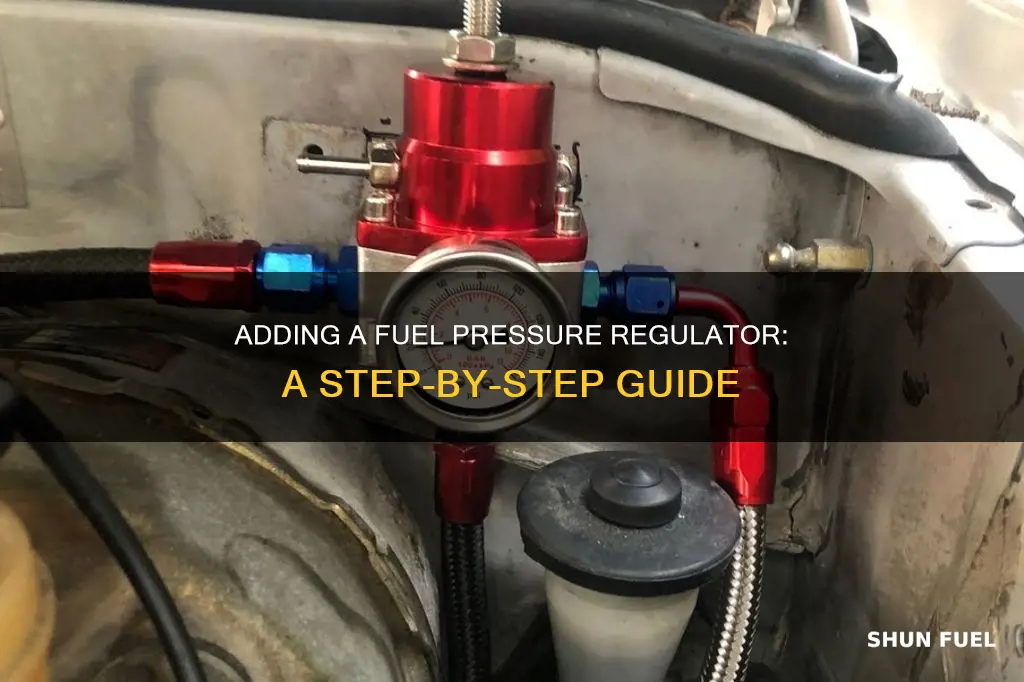

Fuel pressure regulators are essential for maintaining a constant fuel pressure for optimal fuel usage. They work with the fuel pump to maintain a steady pressure relationship between the fuel line side of the injectors and the intake manifold. When choosing a fuel pressure regulator, it is important to consider the type of fuel delivery system and fuel pump being used. The regulator's location can also impact performance, with the potential for fuel pressure loss increasing the further away it is from the fuel's destination.

What You'll Learn

Choosing the right fuel pressure regulator

Fuel System Type

Firstly, it's crucial to understand the type of fuel system your vehicle has. Your vehicle will typically have either a carburetor or an Electronic Fuel Injection (EFI) system. Carburetors are commonly found in older vehicles and operate at lower fuel pressures, around 4 to 7 psi. On the other hand, EFI systems deliver fuel more accurately and run at higher fuel pressures, usually between 30 and 60 psi.

Performance Requirements

If you have a high-performance engine, you'll need a fuel pressure regulator to manage the increased fuel volume and pressure. These regulators ensure the engine receives the ideal fuel pressure for efficient performance. Choosing the wrong regulator can lead to decreased performance, higher fuel consumption, and fuel leaks.

Regulator Type

There are two main types of fuel pressure regulators: return style (or bypass) and deadhead (or blocking) regulators. Return-style regulators stabilize fuel pressure by directing excess fuel back to the tank, making them ideal for EFI systems and setups with carburetors used with high-pressure fuel pumps. Deadhead regulators, on the other hand, have no return line and restrict fuel flow once the pressure reaches a predetermined level. They are simpler and more cost-effective but can cause fuel temperatures to rise.

Vehicle Usage

Consider how you use your vehicle. Deadhead regulators are suitable for classic cars with carbureted engines used for regular driving, where fuel demands are consistent. Return-style regulators, with their ability to handle higher pressures, are often the standard for modern vehicles with EFI systems or carburetors with high-pressure fuel pumps.

Installation Complexity

Return-style regulators require a return line back to the fuel tank, making the installation more complex. Deadhead regulators, with their simpler design and fewer components, are generally easier to install and maintain.

