Bleed air from the fuel line of a Grasshopper722 to ensure optimal performance and prevent issues. This process involves releasing trapped air bubbles from the fuel system, which can cause engine problems if left unchecked. By following a systematic approach, you can effectively bleed the air and maintain the engine's efficiency. Here's a step-by-step guide to help you through the process, ensuring a smooth and successful outcome.

What You'll Learn

- Fuel Line Access: Locate and expose the fuel line valve (VB) on the Grasshopper722

- Valve Identification: Identify the VB valve and ensure it's the correct one for bleeding

- Air Release Method: Use a bleed kit or compressed air to release trapped air

- Bleeding Process: Open the VB valve slowly to allow air to escape

- System Flushing: Repeat bleeding until no more air is released, then flush the system

Fuel Line Access: Locate and expose the fuel line valve (VB) on the Grasshopper722

To access the fuel line valve (VB) on a Grasshopper722 and bleed air from the fuel line, you'll need to follow a series of steps to ensure a safe and effective process. Here's a detailed guide to help you through the process:

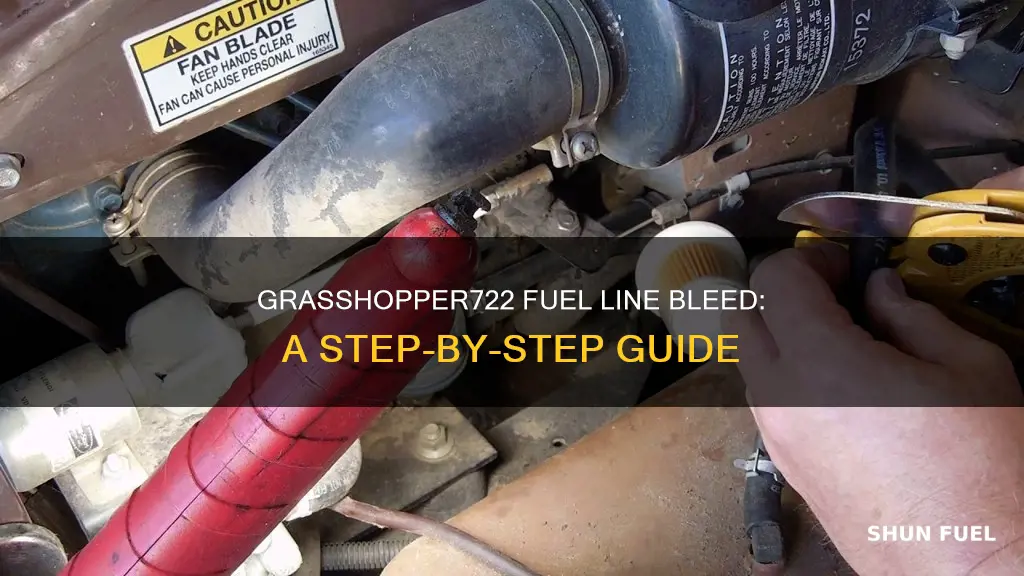

Locate the Fuel Line Valve: The first step is to identify the fuel line valve on your Grasshopper722. This valve is typically located near the fuel tank, often along the fuel line. It is usually a small, screw-capped opening or a dedicated fuel line valve. Refer to your Grasshopper722's owner's manual for a precise location, as it may vary depending on the model and year.

Prepare the Equipment: Before you begin, ensure you have the necessary tools. You will need a fuel line bleeding kit, which includes a gauge, a small container for collecting fuel, and a syringe or similar tool for drawing out air. Additionally, have a supply of fresh fuel ready to refill the tank after bleeding.

Safety Precautions: It is crucial to prioritize safety. Park the Grasshopper722 on a level surface and engage the parking brake. Allow the engine to cool down if it has been running. Ensure you are wearing appropriate personal protective equipment, such as gloves and safety goggles, to protect yourself from any potential fuel spills or splashes.

Access the Fuel Line: Locate the fuel line valve and use a suitable tool to open it. This valve is designed to allow access to the fuel line for maintenance and bleeding purposes. Once open, you should see the fuel line, which may be connected to a filter or a small pump, depending on the model.

Bleed Air from the Fuel Line: Insert the bleeding kit's gauge into the fuel line opening. You might need to adjust the gauge to find the right position. With the gauge in place, start the engine and allow it to run for a few minutes. As the engine runs, the air will be drawn out of the fuel line and into the gauge. Collect any fuel that may be drawn out in the container provided. Continue this process until no more air is being drawn into the gauge.

Close the Valve and Refill Fuel: Once you've bled the air, carefully close the fuel line valve. Refill the fuel tank with fresh fuel to ensure the system is properly lubricated and functioning correctly. Start the engine again and check for any leaks or unusual noises.

