Building fuel pressure is a crucial aspect of maintaining optimal engine performance. Low fuel pressure can lead to issues such as a lack of horsepower, stalling, and difficulty starting the engine. Various factors, such as a faulty fuel pump or a clogged fuel filter, can contribute to low fuel pressure. On the other hand, high fuel pressure can result from a kink in the fuel return line, leading to increased emissions and potential damage to the catalytic converter. To ensure proper fuel pressure, it is essential to monitor and test the fuel system using tools like fuel pressure gauges and vacuum-operated fuel pressure regulator tests. Understanding how to build and regulate fuel pressure is essential for vehicle maintenance and performance.

What You'll Learn

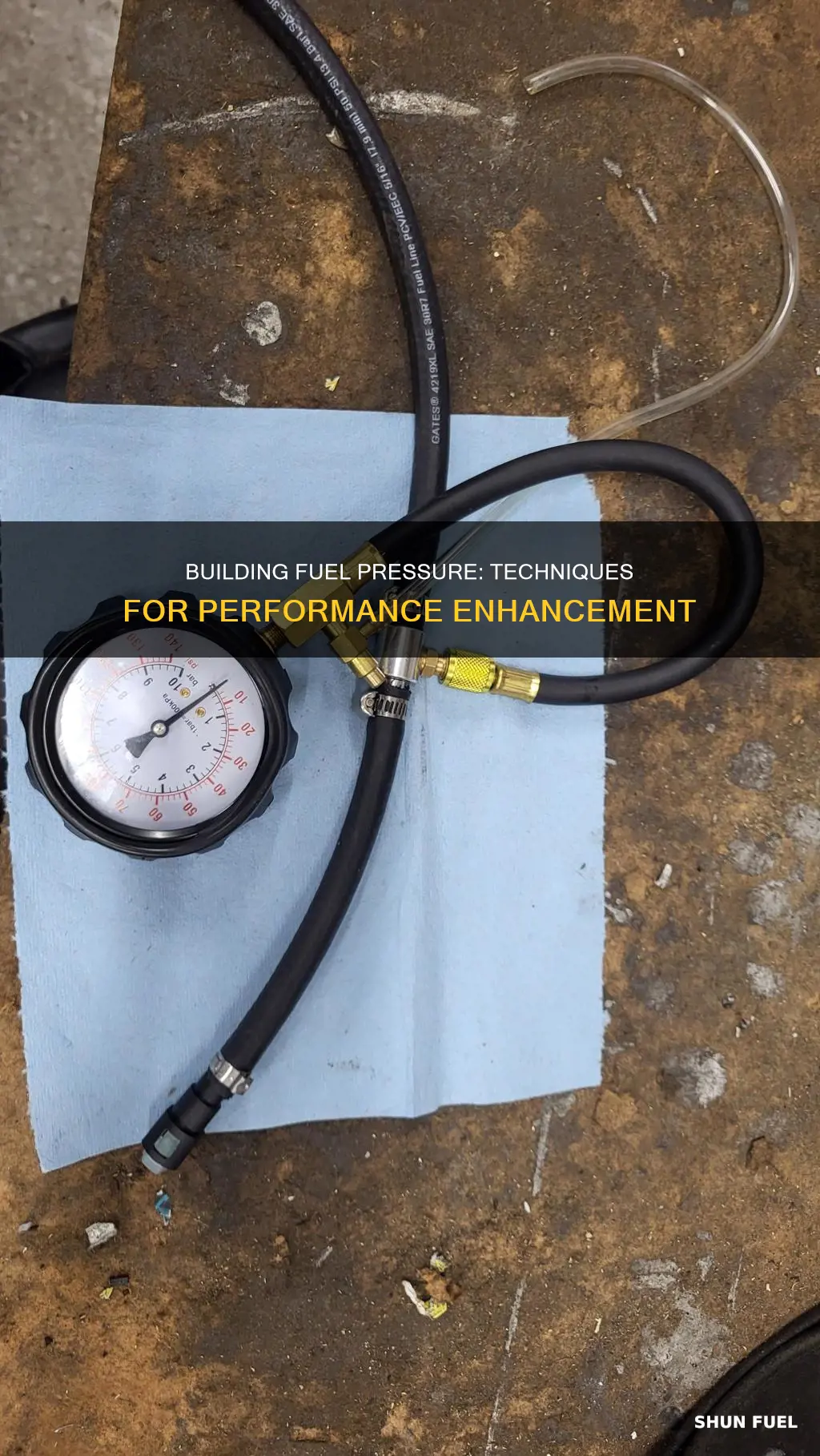

Check fuel pressure with a gauge

Checking your fuel pressure with a gauge is a straightforward process, but it requires careful attention to detail. Here is a step-by-step guide to help you through the process:

Step 1: Prepare Your Vehicle

Before you begin, ensure your vehicle is parked on a level surface and the engine is turned off. You will also need to refer to your vehicle's manual to locate the fuel pressure test port, which is usually found on the fuel rail or fuel filter housing.

Step 2: Connect the Fuel Pressure Gauge

Locate the correct adapter for your vehicle and connect the fuel pressure gauge to the test port. Ensure that you have a secure connection to get an accurate reading.

Step 3: Turn on the Ignition

Turn the ignition key to the "On" position without starting the engine. This will activate the fuel pump, allowing you to take a pressure reading.

Step 4: Take the Pressure Reading

With the ignition on, carefully monitor the fuel pressure gauge and record the reading. The ideal fuel pressure at idle typically falls within the range of 30 to 40 psi for most vehicles equipped with electronic fuel injection systems. However, specific values can vary, so it is crucial to refer to your vehicle's specifications or service manual for precise information.

Step 5: Interpret the Results

