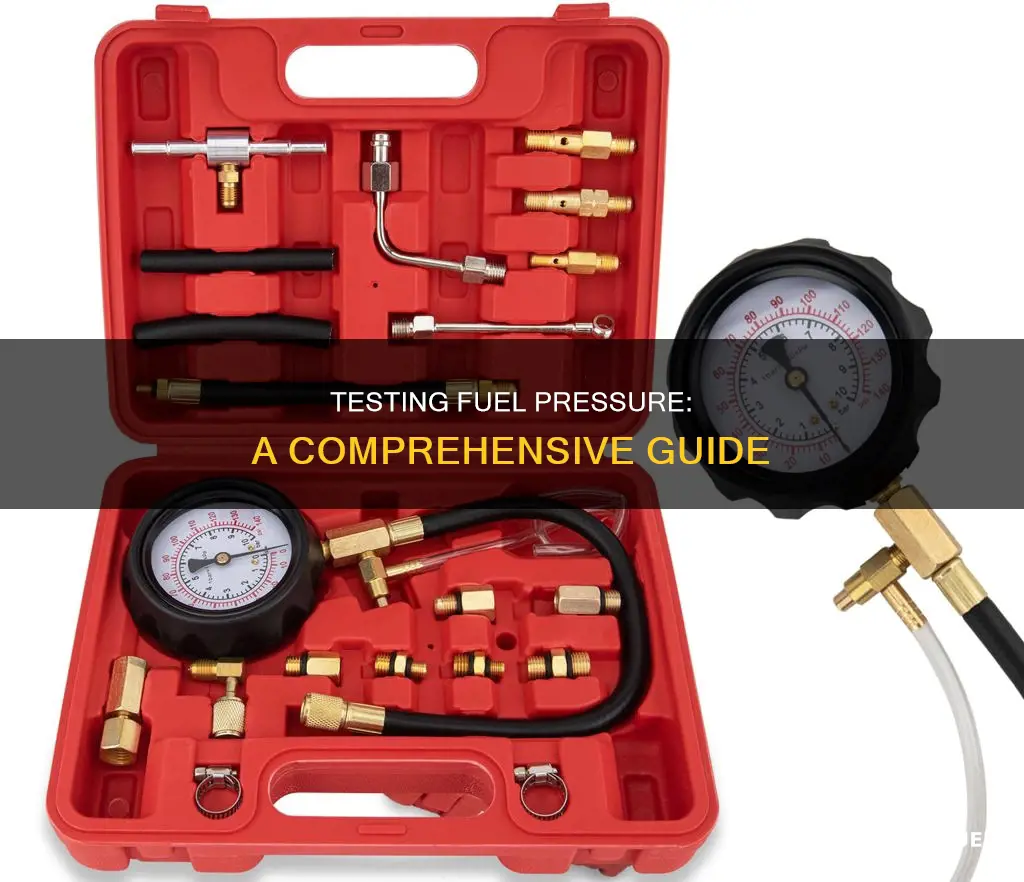

Testing the fuel pressure in your car is an important part of car maintenance. A malfunctioning fuel pump can cause a decline in engine power and, in some cases, lead to a complete breakdown. Before testing, it is important to ensure you are working in a well-ventilated area and are wearing protective gear, as fuel vapours are highly flammable. You will need a fuel pressure tester, which consists of a gauge attached to a fuel hose with multiple fittings. The tester will display the pressure in psi on a large gauge that can be read from inside the vehicle. The amount of pressure required differs depending on the engine. For example, older throttle-body injected systems may need as little as 10 psi, while multi-port injection can see as high as 60 psi. To test, simply connect the tester to the fuel system, start the engine, and check the psi reading. If the pressure drops over 10 minutes, this indicates a leak in the fuel system.

