liquids.

Before starting the bleeding process, it's important to inspect the tools and equipment. Check for any signs of damage or wear, and ensure they are in good working condition. Having these tools ready will make the bleeding process more efficient and effective, allowing you to quickly identify and resolve any issues with the fuel injectors. Remember to follow the manufacturer's instructions for each tool to ensure proper usage and maintenance.

Mastering Fuel Line Antifreeze: A Comprehensive Guide to Winter Car Care

You may want to see also

Locate the Injector: Identify the specific fuel injector line to be bled

To begin the process of bleeding the fuel injector lines on your Kubota machine, you must first locate the specific fuel injector line that requires bleeding. This step is crucial as it ensures you target the correct line and avoids unnecessary complications. Here's a detailed guide to help you identify the right line:

Start by consulting your Kubota machine's manual or service guide. These resources provide detailed diagrams and illustrations of the fuel injection system, making it easier to identify the various lines and components. Look for the specific injector line you want to bleed, as each line may have a unique identifier or color-coding system. This information is essential to ensure you are working on the correct line.

In many cases, the fuel injector lines are color-coded to differentiate them. For instance, you might find a red line for the primary fuel injector and a blue line for the secondary injector. Identify the color of the line you need to bleed and locate it accordingly. This visual identification method is widely used in automotive applications and can be adapted for Kubota machines.

Another approach is to inspect the fuel injector lines for any visible signs of damage or wear. Over time, these lines can develop cracks or leaks, requiring bleeding to restore proper fuel flow. Carefully examine the lines for any visible issues, such as bulging or discolored areas. These visual cues can help you pinpoint the specific line that needs attention.

If you are unsure about the location or identification of the injector line, consider consulting a qualified mechanic or referring to online forums and communities dedicated to Kubota machinery. These resources can provide valuable insights and guidance tailored to your specific machine model.

By following these steps, you can accurately locate and identify the fuel injector line that requires bleeding, ensuring a successful and efficient maintenance process for your Kubota machine.

Boat Fuel Line Removal: A Step-by-Step Guide

You may want to see also

Remove the Line: Carefully disconnect the line from the injector and fuel tank

To begin the process of bleeding the fuel injectors on your Kubota machine, you'll need to carefully remove the fuel lines connected to the injectors and the fuel tank. This step is crucial as it allows you to access the internal components of the fuel system and ensure that any air bubbles or contaminants are removed. Here's a detailed guide on how to safely and effectively disconnect these lines:

Start by locating the fuel lines that connect the fuel tank to the injectors. These lines are typically made of rubber or plastic and are often color-coded for easy identification. Identify the specific line that you need to disconnect, ensuring you have the correct one as there may be multiple lines leading to different injectors. Use a fuel line disconnect tool or a pair of sharp, clean pliers to carefully grip the line. Apply gentle but firm pressure to release the fittings or connectors. Be cautious not to force anything to avoid damaging the fuel lines or the surrounding components.

Once the line is disconnected from the fuel tank, you'll need to carefully remove it from the injector. Locate the mounting points or clips that hold the line in place near the injector. Carefully remove these fasteners, being mindful of any O-rings or seals that may be present. Gently pull the line away from the injector, ensuring you don't twist or kink the line during the process. It's important to maintain the integrity of the fuel line to prevent any potential leaks.

As you disconnect the line, inspect the interior for any signs of contamination or damage. If you notice any debris or contaminants, use a soft brush or compressed air to gently clean the area. Ensure that all connections are free of any obstructions or blockages. Once the line is completely removed from the injector and the fuel tank, you can proceed to the next step of bleeding the system.

Remember, when working with fuel lines, it's essential to exercise caution to avoid any fuel spills or damage to the machine. Take your time, follow the manufacturer's guidelines, and seek assistance if needed to ensure a safe and successful bleeding process for your Kubota fuel injectors.

Fuel Line Shopping: Top Stores and Online Sources

You may want to see also

Prime the Pump: Use the primer to create a vacuum, drawing fuel into the line

To prime the pump and ensure a smooth fuel flow through your Kubota fuel injector lines, you'll need to follow a precise process. Start by locating the fuel primer, which is typically a small, hand-operated pump attached to the fuel line. This primer is designed to create a vacuum, which will draw fuel into the line and prepare it for the engine.