Remember, this process requires caution and attention to detail. If you are unsure about any step, consult a professional or refer to the manufacturer's guidelines for specific instructions tailored to your Grasshopper722 model.

Fuel Line Clog Symptoms: Engine Issues Revealed

You may want to see also

Valve Identification: Identify the VB valve and ensure it's the correct one for bleeding

When dealing with the fuel system of a Grasshopper722, identifying the correct valve for air bleeding is crucial. The VB valve, often referred to as the fuel bowl valve, is a critical component in this process. This valve is typically located near the fuel bowl or the fuel tank, and its primary function is to control the flow of fuel into the engine. To ensure you are bleeding the correct valve, follow these steps:

Locate the VB valve by referring to your Grasshopper722's service manual or a detailed diagram specific to your model. The valve is usually a small, cylindrical component with a thread or a quick-connect fitting. It may be positioned near the fuel bowl, which is the part of the engine that holds the fuel before it enters the carburetor. Identifying the correct valve is essential to avoid any potential issues during the bleeding process.

Once you've located the VB valve, inspect it for any signs of damage or wear. Ensure that it is in good condition and securely attached to the fuel line. If the valve appears damaged or is not the correct one for your model, it might be necessary to replace it with a compatible part. Always refer to the manufacturer's specifications to ensure you select the right replacement.

Before proceeding with the air bleeding procedure, double-check that you have the correct valve. Using the right valve ensures that you are addressing the specific component that needs air removal. This attention to detail is crucial to avoid any complications during the maintenance process.

In summary, identifying the VB valve is the first step in the air bleeding process for the Grasshopper722's fuel system. By carefully locating and verifying the valve, you can ensure that the correct component is bled, leading to a successful and efficient fuel system maintenance routine.

Spraying Fuel Lines: A Protective Coating Solution

You may want to see also

Air Release Method: Use a bleed kit or compressed air to release trapped air

To effectively release trapped air from the fuel line of a Grasshopper722, you can employ a bleed kit or compressed air. This method is particularly useful when you suspect that air bubbles are causing fuel flow issues or when you need to ensure a clean and efficient fuel supply to the engine. Here's a step-by-step guide on how to perform this procedure:

Step 1: Prepare the Tools and Materials

Before you begin, ensure you have the necessary tools and materials. You will need a bleed kit specifically designed for fuel lines, which typically includes a gauge, a bleed valve, and a set of adapters. Alternatively, you can use compressed air from a reliable source, such as an air compressor. It's essential to have a clean workspace and wear appropriate personal protective equipment (PPE) to ensure safety.

Step 2: Locate the Fuel Line and Bleed Kit

Locate the fuel line that connects the fuel tank to the engine. Identify the bleeder valve or port, which is usually a small opening on the fuel line. Attach the bleed kit to the fuel line, ensuring a secure connection. The kit's gauge will help you monitor the pressure and detect any air pockets.

Step 3: Release Air Using the Bleed Kit

Turn on the bleed kit's valve to release the air. Start by slowly opening the valve to allow air to escape. Listen for any hissing or bubbling sounds, which indicate the release of air. As you release the air, you may notice a slight decrease in pressure on the gauge. Continue this process until no further air is heard or detected on the gauge. Be patient and methodical to ensure you remove all air bubbles.

Step 4: Alternative: Using Compressed Air

If you prefer, you can use compressed air to release the trapped air. Connect the air compressor's nozzle to the fuel line's bleeder valve. Apply steady pressure and listen for the air escaping. This method may require more force, but it can be equally effective. Ensure you have good control over the air flow to avoid over-pressurizing the system.

Step 5: Final Checks

After releasing the air, it's crucial to perform final checks. Start the engine and observe its performance. Listen for any unusual noises or vibrations that might indicate the presence of air in the fuel system. If the engine runs smoothly and without any issues, you have successfully bled the air from the fuel line.

Remember, this process requires careful attention to detail and a systematic approach. Always follow safety guidelines when working with fuel lines and compressed air to prevent any accidents or damage to the equipment.

Understanding Fuel Line Banjo Fittings: A Comprehensive Guide

You may want to see also

Bleeding Process: Open the VB valve slowly to allow air to escape

The process of bleeding air from the fuel line of a Grasshopper722 involves a careful and methodical approach to ensure the engine's optimal performance. When you encounter issues with air bubbles in the fuel line, it's crucial to follow a systematic procedure to resolve the problem. Here's a detailed guide on how to bleed the air from the fuel line, specifically focusing on the step of opening the VB valve:

Step 1: Identify the VB Valve: Begin by locating the VB valve, which is typically a small, screw-capped opening on the fuel line. This valve is designed to allow air to escape from the fuel line when opened. It is usually positioned in a convenient location for easy access during the bleeding process.