| Characteristics | Values |

|---|---|

| Engine requirements | Air, fuel, spark, and compression |

| Fuel pressure tester | A gauge attached to a fuel hose with multiple fittings |

| Fuel pressure tester cost | Rent or buy |

| Fuel pressure tester connection | Schrader valve fitting on the fuel rail |

| Fuel pressure tester process | Turn ignition to "on," check psi reading, wait and watch for a psi drop |

| Zero fuel pressure | Engine won't run |

| Low fuel pressure | Slow start-up, low performance, misfires, and stalling |

| High fuel pressure | Excessive fuel consumption, black smoke from unburned gas, an overheating catalytic convertor, and rough idle |

| Fuel pump location | Inside the fuel tank |

| Fuel pump malfunction signs | Low engine power delivery, lack of fuel delivery to the engine, and lower power output |

| Fuel pressure test tools | Screwdriver, fuel pressure gauge, ratchets, and sockets |

| Fuel pressure test process | Park the vehicle, apply the parking brake, turn off the engine, locate the fuel pressure test port, install the pressure tester, turn on the ignition, run the engine, and check for required pressure |

What You'll Learn

Using a fuel pressure tester

Testing the fuel pressure can help you diagnose any starting or running issues with your car. Before you buy or rent a fuel pressure tester, there are a few things you should try first to see if they solve the problem.

Firstly, check that there is gas in the tank. Even if the gauge shows a full tank, it could be faulty, so add at least two gallons to the tank and try to start the car again. If it starts, check the fuel gauge for internal failure and replace it if necessary. If the new gauge still shows a high fuel level, the issue is likely a failed fuel sending unit in the gas tank.

The next step is to verify that the fuel pump is working. To do this, ask an assistant to turn the ignition switch to "On" and listen for a two-second whir, hum, or series of rapid clicks as the fuel pump pressurizes the fuel line to the engine. If there is no noise, the pump is either not getting power or it has failed. Check the fuel pump fuse and relay, and if they are both fine, check the wiring to the pump. If there is voltage when turned on, then the pump has failed and needs to be replaced.

Now it's time to break out the fuel pressure tester. Note that fuel vapors are highly flammable, so ensure these steps are performed in a well-ventilated area with a fire extinguisher nearby.

With the engine entirely cold, open the hood and find the Schrader valve fitting on the fuel rail. Remove the Schrader valve cap and attach the appropriate fuel pressure tester fitting, making sure it threads on properly for a leak-proof fit. Do not start the car, but turn the ignition to "On" and check the psi reading. Wait and watch for a drop in psi, which indicates a leak in the system. If the reading stays the same after 5-10 minutes, the system is holding pressure well.

If the fuel pressure drops over 10 minutes, there is a leak in the fuel system. Look for drips underneath to help locate the source of the leak. However, be aware that it could be leaking internally from a faulty fuel injector.

Now, start the engine and let it idle. The fuel pressure should be steady, within a few psi of the recommended pressure. Once the engine is warmed up, slowly rev it and check that the pressure rises with the RPMs. If your fuel pressure holds steady and rises with engine speed, and is at the recommended pressure, then your engine problem does not seem to be fuel-related.

Understanding Fuel Pressure Readings

Zero fuel pressure means the pump is dead or not getting power. Check the fuel pump fuse and then verify power to the pump with a multimeter. If it is getting power, replace the pump.

Low fuel pressure could be caused by a clogged fuel filter or a failing pump. If it is a serviceable type filter, replace it. It could also be caused by improper tank venting or a loose gas cap. Check that the cap gasket is not damaged and tighten it until it clicks.

High fuel pressure has a few potential causes. Start by looking for a clogged or kinked fuel return line, a bad fuel pump driver module, or a faulty fuel pressure regulator. A bad fuel pump driver module or powertrain control module will likely store a code and show a "check engine" light.

Ford Taurus Fuel Line: Understanding Pressure Performance

You may want to see also

Checking for fuel leaks

To check for fuel leaks, you must first take precautions to prevent risks to your health and home. Do not smoke while performing the work, and park your vehicle outside to prevent an accumulation of dangerous fumes. If your clothes become fuel-soaked, immediately change them, and wash contacted skin with mild soap and plenty of fresh water.

Begin by raising the vehicle and supporting it on jack stands. Using a flashlight, trace the fuel lines from the tank to the engine, looking for evidence of leaks. This may include spots with a greater accumulation of dust and road grime, wet spots or streaks, and clean spots where the fuel has washed away all the grime. If you find evidence of fuel dripping from a frame member or other structural component, follow that member to discover the source of the leak. Remember that gravity and wind pressure can affect the path of travel, so the fuel may be running along a series of members before it drips out.

