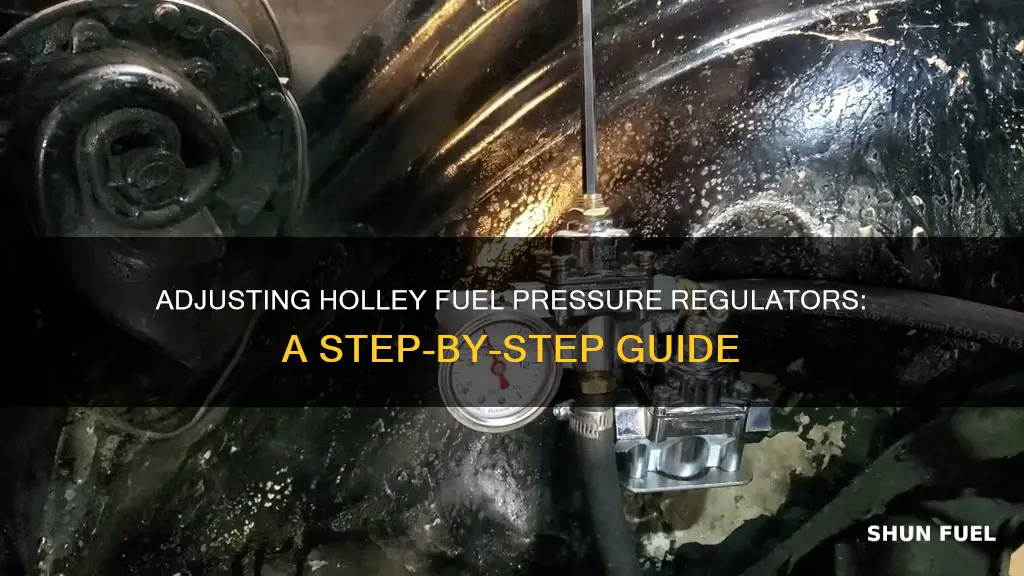

Adjusting the fuel pressure regulator on a Holley carburettor can be a tricky process. The regulator is adjusted by turning the hex screw on top, but it's difficult to tell how much pressure is being applied without a fuel pressure gauge. While it's possible to estimate the pressure by eye, the most accurate way to adjust the regulator is to temporarily tee in a handheld gauge and adjust until the desired pressure is reached. With the engine off, the screw can be turned out to lower the pressure, and then slowly adjusted to the desired level once the engine is running.

What You'll Learn

The engine needs to be running to adjust fuel pressure

When adjusting the fuel pressure on a Holley fuel pressure regulator, it is important to note that the engine needs to be running. This is because a stagnant system will not allow for accurate adjustments, particularly if you are trying to adjust the pressure down.

To start the adjustment process, turn on the electric fuel pump and let it run for a while. Then, start the engine and make the necessary adjustments while it is running. This is because some flow is necessary for the initial adjustment to be accurate. It is important to note that even after adjusting the regulator, the pressure may drop over time, so keep a close eye on it.

The specific steps to adjust the fuel pressure will depend on the type of Holley fuel pressure regulator you have. If you have the Holley 12-804 fuel pressure regulator, the factory preset is 2.8 pounds. To adjust this regulator, you need to turn the hex screw on top. However, there is no precise way to determine how many turns will result in a specific amount of pressure drop due to the spring and diaphragm design. The best way to set the desired pressure is by using a fuel pressure gauge.

If you do not want to permanently install a fuel pressure gauge, you can temporarily tee one in to get an accurate setting. A handheld gauge can also be used, but ensure that it is a low-pressure gauge that can handle fuel. When choosing a fuel pressure gauge, consider the range that you need to measure accurately. For example, if your desired pressure is 2 psi at idle, a 5 psi max gauge may be suitable. Additionally, if the pressure changes with throttle, a larger range gauge may be necessary to avoid damaging the gauge.

Installing a Fuel Pressure Regulator: Step-by-Step Guide for Your VW

You may want to see also

A return line is required for a bypass-type regulator

A bypass-type regulator, also known as a return-style regulator, is a component that controls fuel system pressure using a spring and diaphragm that is either adjustable or preset. This type of regulator is designed to improve the performance and reliability of any street or race fuel system. It does so by bleeding off excess fuel pressure, dumping it into a return line, and recirculating the fuel back into the tank. This process yields several benefits, including cooler, freer-flowing fuel, reduced fuel pump noise, and increased fuel pump life.

The return line plays a crucial role in the proper functioning of the bypass-type regulator. It ensures a continuous flow of fuel within the system, allowing for consistent fuel delivery to the engine. Additionally, it prevents fuel system overpressure by relieving excess pressure that could build up if the fuel was not returned to the tank. By regulating the fuel pressure and facilitating the return of unused fuel, the return line helps to maintain the proper fuel pressure and protects the fuel system from potential damage caused by excessive fuel pressure.