If the pressure reading falls outside the specified range, it may indicate a problem with your fuel system. Common issues include a faulty fuel pump, clogged fuel filter, or a leak in the fuel lines.

Step 6: Further Troubleshooting

If you suspect an issue, you can perform additional checks, such as listening for the fuel pump operation, checking fuel injector clicks, and observing the fuel injector spray pattern. These steps can help you further diagnose potential problems with your fuel system.

Remember that fuel pressure plays a pivotal role in the reliable operation of your engine, and any deviations from the specified range can impact performance and fuel efficiency. Always refer to your vehicle's manual for specific instructions and take appropriate safety precautions when working on your vehicle.

Testing Fuel Pressure in an E36: A Step-by-Step Guide

You may want to see also

Test the fuel pressure regulator

Testing your fuel pressure regulator can be done in a few different ways, some of which require a fuel pressure gauge, a vacuum gauge, or a vacuum hand pump.

Testing for Fuel Leaks

First, open the hood and locate the fuel pressure regulator on one end of the fuel rail. This rail holds the fuel injectors in place. A standard regulator is a small metallic cylinder with a thin vacuum hose connected on top. You may also see an incoming fuel line and a return fuel line connected to it, depending on your particular configuration. Check the vacuum hose for a tight connection, as a loose hose will prevent the regulator from working properly. Also, check the hose for damage and wear. Then disconnect the vacuum line from the regulator. If you see any signs of fuel in the vacuum line, the diaphragm inside the pressure regulator has a leak and you need to replace the regulator.

Checking the Fuel Pressure Regulator

Locate the Schrader valve. Most modern fuel injection systems come equipped with a Schrader or test valve located on the fuel rail. The valve is similar to the air valve on your tires. Connect your fuel pressure gauge to the Schrader valve or test port. If your system doesn't have this valve or has an older fuel system, check the repair manual for your particular vehicle model for the best way to connect the gauge to the system.