If you are unable to locate the leak through a preliminary inspection, there are several products available that can be added to your fuel to help locate the source of the leak. These products contain a dye that will glow under fluorescent or ultraviolet light. After adding the dye to your fuel, run the engine so that it leaks some of the treated fuel, then perform a visual inspection with a handheld light.

If the leak still cannot be found, a device known as a leak detector can be used to zero in on the source. This device has a probe that can be inserted into areas that aren't readily visible, and it detects the presence of compounds within both gasoline and diesel.

It is important to note that fuel leaks can be very dangerous when left untreated. In addition to the possibility of fire or explosion, fuel can also damage rubber tires and bushings, painted sheet metal, and plastic components. Repairs should be made as soon as a fuel leak is detected.

Fuel Pressure Sweet Spot for Holley Avenger Carburetor

You may want to see also

Testing the fuel pump

Step 1: Prepare the Car and Your Work Area

Park your vehicle and engage the parking brake. Turn off the engine and allow it to cool down completely. This step is crucial for safety, as you will be working with fuel, which can be flammable. Put on safety gear, such as gloves and safety glasses, and ensure your work area is well-ventilated.

Step 2: Locate the Fuel Pressure Test Port

Find the fuel pressure test port, which is usually located on the fuel rail. Place a rag under the test port to catch any fuel that may be released during the testing process.

Step 3: Install the Fuel Pressure Tester

Install the pressure tester onto the test port. Make sure it is securely attached to prevent any leaks.

Step 4: Start the Engine and Check Pressure

Turn on the ignition and start the engine. Let it idle, and then record the pressure reading on the tester. Compare this reading to the manufacturer's specifications, which can be found in the vehicle's manual. A typical port-injected vehicle requires fuel pressure between 30 and 80 PSI. If the pressure is below the specified range, there may be an issue with the fuel pump.

Step 5: Perform a Fuel Volume Test (Optional)

If your fuel pump is supplying sufficient pressure, you can perform an optional fuel volume test to ensure the proper amount of fuel is being delivered to the fuel injectors. For this test, you will need a flowmeter or a glass measuring container. Start the car and let it idle. Collect a fuel sample for a specified time, typically around five seconds, and compare the amount of fuel collected to the manufacturer's specifications.

By following these steps, you can effectively test your fuel pump for any issues related to fuel pressure and volume. If you find any discrepancies or unusual readings, it is recommended to consult a professional mechanic for further diagnosis and repair.

Kia Spectra5 Fuel Pressure Regulator: Location and Maintenance Guide

You may want to see also

Understanding fuel pressure readings

Fuel pressure readings are an essential part of fuel injection system troubleshooting. High fuel pressure will cause an engine to run rich, leading to excessive fuel consumption, black smoke from unburned gas, an overheating catalytic converter, and rough idling. On the other hand, low fuel pressure will make an engine run lean or not run at all, resulting in a slow startup, low performance, misfires, and stalling.

Zero fuel pressure indicates that the pump is dead or not receiving power. To address this, check the fuel pump fuse and verify power to the pump with a multimeter. If the pump is receiving power, then it needs to be replaced.

Low fuel pressure could be due to a clogged fuel filter or a failing pump. If it is a serviceable type filter, it is recommended to replace it. Low fuel pressure can also be caused by improper tank venting or an emissions issue due to a loose gas cap. In such cases, check the cap gasket for damage and tighten it until it clicks.

High fuel pressure has several potential causes, including a clogged or kinked fuel return line, a faulty fuel pump driver module, or a faulty powertrain control module. These issues would likely trigger a "check engine" light and store a code. High fuel pressure can also be caused by a faulty fuel pressure regulator.

It is important to refer to the manufacturer's specifications for fuel pressure readings. Readings that are higher than the specified range are typically caused by problems in the return line fuel components, while readings that are lower than the range are usually due to issues in the pressure line fuel components. If the fuel pressure readings are not within the specified range, refer to a vehicle service manual for diagnostic procedures to identify the faulty component.

How to Check Fuel Pressure in Your Maxima

You may want to see also

Safety precautions

Testing fuel pressure can be dangerous, so it is important to take safety precautions to avoid accidents or injuries. Here are some essential safety measures to follow when testing fuel pressure:

Work in a Well-Ventilated Area

Fuel vapors are highly flammable and can easily ignite, so it is crucial to work in a well-ventilated area. This will help reduce the risk of fire and explosion. Make sure the area is free of any potential sources of ignition, such as open flames or sparks.