When connecting a bypass-type regulator, it is important to use the correct fittings and fuel lines that are compatible with the fuel system and can handle the pressure and flow requirements. The regulator needs to be connected to the return line at the return or bypass port, typically located at the bottom. The other end of the return line connects to the top of the fuel tank. The feed from the tank enters the inlet of the regulator and exits to the carburetor fuel inlet to complete the installation.

It is worth noting that the placement of the bypass-type regulator is important for optimal performance. It should be mounted as close to the carburetor as possible to ensure faster fuel flow and quicker reaction to changes in engine load. Additionally, the return line should be sized appropriately to avoid building up pressure. As a rule of thumb, using a return line that is the same size as the feed line can help maintain proper fuel pressure and maximize the pump's capacity.

Checking Fuel Pressure in Your 2000 Subaru Outback

You may want to see also

A deadhead regulator is fine for street use

A deadhead regulator is a simple and effective setup for a fuel system. It involves placing a pressure regulator between the fuel pump and the carburetor. The regulator holds the pressure steady between 4.5 and 9 psi, acting as a restriction in the fuel line to lower the fuel pressure and decrease fuel flow. This setup works well for a 400 horsepower crate motor, but for higher-power engines, a deadhead regulator may struggle to maintain steady fuel pressure, leading to potential issues like engine flooding and heat.

Despite these potential drawbacks, a deadhead regulator is fine for street use, especially for carbureted engines. It offers a simple, one-line installation, making it a straightforward choice for those seeking convenience and ease of use. This type of regulator does not require a return line, reducing system complexity. Additionally, it can be used in systems with multiple regulators, providing flexibility in fuel system design.

Deadhead regulators are also suitable for certain fuel pump configurations. Low-pressure electric pumps, for example, often operate within a predetermined pressure range, and a deadhead regulator can help adjust the pressure to match the carburetor's requirements. In such cases, a deadhead style regulator is a practical solution.

While a bypass regulator offers advantages like improved fuel temperature management and reduced strain on the fuel pump, a deadhead regulator's simplicity and compatibility with various fuel systems make it a viable option for street use, particularly when paired with appropriate fuel pumps and lower-power engines.

Understanding Fuel Pressure Requirements for the 318 JD Engine

You may want to see also

A low-pressure Holley regulator goes up to 4 lbs

If you want to avoid plumbing in a gauge, you can try adjusting the regulator by eye. The washer holding the hex screw is usually set halfway down the threads from the factory for a pressure of 2.8 lbs. Considering the pressure range of 2-4 lbs, you could try turning the screw all the way in either direction to reach your desired pressure of 2 or 4 lbs. However, this method may not be entirely accurate, and it is recommended to use a gauge for a more precise adjustment.

If you decide to use a gauge, you can temporarily tee it in without making it permanent. A handheld gauge can also be used if you install a Schrader valve, commonly used on fuel injector rails. However, at very low pressures (around 2 lbs), a handheld gauge may not provide an accurate reading.

When adjusting the fuel pressure regulator, it is important to match the fuel pump pressure to the engine's requirements to avoid carburetor flooding issues. The pressure should be set at idle, and the lines should be large enough to ensure adequate flow at wide-open throttle (WOT). Additionally, ensure that the regulator is mounted near the engine for better performance.

Relieving Fuel Injector Pressure: A Step-by-Step Guide

You may want to see also

A higher-pressure Holley regulator goes from 4.5 to 9 PSI

Adjusting the fuel pressure on a Holley regulator is a simple task, but it's important to understand the system and the risks associated with incorrect adjustment.

Firstly, it's worth noting that Holley regulators come with a factory preset, so adjustment may not always be necessary. However, if you have the higher-pressure Holley regulator that goes from 4.5 to 9 PSI, you can adjust it to suit your engine's specific needs.

To increase the pressure, locate the lock nut at the top of the regulator and turn it clockwise. To decrease the pressure, turn the lock nut counterclockwise. It's important to note that you should always use a fuel pressure gauge when making these adjustments to ensure accuracy and avoid the risk of flooding the fuel system, which could lead to fire or explosion. The gauge should be located between the carburetor and the regulator, or between the regulator and the pump if you have a high-pressure fuel pump.

When adjusting the regulator, ensure that all fuel connections are leak-proof. Also, remember that the fuel bowl float level will change when the regulator is adjusted, so you may need to readjust the fuel bowl accordingly.

If you're unsure about the process or the specific needs of your engine, it's always best to consult a qualified professional. Incorrect adjustment of the fuel pressure regulator can lead to various issues, including decreased engine power, fuel leaks, black exhaust smoke, a noisy fuel pump, and fuel in the vacuum pipe or tailpipe.

Building Fuel Pressure: Techniques for Performance Enhancement

You may want to see also

Frequently asked questions

You can adjust the regulator by turning the hex screw on top. To lower the pressure, turn the screw out.

Yes, you need to have the engine running to adjust the fuel pressure accurately.

The low-pressure Holley regulator has a maximum pressure of 4 psi, while the high-pressure version ranges from 4.5 to 9 psi.

You will need a fuel pressure gauge to get an accurate reading. You may also need an Allen key or a hex screwdriver to adjust the screw.