Then find the fuel system pressure specification for your particular model with the engine running and off. Look up this number in your car repair manual. Start the engine and let it idle (or have an assistant crank the engine for a few seconds, if the engine doesn't start). Then turn off the engine. Observe the fuel pressure gauge while the engine runs and after shutting off the engine. Fuel pressure should hold to specs, while the engine is running, and after turning off the engine. With the engine off, pressure should hold for about 5 minutes. If necessary, consult your repair manual.

Make a note of the pressure gauge reading. Ask an assistant to turn the ignition key to the On position (without starting the engine) for 5 seconds, and then to turn it off. Repeat this step at least 5 times to make sure fuel pressure is consistent; otherwise, the FPR might be sticking. Compare your readings to specification in your repair manual.

Testing for Maximum Pressure

You want to do this test if your previous test showed low fuel system pressure after shutting off the engine. The test may help locate the point of failure, provided your fuel filter is not clogged or due for replacement. Connect the fuel pressure gauge to the fuel system as you did in the previous section. Now, place a rag over the fuel incoming line (hose) and another rag over the fuel return line (hose). If you need more help to locate these lines, consult the repair manual for your particular vehicle model. Have an assistant start the engine, let it idle for a minute, and then turn it off. As the engine turns off, use a pair of slip joint or vise grip pliers to squeeze and block the incoming and return lines. The rag should be between the pliers and fuel line to prevent damage to the hose. Note the fuel pressure gauge reading for a few minutes.

Replacing the Vacuum Line

An easy way to test for an FPR leak in the vacuum side is to replace the vacuum line going into the FPR with a length of clear tubing. You'll need to find some clear tubing in the same diameter as your vacuum line. If your line is a standard small diameter line, a piece of airline tubing from your local aquarium supply store works perfectly. If not, there are always a selection of tubing sizes to be found at your local hardware store. With your clear vacuum hose in place, rev the engine up and down over and over. The best way to do this test is with two people so you can see anything that happens in your clear tube in real time. If the fuel pressure regulator is failing at the vacuum port, as your partner revs the engine you'll actually see fuel seeping or spraying into the vacuum line. This blowback means there isn't a good vacuum signal to work with at the fuel pressure regulator anymore, and the regulator will need to be replaced.

Understanding the P7100: Fuel Pressure Requirements Explained

You may want to see also

Ensure a constant fuel supply

To ensure a constant fuel supply, it is important to maintain proper fuel pressure. Low fuel pressure can cause a range of issues, including a lack of horsepower, stalling, and difficulty starting the engine.

One way to ensure a constant fuel supply is to regularly check and maintain your fuel pump and fuel filter. A faulty fuel pump or a clogged fuel filter can cause low fuel pressure. It is recommended to refer to the service manual for your vehicle's specific fuel pressure specifications. You can use a fuel pressure gauge to test the fuel pressure. This gauge is typically installed on the fuel rail, but if not, you may need a special fitting from a fuel injection kit. Once the gauge is properly installed and secured, turn the ignition key to the "on" position and observe the fuel pressure reading. With the engine running, the fuel pressure should remain constant and increase slightly when you snap the throttle.

Additionally, it is important to monitor the fuel return line for any kinks or blockages. A kink in this line can result in higher-than-normal fuel pressure, leading to an excessive amount of fuel being forced through the injectors. This can cause increased emissions and damage to the catalytic converter.

In some cases, issues with the fuel pressure regulator can also affect fuel supply. To test a vacuum-operated fuel pressure regulator, remove the vacuum line while monitoring the fuel pressure. The pressure should increase by 5-15 psi. If it doesn't, there may be an issue with the fuel pressure diaphragm leaking fuel into the vacuum line. Refer to the manufacturer's manual for specific testing procedures, as some fuel pressure regulators are electric and controlled by a control module (ECM).

Finally, it is worth noting that running your fuel tank below a quarter full can also impact fuel pressure and supply. While it may not cause immediate damage to the fuel pump, it is advisable to maintain adequate fuel levels to ensure optimal fuel pressure and engine performance.