Wear Protective Gear

Always wear appropriate protective gear when testing fuel pressure. This includes safety glasses to shield your eyes from fuel splashes, gloves to prevent skin contact with fuel or chemicals, and clothing that covers your body to minimize exposure to fuel vapors. These precautions will help protect you from potential fuel spills or accidents.

Have a Fire Extinguisher Nearby

Keep a fire extinguisher nearby in case of emergencies. Ensure that the fire extinguisher is rated for use with flammable liquids and that you know how to use it effectively. This will help you quickly respond to any fires or explosions that may occur during the testing process.

Check for Fuel Leaks

Before starting the test, carefully inspect the vehicle for any signs of fuel leaks. Look for drips or puddles of fuel underneath the vehicle and check for any damaged or loose fuel lines. If you notice any leaks, address them before proceeding with the test to prevent accidents.

Disconnect the Battery

Before connecting the fuel pressure tester, disconnect the negative terminal of the battery. This will prevent any accidental electrical shorts during the testing process. Reconnect the battery only when instructed to do so in the testing procedure.

Follow Manufacturer's Instructions

When using a fuel pressure tester, carefully follow the manufacturer's instructions for connecting and operating the device. Incorrect use of the tester can lead to inaccurate readings and potential safety hazards. Refer to the tester's manual or instructions for proper usage guidelines.

Relieve Residual Fuel Pressure

Before beginning the test, relieve any residual fuel pressure in the system. This step is crucial for reducing the risk of fire when opening the fuel line. Refer to the vehicle's repair manual or seek guidance from a professional if you are unsure about how to safely relieve fuel pressure.

Check Fuel Pump Electrical Circuit

Before testing fuel pressure, verify the proper functioning of the fuel pump electrical circuit. This includes checking the fuse, relay, and wiring connections for any damage or loose connections. Replace the fuse if necessary and ensure that the relay and wiring connections are secure and free of corrosion.

Be Mindful of Hot Engine Components

When working on the engine, be cautious of hot components. Allow the engine to cool down before starting the test to reduce the risk of burns or injuries. Avoid touching hot engine parts and be mindful of any flammable liquids or vapors that may be present.

Do Not Smoke

Refrain from smoking while performing the test. Smoking near flammable liquids or vapors can easily lead to fires or explosions. Ensure that you and anyone assisting you during the test refrain from smoking until the testing procedure is complete and all safety precautions have been addressed.

Testing Fuel Pressure on a 1995 Mustang: A Step-by-Step Guide

You may want to see also

Frequently asked questions

First, check if your car is exhibiting signs of low fuel pressure, such as slow start-up, low performance, misfires, and stalling. Then, check your fuel tank to ensure there is gas in it. If your car still won't start, verify that the fuel pump works by turning the ignition switch to "On" and listening for a two-second whirring, humming, or series of rapid clicks. If you don't hear any of these sounds, check the fuel pump fuse and relay. If both are intact, check the wiring to the pump. If voltage is present, then the pump has failed. If you suspect that your fuel pump is malfunctioning, you can test its pressure using a fuel pressure tester.

You will need a fuel pressure tester, a screwdriver, a fuel pressure gauge, ratchets, and sockets.

Park your car, apply the parking brake, and turn off the engine. Allow the engine to cool down, then locate the Schrader valve fitting on the fuel rail. Remove the Schrader valve cap and attach the appropriate fuel pressure tester fitting, ensuring a leakproof fit. Turn the ignition to "On", then check and record the psi reading. If the pressure drops, this indicates a leak in the system. Start your engine and let it idle. You should see a steady fuel pressure, within a few psi of the recommended pressure. Once warmed up, slowly rev the engine and check that the pressure rises with the RPMs. If your fuel pressure holds steady, rises with engine speed, and is at the recommended pressure, then your engine problem does not seem fuel-related.

It depends on the engine. Some older throttle-body injected systems need as little as 10 psi, while multi-port injection can see as high as 60 psi. Check your vehicle's repair manual for the specific fuel pressure requirements.