Begin by ensuring the engine is off and the fuel tank is empty. This step is crucial to avoid any potential fuel-related issues during the priming process. Then, locate the primer and position it so that the suction side is facing downward, creating a natural vacuum. This simple action will initiate the priming process.

Next, pump the primer several times, ensuring each stroke is firm and consistent. The goal is to create a strong suction force that will draw fuel from the tank into the primer and then into the fuel line. As you pump, you should hear a gentle hissing sound, indicating that fuel is being drawn into the system.

Continue priming until you observe a steady flow of fuel exiting the primer. This indicates that the fuel line is now filled with fuel, and the priming process is complete. It's important to maintain a consistent priming action to ensure the fuel line is properly filled and any air bubbles are eliminated.

Once you've achieved a steady flow, release the pressure by slowly opening the fuel valve on the engine. This will allow the fuel to flow into the engine's fuel system, ensuring a clean and efficient start when you turn the engine on. Remember, proper priming is essential to prevent engine issues and maintain optimal performance.

Corolla's Fuel System: Return Lines Explained

You may want to see also

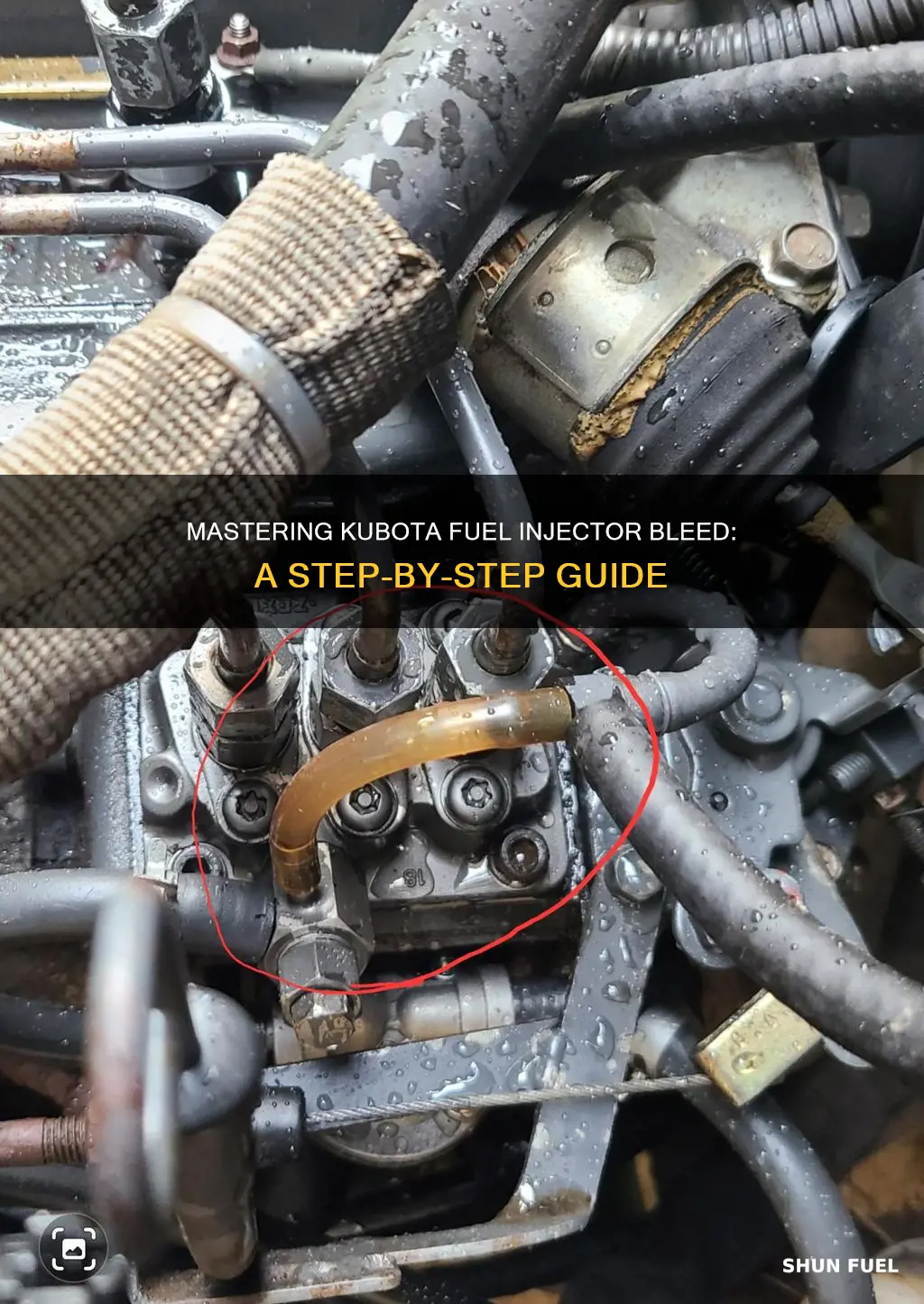

Bleed the Line: Open the bleed valve to release air and ensure fuel flow

Bleed the Line: A Step-by-Step Guide to Ensuring Fuel Flow

When dealing with fuel injectors, ensuring that the fuel lines are free of air bubbles is crucial for optimal engine performance. Here's a detailed guide on how to bleed the fuel lines on a Kubota engine, specifically focusing on opening the bleed valve to release air and ensure fuel flow.

Step 1: Locate the Bleed Valve

Start by identifying the bleed valve on your Kubota engine. This valve is typically located near the fuel filter or in the fuel line itself. It is often a small, screw-capped opening or a dedicated port. Refer to your Kubota engine manual if you're unsure about its exact location.

Step 2: Prepare the Engine

Before proceeding, ensure that the engine is cool to the touch. Hot engines can cause fuel to expand, making it more difficult to bleed the lines. Additionally, park the vehicle on a level surface and engage the parking brake for safety.

Step 3: Open the Bleed Valve

Using a flat-head screwdriver or a similar tool, carefully turn the bleed valve counterclockwise to open it. You may feel a slight resistance as you start turning it. Once open, you should see a small opening.