Pressurizing Boat Fuel Tanks: The Complete Guide

You may want to see also

Remove the DME relay

Removing the DME relay is a straightforward process that can be done in a few simple steps. The DME relay is located in different places depending on the Porsche model. For the 924S and earlier 944s, it is under the passenger's side of the dashboard, obscured by a fuse holder. For the 964 and 993 models, it is inside the main fuse box in the right-hand rear corner of the luggage compartment. For the 944, 944S, 944S2 and Turbo, and 968 models, it is inside the main fuse box in the left-hand rear corner of the engine compartment.

Once you have located the DME relay, the next step is to remove it. First, pull back the carpet in the front by the right-side A-pillar and release the two clips on the fuse/relay panel cover. Then, remove the cover and gently wiggle and pull the relay out from its location in the panel. Be careful not to just grab the relay and pull, as you may end up pulling off the cover instead.

It is important to note that disconnecting power to the DME relay will cause it to erase its adaptive memory, so you will need to drive the car for approximately ten minutes after repowering the DME to restore normal performance.

Additionally, the DME relay should not be left disconnected for an extended period, as it will cause the DME computer to be continuously energized, draining the battery.

Now that you have removed the DME relay, you can proceed to the next steps in building fuel pressure.

Setting Fuel Pressure in Your Integra: A Step-by-Step Guide

You may want to see also

Check the fuel filter

Checking your fuel filter is an important step in maintaining your vehicle's performance and fuel efficiency. Here are some detailed steps and information to guide you through the process of checking your fuel filter:

Locate the Fuel Filter: Most vehicles have two fuel filters. One is located in the fuel tank, often called the strainer, and the other is in the main fuel line. Refer to your vehicle's owner's manual to identify their exact locations.

Understand the Function of the Fuel Filter: The fuel filter plays a critical role in trapping dirt, rust, scale, and other impurities to prevent them from entering the fuel pump, fuel injectors, and engine. This helps maintain fuel pressure and ensures a clean fuel supply to the engine.

Recognize the Signs of a Clogged Fuel Filter: A clogged fuel filter can cause various issues, including poor engine performance, especially under heavy loads or during acceleration. You may experience engine hesitation, surging, or sputtering. In some cases, the engine may stall repeatedly while driving. Additionally, a clogged fuel filter can lead to low fuel pressure, resulting in rough idling, reduced fuel mileage, and the check engine light coming on.

Check the Condition of the Fuel Filter: Start by consulting your owner's manual to determine the recommended interval for fuel filter replacement. If you haven't replaced the fuel filter in a while, it's a good idea to inspect it. Remove the fuel filter and visually examine it for any signs of clogging or damage. Look for debris, rust, or other impurities that may be trapped in the filter. If the filter appears severely clogged or damaged, it's time for a replacement.

Replace the Fuel Filter: Depending on the condition of the fuel filter, you may need to replace it. Before attempting any DIY replacement, ensure the engine is cool, you have the proper tools, and you release the fuel system pressure. Refer to your owner's manual for detailed instructions on releasing fuel system pressure. When replacing the fuel filter, also replace all O-rings, gaskets, and seals. Reinstall mounting brackets and retaining clips correctly, and don't forget to check for leaks after installation.

By regularly checking and maintaining your fuel filter, you can help ensure optimal fuel pressure and engine performance. Remember to consult a professional mechanic if you have any doubts or concerns during the process.

Understanding Fuel Pressure Regulators: Performance and Functionality

You may want to see also

Frequently asked questions

Turn the ignition key to the "on" position.

Symptoms of low fuel pressure include a lack of horsepower, stalling, and a slow or no-start condition.

A faulty fuel pump or a clogged fuel filter.

Use a fuel pressure gauge. The fitting is typically on the fuel rail. If not, a special fitting from a fuel injection kit will be required. After properly installing the gauge, secure it, and turn the ignition key to the "on" position. It should indicate fuel pressure.

Check your fuel filter and fuel pump.