Fuel Type

The type of fuel you use should also be considered when choosing a fuel pressure regulator. For street cars using pump fuel, a regulator like the Turbosmart FPR800 is suitable. However, for race cars utilizing race fuel or alcohol, a higher-end regulator such as the FPR1200, FPR2000, or FPR3000 is necessary to handle these fuels without damaging the regulator.

Power Requirements

Finally, the target power level of your vehicle will determine how much fuel is needed and, consequently, the size of the fuel pressure regulator required. Turbosmart offers a range of FPRs that are horsepower-rated, so you can select the appropriate regulator for your power requirements.

In summary, choosing the right fuel pressure regulator involves understanding your fuel system, vehicle performance needs, regulator types, installation considerations, fuel type, and power requirements. Making an informed decision will ensure optimal engine performance, fuel efficiency, and the longevity of your vehicle's fuel system.

Ford F550: Is the High-Pressure Oil Pump a Fuel Pump?

You may want to see also

Installing a deadhead-style regulator

Deadhead regulators do not use a return line, so there is no fuel redirected back to the fuel tank. This absence of a return line reduces installation costs but can limit performance capabilities. Deadhead regulators are typically used with low-pressure mechanical or some electric fuel pumps and regulate fuel pressures in the 1-9 psi range.

To install a deadhead-style regulator, you will need to identify the correct location for the regulator and determine which ports are fuel in and fuel out. You will also need to ensure that you have the correct fittings and adapters for your specific setup. Refer to your vehicle's repair manual or seek advice from a professional if you are unsure about the installation process.

Before beginning the installation, depressurize the fuel lines and remove the old regulator. This may involve removing screws or clamps, so have the appropriate tools on hand. Once the old regulator is removed, you can install the new deadhead-style regulator, ensuring that all connections are secure and any necessary seals or O-rings are in place.

After installation, you may need to adjust the fuel pressure to the desired setting. This can be done by adjusting a nut or bolt on top of the regulator, depending on the specific regulator design. Always refer to the manufacturer's instructions for proper installation and adjustment procedures.

Fuel Pressure Sensors: Cost and Functionality Explored

You may want to see also

Avoiding pressure creep

Pressure creep is a phenomenon that occurs in Blocking Style Regulators, also known as Traditional Style Regulators. It is characterised by a spike in fuel pressure as the fuel control valve reaches the closed position, resulting in inconsistent fuel pressure readings. This happens because, as fuel pressure reaches the maximum value, the fuel control valve must shut off inlet pressure from reaching the outlet port, and this action requires extra fuel pressure to fully shut the valve.

To avoid pressure creep, a small amount of fuel flow must be maintained through the regulator while making adjustments. This can be achieved by keeping the engine running at idle speed. However, this method won't work when adjustments need to be made with the engine turned off (but with the fuel pump energised), or in the case of nitrous oxide applications that use an additional regulator, which only allow fuel flow when the fuel solenoid is activated under full throttle.

In these situations, a bleed return can be used to simulate a flow rate (trickle flow). This can be achieved by plumbing a permanent -3AN fuel return line from the outlet port(s) to the fuel tank. Alternatively, an external flow source can be used to quickly hook up a temporary fuel line, allowing fuel to flow into a fuel-safe container outside of the vehicle.

Another solution to pressure creep is to switch to a Bypass Style Regulator, also known as a Return Style Regulator. This type of regulator does not experience pressure creep because fuel is always flowing, even when there is no fuel demand from the engine, as it is rerouted back to the fuel tank.

Understanding the Role of Low-Pressure Fuel Pumps in Engines

You may want to see also

Removing the old regulator

Step 1: Park Your Vehicle and Prepare the Workspace

Park your vehicle on a flat, hard surface and ensure that the transmission is in park for automatics or in first gear for manuals. It is crucial to work on a level surface to avoid any accidental movements of the vehicle during the process. Secure the front tires with wheel chocks and engage the parking brake.

Step 2: Disconnect the Battery

Open the vehicle's hood and disconnect the battery. Remove the ground cable from the battery's negative post to disable the power going to the fuel pump. This step is essential for safety and to prevent any accidental electrical issues. Put on protective gloves before handling any battery terminals.

Step 3: Relieve Fuel System Pressure

Before proceeding, it is crucial to relieve the pressure in the fuel system. Park in a well-ventilated area, away from open flames or ignition sources. For Throttle Body Injection (TBI) models, you can simply turn off the engine, and the system pressure will drop. For TBI models and multiport fuel injection systems, remove the fuel pump fuse or relay, start the engine, and let it idle until it stalls.