Step 2: Prepare the Equipment: Before proceeding, ensure you have the necessary tools. You will need a fuel line bleeding kit, which often includes a small gauge or a specialized tool to assist in the process. Additionally, have a container ready to catch any fuel that may drain from the line during bleeding.

Step 3: Open the VB Valve: Now, carefully open the VB valve. Start by loosening the screw or cap that secures it. Remember, the key here is to open it slowly and steadily. Rapid movements can cause fuel to spray out, which is undesirable. As you open the valve, you should hear a gentle hissing sound, indicating the escape of air. If no sound is heard, it might suggest that the valve is not properly aligned or that there is a blockage nearby.

Step 4: Monitor the Process: While opening the valve, keep an eye on the fuel line and the container below. The air should start to flow out, and you might notice a slight decrease in fuel pressure. This is a normal part of the bleeding process. Continue the slow and controlled opening until you are satisfied that all the air has been bled out.

Step 5: Close and Secure: Once you've completed the bleeding, slowly close the VB valve by tightening the screw or cap. Ensure it is securely fastened to prevent any accidental opening during storage or transportation. Properly securing the valve is essential to maintain the integrity of the fuel system.

Remember, patience and precision are vital during this process. Taking your time will help ensure that you effectively remove all air bubbles, leading to a smooth and efficient fuel supply to the engine.

Mastering Fuel Rail Bleed: A Comprehensive Guide to Efficient Fuel Line Maintenance

You may want to see also

System Flushing: Repeat bleeding until no more air is released, then flush the system

To ensure a thorough and effective process of removing air from the fuel line of your Grasshopper722, it's important to follow a systematic approach. Here's a step-by-step guide for the system flushing process:

Step 1: Repeat Bleeding Process

Start by repeating the bleeding process you learned from your research. Locate the fuel line and identify the air bleed valve, often located near the fuel tank or the engine. Use a flathead screwdriver or a similar tool to gently tap the valve, allowing air to escape. This process may require some patience, as you might need to repeat it several times to release all the air. Ensure that you check the fuel line for any signs of air bubbles after each tap.

Step 2: Observe Air Release

Continue tapping the air bleed valve until you notice a significant reduction in the release of air. At this point, you should be able to hear or feel the air escaping, indicating that the fuel line is almost free of air. It's crucial to be persistent and repeat this step until no more air is released, as even a small amount of air can cause issues in the fuel system.

Step 3: Begin Flushing

Once you've confirmed that no more air is escaping, it's time to flush the system. This step is essential to remove any remaining contaminants and ensure a clean fuel supply. Start by attaching a fuel filter flush kit or a similar device to the fuel line, ensuring a secure connection. Open the fuel valve and allow the fuel to flow through the system, flushing out any debris or old fuel. This process might take some time, so be prepared to wait and monitor the flow.

Step 4: Monitor and Adjust

During the flushing process, keep an eye on the fuel line and the surrounding areas for any signs of contamination or fuel leaks. If you notice any issues, adjust your technique or seek further advice from online resources. It's important to be methodical and ensure that the entire fuel system is thoroughly cleaned.

Remember, the key to successful air removal and system flushing is patience and attention to detail. By following these steps, you can effectively eliminate air from the fuel line, ensuring optimal performance for your Grasshopper722.

Mastering the Art of Fuel Line Removal: A Step-by-Step Guide

You may want to see also

Frequently asked questions

To bleed air from the fuel line, locate the fuel line's bleeder valve, typically found near the engine. Open the valve to release any trapped air, ensuring you do this in a well-ventilated area to avoid inhaling any fuel vapor.

Bleeding the fuel line is essential to ensure proper fuel flow and engine performance. Air bubbles in the fuel line can cause engine misfires, reduced power, and even stall. By bleeding, you remove these bubbles, allowing for a smooth and efficient fuel supply.

Yes, you can bleed the fuel line without removing the fuel tank. The bleeder valve is often accessible from the outside of the engine bay, allowing you to release air pressure without disturbing the fuel tank's position.

You will typically need a wrench or a pair of pliers to open the bleeder valve. Some fuel lines may have a built-in bleeder screw, which can be turned with a small screwdriver. Ensure you have the appropriate tools for your specific fuel line design.

Regular maintenance and after any fuel system repairs or replacements are recommended. It's a good practice to bleed the fuel line whenever you add new fuel or suspect air bubbles, ensuring optimal engine performance and longevity.