Step 4: Release Air and Bleed Fuel

Place a clean container or a fuel catch can beneath the bleed valve opening. Slowly turn the valve counterclockwise again, allowing air to escape from the line. You may hear a hissing sound as air is released. As the air is expelled, you should start to see fuel flow out of the valve. This process can take a few minutes, depending on the engine's age and condition.

Step 5: Ensure Fuel Flow

Continue turning the bleed valve counterclockwise until you no longer hear the hissing sound and the fuel flow slows down. At this point, you've successfully bled the air from the line. Close the bleed valve by turning it clockwise.

Step 6: Reassemble and Test

Carefully reassemble any components you removed during the bleeding process. Start the engine and let it run for a few minutes. Check for any unusual noises or vibrations, and ensure that the engine is running smoothly. If you notice any issues, repeat the bleeding process or consult a professional mechanic.

Remember, proper bleeding of fuel lines is essential for maintaining engine performance and longevity. By following these steps, you can ensure that your Kubota engine receives a steady supply of fuel, free from air bubbles.

Can Transmission Cooler Hose Be Used for Fuel Lines?

You may want to see also

Frequently asked questions

Bleeding the fuel injector lines is a process to remove air bubbles and ensure a smooth, consistent fuel flow to the injectors. This is crucial for maintaining optimal engine performance and preventing issues like misfires or reduced power.

It is recommended to bleed the fuel lines whenever you notice a change in engine performance, such as reduced power or rough idling. Additionally, regular maintenance, especially after long periods of storage or use in varying weather conditions, can help ensure the fuel system remains healthy.

While it is possible to bleed the fuel lines yourself, especially on smaller machines, it is generally recommended to have a professional mechanic perform this task. They have the necessary tools and expertise to ensure the process is done correctly and safely, especially when dealing with larger or more complex fuel systems.

You will typically need a fuel pressure gauge, a fuel line bleeding kit (which includes various-sized bleeds screws and adapters), and a container to collect any removed fuel. Some machines may also require a fuel pump primer or a specialized fuel line bleeding tool, depending on the specific model and its fuel system design.