For Electronic Fuel Injection (EFI) systems, locate the Schrader valve on the fuel rail. Cover the valve with a rag and carefully depress it with a screwdriver to release the pressure. Don't forget to loosen the fuel filler cap afterward to release pressure from the gas tank.

Step 4: Accessing the Fuel Pressure Regulator

Locate the fuel pressure regulator by removing any necessary covers or components. In some cases, you may need to remove the intake plenum or similar parts to gain access. Refer to your vehicle's service manual for specific instructions regarding your make and model.

Step 5: Disconnect Vacuum Hose and Fuel Return Line

Carefully pull off the vacuum hose connected to the regulator. Then, loosen the fuel return line fitting. You may need two wrenches for this step: one to hold the molded regulator nut and another to loosen the line nut. If your vehicle uses a quick-connect fitting, you can release it with a specialized tool available at most auto parts stores.

Step 6: Unscrew and Remove the Fuel Pressure Regulator

Finally, unscrew and remove the fuel pressure regulator. In some cases, you may need to remove the mounting bolts before you can take it out. Be cautious, as there may be some corrosion or buildup that makes it challenging to remove. Be gentle but firm, and the regulator will come out.

Additional Notes:

It is important to keep track of the order in which the components are assembled, as you will need to reassemble them in the same order when installing the new regulator. Additionally, always refer to your vehicle's service manual for specific instructions pertaining to your particular make and model.

Now that you have successfully removed the old fuel pressure regulator, you can proceed to install the new one.

When to Change Fuel Lines and Injectors

You may want to see also

Testing for leaks

Step 1: Preliminary Checks

Before beginning any tests, there are a few preliminary checks you should perform. Firstly, open the hood and locate the fuel pressure regulator. It is usually found at one end of the fuel rail, which holds the fuel injectors in place. The regulator typically looks like a small metallic cylinder with a thin vacuum hose connected to its top. Depending on your vehicle's configuration, you may also see an incoming fuel line and a return fuel line connected to it. However, newer vehicle models may have the fuel pressure regulator placed inside the fuel tank as part of the fuel pump assembly, so you may not find the regulator or a return fuel line.

Step 2: Inspect the Vacuum Hose

Once you've located the fuel pressure regulator, check the vacuum hose for any damage or wear, and ensure it is tightly connected. A loose or damaged hose can prevent the regulator from functioning properly.

Step 3: Disconnect the Vacuum Hose

Disconnect the vacuum line from the regulator. If you notice any signs of fuel in the vacuum line, it indicates that the diaphragm inside the pressure regulator has a leak, and you will need to replace the regulator.

Step 4: Perform a Vacuum Test

If there is no fuel in the vacuum line, you can proceed with a vacuum test. For this test, you will need a partner. Find clear tubing and replace the vacuum line with it. One person should rev the engine up and down repeatedly to duplicate the act of accelerating, while the other person observes the clear tubing. If you see any fuel inside the tube, such as spraying or seeping gasoline, it confirms a leak in the diaphragm inside the regulator, and it will need to be replaced.

Step 5: Use a Fuel Pressure Gauge

Another method to test for leaks is by using a fuel pressure gauge. Connect the gauge to the Schrader valve or test port on the fuel rail. If your system lacks a test port or has an older fuel system, refer to your vehicle's repair manual for the best way to connect the gauge. Once connected, start the engine and take a reading. For a fuel-injected engine, the reading should be between 45 to 55 PSI. A reading below 40 or above 60 PSI indicates a potential problem with the fuel pressure regulator.

Step 6: Observe Pressure Changes

After taking the initial reading, turn off the engine and disconnect the vacuum line running to the fuel pressure regulator. Observe the gauge for any changes in pressure. If the pressure drops by around 5 to 10 PSI, the regulator is functioning correctly. However, if the pressure remains the same, it indicates a faulty fuel pressure regulator that needs to be replaced.

Safety Precautions

Always exercise caution when working on your vehicle's fuel system. Ensure the engine is completely cool before beginning any tests. Additionally, relieve fuel system pressure before disconnecting any parts to prevent the sudden discharge of fuel, which can be dangerous.

Fixing Low Fuel Pressure Caused by Low Intake Manifold Vacuum

You may want to see also